Two-component high-solid-content varnish and preparation method thereof

A high solid content, two-component technology, applied in polyester coatings, coatings, etc., can solve problems such as fire, human health hazards, and environmental pollution, and achieve the effects of improving efficiency, saving man-hours, and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

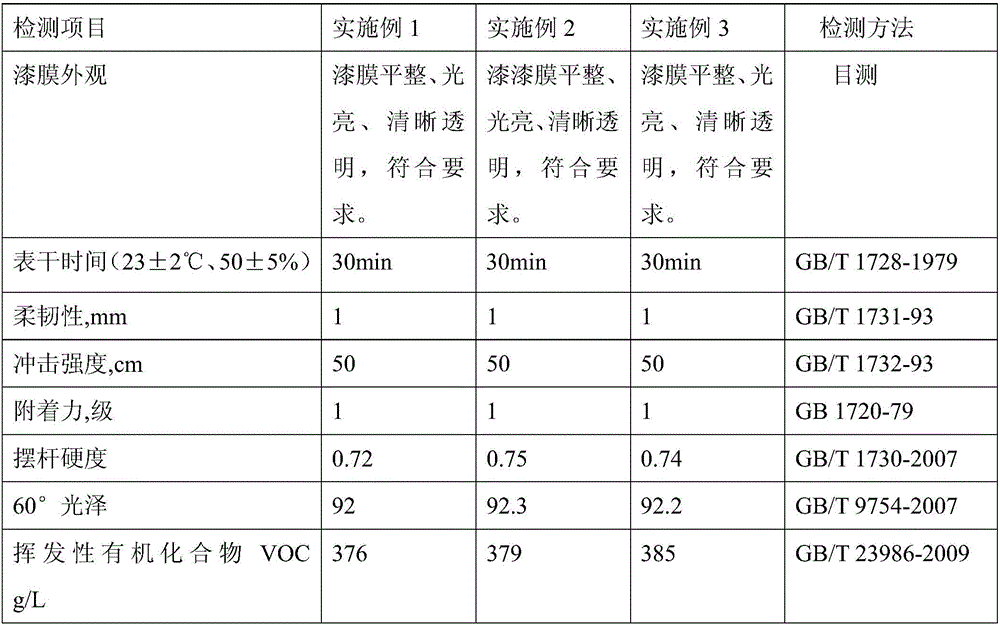

Embodiment 1

[0033] The weight components of the high solid varnish in this example: 65 parts of resin, 0.3 part of defoamer, 0.4 part of leveling agent, 0.1 part of drier, 1 part of light stabilizer, 1 part of light absorber, and 20 parts of organic solvent.

[0034] The preparation method of the coating part is as follows:

[0035] (1) Add 65 parts of resin into a clean container and stir under medium and high shear;

[0036] (2) While stirring, add 0.3 parts of defoamer, 0.4 parts of leveling agent, 0.1 part of drier, 1 part of light stabilizer, 1 part of light absorber, 20 parts of organic solvent, and stir evenly;

[0037] (3) After adding the materials, stir for 10-15 minutes under medium and high shear force;

[0038] (4) After the stirring is finished, let it stand and wait for the bubbles to disappear before use;

[0039] Preparation method of curing agent component: Mix 89 parts of curing agent and 11 parts of organic solvent in proportion, and stir evenly under low shear force...

Embodiment 2

[0042] The high-solid varnish weight components in this embodiment: 70 parts of resin, 0.6 parts of defoamer, 0.7 parts of leveling agent, 0.3 parts of drier, 1.5 parts of light stabilizer, 1.5 parts of light absorber, and 25 parts of organic solvent.

[0043] The preparation method of the coating part is as follows:

[0044] (1) Add 70 parts of resin into a clean container and stir under medium and high shear;

[0045] (2) While stirring, add 0.6 parts of defoamer, 0.7 parts of leveling agent, 0.3 parts of drier, 1.5 parts of light stabilizer, 1.5 parts of light absorber, 25 parts of organic solvent, and stir evenly;

[0046] (3) After adding the materials, stir for 10-15 minutes under medium and high shear force;

[0047] (4) After the stirring is finished, let it stand and wait for the bubbles to disappear before use;

[0048] Preparation method of curing agent component: Mix 89 parts of curing agent and 11 parts of organic solvent in proportion, and stir evenly under low...

Embodiment 3

[0051] The components by weight of the high solid varnish in this example are: 75 parts of resin, 1 part of defoamer, 1 part of leveling agent, 0.5 part of drier, 2 parts of light stabilizer, 2 parts of light absorber, and 30 parts of organic solvent.

[0052] The preparation method of the coating part is as follows:

[0053] (1) Add 75 parts of resin into a clean container and stir under medium and high shear;

[0054] (2) While stirring, add 1 part of defoamer, 1 part of leveling agent, 0.5 part of drier, 2 parts of light stabilizer, 2 parts of light absorber, 30 parts of organic solvent, and stir evenly;

[0055] (3) After adding the materials, stir for 10-15 minutes under medium and high shear force;

[0056] (4) After the stirring is finished, let it stand and wait for the bubbles to disappear before use;

[0057] Preparation method of curing agent component: Mix 89 parts of curing agent and 11 parts of organic solvent in proportion, and stir evenly under low shear forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com