High-solid and low-viscosity short oil alkyd resin and preparation method therefor

An alkyd resin, high-solid and low-viscosity technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as high viscosity, difficulty in preparing low-VOC paint products, and large impact of wood paint, achieving low viscosity and significant Social benefit and economic benefit, low VOC effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

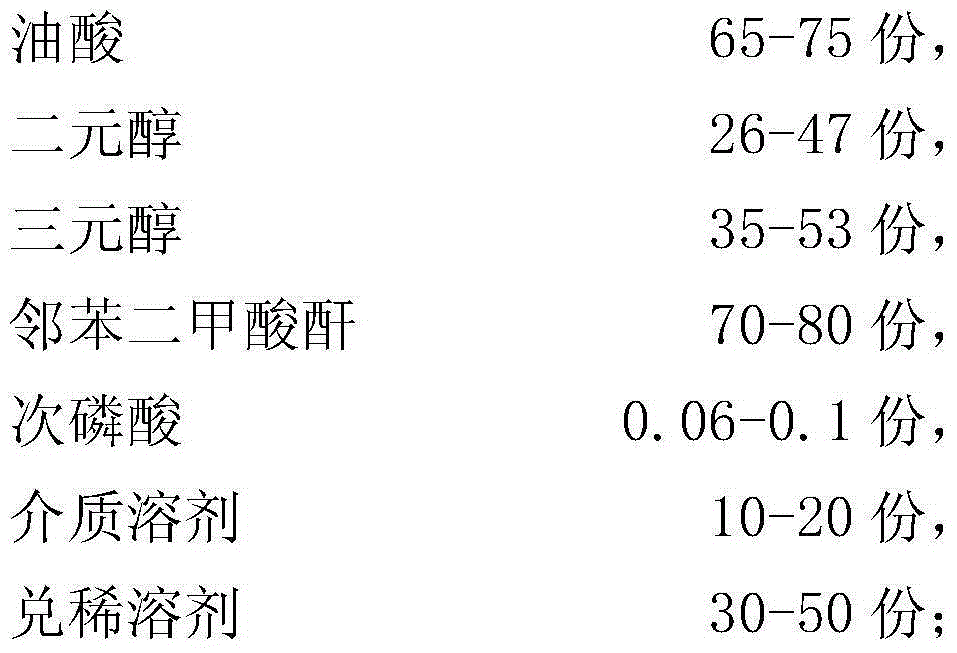

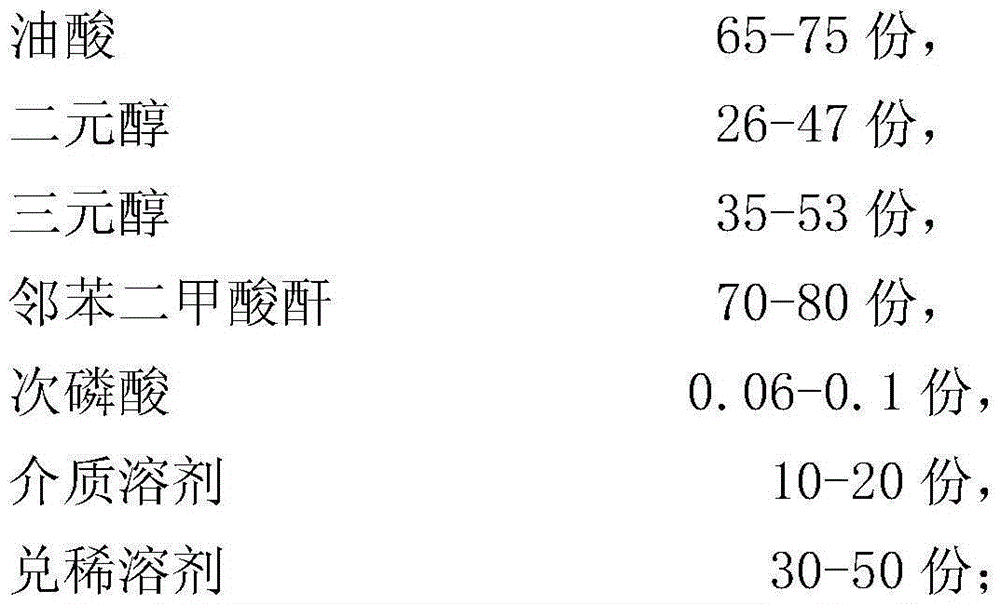

[0018] A high-solid, low-viscosity, short-oil alkyd resin, which is prepared from the following components in the following parts by weight:

[0019]

[0020] The medium solvent is xylene; the diluted solvent is one of toluene and xylene or any combination of the two.

[0021] The dihydric alcohol is one or any combination of ethylene glycol, propylene glycol, diethylene glycol, methylpropanediol, and neopentyl glycol.

[0022] The trihydric alcohol is one of glycerin, trimethylolpropane or any combination of the two.

[0023] Described high-solid low-viscosity short-oil alkyd resin is prepared according to the following method:

[0024] (1) 65-75 parts of oleic acid, 26-47 parts of diols, 35-53 parts of trihydric alcohols, 70-80 parts of phthalic anhydride, 0.03-0.08 parts of hypophosphorous acid, and 10-20 parts of medium solvent into the reactor;

[0025] (2) Pass nitrogen or carbon dioxide protective gas into the reaction kettle, remove the oxygen in the reaction ket...

Embodiment 1

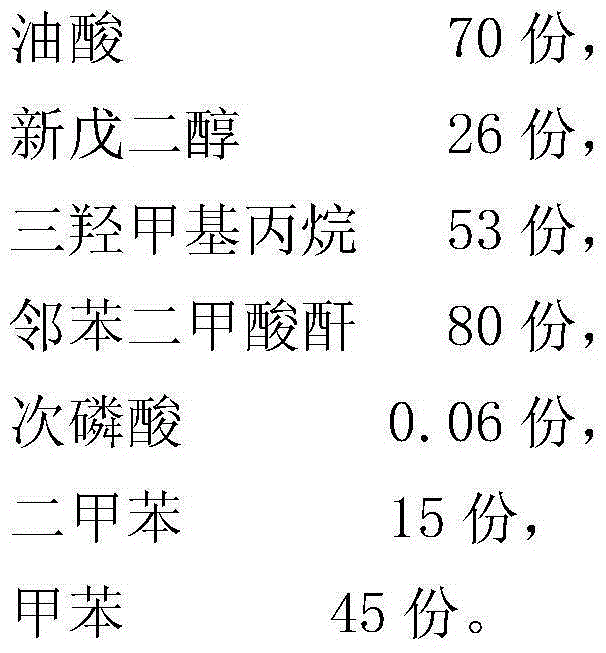

[0031] A high-solid, low-viscosity, short-oil alkyd resin, which is prepared from the following components in the following parts by weight:

[0032]

[0033] The preparation method of the above-mentioned high-solid low-viscosity short-oil alkyd resin is prepared according to the following method:

[0034] (1) 70 parts of oleic acid, 26 parts of neopentyl glycol, 53 parts of trimethylolpropane, 80 parts of phthalic anhydride, 0.06 part of hypophosphorous acid, and 15 parts of xylene are put into the reactor;

[0035] (2) Feed nitrogen or carbon dioxide protective gas into the reactor to remove oxygen in the reactor, then heat up to 150°C, after the material is dissolved, stir for 10 minutes at a speed of 300 rpm, then heat up to 165°C, Allow the material to insulate and reflux in the reactor, and perform esterification reaction for 3 hours;

[0036] (3) Slowly heat up to 190° C. for esterification, and take a sample of the resin during the heat preservation esterification ...

Embodiment 2

[0040] A high-solid, low-viscosity, short-oil alkyd resin, which is prepared from the following components in the following parts by weight:

[0041]

[0042] The preparation method of the above-mentioned high-solid low-viscosity short-oil alkyd resin is characterized in that: it is prepared according to the following method:

[0043] (1) Put 65 parts of oleic acid, 20 parts of diethylene glycol, 16 parts of ethylene glycol, 75 parts of phthalic anhydride, 35 parts of trimethylolpropane, 0.06 parts of hypophosphorous acid, and 10 parts of xylene into the reaction kettle ;

[0044] (2) Feed nitrogen or carbon dioxide protective gas into the reaction kettle to remove the oxygen in the reaction kettle, then heat up to 160°C, after the material is dissolved, stir at a speed of 600 rpm for 20 minutes, then heat up to 180°C, Allow material to insulate and reflux in the reactor, esterify for 4 hours;

[0045] (3) Slowly heat up to 210°C for esterification, and take a sample of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com