Environment-friendly epoxy glass squama antiseptic paint for steel construction protection

A technology of epoxy glass and glass flakes, used in anti-corrosion coatings, epoxy resin coatings, devices for coating liquids on surfaces, etc., can solve problems such as corrosion, and achieve the effects of delaying damage, high mechanical strength, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

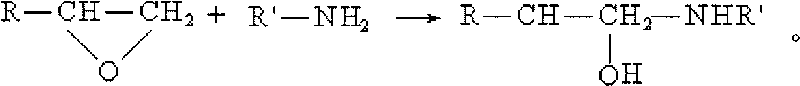

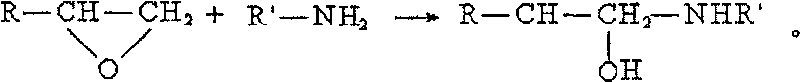

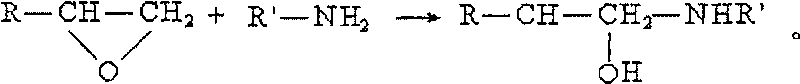

Method used

Image

Examples

no. 1 example

[0036] The first embodiment of the formula of environment-friendly type epoxy glass flake anticorrosion paint of the present invention, its component content is counted as by weight percentage:

[0037] 22.85% epoxy resin, 26.27% amine adduct curing agent, 1.36% modifier, 6.20% glass flakes, 10.80% antirust pigment, 16.33% pigment and filler, 4.18% additive, and 12.01% mixed solvent.

[0038] The second embodiment of the formula of environment-friendly type epoxy glass flake anticorrosion paint of the present invention, its component content is counted as by weight percentage:

[0039] Epoxy resin 24.65%, amine adduct curing agent 28.35%, modifier 1.85%, glass flake 8.20%, antirust pigment 8.82%, pigment and filler 15.89%, additive 4.08%, mixed solvent 8.16%.

[0040] The glass flakes in the anticorrosion paint of the present invention use C-type glass, the thickness of the glass flakes is less than 6 μm, and the sheet diameter is 0.2 to 0.4 mm, which can ensure that there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com