Solvent-free epoxy heavy anti-corrosion coating as well as preparation method and application thereof

A heavy-duty, solvent-free technology, applied in the field of coatings, can solve problems such as unsatisfactory corrosion protection of metal and concrete substrates, unsatisfactory acid, alkali and salt spray resistance of coatings, and affecting the anti-corrosion effect of coatings. Excellent salt spray, excellent acid and alkali resistance, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

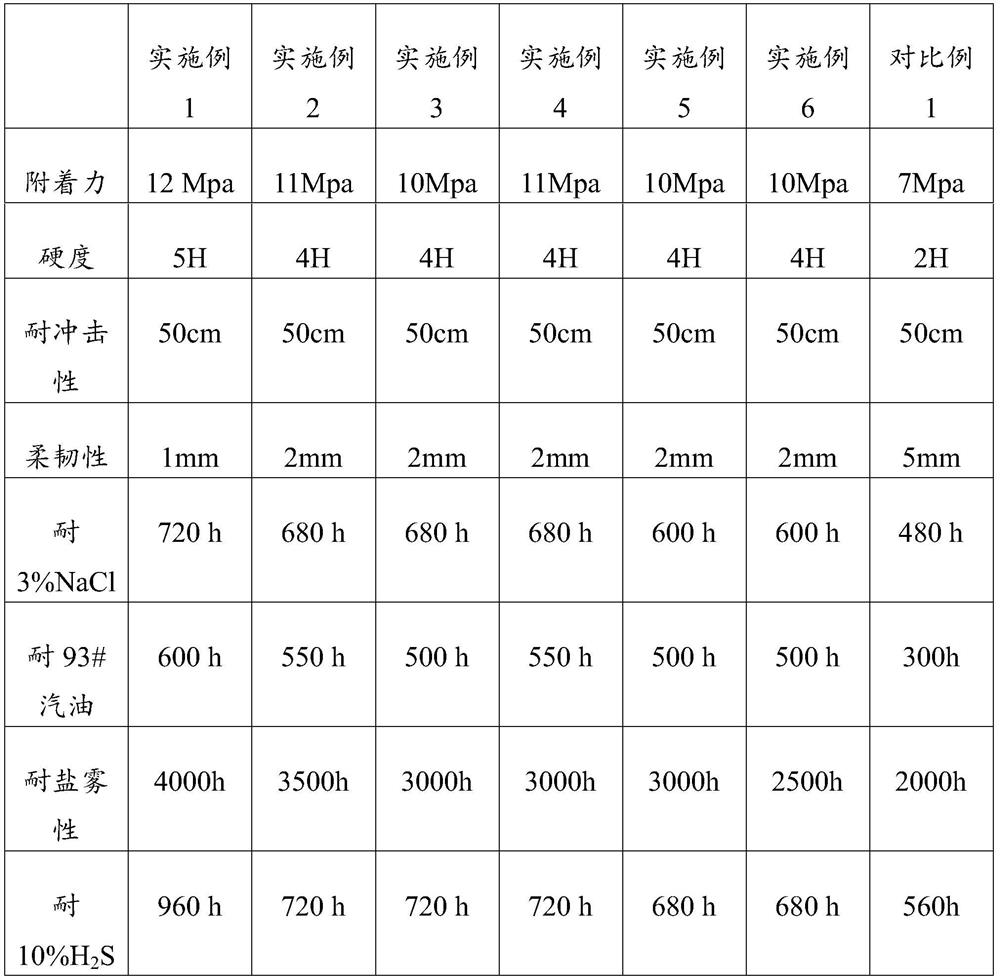

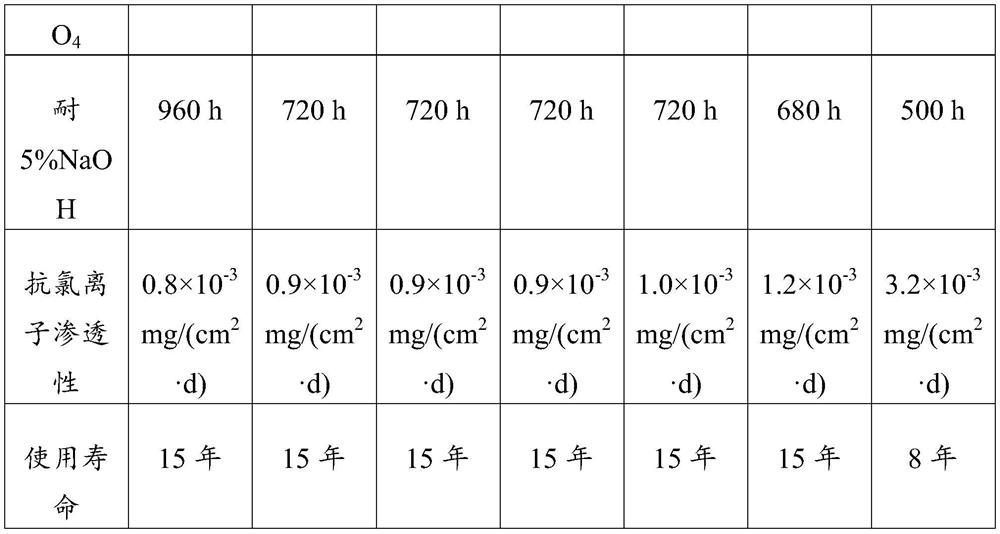

Examples

Embodiment 1

[0021] The components of the solvent-free epoxy heavy-duty anti-corrosion coating described in this embodiment are: 50 parts of epoxy resin, 25 parts of polyamide resin, 7 parts of alkyd resin, 1 part of dispersant, 1 part of defoamer, 2 parts of leveling agent, 2 parts of anti-settling agent, 40 parts of filler, 1 part of rheological additive, and 16.7 parts of curing agent.

[0022] The preparation method of solvent-free epoxy heavy-duty anticorrosion coating described in the present embodiment comprises the following steps:

[0023] (1) Preparation of bisphenol A epoxy resin

[0024] Install the stirrer, return condenser tube and thermometer on the 500mL three-necked flask. Add 12.3 parts of bisphenol A, 41 parts of epichlorohydrin, and 4.1 parts of NaOH and mix and stir. Then slowly heat to 80°C, and finish the reaction after 3 hours of reaction. The reaction solution was filtered to remove by-product NaCl, and excess epichlorohydrin (recovery) was distilled off under r...

Embodiment 2

[0030] The components of the solvent-free epoxy heavy-duty anti-corrosion coating described in this embodiment are: 60 parts of epoxy resin, 30 parts of polyamide resin, 10 parts of alkyd resin, 1 part of dispersant, 1 part of defoamer, 2 parts of leveling agent, 2 parts of anti-settling agent, 70 parts of filler, 1 part of rheological additive, and 20 parts of curing agent.

[0031] The preparation method of solvent-free epoxy heavy-duty anticorrosion coating described in the present embodiment comprises the following steps:

[0032] (1) Preparation of bisphenol A epoxy resin

[0033] Install the stirrer, return condenser tube and thermometer on the 500mL three-necked flask. Add 12.6 parts of bisphenol A, 42 parts of epichlorohydrin, and 4.2 parts of NaOH and mix and stir. Then slowly heat to 80°C, and finish the reaction after 3 hours of reaction. The reaction solution was filtered to remove by-product NaCl, and excess epichlorohydrin (recovery) was distilled off under re...

Embodiment 3

[0039] The components of the solvent-free epoxy heavy-duty anti-corrosion coating described in this embodiment are: 40 parts of epoxy resin, 20 parts of polyamide resin, 5 parts of alkyd resin, 1 part of dispersant, 1 part of defoamer, 2 parts of leveling agent, 2 parts of anti-settling agent, 35 parts of filler, 1 part of rheological additive, and 13.7 parts of curing agent.

[0040] The preparation method of solvent-free epoxy heavy-duty anticorrosion coating described in the present embodiment comprises the following steps:

[0041] (1) Preparation of bisphenol A epoxy resin

[0042] Install the stirrer, return condenser tube and thermometer on the 500mL three-necked flask. Add 11.4 parts of bisphenol A, 38 parts of epichlorohydrin, and 3.8 parts of NaOH, mix and stir, then slowly heat to 80°C, and finish the reaction after 3 hours of reaction. The reaction solution was filtered to remove by-product NaCl, and excess epichlorohydrin (recovery) was distilled off under reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com