Low-temperature thermocuring polyurethane coating, and preparation method and application thereof

A technology of polyurethane coating and low-temperature thermal curing, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of complex construction process, non-environmental protection, high energy consumption of coatings, etc., and achieve high construction solid content, high production efficiency, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: White paint

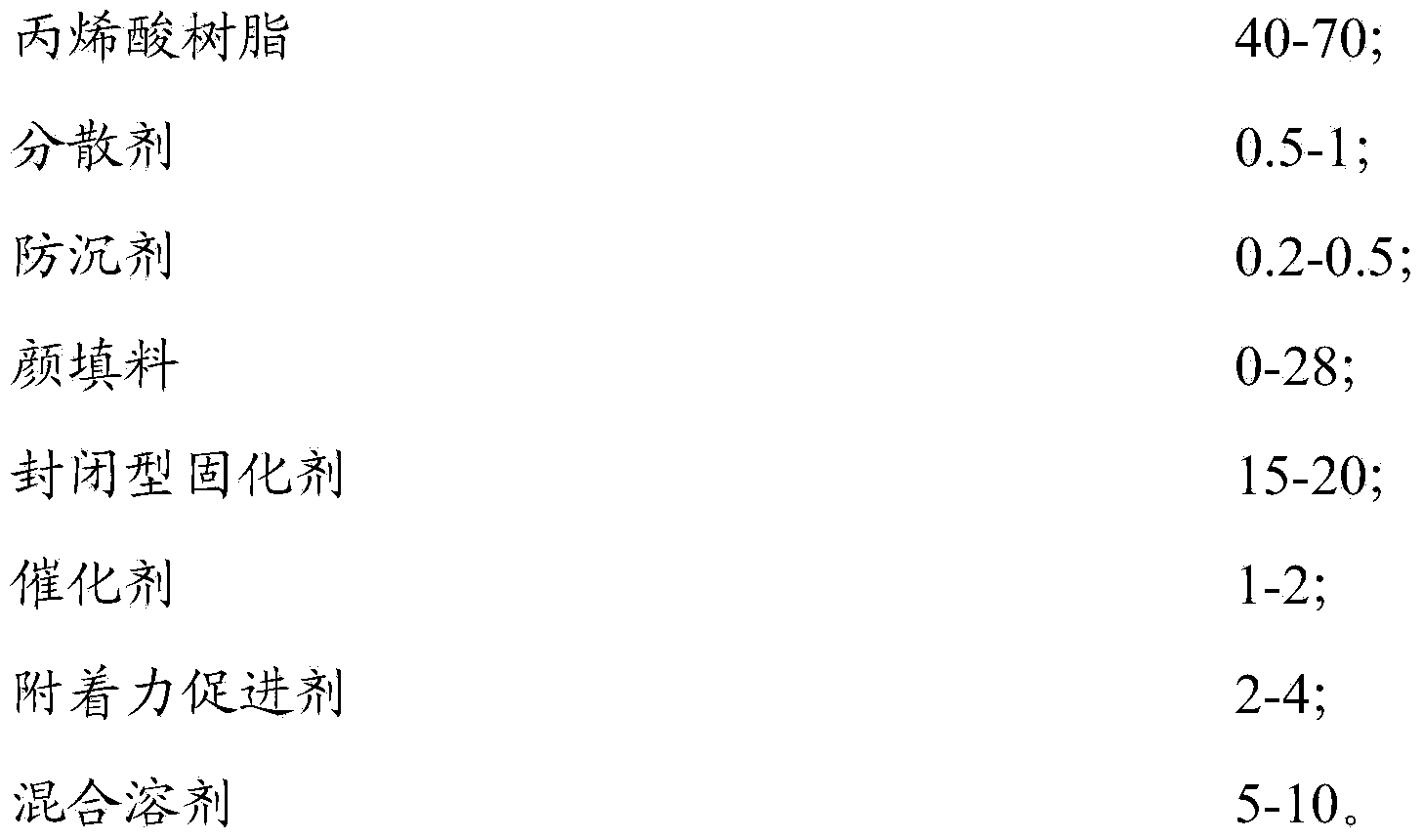

[0056] Table 1

[0057] Name

Mass percentage

Acrylic

45

Dispersant

0.5

Anti-settling agent

0.5

Titanium Dioxide

28

Blocked isocyanate

16

Drier

1.5

Leveling agent

0.3

0.2

Adhesion promoter

2

Mixed solvent

6

[0058] a: Toner pre-dispersed

[0059] Mix the acrylic resin, dispersant, anti-settling agent, and mixed solvent in proportions, and stir for 5-10 minutes at 800-1200rpm in a high-speed disperser; then, add titanium dioxide slowly in proportion at a speed of 600rpm After the addition is complete, increase the speed to 1200rpm and disperse for 30 minutes for use;

[0060] b: Color paste grinding

[0061] Use a sand mill to grind the premixed slurry prepared in the first step above to a fineness of not less than 15μm

[0062] c: paint

[0063] The remaining propylene resin and the sealing curing agent, auxiliary agent, and mixed solvent are mixed in proportion, and stirred in a high-speed disperser at 800-1200 rpm for...

Embodiment 2-7

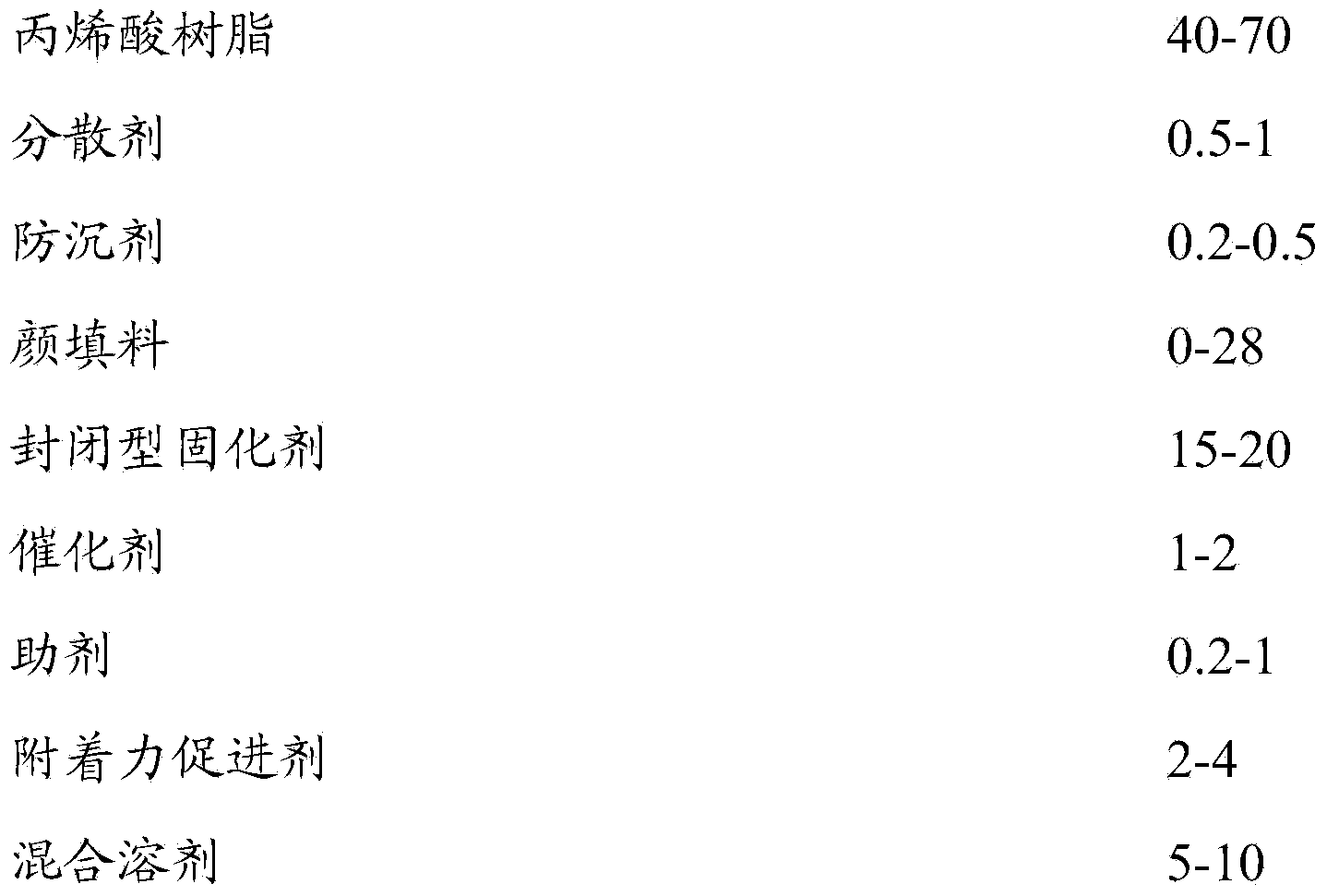

[0066] The operation steps and reaction conditions are the same as in Example 1, and the specific amounts of raw materials are shown in Table 2.

[0067] Table 2

[0068]

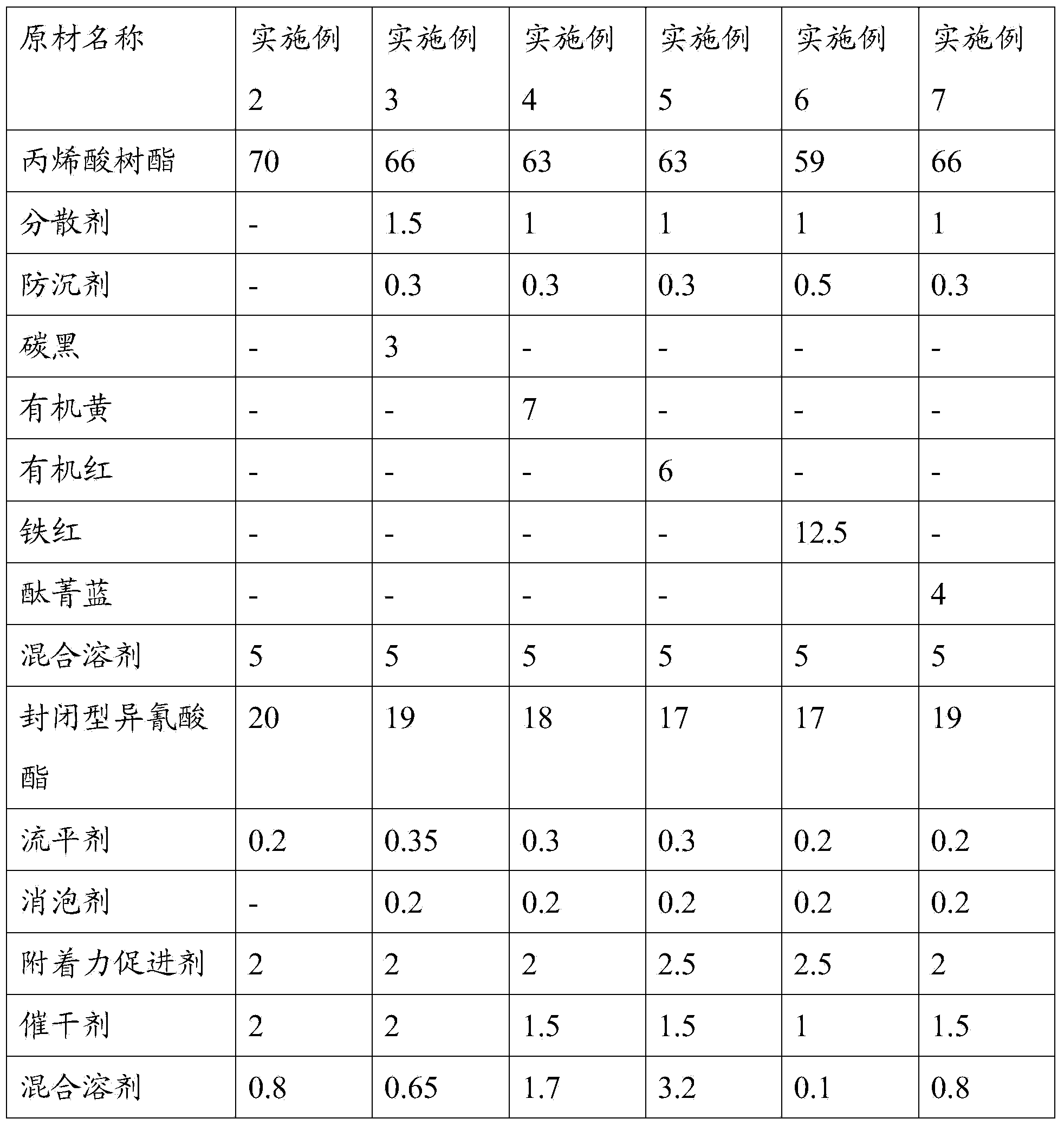

[0069] In Examples 1-7, the specific components of each component used are shown in the following table.

[0070]

[0071] The properties of the low-temperature thermal curing polyurethane coatings are shown in Table 3.

[0072] table 3

[0073]

[0074]

[0075]

[0076] Remarks: The baking temperature for each performance test is 100℃×30 minutes.

[0077] The difference between the product of the present invention and the traditional baking varnish, two-component polyurethane coating and low-temperature baking varnish is shown in Table 4.

[0078] Table 4

[0079]

[0080]

[0081] It can be seen from Table 4 that the product of the present invention can achieve good film properties when baked at 100°C, single-tank packaging, good storage stability, and all properties are better than traditional amino baking paint and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com