Preparation method of simulation wood grain three-dimensional decorative household board

A simulated wood and three-dimensional technology, which is applied in the field of preparation of simulated wood grain three-dimensional decorative home panels, can solve the problems of high production cost, inconspicuous concave-convex effect, and high cost, and achieve a real overall effect, rich 3D patterns and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment imitates the decorative effect of saw marks on oak

[0050] A method for preparing a simulated wood grain three-dimensional decorative home board, comprising the following steps:

[0051] 1. Prepare the standard image of simulated wood grain digital color pattern and the standard image of simulated wood grain digital black and white pattern;

[0052] 2. Standardize the decorative surface of the base material;

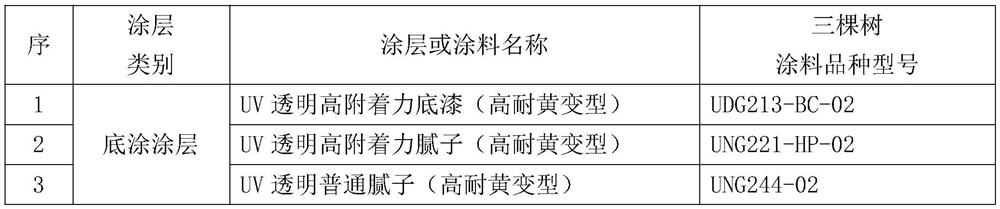

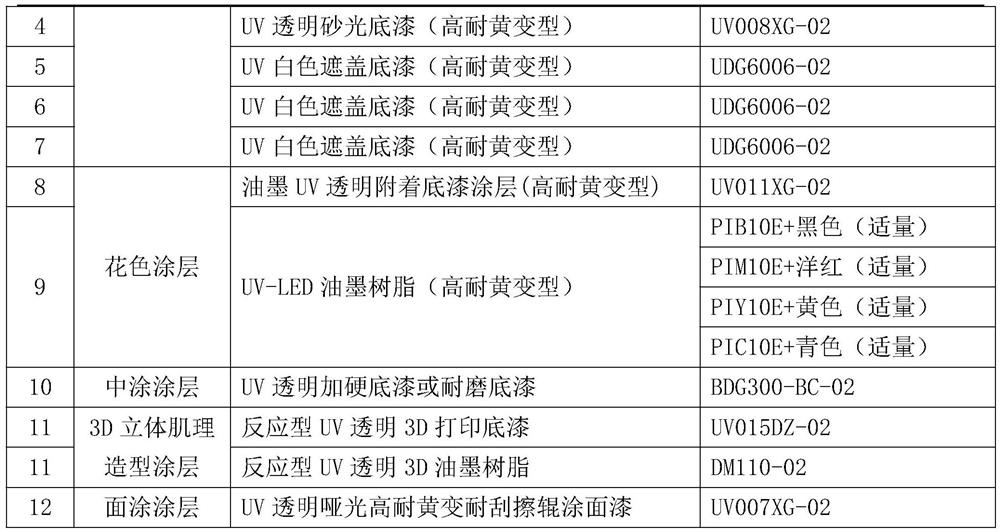

[0053] 3. Apply primer coating on the decorative surface;

[0054] Four, utilize the simulated wood grain digital color pattern standard image that step 1 prepares to coat pattern coating on the primer coating;

[0055] 5. Apply intermediate coating on the design and color coating;

[0056] 6. Apply reactive UV transparent 3D primer coating on the intermediate coating; then use the simulated wood grain digital black and white pattern standard image prepared in step 1 to coat the liquid and uncured reactive UV transparent 3D primer The reactive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing dosage | aaaaa | aaaaa |

| curing dosage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com