Environment-friendly anticorrosive coating material for automobile parts and preparation method thereof

A technology for auto parts and anti-corrosion coatings, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of carcinogenicity, construction personnel and environmental hazards, harmfulness, etc., achieve low VOC emissions, excellent construction performance, Coating matching simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

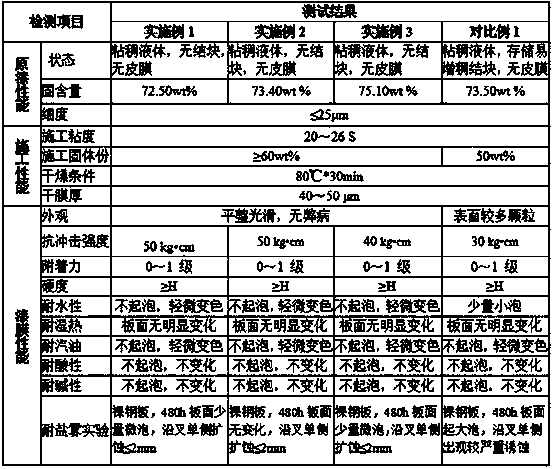

Examples

preparation example Construction

[0034] A preparation method for an anticorrosion coating for environment-friendly auto parts, comprising the following steps:

[0035] 1) Prepare component A:

[0036] Mix the epoxy resin, dispersant and defoamer with a formula amount of 60-80wt% evenly, then add anti-sagging agent and pigments and fillers, mix evenly, pre-disperse for 30-60 minutes under stirring at 500-1000rpm, and then add it to the sand In the mill, grind to a fineness of ≤15 μm, filter, add the remaining epoxy resin, leveling agent and solvent, stir evenly, and filter to obtain component A;

[0037] 2) Prepare Part B:

[0038] Add polyamide resin, siloxane compound, accelerator and solvent into the container in turn according to the formula amount, stir at 300-600 rpm for 30-60 minutes, filter to obtain component B;

[0039] 3) Mix component A and component B according to the ratio before use to obtain an environmentally friendly anticorrosion coating for auto parts;

[0040] The formula of the anticor...

Embodiment 1

[0044] An environment-friendly anticorrosion coating for auto parts, comprising a main agent of component A and a curing agent of component B, the formula of component A is as follows:

[0045] Material % by weight / %

[0046] DER671 24.0,

[0047] DER667 2.0,

[0048] Dispersant BYK ANTI-TERRA?-U 2.0,

[0049] Organic bentonite 0.5,

[0050] Fumed silica 0.5,

[0051] carbon black 2.5,

[0053] Aluminum tripolyphosphate 8.5,

[0054] Precipitated barium sulfate 23.0,

[0055] Defoamer BYK?-054 0.3,

[0056] Leveling agent BYK?-358 N 0.5,

[0057] Xylene 18,

[0058] butanol 7.7.

[0059] The formula of component B is as follows:

[0060] Material % by weight / %

[0061] Polyamide resin (amine value 155) 46.0,

[0062] DMP-30 3.0,

[0063] Aminopropyltriethoxysilane 3.0,

[0064] Xylene 38.0,

[0065] Butanol 10.0.

[0066] The preparation process of the coating is as follows:

[0067] 1) Prepare component A

[0068] First grind ...

Embodiment 2

[0073] An environment-friendly anticorrosion coating for auto parts, comprising A component and B component, and the formula of A component is as follows:

[0074] Material % by weight / %

[0075] Epikote834 22.0,

[0076] Epikote1009 5.0,

[0077] Dispersant DISPERBYK®-110 2.0,

[0078] Organic bentonite 0.5,

[0079] Fumed silica 0.5,

[0080] carbon black 2.5,

[0081] Rutile titanium dioxide 15.0,

[0083] Aluminum tripolyphosphate 8.5,

[0084] Precipitated Barium Sulfate 10.0,

[0085] Defoamer BYK?-052 0.3,

[0086] Leveling agent BYK?-320 0.5,

[0087] Xylene 16,

[0088] Butanol 6.7.

[0089] The formula of component B is as follows:

[0090] Material % by weight / %

[0091] Polyamide resin (amine value 180) 46.0,

[0092] Accelerator DMP-30 1.0,

[0093] N-aminoethyl-aminopropyltriethoxysilane 4.0,

[0094] Xylene 38.0,

[0095] Butanol 11.0.

[0096] The preparation process of the coating is as follows:

[0097] 1) Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com