High-solid-content PU (polyurethane) matte varnish and preparation method thereof

A polyurethane and high solid content technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor storage stability, achieve the effects of reducing dosage, plump paint film, and reducing the number of coating layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] A high-solid-content polyurethane matte varnish is characterized in that: it is formulated by a weight ratio of 1:0.6-1:0.1-0.4 from A component, B component, and an environmentally friendly thinner;

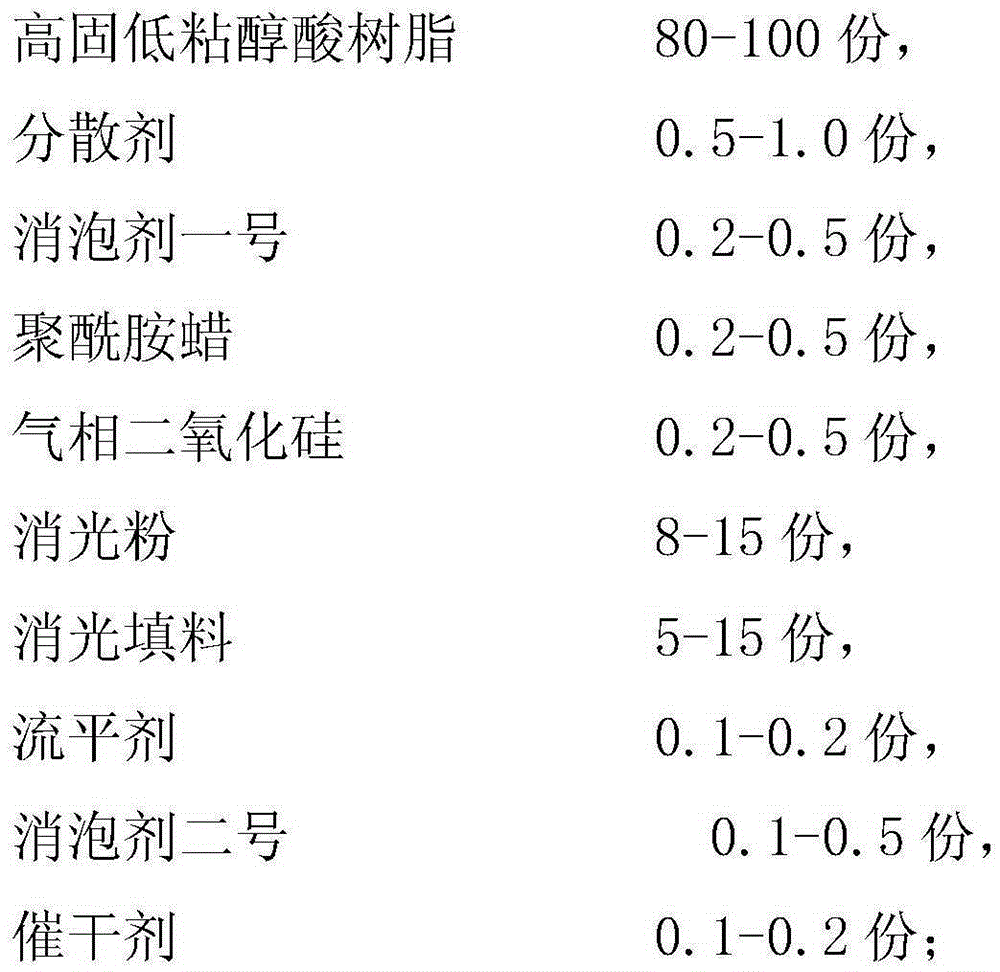

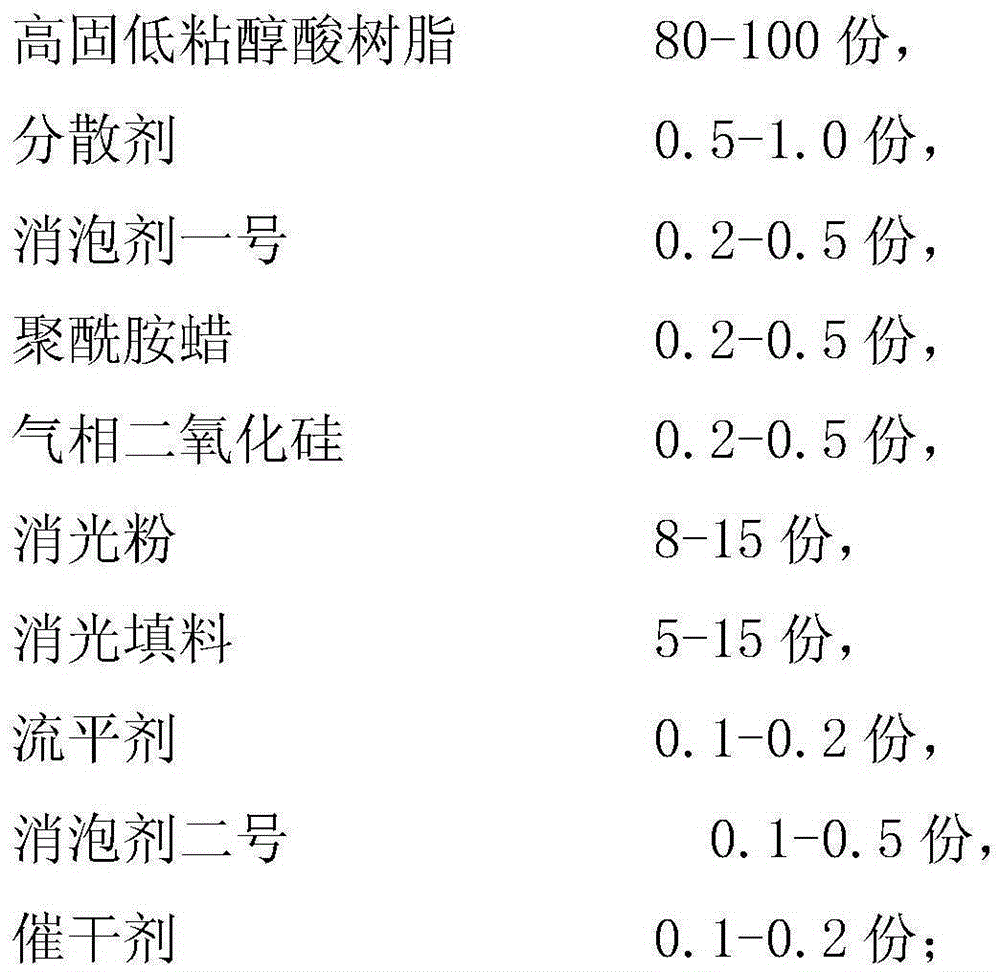

[0029] The first component is made from the raw materials of the following weight ratio:

[0030]

[0031] The B component is made from the raw materials of the following weight ratio:

[0032] 40-70 parts of TDI trimer,

[0033] HDI trimer 20-40 parts,

[0034] 15-30 parts of butyl acetate;

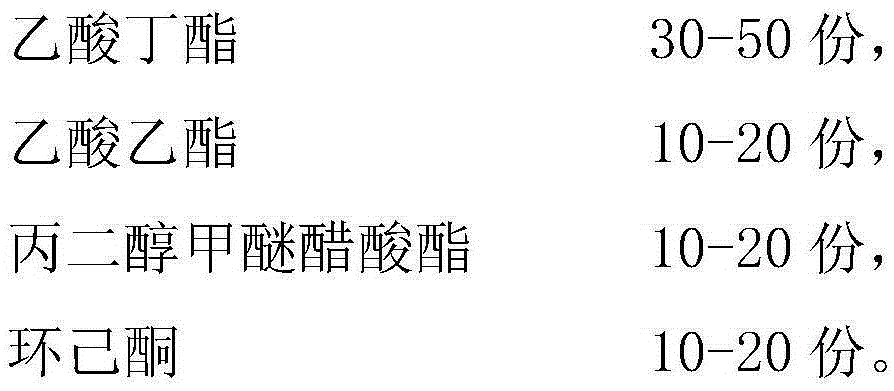

[0035] Described environment-friendly diluent is made from the raw material of following weight ratio:

[0036]

[0037] Further, the matting powder is silicon dioxide with a particle size of 8-15 microns. Through the thickening of the matting powder itself, the matting filler increases the solid content, reduces the amount of anti-settling slurry, and achieves the purpose of high construction solid content and low VOC.

[0038] Further, the matting filler is a filler tha...

Embodiment 1

[0051] Embodiment 1 is the best embodiment:

[0052] High solid content polyurethane matt varnish, which is prepared from component A, component B, and environmentally friendly thinner in a weight ratio of 1:0.6:0.3;

[0053] The first component is made from the raw materials of the following weight ratio:

[0054]

[0055] The B component is made from the raw materials of the following weight ratio:

[0056] 60 parts of TDI trimer,

[0057] 40 parts of HDI trimer,

[0058] 20 parts of butyl acetate;

[0059] Described environment-friendly diluent is made from the raw material of following weight ratio:

[0060]

[0061] The matting powder is silicon dioxide with a particle size of 11 microns.

[0062] The matting filler is glass powder.

[0063] The high-solid low-viscosity alkyd resin is a short-oil alkyd resin for PU matte with a solid content of 80% and a viscosity of 5000cps / 25°C.

[0064] The dispersant is a copolymer dispersant containing filler affinity gr...

Embodiment 2

[0074] Embodiment 2 is the best embodiment:

[0075] High solid content polyurethane matt varnish, which is prepared from component A, component B, and environmentally friendly thinner in a weight ratio of 1:0.7:0.2;

[0076] The first component is made from the raw materials of the following weight ratio:

[0077]

[0078]

[0079] The B component is made from the raw materials of the following weight ratio:

[0080] 70 parts of TDI trimer,

[0081] 35 parts of HDI trimer,

[0082] 15 parts of butyl acetate;

[0083] Described environment-friendly diluent is made from the raw material of following weight ratio:

[0084]

[0085] The matting powder is silicon dioxide with a particle size of 9 microns.

[0086] The matting filler is an organic matting agent and glass powder in a weight ratio of 1:2.

[0087] The high-solid low-viscosity alkyd resin is a short-oil alkyd resin for PU matte with a solid content of 80% and a viscosity of 4000cps / 25°C.

[0088] The d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com