Patents

Literature

60results about How to "High solid content in construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-fullness high-resolution environment protection polyureshane sublight uarnish

InactiveCN1483777AIncreased weight percentageReduce weightPolyurea/polyurethane coatingsKetoneSolvent

The present invention relates to a high-fullness high-distinctness environment-protecting type polyurethane matte varnish. Said varnish consists of the paint component, polyurethane solidifying agent component and diluting agent component according to the ratio of 1:0.5:0.6-0.8. The polyurethane solidifying agent component contains 50-70 wt% of tolylene diisocyanate trimer, and the rest is the affixture of 80% of tolylene diisocyanate and 20% of trimethylol propane, the paint component contains 15-25% of short oil soya alkyd resin whose solid content is 80%, 50-60% of modified saturated polyester resin, 0-5% of castor oil, 10-12% of aldehyde ketone resin whose solid content is 60%, 3-5% of flatting silica, 0.3-1.0% of teflon wax and 4%-10% of conventional adjuvant and solvent, and the diluting agent component contains 70-80% of butyl acetate, 10-20% of mixed diacid dimethyl ester and 10-15% of isophorone.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

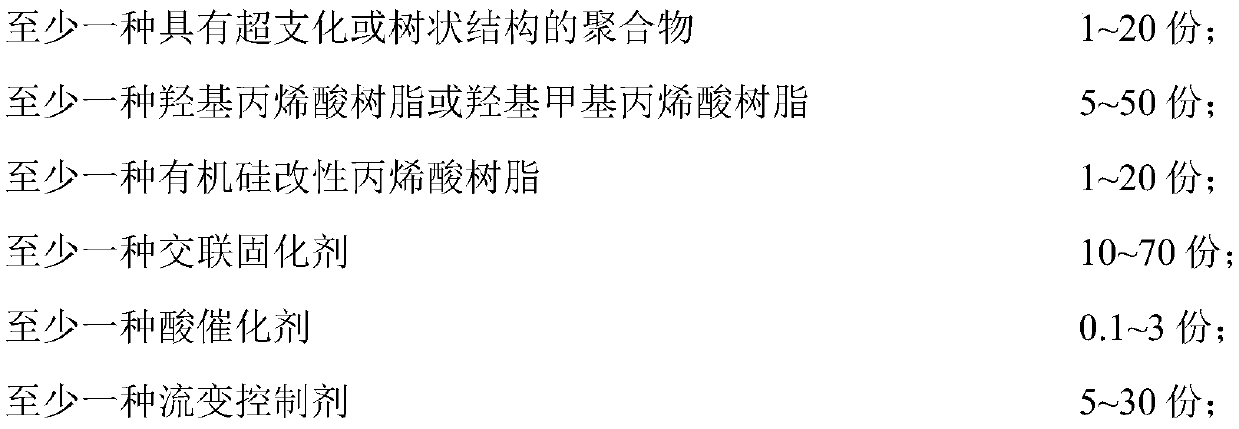

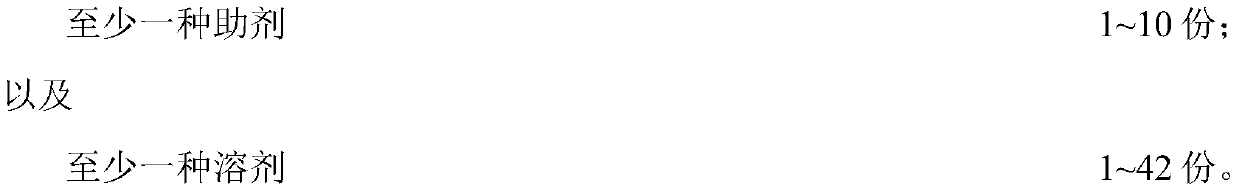

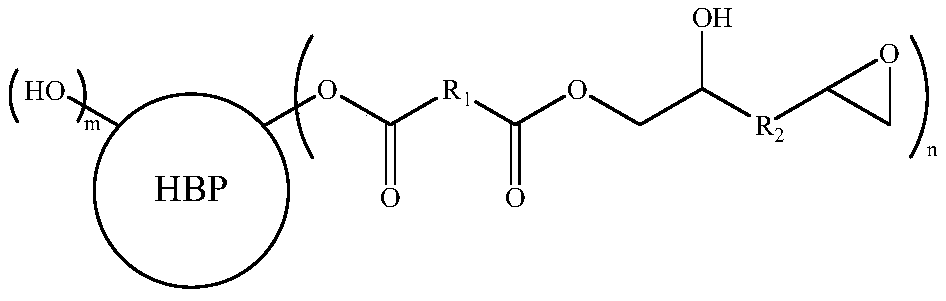

Mono-component varnish composition, preparation method and purpose thereof

ActiveCN106916503AImprove radiation resistanceGood weather resistancePretreated surfacesPolyurea/polyurethane coatingsWeather resistanceAcrylic resin

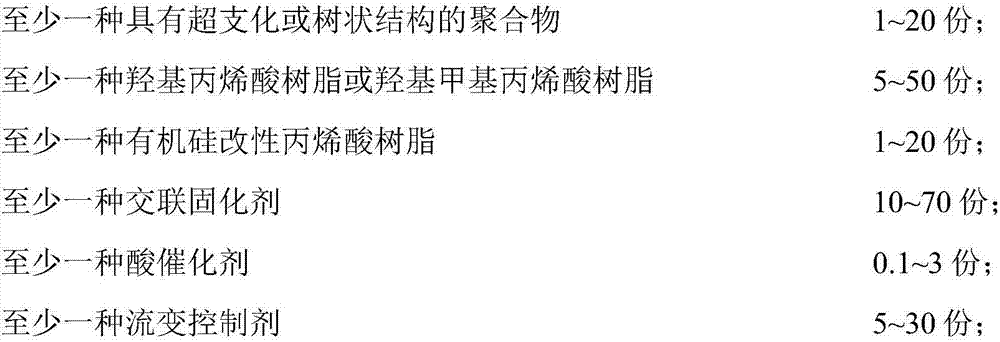

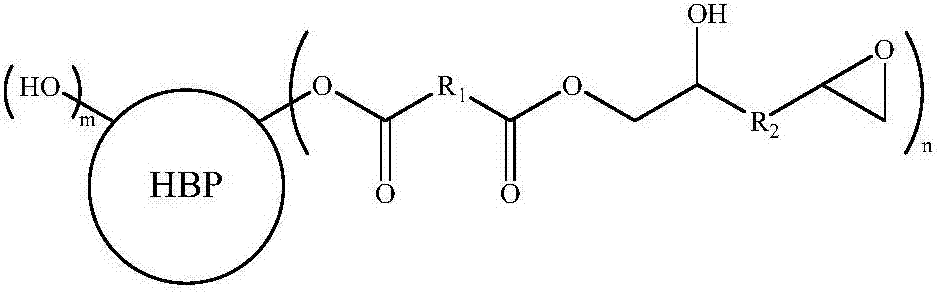

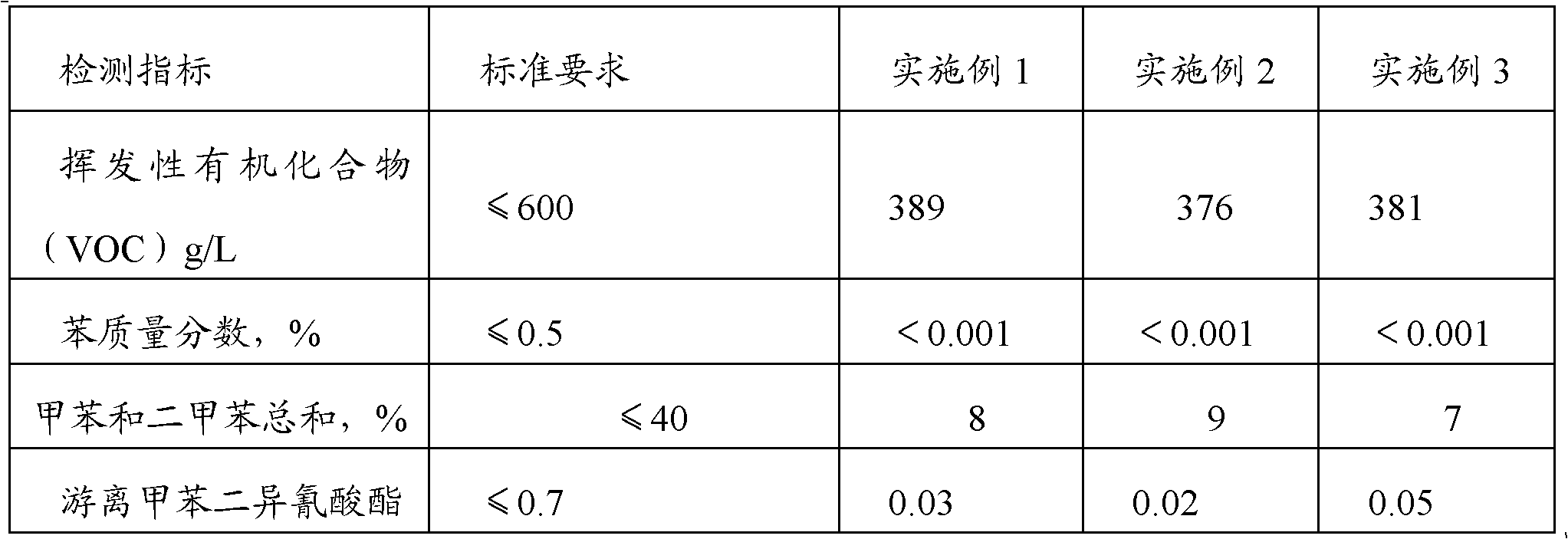

The invention discloses a mono-component varnish composition, which comprises at least a polymer having a hyper branched or dendritical structure; at least one type of hydroxyl acrylic resin or hydroxyl methacrylate resin; at least one type of organosilicon-modified acrylic resins; at least a crosslinking curing agent; at least an acid catalyst; at least a rheological control agent; at least an auxiliary agent and at least a solvent; and the mono-component varnish composition has the advantages of high scratch resistance and high weather resistance. The provided mono-component varnish composition can effectively increase the smoothness of the surface of a varnish composition film, and increases the rub resistance of the film; in addition, the introduction of the organosilicon-modified acrylic resin can further increase the weatherability of the varnish composition film.

Owner:LANGFANG NIPPON PAINT +2

Bicomponent oily polyurethane primer with low VOC (volatile organic compounds)

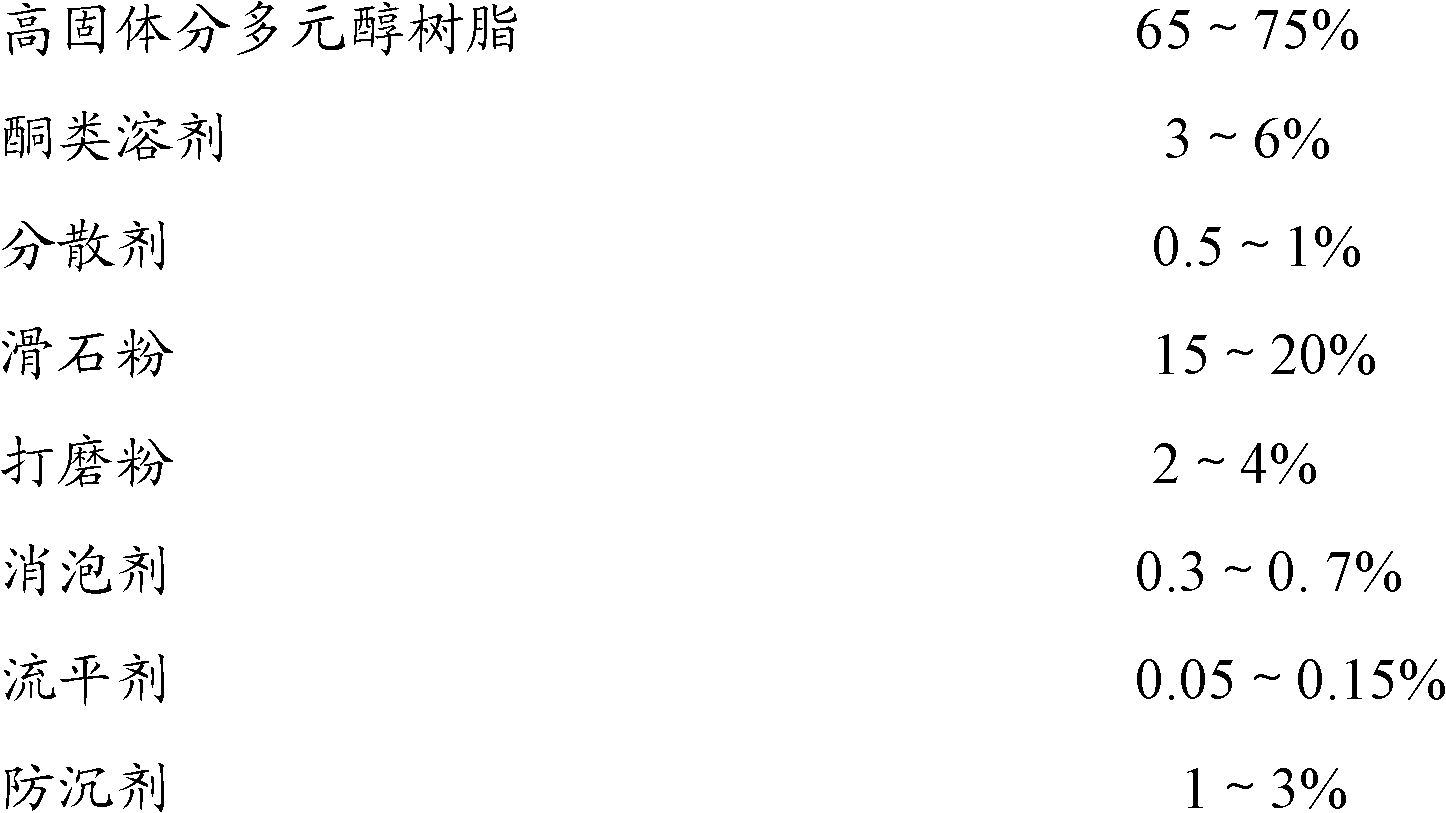

The invention relates to the technical field of coatings, in particular to a bicomponent oily polyurethane primer with low VOC (Volatile Organic Compounds) and a preparation method thereof. The primer comprises a component A, a component B and a diluting agent, wherein the ratio in parts by weight of the component A to the component B is 2:1, wherein the component A comprises polyhydric alcohol resin with high solid content, an ester solvent, a dispersing agent, a matting powder, a defoaming agent and an anti-sediment agent; according to the preparation method, different molecular weights of the polyhydric alcohol resin in the component A and the polyisocyanates in the component B are respectively screened, the optimal molecular weight is intercepted so as to ensure the dissolubility of the polyhydric alcohol resin and the polyisocyanates in a ketone solvent, meanwhile, other auxiliaries are used for carrying out stem grafting improvement on a molecular structure to enhance the miscibility of the two components; and therefore, the bicomponent oily polyurethane primer not only has the characteristics of good application property, good water resisting property, high hardness and thelike owned by the traditional polyurethane paint, but also ensures that the content of the volatile organic compounds is greatly reduced and even is lower than 450g / L.

Owner:东莞大宝化工制品有限公司 +1

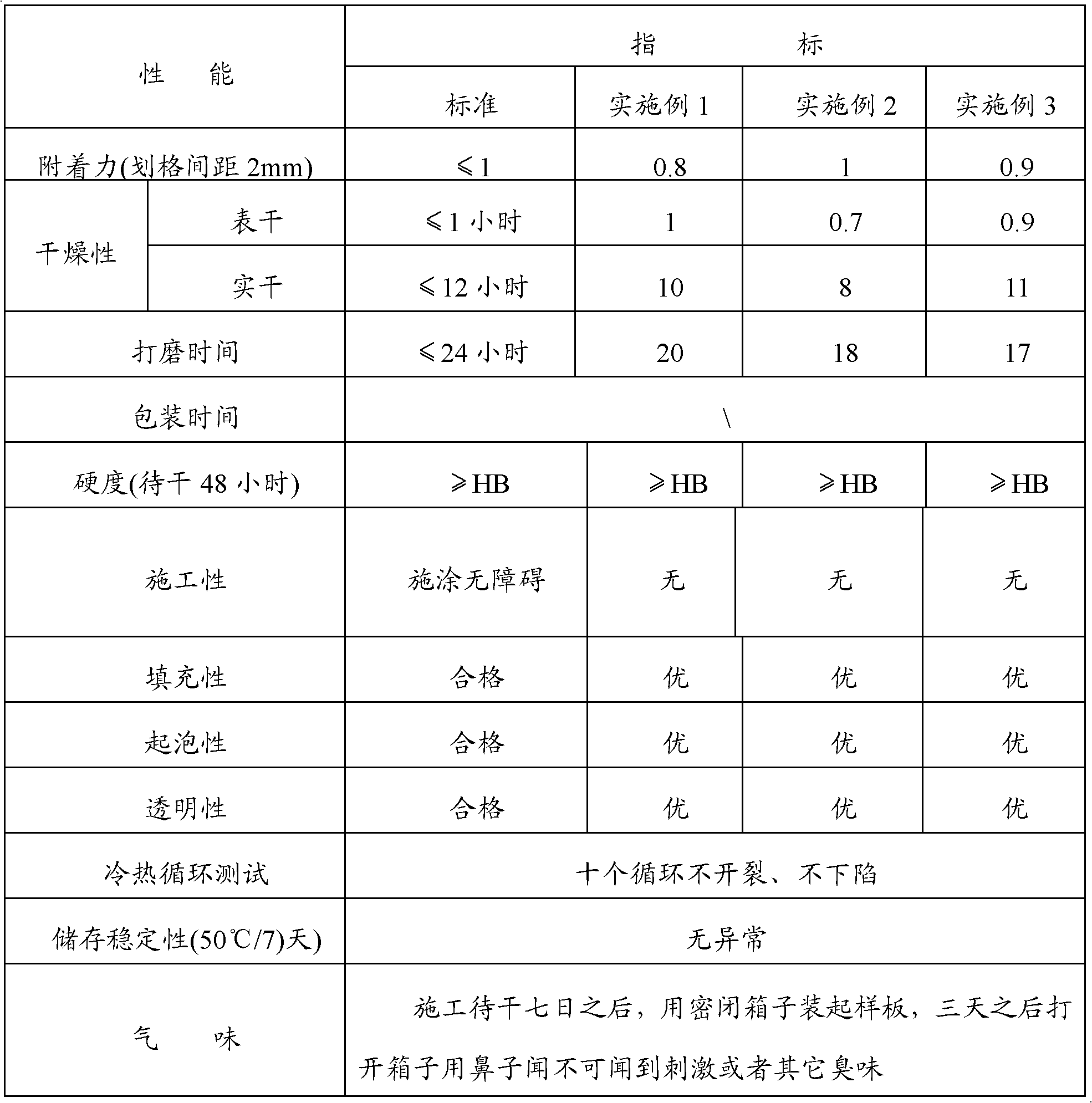

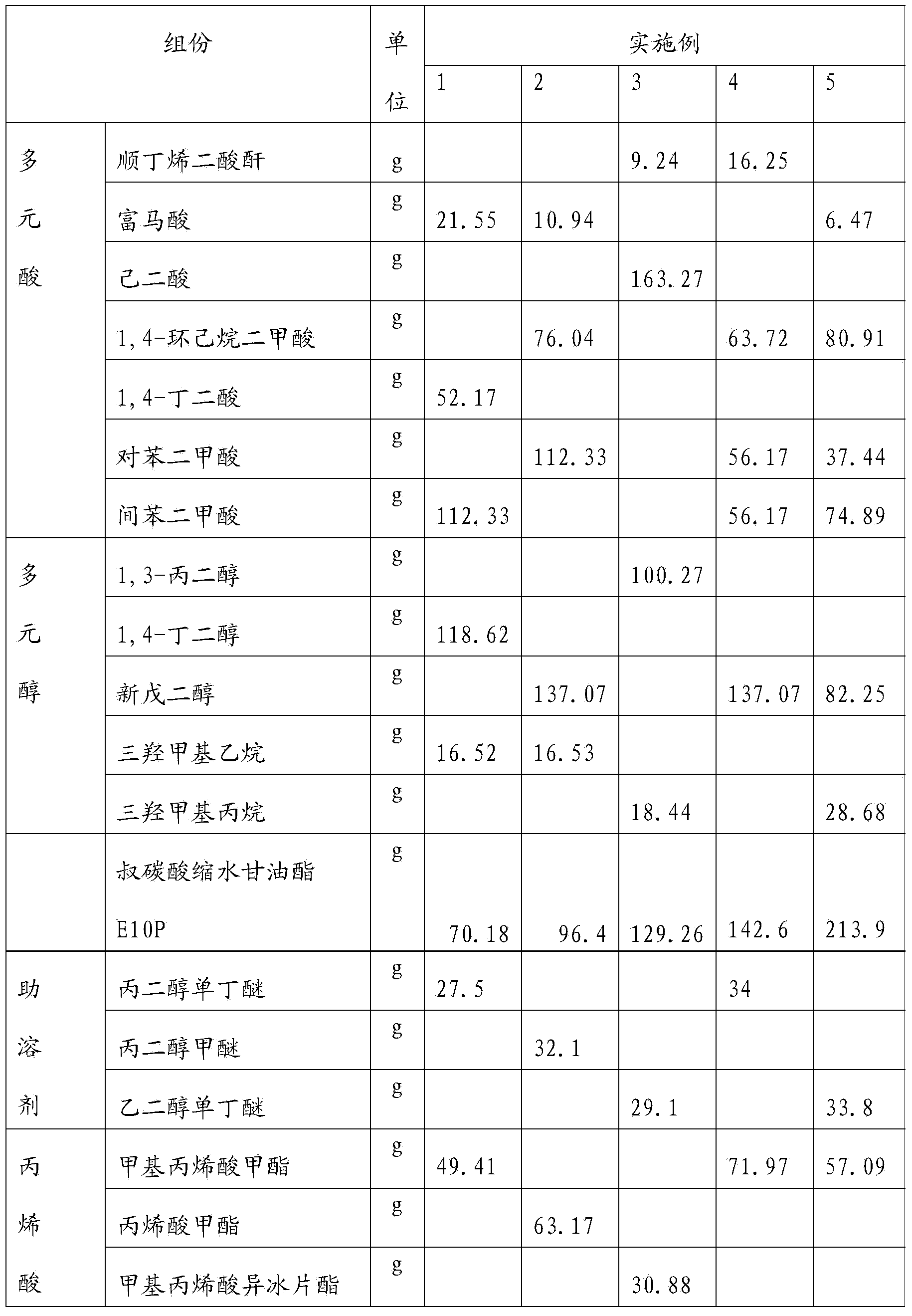

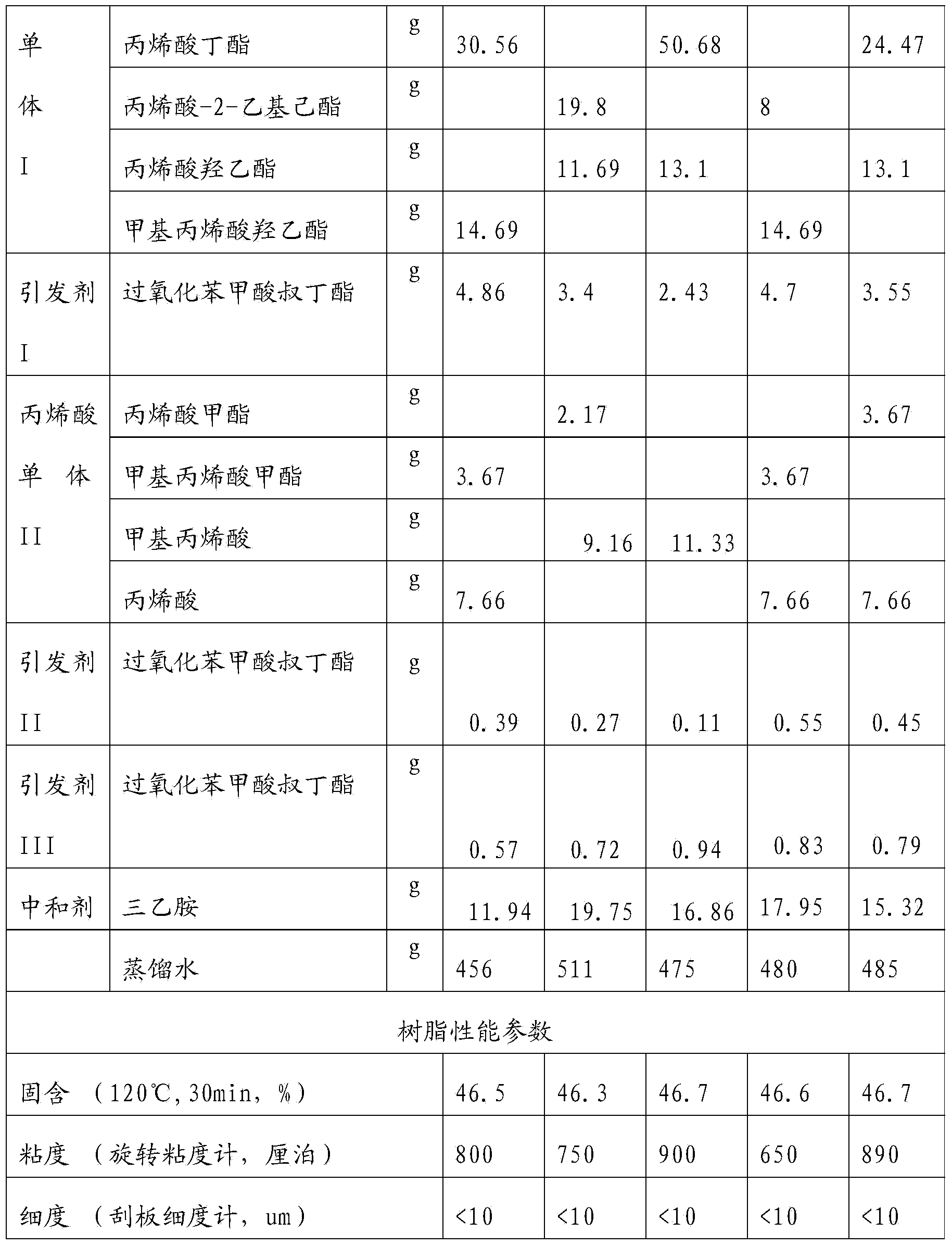

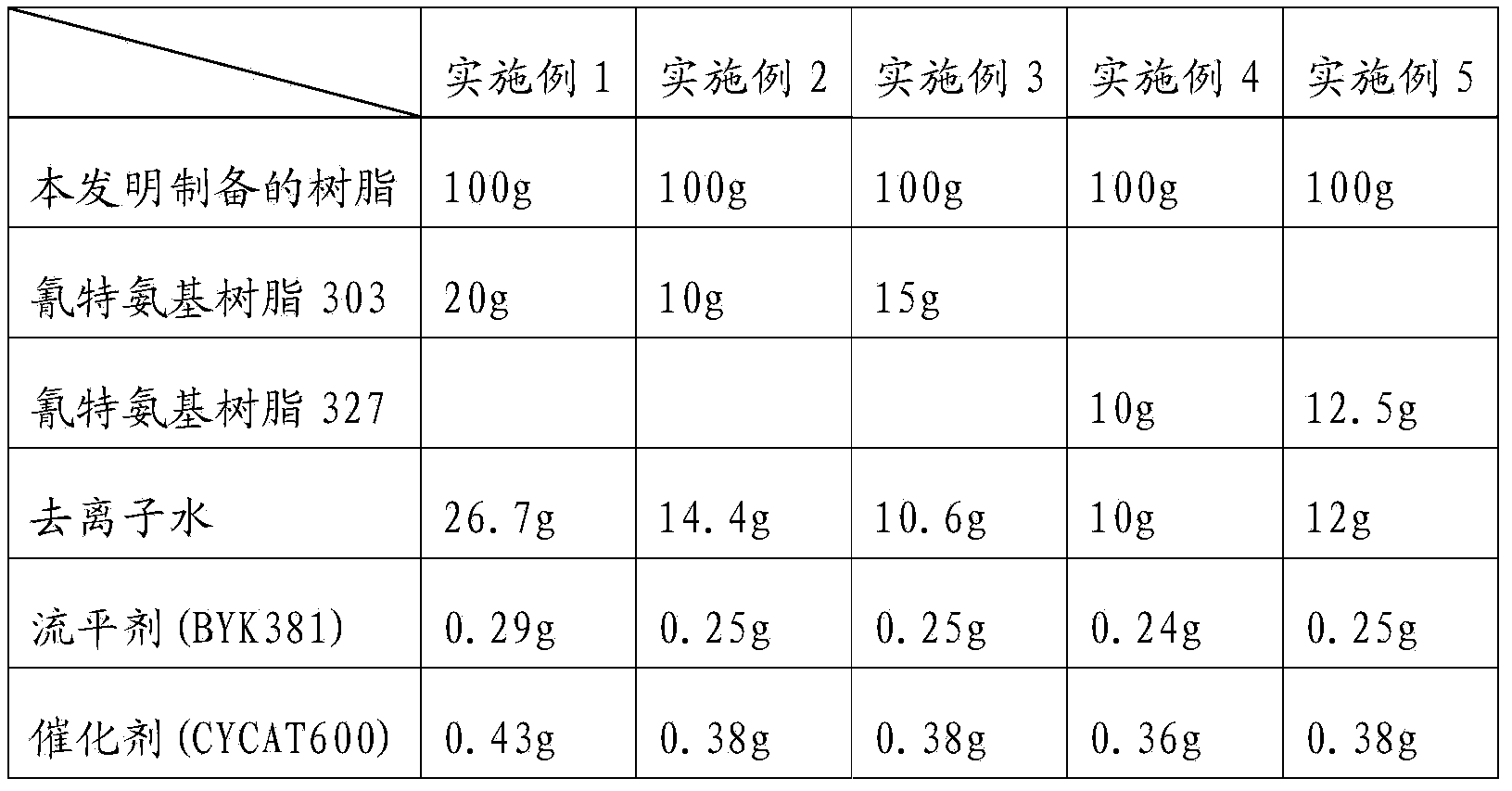

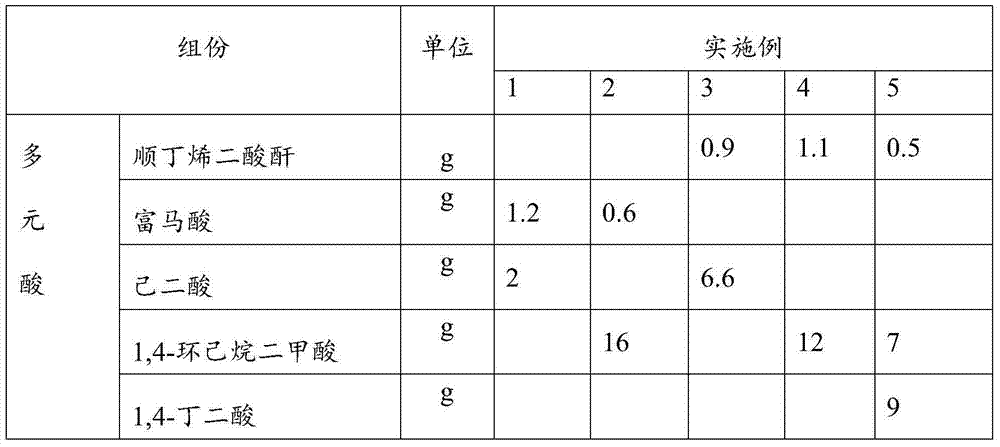

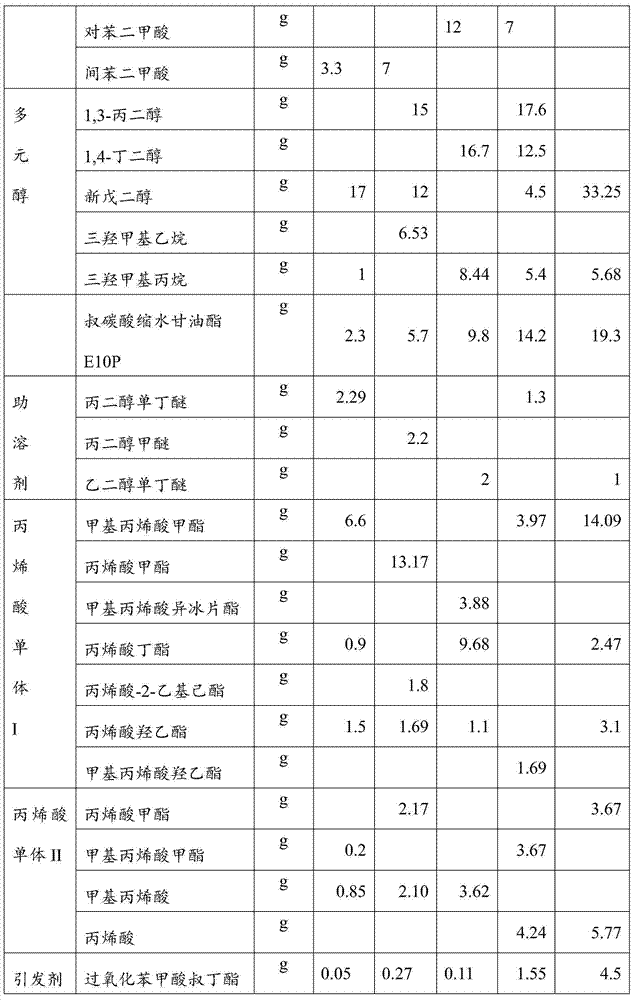

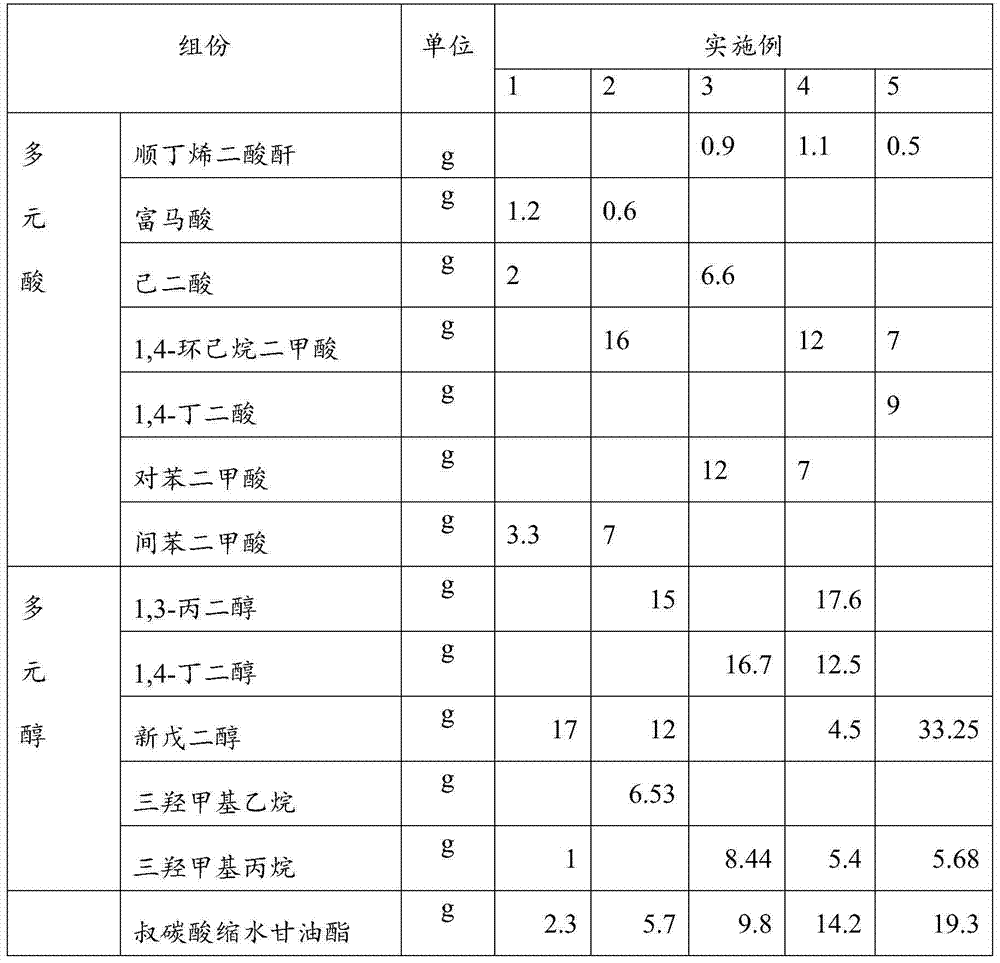

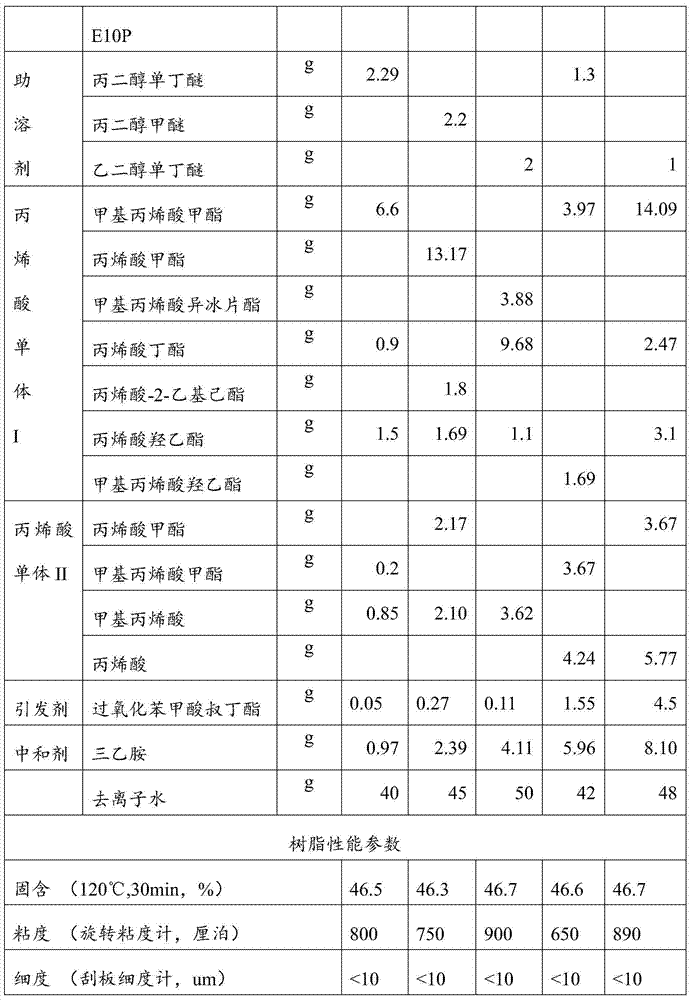

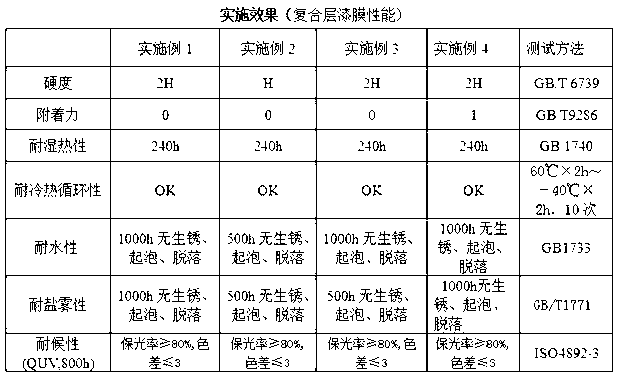

Water-based acrylic acid modified saturated polyester resin and preparation method thereof

The invention relates to a water-based acrylic acid modified saturated polyester resin and a preparation method thereof. The water-based acrylic acid modified saturated polyester resin is prepared from the following raw materials in percentage by weight: 5-40% of polyatomic acid, 3-40% of polyhydric alcohol, 0.5-5% of cosolvent, 5-20% of acrylic monomer I, 0.5-5% of acrylic monomer II, 0.01-5% of initiator, 0.5-5% of neutralizer,2-20% of glycidyl tertiary carboxylic ester and 40-50% of distilled water. The water-based acrylic acid modified saturated polyester resin prepared by the invention has the advantages of excellent stability, high solids, low viscosity and low content of VOC (Volatile Organic Compounds) and is mainly applicable to amino-baking paint for waterborne coatings.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD +1

Single-component, high-solid-content and low-volatility organic compound and environment-friendly type varnish composition and preparation method and application of varnish composition

The invention discloses a single-component, high-solid-content and low-volatility organic compound (VOC) and environment-friendly type varnish composition. The varnish composition comprises at least one polymer with a hyper-branched or tree-shaped structure, at least one hydroxyl acrylic resin or hydroxyl methacrylic resin, at least one cross-linking curing agent, at least one acid catalyst, at least one rheology control agent and at least one auxiliary agent. With the adoption of the varnish composition and application of the varnish composition, disclosed by the invention, the viscosity of a varnish coating system can be effectively reduced, and the solid content of the construction can be easily improved to be 58 percent or above; construction VOC emission is reduced to be smaller than or equal to 420g / L; varnish film shrinkage caused in a curing process can also be effectively reduced and a cured multi-coating varnish film has better appearance effect; particularly, the effect in a wet-on-wet process, a three-coating and one-drying process of curing three coatings together or an IPP system of primers, paints and varnishes is obvious.

Owner:LANGFANG NIPPON PAINT

Coating process applying water-based paint to metal parts of construction machinery

InactiveCN102974520AMeet the use requirementsGood lookingAnti-corrosive paintsPolyurea/polyurethane coatingsProcess engineeringMechanic - metal

The invention discloses a coating process applying water-based paint to metal parts of construction machinery. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the metal parts of the construction machinery. The coating process applying the water-based paint to the metal parts of the construction machinery enables the water-based paint to be correctly used for the coating of the metal parts of the construction machinery, not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

Coating process applying water-based paint to cast iron parts

InactiveCN102974518AMeet the use requirementsGood lookingPretreated surfacesAnti-corrosive paintsCast ironCoating

The invention discloses a coating process applying water-based paint to cast iron parts. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the cast iron parts of machinery. The coating process applying the water-based paint to the cast iron parts enables the water-based paint to be correctly used the coating of the cast iron parts of the machinery, and not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

Waterborne acrylic modified saturated polyester resin

InactiveCN104761684AImprove hydrolysis resistanceImprove protectionPolyester coatingsGlycerol ester of wood rosinPolyol

The present invention relates to an aqueous acrylic acid modified saturated polyester resin, comprising the following materials of parts by weight: 5-25 parts of a polyacid, 15-40 parts of a polyol, 1-3 parts of a solubilizing agent, 5-20 parts of an acrylic acid monomer I, 0.5-10 parts of acrylic acid monomer II, 0.01-8 parts of an initiator, 0.5-10 parts of a neutralizer, 2-20 parts of glycidyl ester tertcarbonate, and 40-50 parts of deionized water. The aqueous acrylic acid modified saturated polyester resin prepared in the present invention has excellent stability, high solid-ness, low viscosity, and low VOC content, and can be mainly used for amino baked-on coating for aqueous coatings.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD +1

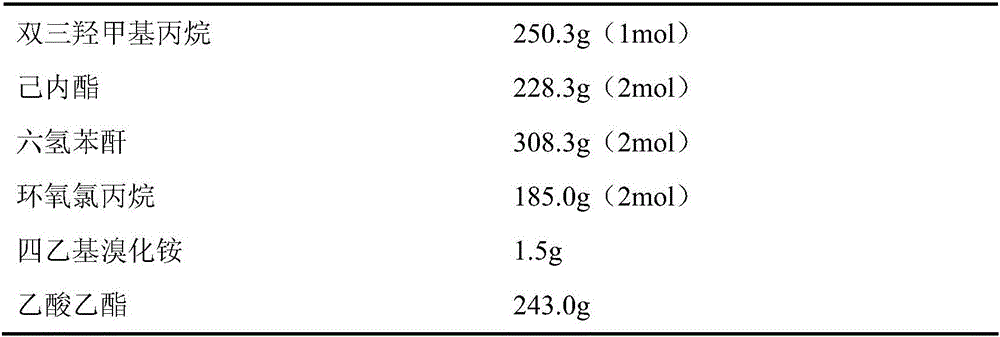

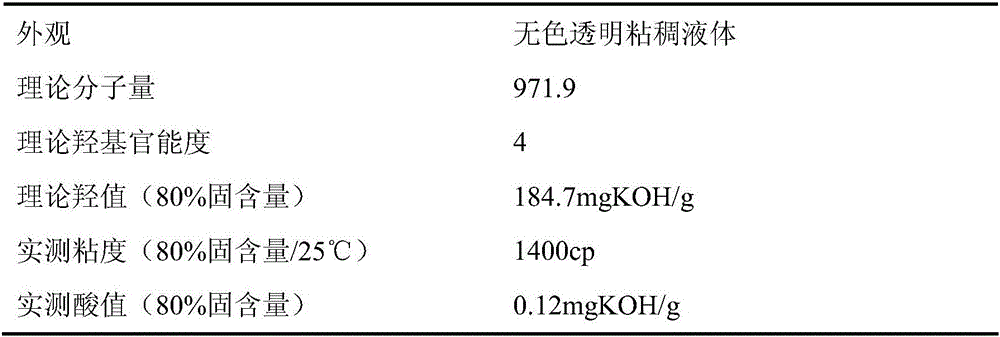

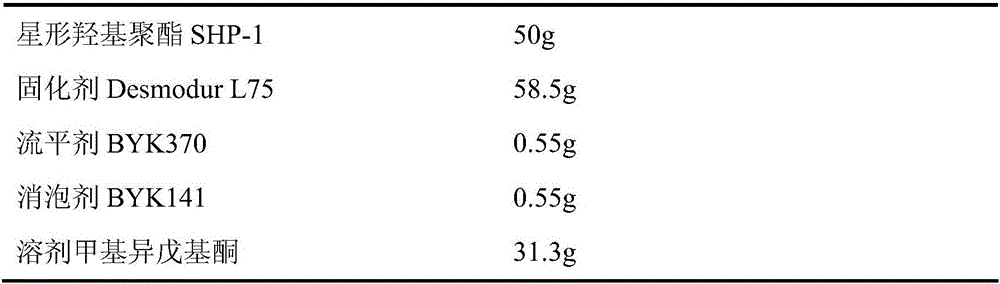

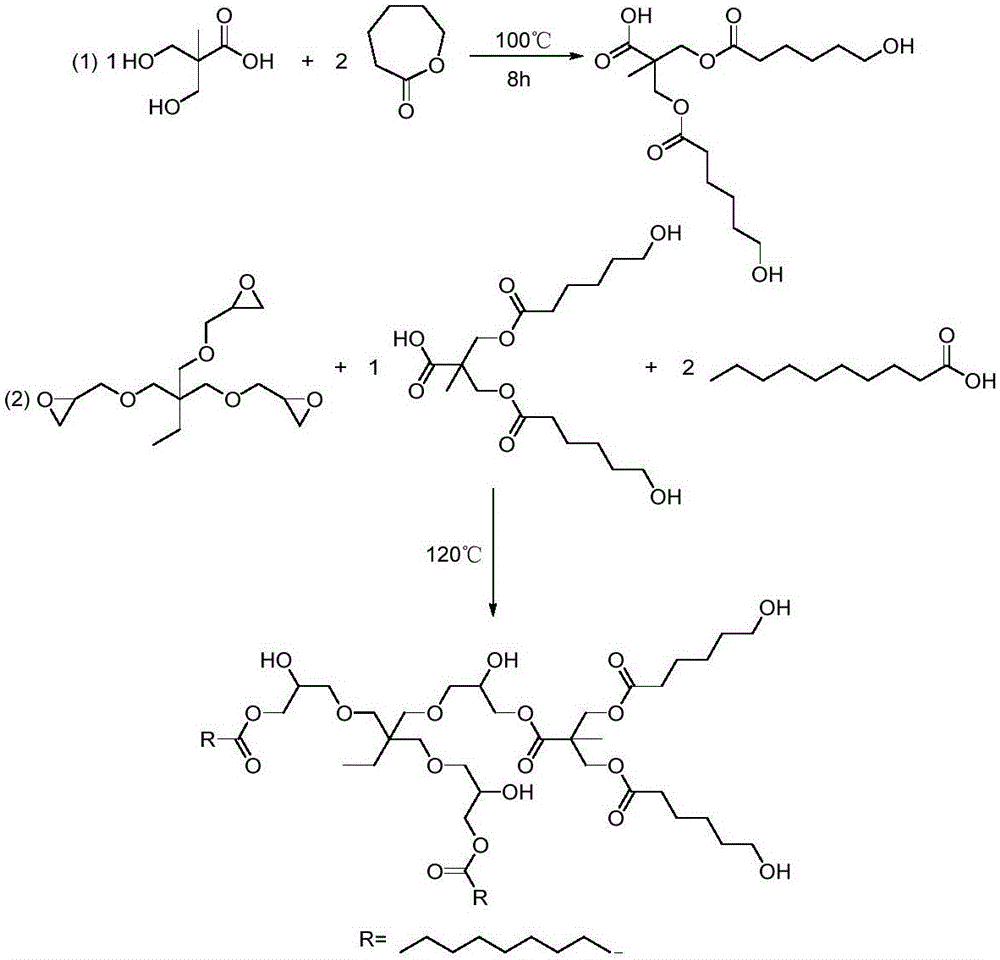

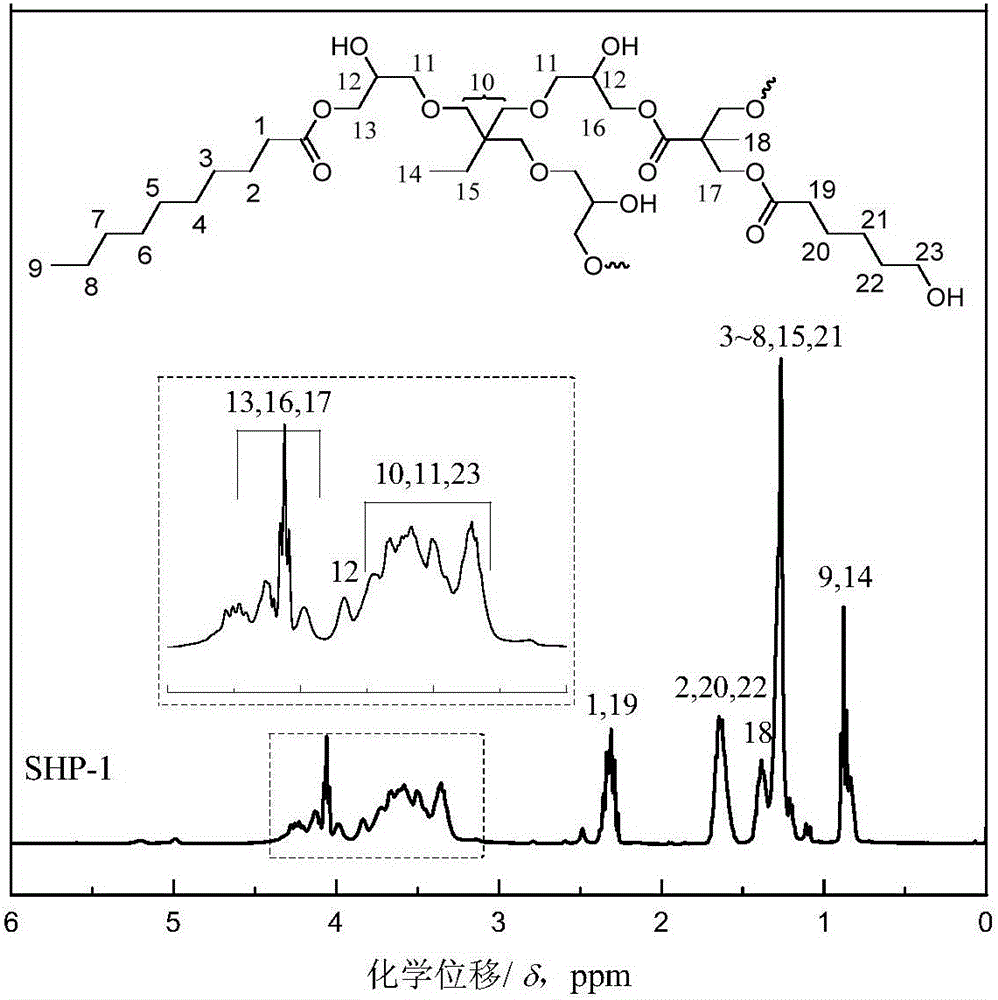

Star-shaped hydroxyl polyester adopting polyhydric alcohol as nucleus and preparation method and application of star-shaped hydroxyl polyester

ActiveCN106279659AAffect activation periodImprove catalytic abilityPolyurea/polyurethane coatingsPolyesterSolvent

The invention discloses star-shaped hydroxyl polyester adopting polyhydric alcoho as a nucleus and a preparation method and an application of the star-shaped hydroxyl polyester. The preparation method comprises the following steps: enabling 1 to 8 molar caprolactone and 1 to 4 molar anhydride to react for 6 to 10 h at 80 to 140 DEG C by adopting 1 molar small molecular polylasic alcohol as a core molecule to obtain a matrix star-shaped polyester, then reacting with 1 to 4 molar monoglycidyl ether at 90 to 150 DEG C to obtain star-shaped hydroxyl polyester. The prepared star-shaped hydroxyl polyester has the advantages of simple synthesis process, high solid content and low viscosity, a hydroxyl value is 140 to 250 mg KOH / g (80 percent of solid content), the viscosity at 25 DEG C when the solid content is 80 percent is 300 to 3000cp, the star-shaped hydroxyl polyester can be cross-linked with a polyurethane curing agent containing an isocyanate group and can be used for preparing a coating with a high solid content, the VOC content at the construction viscosity is smaller than 380 g / L, and the film performance can satisfy the national standard of the solvent-type dual-component polyurethane wood coatings.

Owner:SOUTH CHINA UNIV OF TECH +1

Low-viscosity star-shaped hydroxyl polyester as well as preparation method and application thereof

ActiveCN105820048ALow viscosityHigh solid contentOrganic compound preparationCarboxylic acid esters preparationPolyesterCarboxylic acid

The invention discloses low-viscosity star-shaped hydroxyl polyester as well as a preparation method and application thereof, and belongs to the field of macromolecules of polyester. According to the preparation method, a caprolactone modified AB2 type branched monomer is first prepared, and is prepared by a reaction between 1 mole of dihydroxymethyl alkyl carboxylic acid and 1-4 moles of caprolactone at 80-160 DEG C, afterwards, a polybasic glycidyl ether nucleus, monocarboxylic acid and the caprolactone modified AB2 type branched monomer are mixed and subjected to reaction at 100-160 DEG C, and a ring cleavage reaction between a carboxyl group and an epoxy group is catalyzed by utilizing a quaternary ammonium salt as a catalyst to generate a secondary carbonyl group for preparing the low-viscosity star-shaped hydroxyl polyester. The low-viscosity star-shaped hydroxyl polyester provided by the invention has the advantages that a synthetic process is simple, the adjustable range of the hydroxyl value of a product is large, the viscosity is low, and the like; the low-viscosity star-shaped hydroxyl polyester has the hydroxyl value between 1500mgKOH / g and 350mgKOH / g, has the viscosity as low as 3000-15000cp below 25 DEG C, and can be cross-linked with a polyurethane curing agent containing an isocyanate group; high-solid-content paint can be prepared, and the film coating performance meets a national standard for solvent type bi-component polyurethane paint for woodenware.

Owner:SOUTH CHINA UNIV OF TECH +1

Coating process applying water-based paint to metal parts of engineering machinery

InactiveCN102974522AMeet the use requirementsGood lookingAnti-corrosive paintsPolyurea/polyurethane coatingsMetallurgyEngineering

The invention discloses a coating process applying water-based paint to metal parts of engineering machinery. The coating process applying the water-based paint to the metal parts of the engineering machinery is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the metal parts of the engineering machinery. The coating process applying the water-based paint to the metal parts of the engineering machinery enables the water-based paint to be correctly used for the coating of the metal parts of the engineering machinery, and not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and physical and chemical performance coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

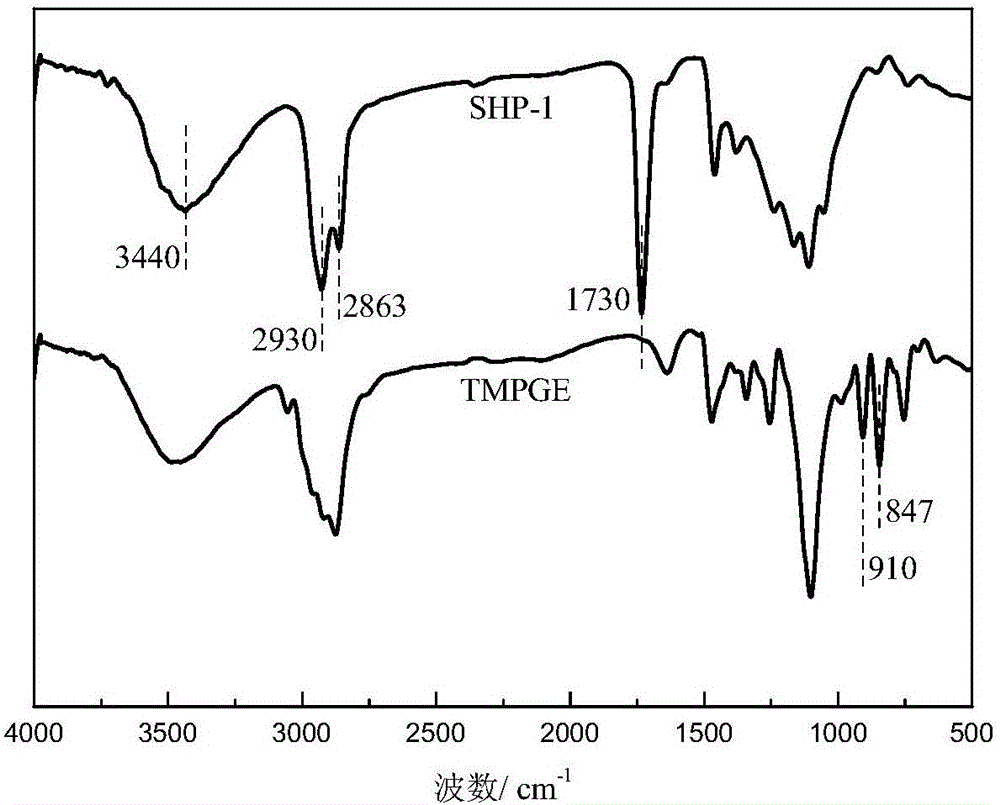

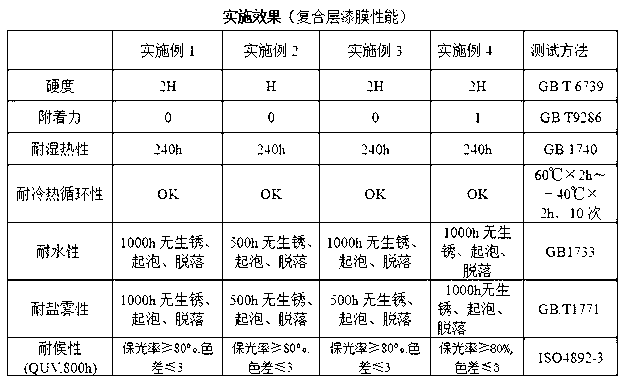

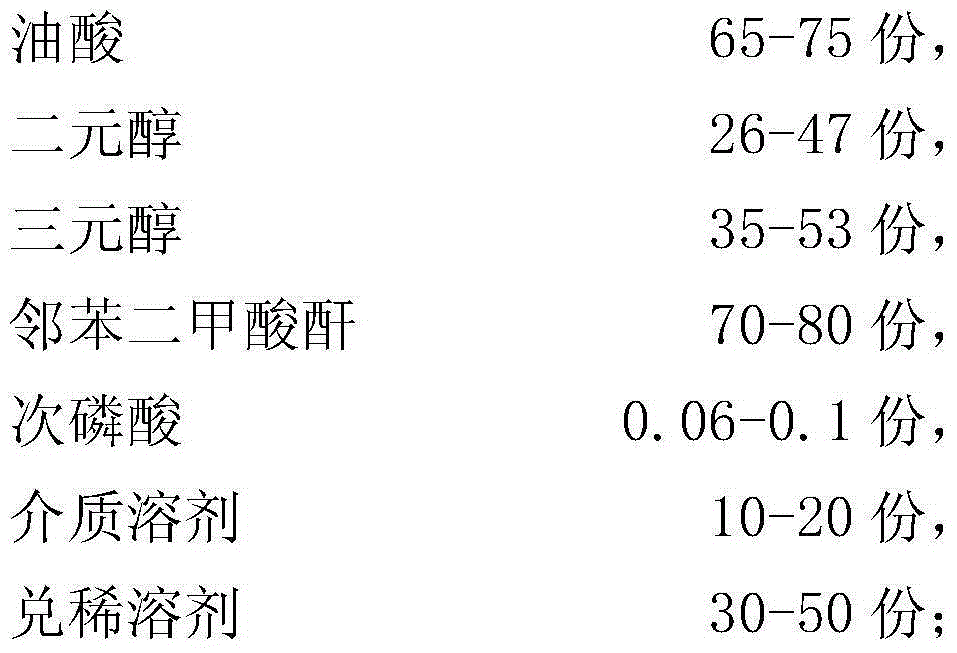

High-solid and low-viscosity short oil alkyd resin and preparation method therefor

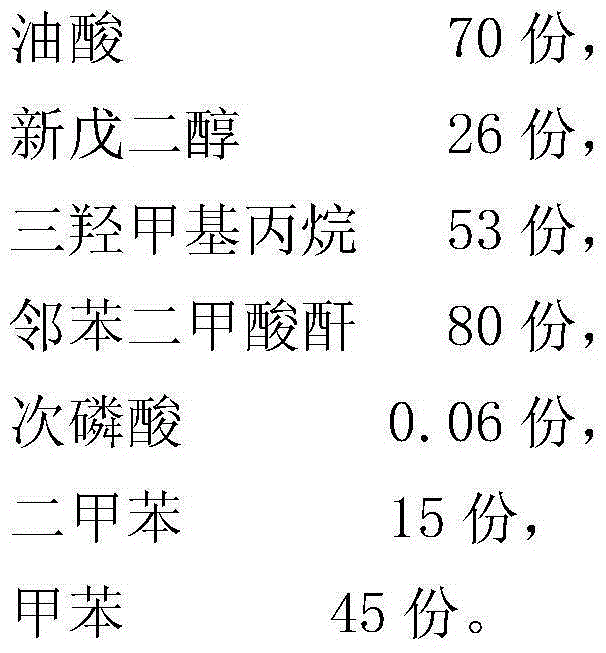

The invention relates to alkyd resin, particularly high-solid and low-viscosity short oil alkyd resin and a preparation method therefor. The high-solid and low-viscosity short oil alkyd resin provided by the invention is prepared from the following components in parts by weight: 65-75 parts of oleic acid, 26-47 parts of dihydric alcohol, 35-53 parts of trihydric alcohol, 70-80 parts of phthalic anhydride, 0.06-0.1 part of hypophosphorous acid, 10-20 parts of a medium solvent, and 30-50 parts of a diluting solvent. The short oil alkyd resin prepared by the invention is high in solid content and low in viscosity, can be used in light or matte polyurethane wood lacquer at the same time, remarkably reduces the content of VOC in paint, and has a good film effect.

Owner:SKSHU PAINT

Waterborne hydroxyl acrylic finish paint and preparation method thereof

The invention relates to a waterborne hydroxyl acrylic finish paint and a preparation method thereof. The waterborne hydroxyl acrylic finish paint comprises a component A and a component B, and the component A comprises, by mass, 50-55 parts of an aqueous hydroxyl acrylic dispersion, 4.5-9 parts of deionized water, 0.2-0.3 part of a pH adjuster, 2-3 parts of a cosolvent, 1-1.2 parts of a wetting and leveling agent, 1-1.2 parts of a brightener, 1-1.2 parts of an emulsifier, 3-4 parts of an anti-settling agent, 0.5-0.7 part of a thickener, 0.2-0.4 part of an antifoaming agent, 0.8-1.5 parts of adispersant, 2-21 parts of a pigment and 10-26 parts of a filler; the component B comprises, by mass, 75-85 parts of an aqueous isocyanate curing agent and 15-25 parts of an environmentally friendly solvent; and a mass ratio of the component A to the component B is (8-10):1 . The finish paint in the invention has far higher hardness and glossiness than existing low-hydroxyl waterborne acrylic polyurethane finish paints, and has a far lower cost than high-hydroxyl waterborne acrylic polyurethane finish paints.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Preparation method of waterborne acrylic modified saturated polyester resin

InactiveCN104761685AImprove hydrolysis resistanceImprove protectionPolyester coatingsPolymer sciencePolyol

The present invention relates to an aqueous acrylic acid modified saturated polyester resin, comprising the following materials of parts by weight: 5-25 parts of a polyacid, 15-40 parts of a polyol, 1-3 parts of a solubilizing agent, 5-20 parts of an acrylic acid monomer I, 0.5-10 parts of acrylic acid monomer II, 0.01-8 parts of an initiator, 0.5-10 parts of a neutralizer, 2-20 parts of glycidyl ester tertcarbonate, and 40-50 parts of deionized water. The aqueous acrylic acid modified saturated polyester resin prepared in the present invention has excellent stability, high solid-ness, low viscosity, and low VOC content, and can be mainly used for amino baked-on coating for aqueous coatings.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD +1

Coating process applying water-based paint to forklift metal parts

InactiveCN102974521AGood lookingGood decorative effectAnti-corrosive paintsPolyurea/polyurethane coatingsProcess engineeringManufacturing engineering

The invention discloses a coating process applying water-based paint to forklift metal parts. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of a critical component of a forklift. The water-based paint is enabled to be correctly used for coating of the critical component of the forklift, and the coating process applying the water-based paint to the forklift metal parts not only solves harm and potential safety hazards brought about by a traditional coating process to the forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

High-solid-content finishing oil-based acrylic resin for automobiles and preparation method thereof

The invention discloses a high-solid-content finishing oil-based acrylic resin for automobiles and a preparation method thereof, which belong to the field of automobile paints and solve the problems of low solid content, high viscosity, poor solubility and the like in the existing acrylic resin paint. The resin contains acrylic acid, styrene, butyl acrylate, hydroxyethyl methacrylate, methyl methacrylate, methacrylic acid, butyl methacrylate, 2-ethylhexyl acrylate, n-dodecyl mercaptan, lauryl methacrylate, isoborneol methacrylate, 2-hydroxyethyl acrylate, 2-hydroxypropyl acrylate, 100# solvent oil, di-tert-pentyl peroxide, glycidol tert-carboxylate and a resin reactive diluent. The solid content can reach 90%. The acrylic resin has the advantages of favorable dilution property and low viscosity. The self-made reactive diluent can greatly enhance the water resistance and acid resistance of the paint. The construction solid content of the resin is nearly 70%. The acrylic resin greatly lowers the discharge of VOC (volatile organic compound), and is environment-friendly and practical.

Owner:安徽优科新材料科技有限公司

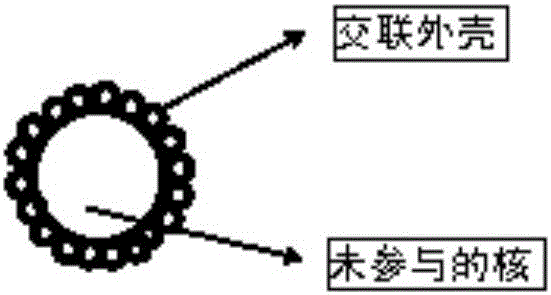

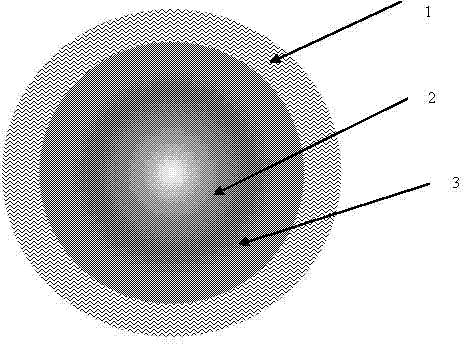

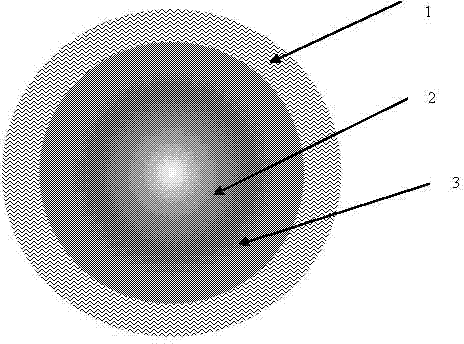

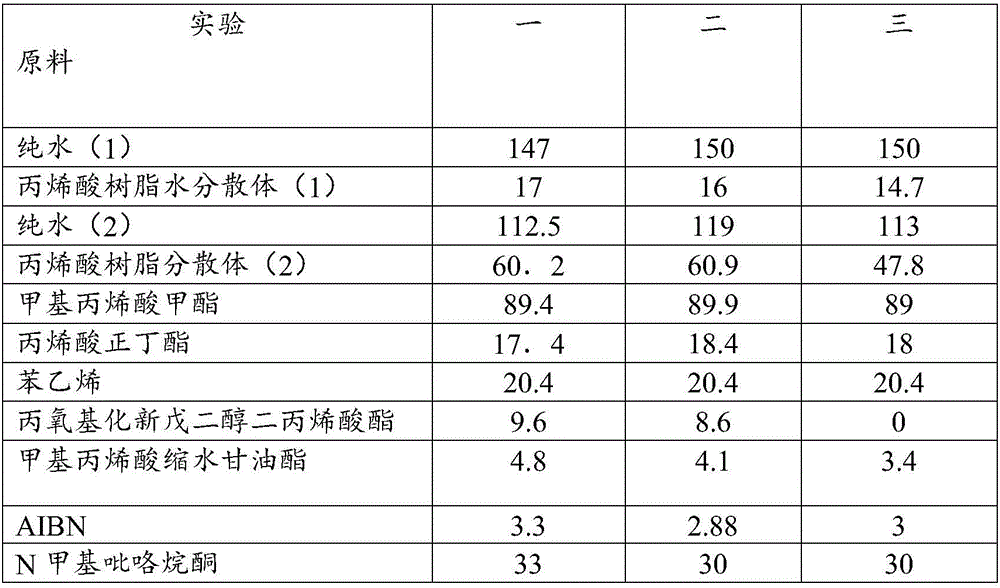

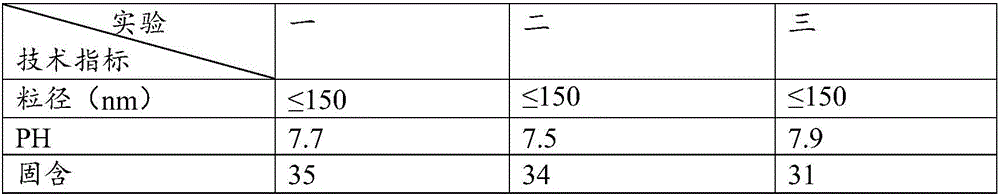

Microgel aqueous acrylic acid shell-core resin emulsion and preparation method thereof

The invention belongs to the field of aqueous coatings, and relates to a microgel aqueous acrylic acid shell-core resin emulsion. The resin emulsion is prepared through a reaction of 13-16 parts of an acrylic acid resin water dispersion (with the solid content of 28-34%), 18-21 parts of a vinyl monomer, 20.5-27.6 parts of an acrylic acid and acrylate monomer, 0.3-0.6 parts of an initiator, 5-6 parts of an organic solvent and 49-53 parts of water. The microgel resin emulsion is added to an aqueous coating, so the sagging property of a paint film is obviously improved, a good anti-sagging effect is reached, the thickness of the paint film in closed angles or edges and other difficult coating positions of a coated member is obviously increased, and the corrosion resistance of the surface of the coated member is improved. The nanometer-level aqueous acrylic acid emulsion with the particle size being smaller than 150nm is produced through the method, can be added to the aqueous coating without thickening the coating, and facilitates maintenance of high construction solid content.

Owner:LANGFANG JINHUILI INDAL PAINT

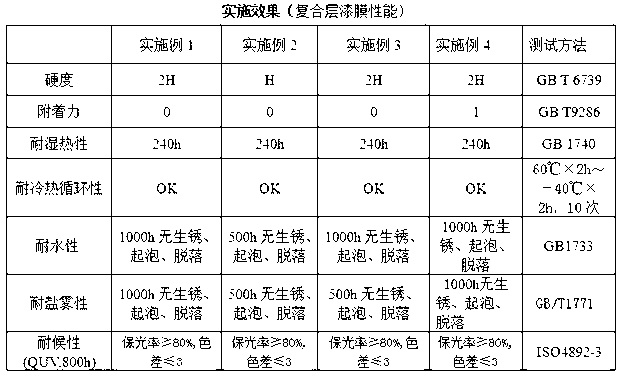

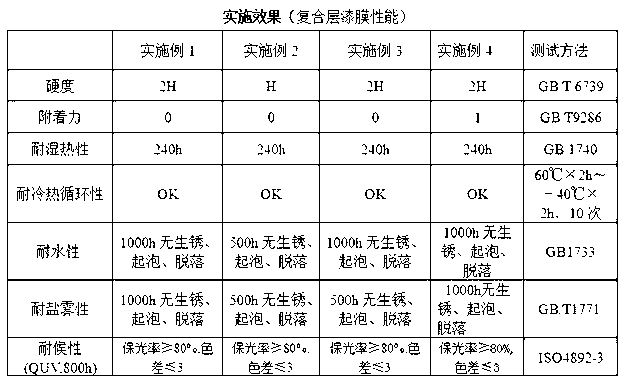

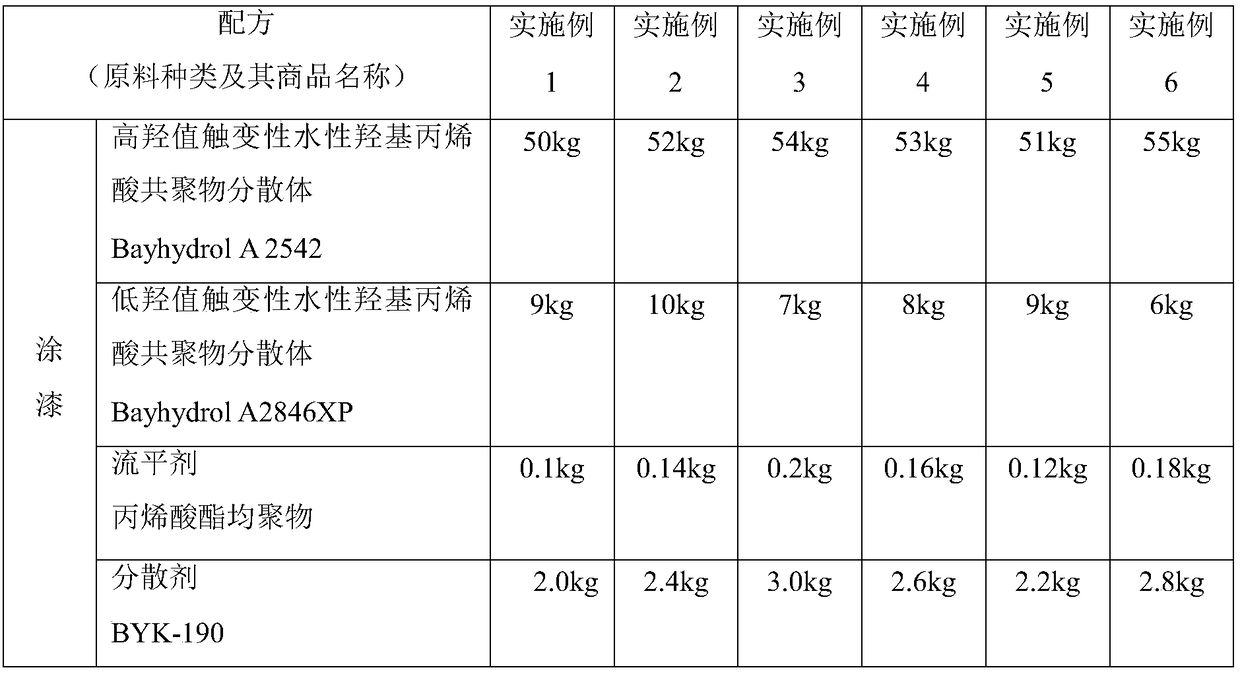

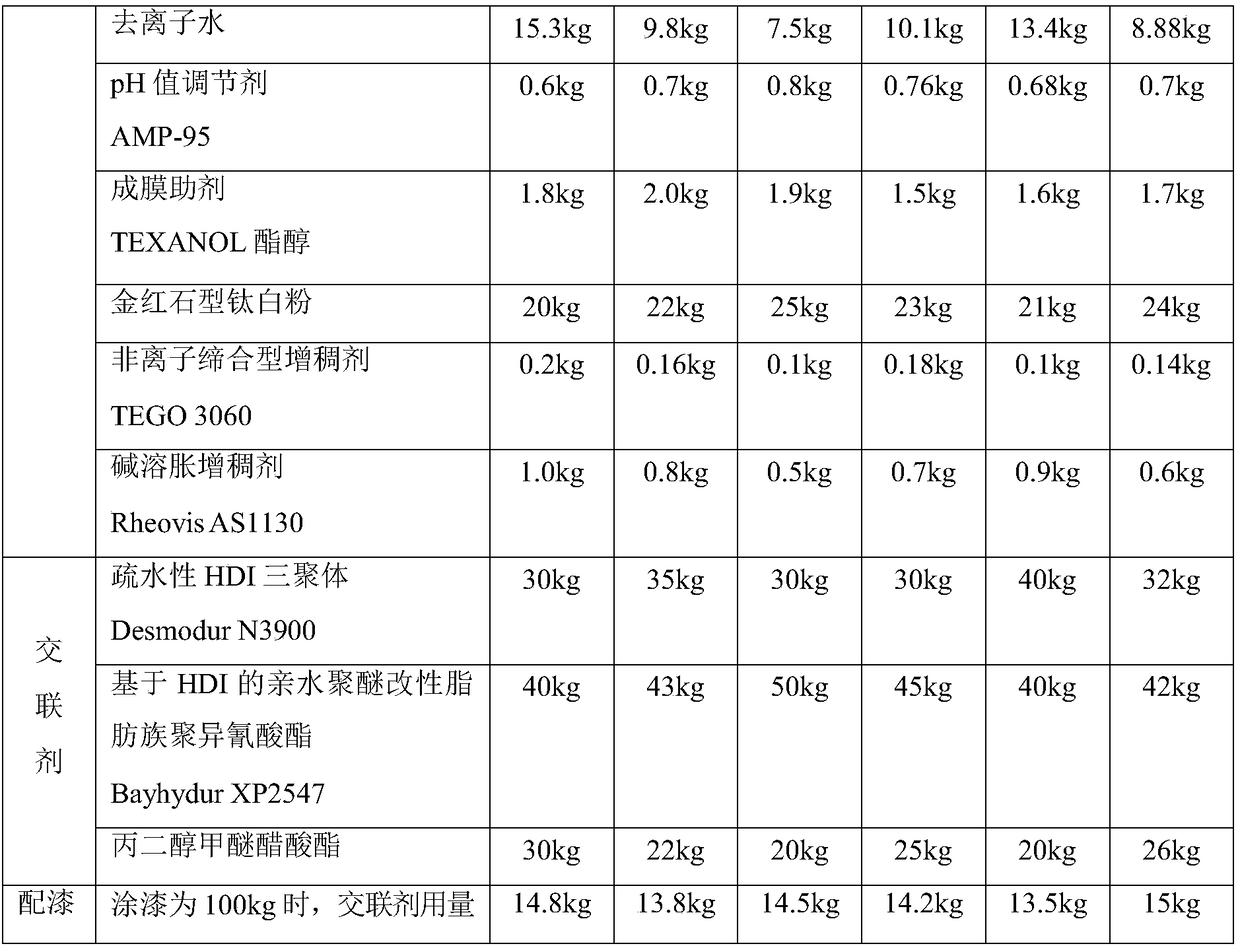

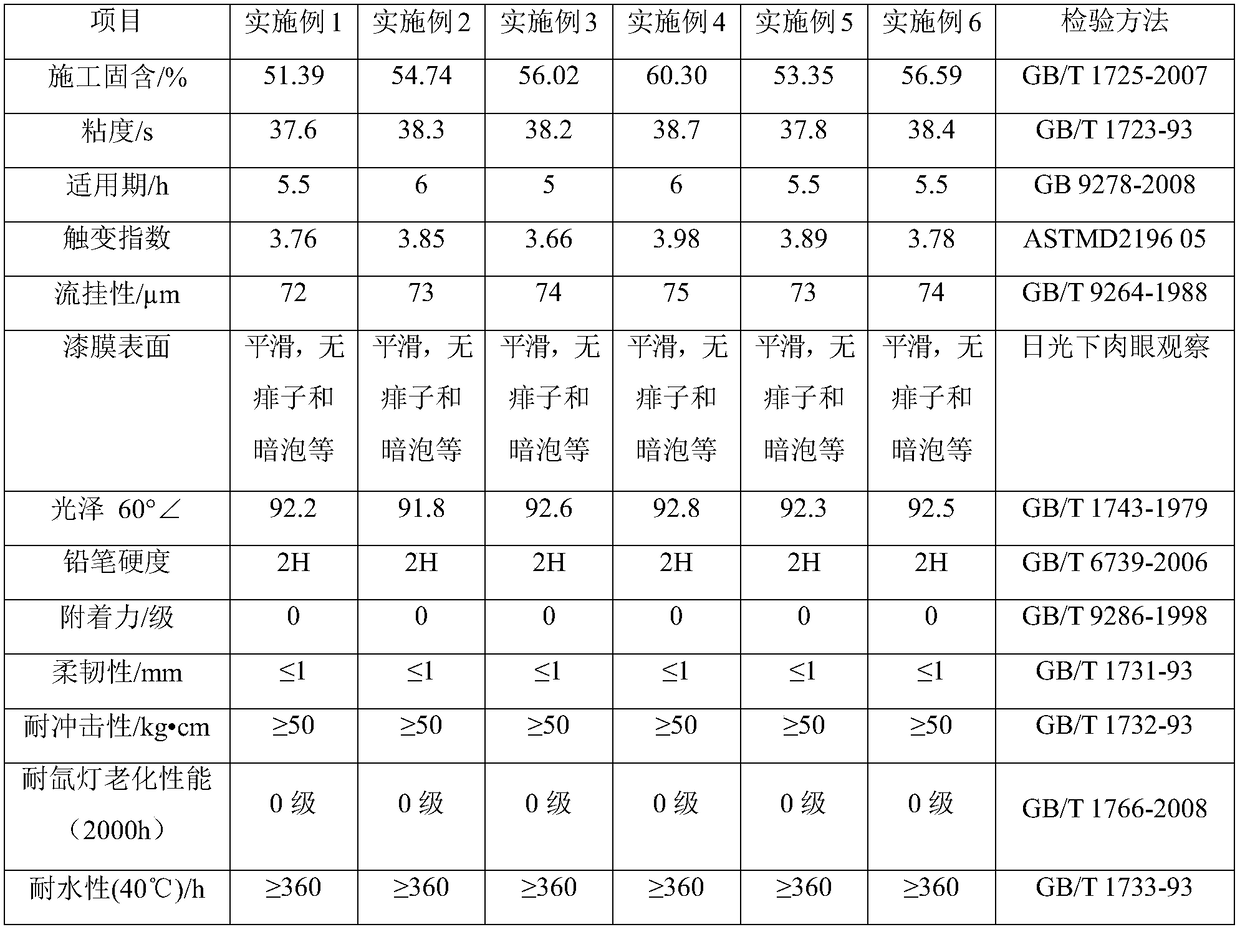

High-thixotropy water-based double-component high-glossiness automotive topcoat and preparation method thereof

ActiveCN109135534AImprove thixotropyHigh solid content in constructionPolyurea/polyurethane coatingsWater basedCross-link

The invention belongs to the technical field of coatings and particularly relates to a high-thixotropy water-based double-component high-glossiness automotive topcoat and a preparation method thereof.The topcoat is prepared from japanning and a cross-linking agent according to the weight ratio of 100 to (13.5-15), wherein the japanning is prepared from a high-hydroxyl-value water-based acrylic copolymer dispersion, a low-hydroxyl-value water-based acrylic copolymer dispersion, a leveling agent, a dispersant, a pH value regulator, a film coalescing aid, titanium dioxide, a non-ionic associative thickener, an alkali swelling thickener and deionized water, and the cross-linking agent is prepared from a hydrophobic HDI trimer, HDI based hydrophilic polyether modified aliphatic polyisocyanateand propylene glycol methyl ether acetate. The topcoat has the advantages of long application period, high hardness and good thixotropy. The wet film thickness is 70 microns or more, the defects of sagging, blistering and dark bubbles do not exist, and the technical problems of poor fullness and poor appearance caused by low solid content in construction of water-based coatings are solved.

Owner:GUANGDONG YATU CHEM

High-adhesion aqueous thermosetting acrylic resin, preparation method and applications thereof

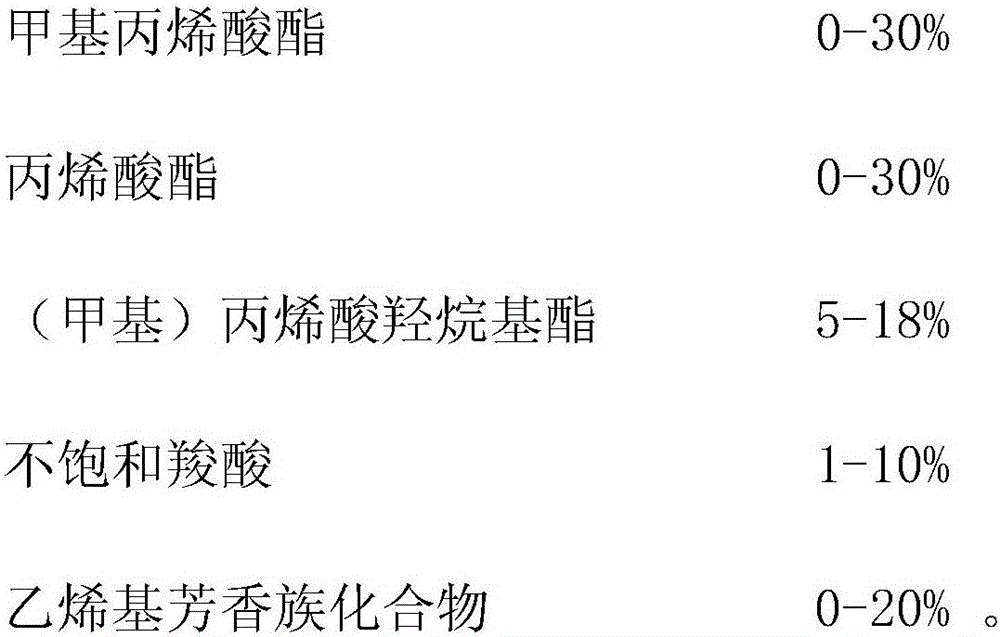

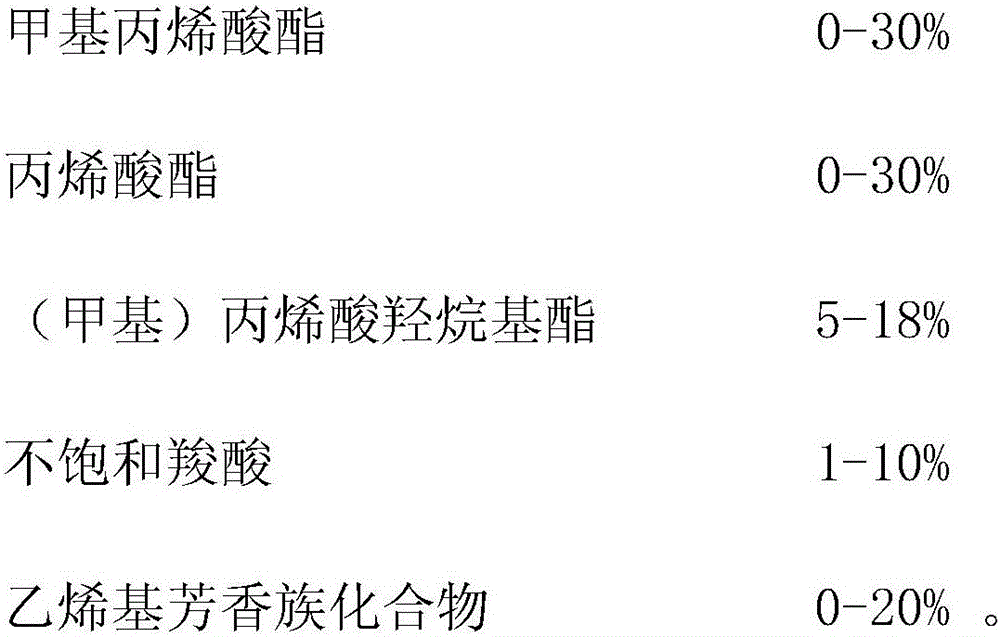

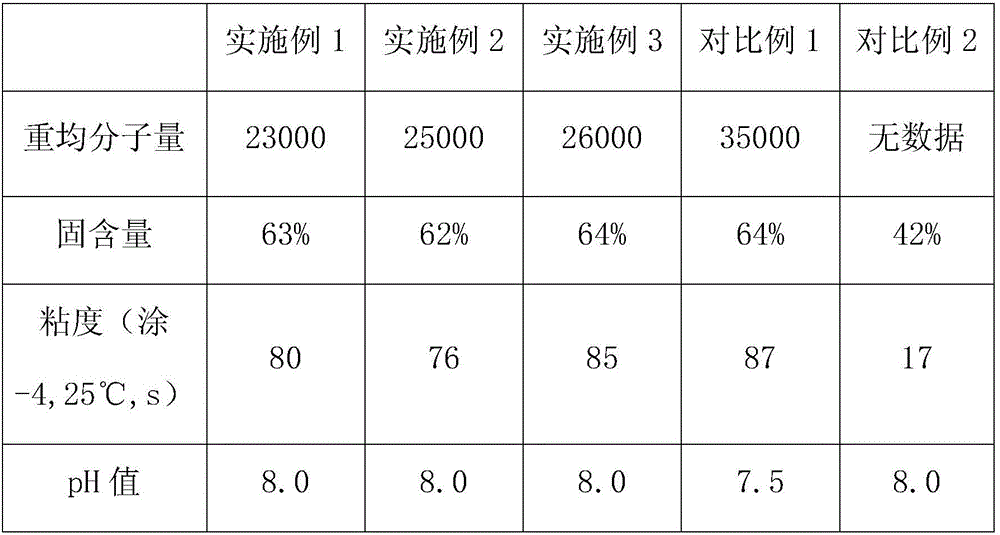

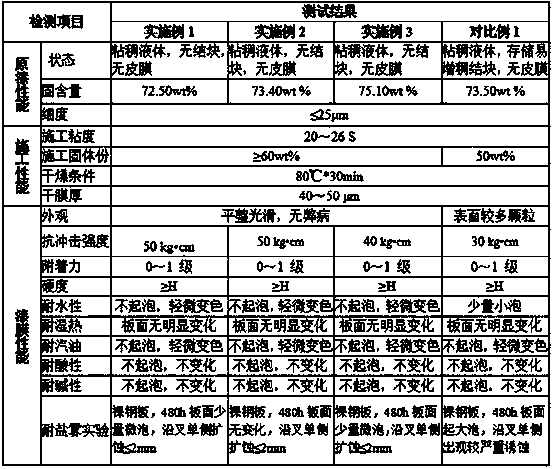

The invention discloses a high-adhesion aqueous thermosetting acrylic resin, a preparation method and applications thereof. According to the present invention, a reaction monomer is modified with a silane coupling agent, a polymerization reaction is performed in an alcohol ether type solvent medium under the effect of an initiator, and neutralization salification is performed with an organic amine to prepare the acrylic resin, wherein the reaction monomer comprises, by mass, 0-30% of methyl propiolate, 0-30% of acrylic acid ester, 5-18% of (methyl) hydroxyalkyl acrylate, 1-10% of unsaturated carboxylic acid, and 0-20% of a vinyl aromatic compound. According to the present invention, the prepared acrylic resin coating material has excellent adhesion to the aluminum material, the paint film has characteristics of high luster, good fullness and high strength, and the excellent protection performance and the excellent decorative effect can be provided for the high-grade aluminum material.

Owner:FOSHAN KINNO METAL TECH

Environment-friendly anticorrosive coating material for automobile parts and preparation method thereof

ActiveCN103937369AHigh solid content in constructionEmission reductionAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention discloses an environment-friendly anticorrosive coating material for automobile parts and a preparation method thereof. The environment-friendly anticorrosive coating material comprises an ingredient A and an ingredient B, wherein the ingredient A comprises epoxy resin, pigment / filler, auxiliaries and an organic solvent, and the ingredient B comprises polyamide resin, a siloxane compound, a tertiary amine curing accelerator and an organic solvent. According to the anticorrosive coating material disclosed by the invention, the construction solid content is high (not lower than 60wt%), the VOC (Volatile Organic Compound) emission is low during construction, and the construction performance and film coating property are excellent; the coating material can be applied to anticorrosive coating layers of automobile metal parts, such as transmission cases, chassis parts, axles and other castings, the coating supporting is simple, the requirements on substrate pretreatment are low, sandblasting and phosphating treatment are not required, and good film coating performance can be guaranteed by only cleaning and degreasing; and the environment-friendly anticorrosive coating material for the automobile parts, disclosed by the invention, is simple in preparation process and is energy-saving and environment-friendly, and the prepared product is stable in performance.

Owner:中山大桥化工集团有限公司

Acid epoxy high-temperature curing type coating varnish for automobile exterior coating and preparation method thereof

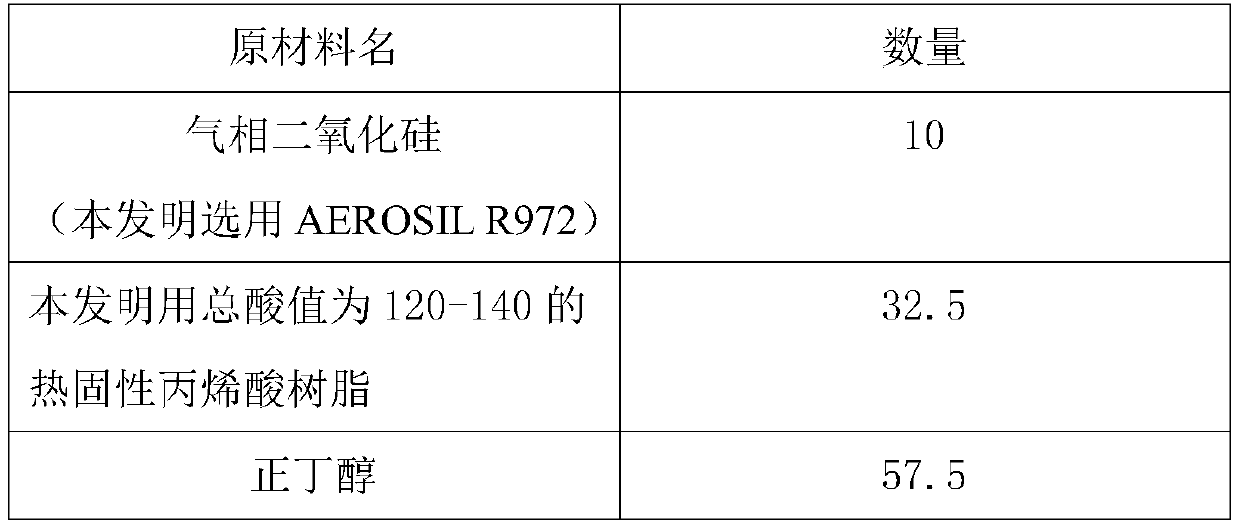

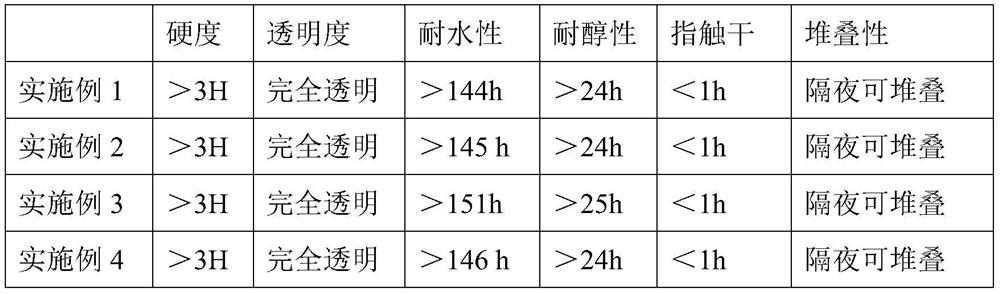

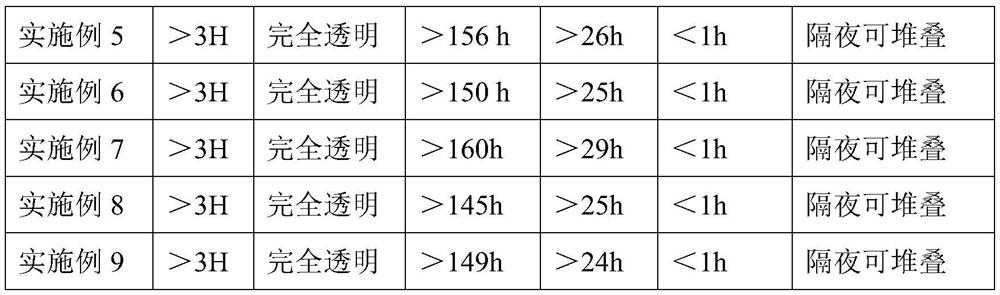

The invention discloses an acid epoxy high-temperature curing type coating varnish for automobile exterior coating and a preparation method thereof. The varnish is prepared from the following components: thermosetting acrylic resin having a total acid value of 120 to 140, thermosetting acrylic resin having an epoxy value of 2.0 to 4.0, anti-sagging resin, saturated polyester containing a hexahydrophthalic anhydride monomer, amino resin, an ammonium bromide catalyst, a catalyst blocking agent, a leveling agent, a polyacrylate antifoaming agent, an ultraviolet absorber, a hindered amine light stabilizer, an anti-sagging aid containing fumed silica, an alcohol solvent and a diluent. The invention also discloses a preparation method of the varnish. The varnish disclosed by the invention has the characteristics of high construction solid content, attractive appearance, high acid resistance and the like, and has relatively high competitiveness in the market.

Owner:湖南湘江关西涂料(长沙)有限公司

Water-based organic silicon modified cationic acrylic resin and synthesis method thereof

The invention discloses water-based organic silicon modified cationic acrylic resin and a synthesis method. The water-based organic silicon modified cationic acrylic resin is prepared from the following raw materials: a monomer, a functional monomer, a solvent, acid, a chain transfer agent and an initiator, wherein the monomer comprises, by weight, 100-400 parts of methyl methacrylate, 5-50 partsof butyl acrylate and 20-200 parts of styrene, the functional monomer comprises, by weight, 10-100 parts of vinyltriethoxysilane, 20-200 parts of dimethylaminoethyl methacrylate and 30-250 parts of hydroxyethyl acrylate, the solvent comprises, by weight, 100-400 parts of propylene glycol monomethyl ether, 50-400 parts of absolute ethyl alcohol and 20-200 parts of N, N-dimethylformamide, the acid is 5-60 parts by weight of lactic acid, the chain transfer agent is 1-50 parts by weight of a methyl styrene linear dimer, and the initiator is 1-50 parts by weight of azodiisobutyronitrile. The invention solves the fundamental problems of unsatisfactory hardness, transparency, solvent resistance and other properties, high cost and the like of the traditional water-based wood paint, can completelyreplace the oil-based PU wood paint, and can generate great advantages for environmental beautification without losing the properties under the large situation of environmental protection.

Owner:HUBEI JIADE PUAN PAINT

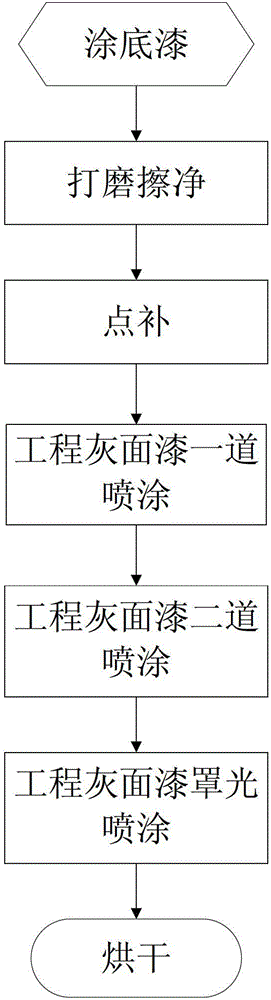

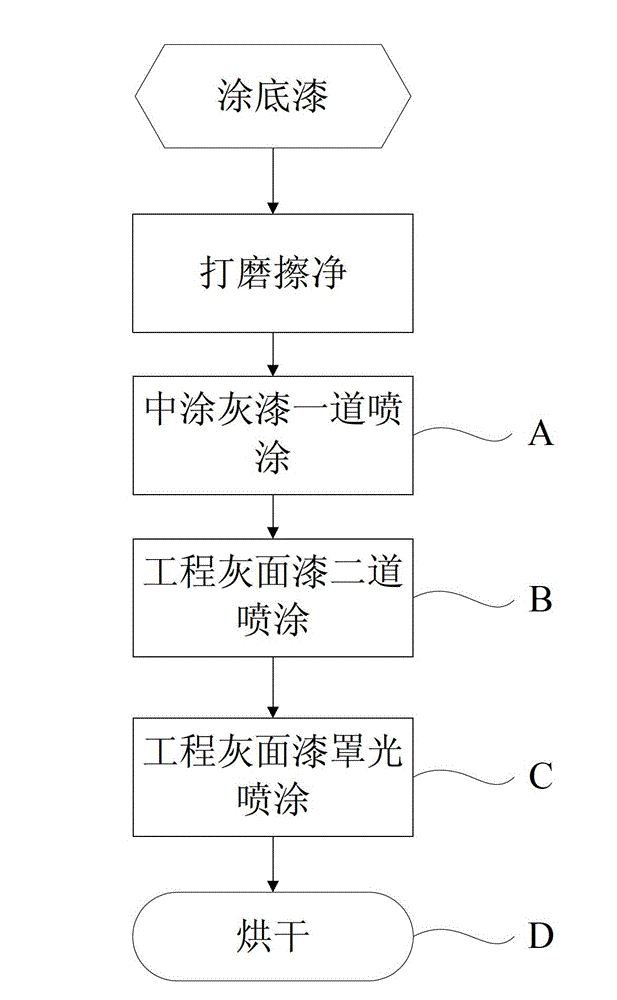

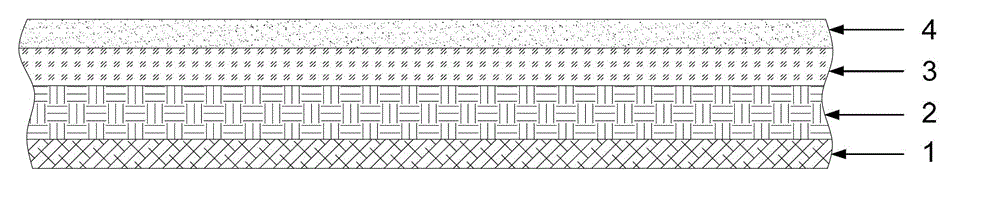

Construction machinery and painting process thereof

InactiveCN103182371AIncrease film thicknessHigh solid content in constructionLiquid surface applicatorsCoatingsSpray coatingSolid content

The invention discloses a painting process of construction machinery, which includes the following steps: A, first-time spray coating of floating coat gray paint, namely, performing spray coating of the floating coat gray paint for one time on a polished and cleaned primer; B, second-time spray coating of engineering gray finishing paint, namely, performing flash evaporation after spray coating of the floating coat gray paint for certain time, then directly spray coating the engineering gray finishing paint; C, spray coating of the engineering gray finishing varnish, namely, directly spray coating the engineering gray finishing varnish after the engineering gray finishing paint is subjected to flash evaporation for certain time; and D, drying, namely, drying the whole paint coating by fire after performing flash evaporation on the engineering gray finishing varnish for certain time. According to the painting process of the construction machinery, provided by the invention, the first-time spray coating process of the engineering gray finishing paint in the prior art is replaced by the first-time spray coating process of the floating coat gray paint, and the coating coat gray paint can improve the film thickness through improving the self construction solid content, therefore, the film thickness of the coating can be improved on the premise of not adding new spray coating process, equipment, personnel and stations. The invention further discloses the construction mechanism adopting the painting process.

Owner:LIUZHOU WULING MOTORS +1

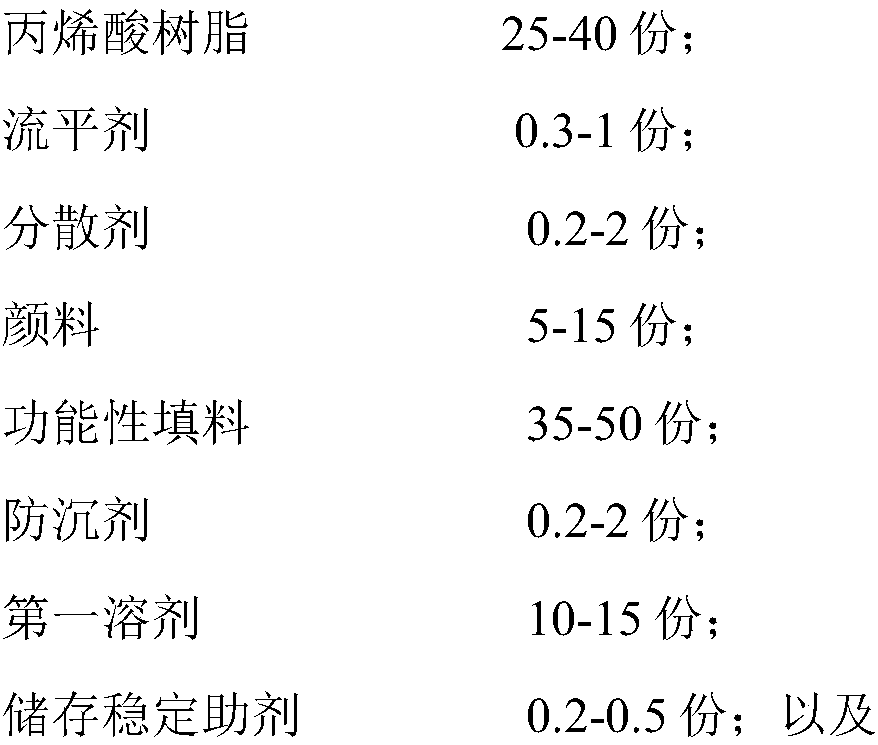

High-solid multifunctional quick-drying intermediate coating composition and purpose thereof

ActiveCN109535977AHigh solid content in constructionHigh hardnessPolyurea/polyurethane coatingsAcrylic resinAutomotive paint

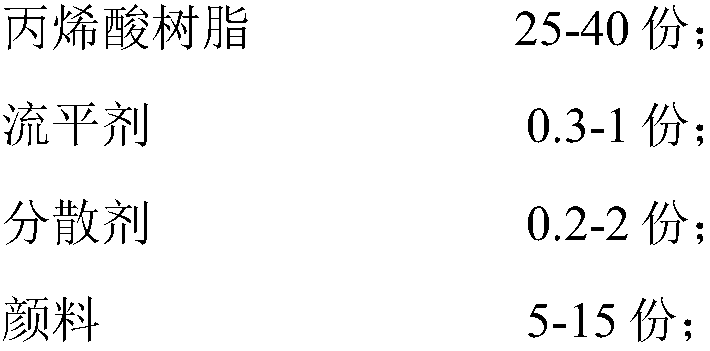

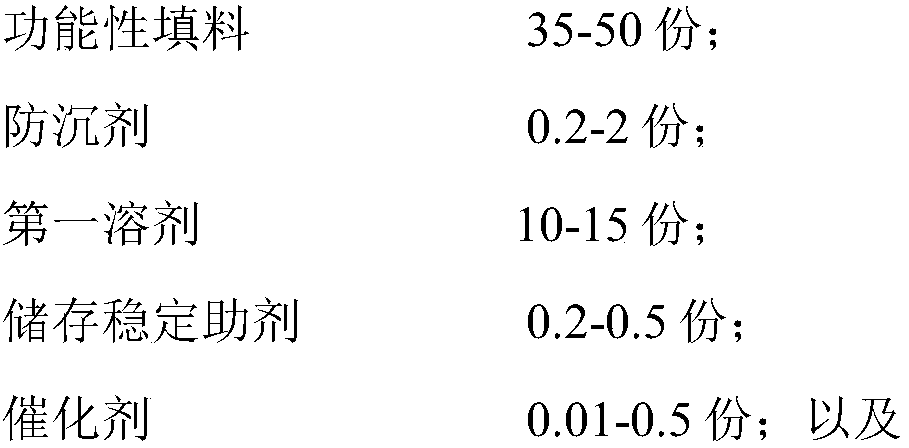

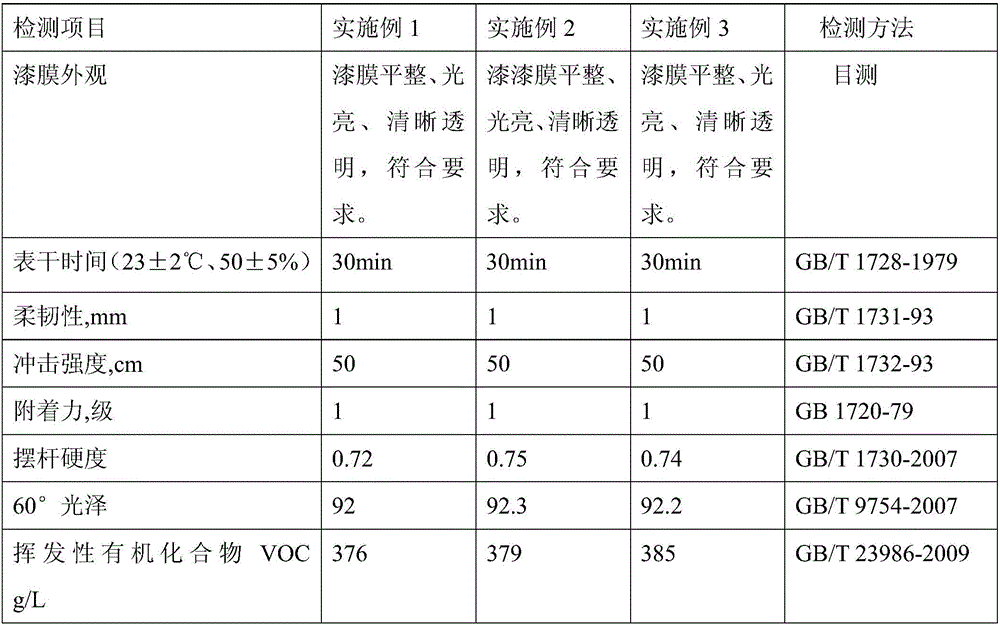

The invention discloses a high-solid multifunctional quick-drying intermediate coating composition. The composition comprises the following components in parts by weight: an intermediate coating comprises the following components in parts by weight: 25-40 parts of acrylic resin, 0.3-1 part of a leveling agent, 0.2-2 parts of a dispersing agent, 5-15 parts of a pigment, 35-50 parts of a functionalfiller, 0.2-2 parts of an anti-settling agent, 10-15 parts of a first solvent, 0.2-0.5 parts of a storage stabilizer; and a curing agent comprises the following components in parts by weight: 40 to 60parts of isocyanate, 40 to 60 parts of a second solvent; or the curing agent comprises the following components in parts by weight: 40 to 60 parts of isocyanate, 40 to 60 parts of the second solvent,and 0.01-1 part of a water-removal additive. The invention also discloses a purpose of the high-solid multifunctional quick-drying intermediate coating composition as an automotive paint. The high-solid multifunctional quick-drying intermediate coating composition has good workability and paint film, and has high production efficiency and low VOC.

Owner:NIPPON PAINT CHINA

Environment-friendly type bright white finish with high solid content and high fullness for woodware

ActiveCN103525255AImprove poor yellowing resistanceReduce pollutionEpoxy resin coatingsKetone solventsPollution

The invention discloses environment-friendly type bright white finish with high solid content and high fullness for woodware. The environment-friendly type bright white finish comprises the following components in parts by weight: components A: 15-25 parts of bisphenol A epoxy resin, 25-35 parts of hydrogenated bisphenol A epoxy resin, 8-12 parts of active flux butyl glycidyl ether, 5-10 parts of titanium dioxide, 25-35 parts of inorganic fillers, 0.5-1 part of an anti-settling agent, 0.5-1 part of a dispersing agent, 0.1-0.5 part of an antifoaming agent, 0.6-1.5 parts of a flatting agent, 1-2 parts of anti-yellowing auxiliaries; component B: modified alicyclic amine curing agent; component C: ketones solvent, wherein the weight ratio of the components A:component B:component C is 100:(30-35):(5-8). The environment-friendly type bright white finish with high solid content and high fullness for woodware, disclosed by the invention, saves labor cost and shortens working hours; moreover, construction solid content (greater than 90%) is far higher than that (50%-55%) of the common polyurethane bright white finish. Moreover, requirements of paint with ultrahigh solid content are achieved, and pollution to environment caused by volatilization of an organic solvent is reduced.

Owner:CHENGDU ZHANCHEN PAINT

Two-component high-solid-content varnish and preparation method thereof

InactiveCN106433413AImprove the decorative effectGood film formingPolyester coatingsOrganic solventSolvent

The invention discloses two-component high-solid-content varnish and a preparation method thereof. A paint part is prepared from, by weight, 65-75 parts of resin, 0.3-1 part of a defoaming agent, 0.4-1 part of a levelling agent, 0.1-0.5 part of a drying promotor, 1-2 parts of a light stabilizer, 1-2 parts of a light absorber and 20-30 parts of a solvent; a curing agent part is prepared from 89 parts of a curing agent and 11 parts of a solvent. A varnish film formed by the varnish has the good appearance; compared with the prior art, the solid content is high, the spraying solid content reaches 60% or above, volatilization of the solvent is significantly reduced, and the plumpness of the varnish can be effectively improved.

Owner:江苏足迹涂料有限公司

Low-temperature thermocuring polyurethane coating, and preparation method and application thereof

ActiveCN102382563BHigh fullnessGood chemical resistancePolyurea/polyurethane coatingsAcrylic resinLow temperature curing

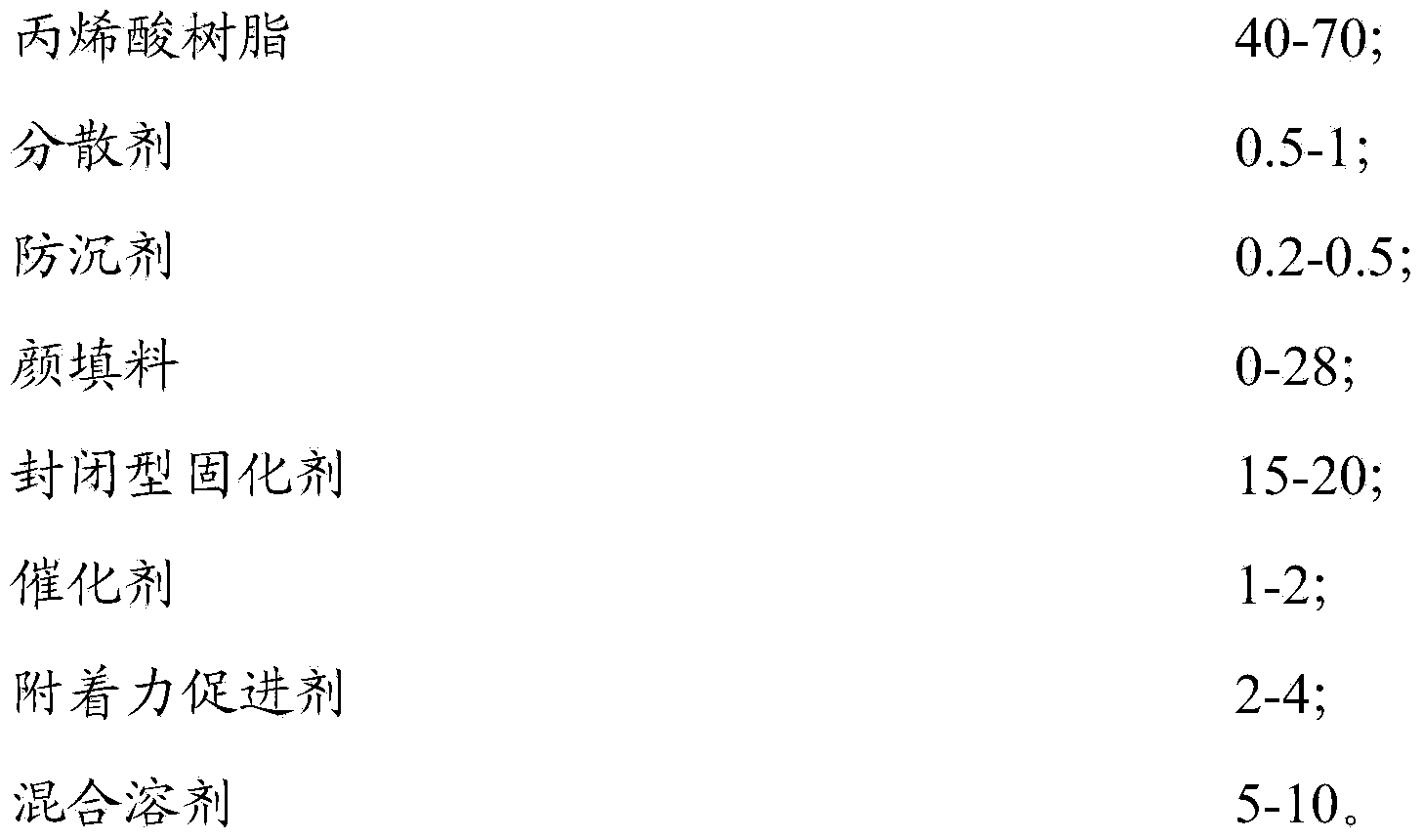

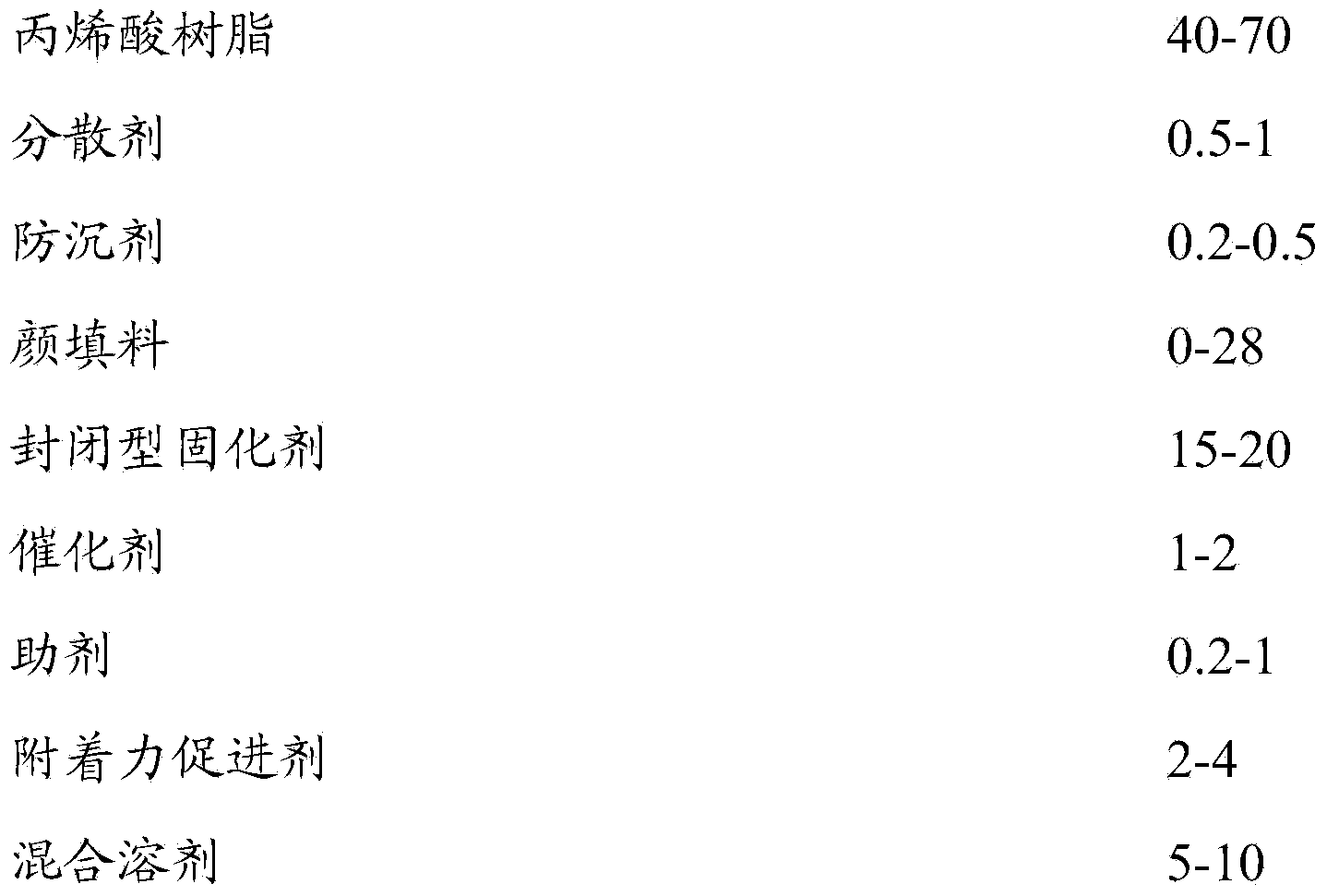

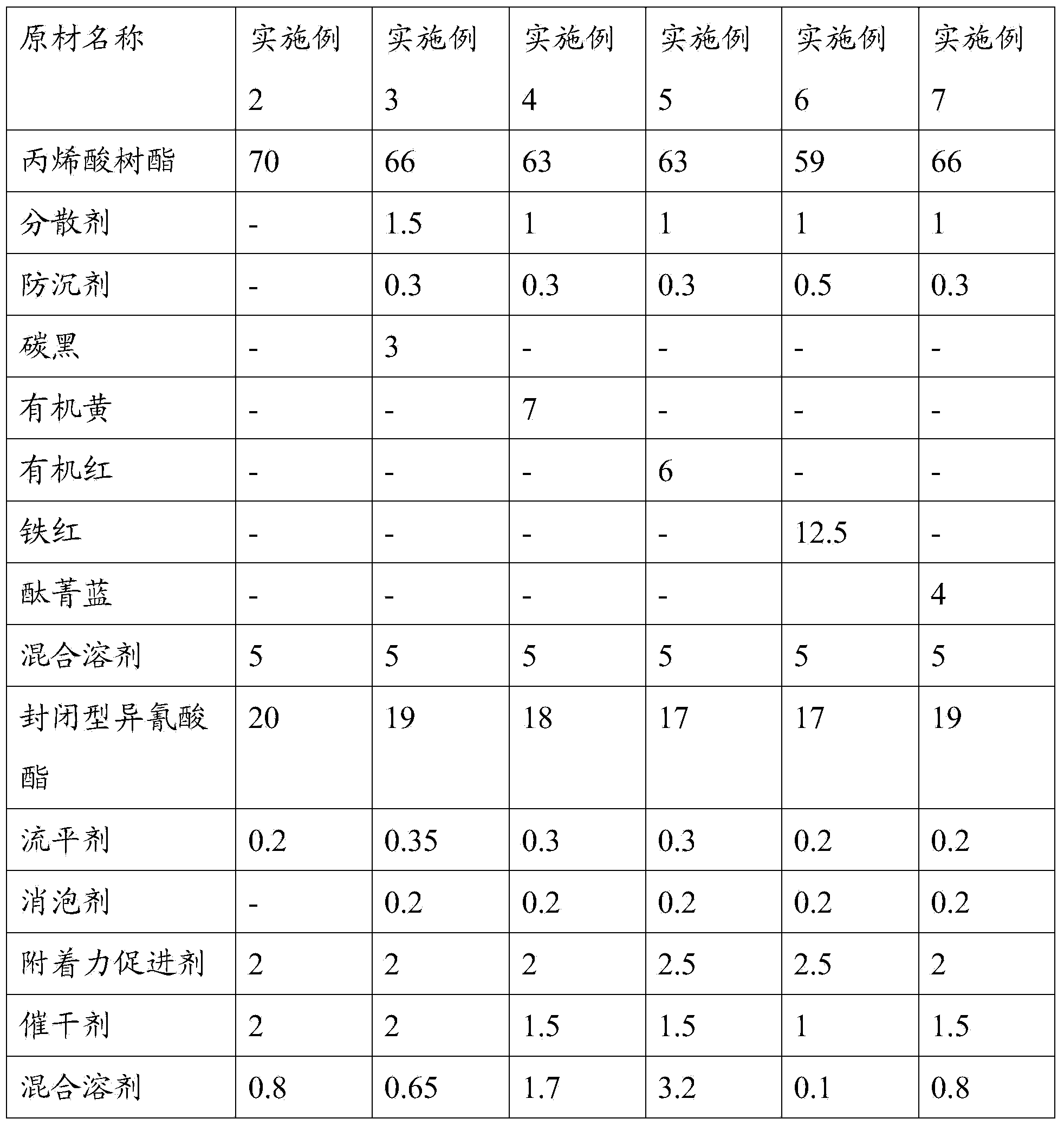

The invention relates to a low-temperature thermocuring polyurethane coating, and a preparation method and application thereof. The low-temperature thermocuring polyurethane coating mainly comprises, by weight, 40 to 70 parts of acrylic resin, 0.5 to 1 part of dispersing agent, 0.2 to 0.5 part of anti-settling agent, 0 to 28 parts of pigment and filler, 15 to 20 parts of closed curing agent, 1 to 2 parts of catalyst, 2 to 4 parts of adhesion accelerant and 5 to 10 parts of mixed solvent. The low-temperature thermocuring polyurethane coating has the advantages of short reaction time, shallow chromaticity, good stability, using convenience in single component, small energy consumption in low temperature solidification and the like, can be widely applied to decoration and protection of electroplating pieces, metal machine casings, buttons, automobile paints and the like, is a formaldehyde-free high-performance coating meeting the standard of toy paints, and has great implementing value and social and economic benefits.

Owner:中华制漆(新丰)有限公司

UV finish paint for wheel hub and preparation method of UV finish paint

InactiveCN108059910AEfficient arrangementConvenient ArrangementPolyurea/polyurethane coatingsFunctional monomerSolvent

The invention relates to the technical field of colored finish paint, in particular to UV finish paint for a wheel hub and a preparation method of the UV finish paint. The finish paint is composed ofthe following components: 50 to 55 wt% of UV-PU dual-cured resin, 15 to 30 wt% of UV-PUA resin, 4 to 6 wt% of deep-curing photoinitiator, and 4 to 8 wt% of aluminum powder, 7 to 15 wt% of functional monomer, 0.5 to 1 wt% of organic silicone substrate wetting and leveling agent, 4 to 20 wt% of UV color pastes, 1.5 to 2 wt% of UV absorber, 4 to 8wt% of solvent, and 5 to 7wt% of HDI curing agent. Theinvention has good application properties, can be used in combination with powder primers, powder varnishes and UV varnishes, and can ensure interlayer adhesion and various performance of films. TheUV finish paint has the characteristics that the aluminum powder is well arranged, the construction solid content reaches 60%, and the curing efficiency is high. The UV finish paint disclosed by the invention is environmentally friendly and energy-saving, and improves the poor weather resistance and poor impact resistance of ordinary UV coatings.

Owner:CHANGZHOU HUASHI CHEM

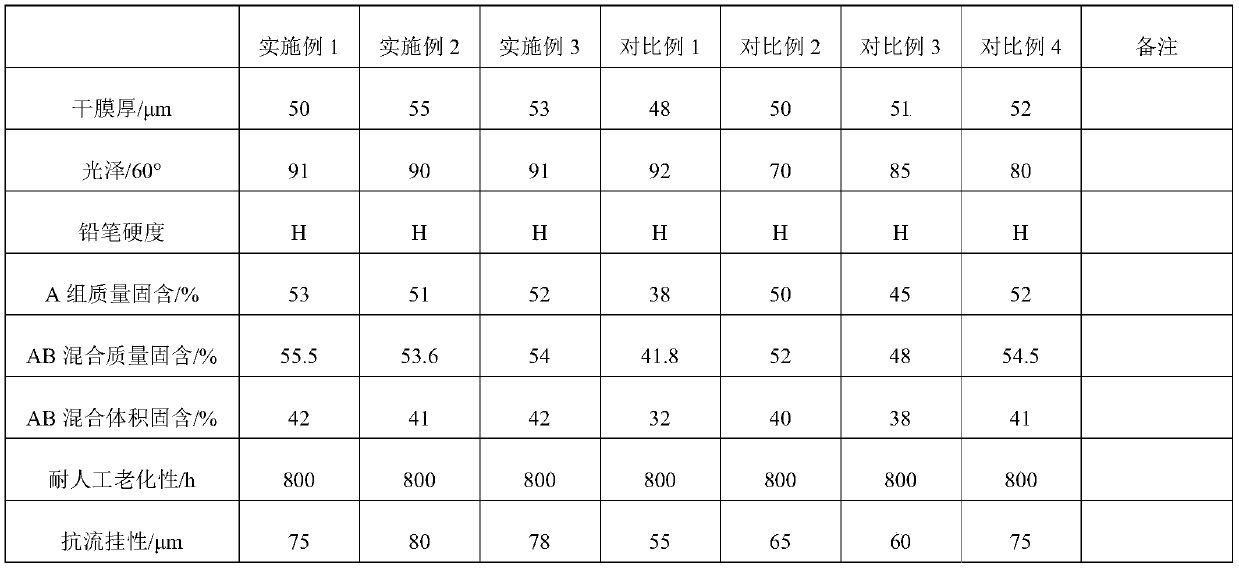

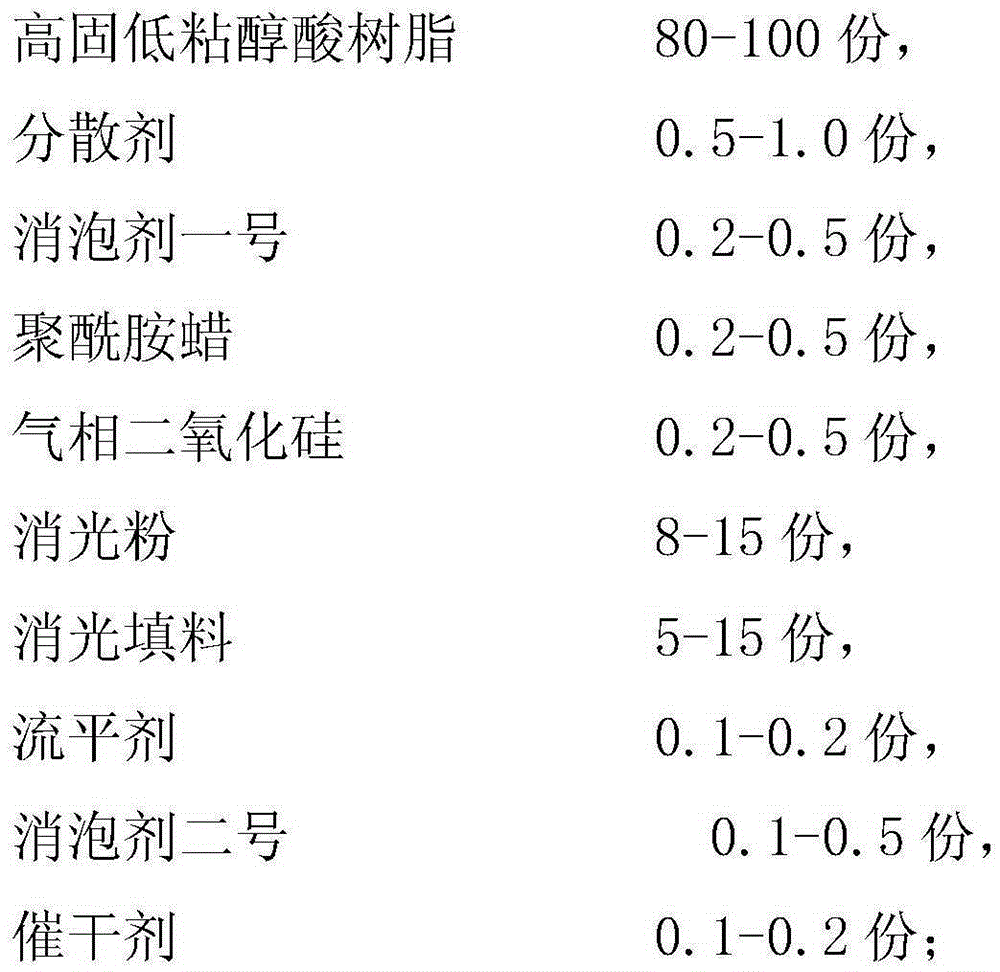

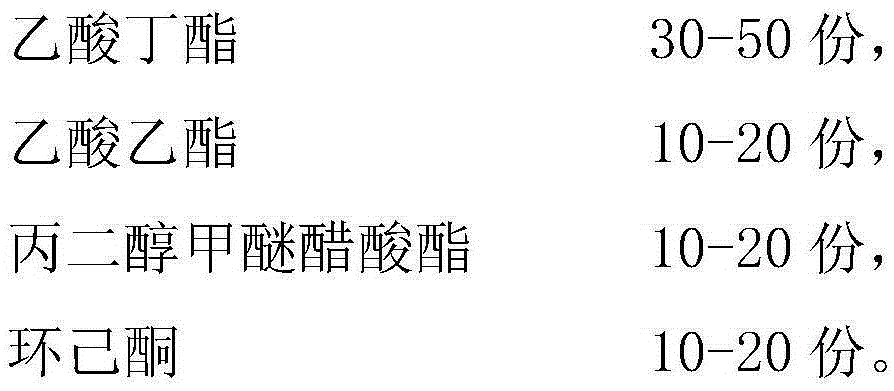

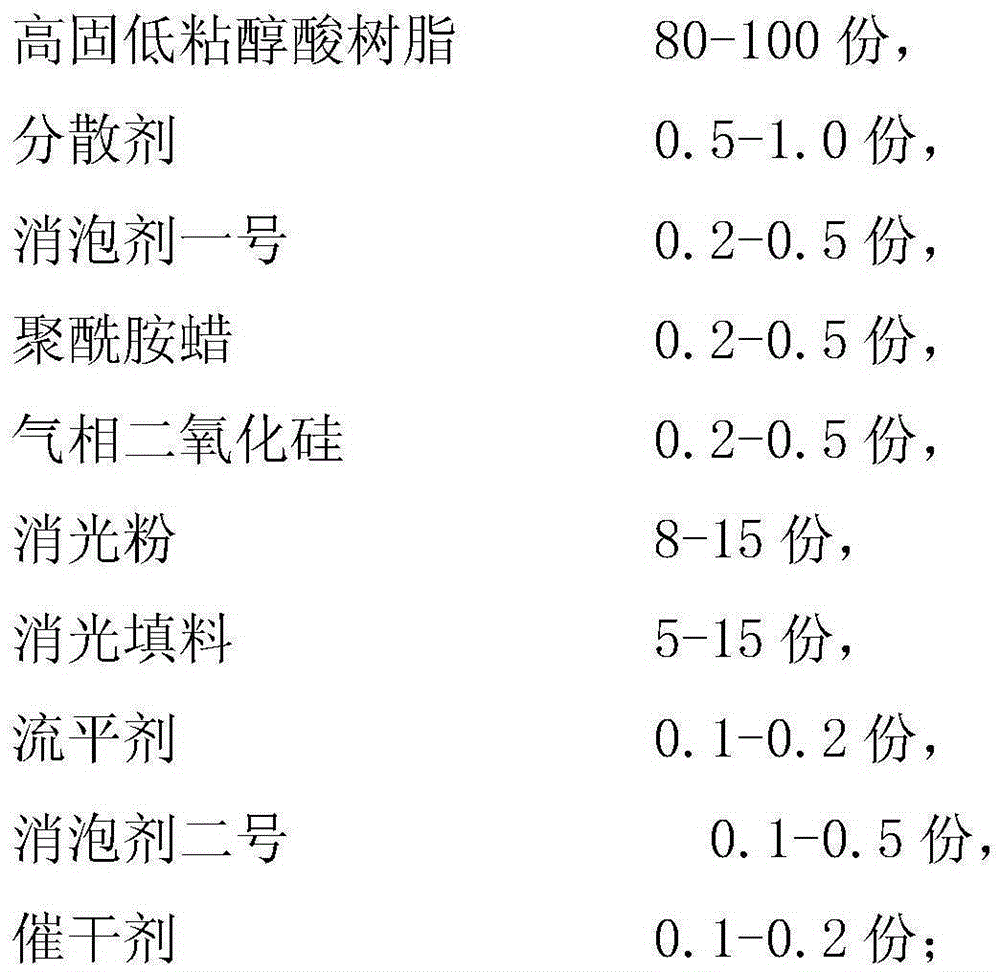

High-solid-content PU (polyurethane) matte varnish and preparation method thereof

ActiveCN105255357ASolve the technical problem of poor storage stabilityHigh solid content in constructionPolyurea/polyurethane coatingsLacquerDiluent

The invention relates to high-solid-content PU (polyurethane) matte varnish and a preparation method thereof. The matte varnish is prepared from a component A, a component B and an environment-friendly diluent. The matte varnish has the benefits as follows: the problem of poorer storage stability under low viscosity is effectively solved, meanwhile, by means of low system viscosity, the VOC (volatile organic compound) content of construction is further reduced, the purpose of consumption tax exemption is achieved, besides, the usage of a solvent and the number of coating layers of the varnish can be greatly reduced due to the high solid content of the construction, accordingly, the cost reduction is facilitated, and raw materials are saved; a paint film has high hardness and is scratch-resistant, and the grade of wood lacquer is improved.

Owner:SKSHU PAINT

One-component varnish composition, preparation method and use thereof

ActiveCN106916503BImprove radiation resistanceGood weather resistancePretreated surfacesPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a one-component varnish composition, comprising at least one polymer with hyperbranched or tree structure; at least one hydroxyacrylic resin or hydroxymethacrylic resin; at least one silicone-modified acrylic resin at least one crosslinking curing agent; at least one acid catalyst; at least one rheology control agent; at least one auxiliary agent, and at least one solvent; the one-component varnish composition is high scratch resistance and high Weather resistant one-component clearcoat composition. The one-component varnish composition with high scratch resistance and high weather resistance provided by the present invention can effectively improve the slipperiness of the coating film surface of the varnish composition, thereby increasing the friction resistance of the coating film; in addition, silicone-modified acrylic acid The introduction of the resin can further improve the weather resistance of the coating film of the varnish composition.

Owner:LANGFANG NIPPON PAINT +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com