UV special release coating for PET or BOPP film and preparation method thereof

A special, off-type technology, applied in the direction of coating, etc., can solve the problems of low production efficiency and unsuitable performance of vacuum aluminum-plated paperboard, and achieve the effect of increasing the number of reusable times, increasing the number of reusable times, and reducing the number of coating times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

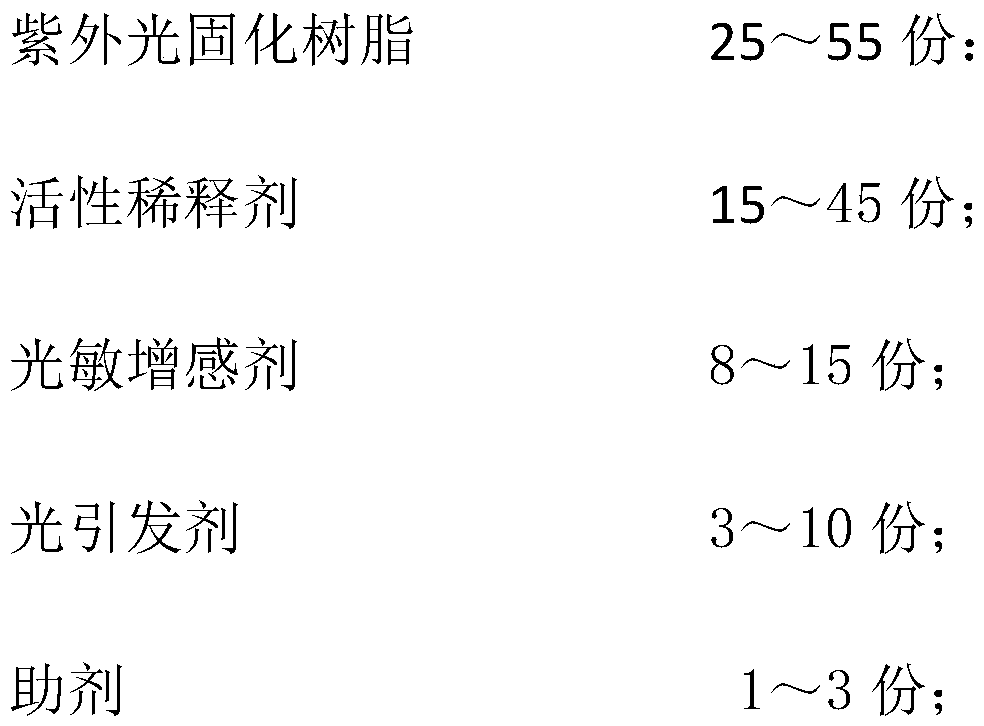

[0030] Embodiment 1: present embodiment provides a kind of UV special release coating for PET or BOPP film, by number, parts by weight, comprising the following components:

[0031]

[0032] Wherein, the UV curable resin is made by mixing 16.67 parts of modified epoxy silicone acrylic resin and 8.33 parts of multi-crown pure acrylic resin, and the reactive diluent is made of 8 parts of ethoxylated trimethylolpropane Made from a mixture of triacrylate (TMP3EOTA), 6 parts of tripropylene glycol diacrylate (TPGDA), and 2 parts of 1,6-hexanediol diacrylate (HDDA).

[0033] The photosensitizer is 2 parts of trimethylamine modified acrylate, 1 part of tri-n-butylamine modified acrylate, 1 part of triethanolamine modified acrylate, 3 parts of diisopropylethylamine, 1 part of six Mixture of methylphosphoric triamides. The photoinitiator is 1 part of 2,4-diethylthioxanthone (DETX), 1 part of 1-hydroxycyclohexyl phenyl ketone (184), 0.75 part of 2,4,6-trimethylbenzene A mixture of ...

Embodiment 2

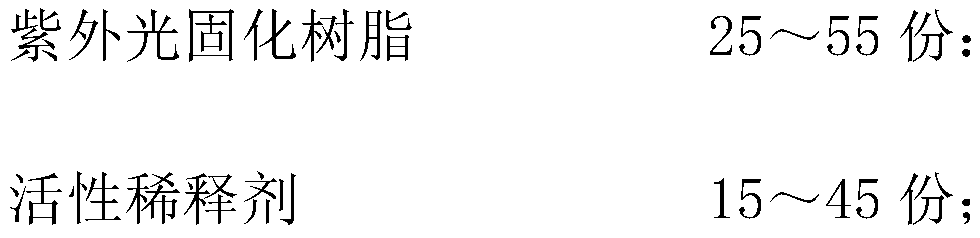

[0034] Embodiment 2: present embodiment provides a kind of UV special release coating for PET or BOPP film, by number, parts by weight, comprising the following components:

[0035]

[0036] Wherein, the UV curable resin is made by mixing 21.33 parts of modified epoxy silicone acrylic resin and 10.67 parts of polycrown pure acrylic resin, and the reactive diluent is made of 9 parts of ethoxylated trimethylolpropane triacrylate (TMP3EOTA), 5 parts tripropylene glycol diacrylate (TPGDA), 1 part 1,6-hexanediol diacrylate (HDDA), 1 part trimethylolpropane triacrylate (TMPTA), and 2 parts Made from a mixture of dipropylene glycol diacrylate (DPGDA).

[0037]The photosensitizer is 1 part of trimethylamine modified acrylate, 2 parts of tri-n-butylamine modified acrylate, 2 parts of triethanolamine modified acrylate, 1 part of triethylamine, 2 parts of tri-n-butyl Amine, a mixture of 1 part triethanolamine. The photoinitiator is 1 part of 2,4-diethylthioxanthone (DETX), 1 part of...

Embodiment 3

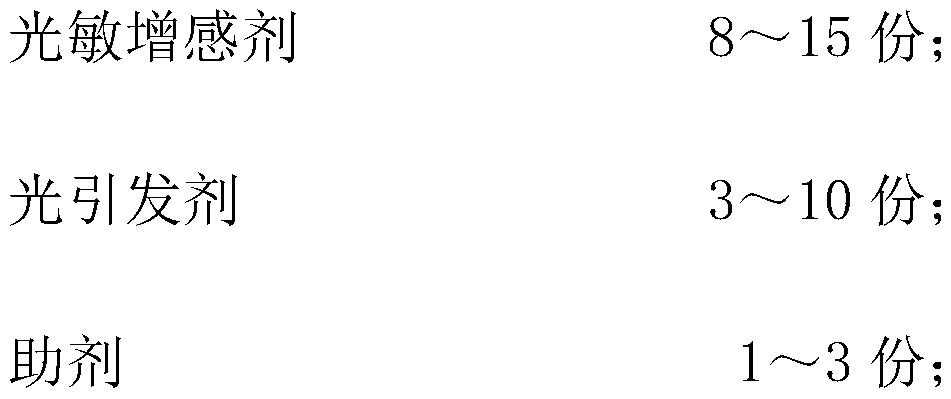

[0038] Embodiment 3: present embodiment provides a kind of UV special release coating for PET or BOPP film, by number, parts by weight, comprising the following components:

[0039]

[0040] Wherein, the UV curable resin is made by mixing 25.33 parts of modified epoxy silicone acrylic resin and 12.67 parts of polycrown pure acrylic resin, and the reactive diluent is made of 11 parts of ethoxylated trimethylolpropane Made from a mixture of Triacrylate (TMP3EOTA), 8 parts Tripropylene Glycol Diacrylate Alcohol (TPGDA), 3 parts Trimethylolpropane Triacrylate (TMPTA), and 3 parts Dipropylene Glycol Diacrylate (DPGDA).

[0041] The photosensitizer is 1 part of triethylamine modified acrylate, 1 part of tributylamine modified acrylate, 2 parts of triethanolamine modified acrylate, 2 parts of diisopropylethylamine modified acrylate , a mixture of 1 part of hexamethylphosphoric triamide and 3 parts of tetramethylethylenediamine. The photoinitiator is a mixture of 2 parts of 2,4-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com