Patents

Literature

31results about How to "Reduce the number of coating layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Investment casting formwork and method of producing the same

InactiveCN101138781ALow priceWide variety of sourcesFoundry mouldsFoundry coresInvestment castingMaterials science

The present invention relates to a casting technology, which, to be specific, is an invest shell casting and a method of manufacturing the invest shell casting. The invest shell casting comprises a plurality of layers of surface refractory coating, a plurality of consolidation layers of refractory coating and sand materials that is positioned between two layers of refractory coating. The present invention is characterized in that the consolidation layers of refractory coating contain wollastonite in power. Utilizing the method can easily increase strength of the invest shell casting at low cost, thereby not only ensuring required strength of the invest shell casting but also reducing layers of the coating and quantity of iron wires. Even with the method used, the iron wires do not need to be used and required strength of the invest shell casting also can be guaranteed, thereby greatly increasing efficiency of manufacturing the invest shell casting and decreasing the amount of human labor needed.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

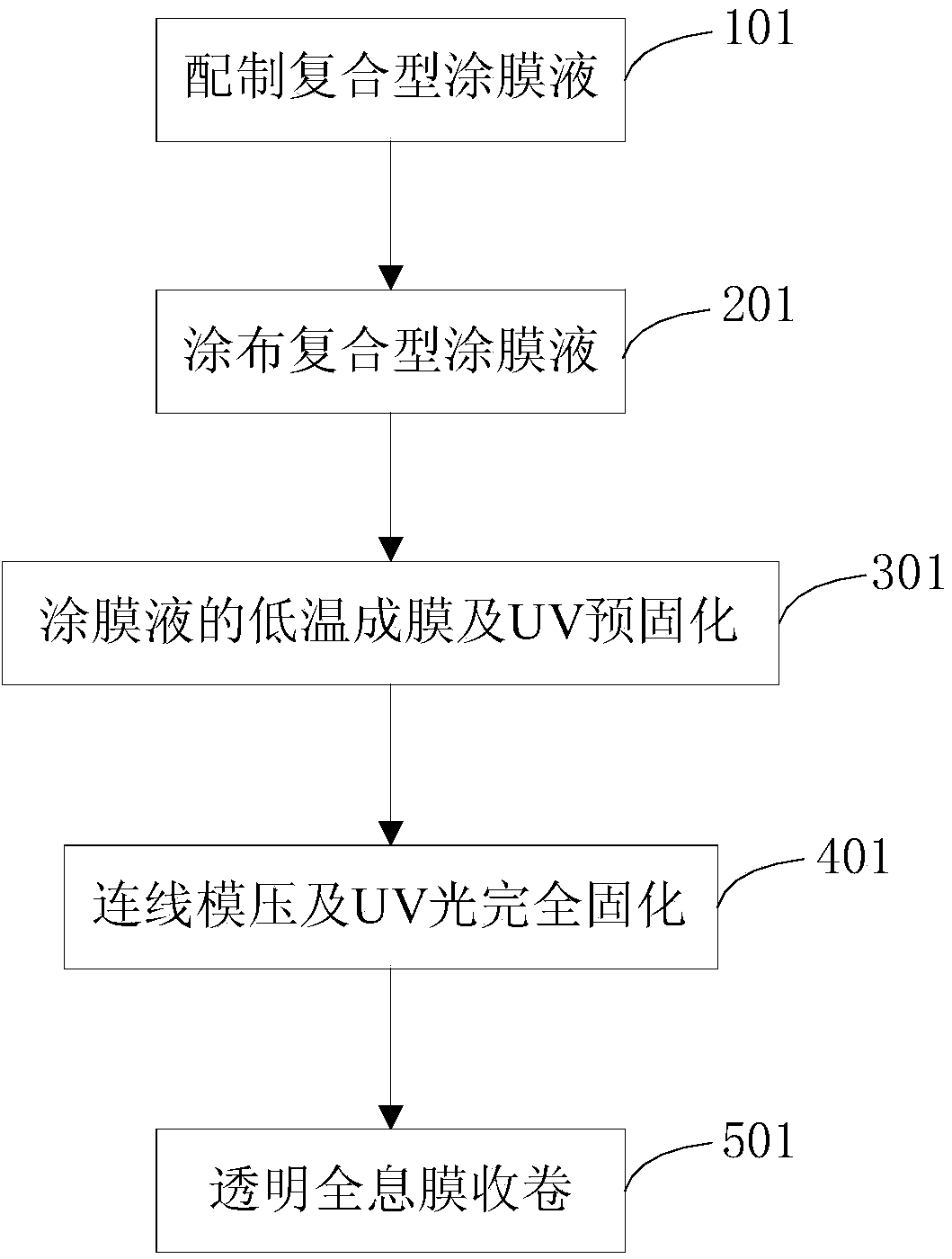

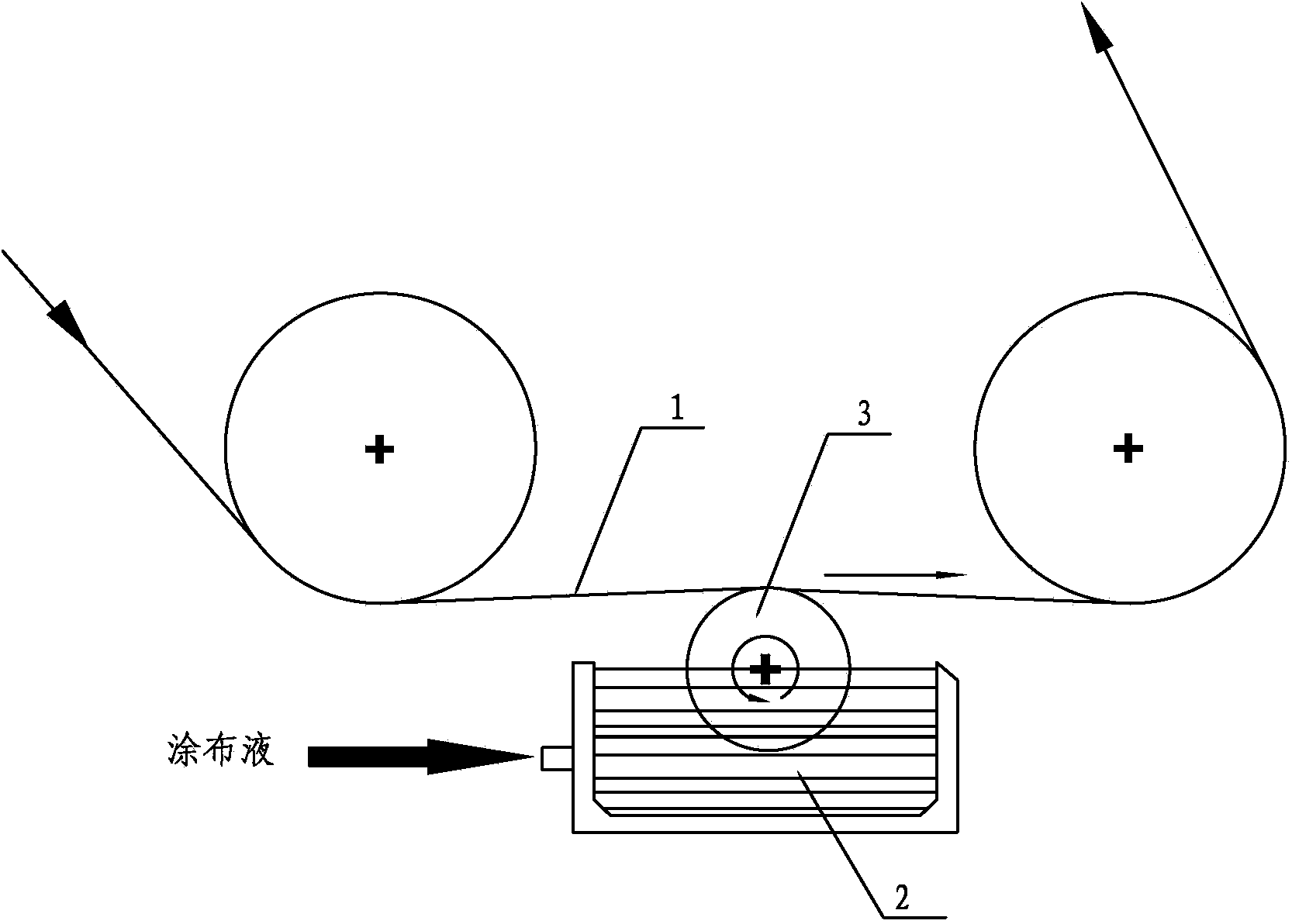

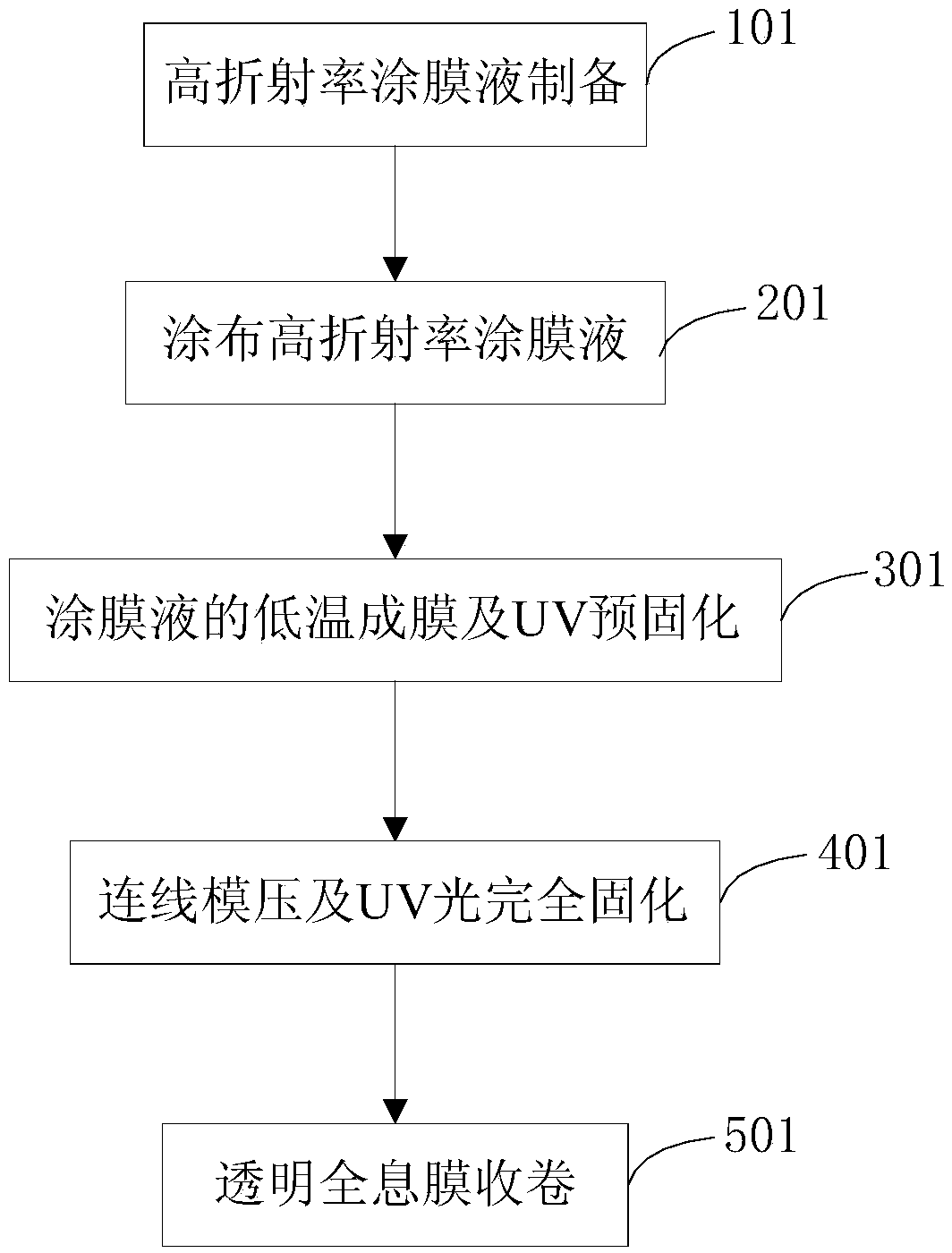

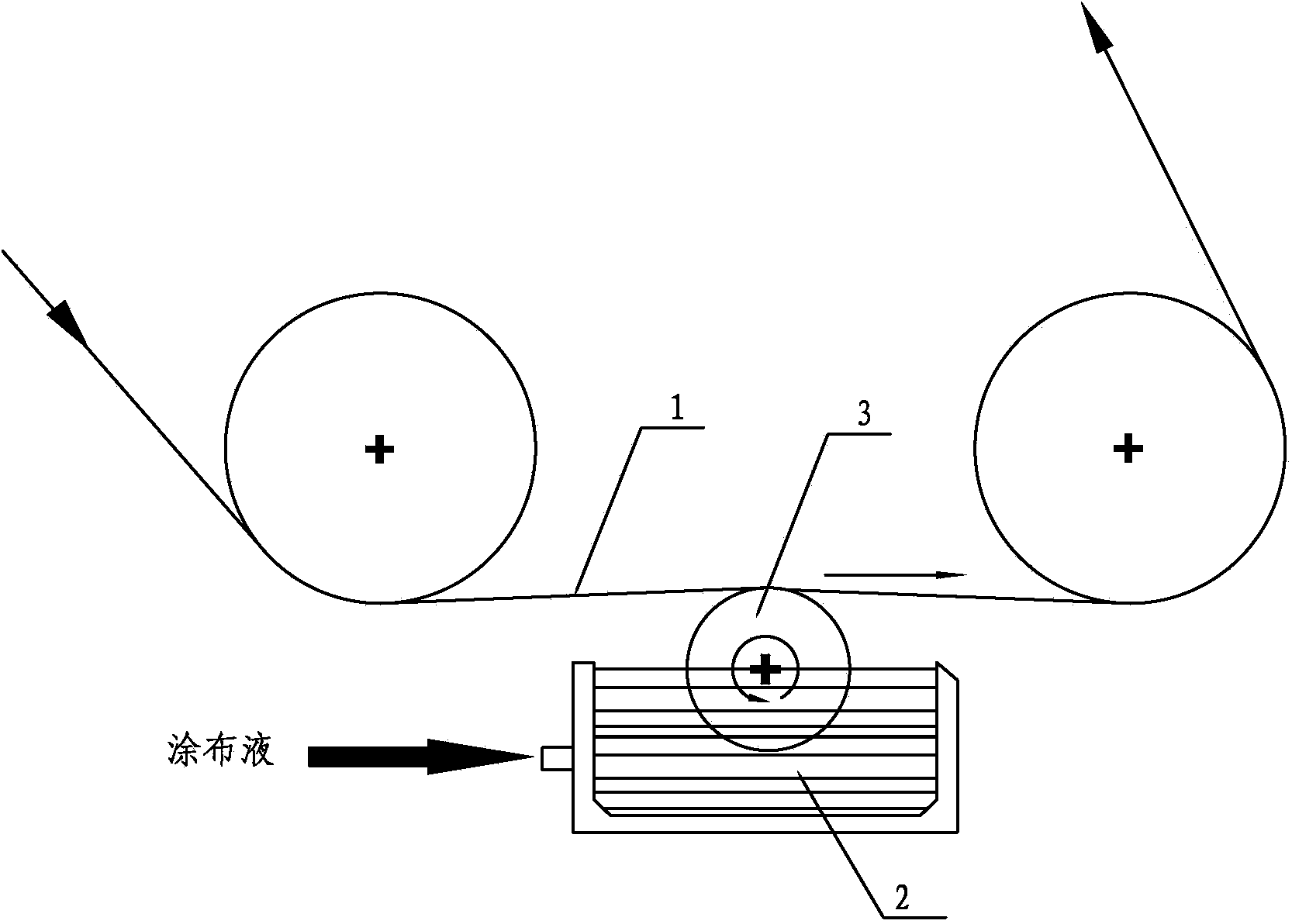

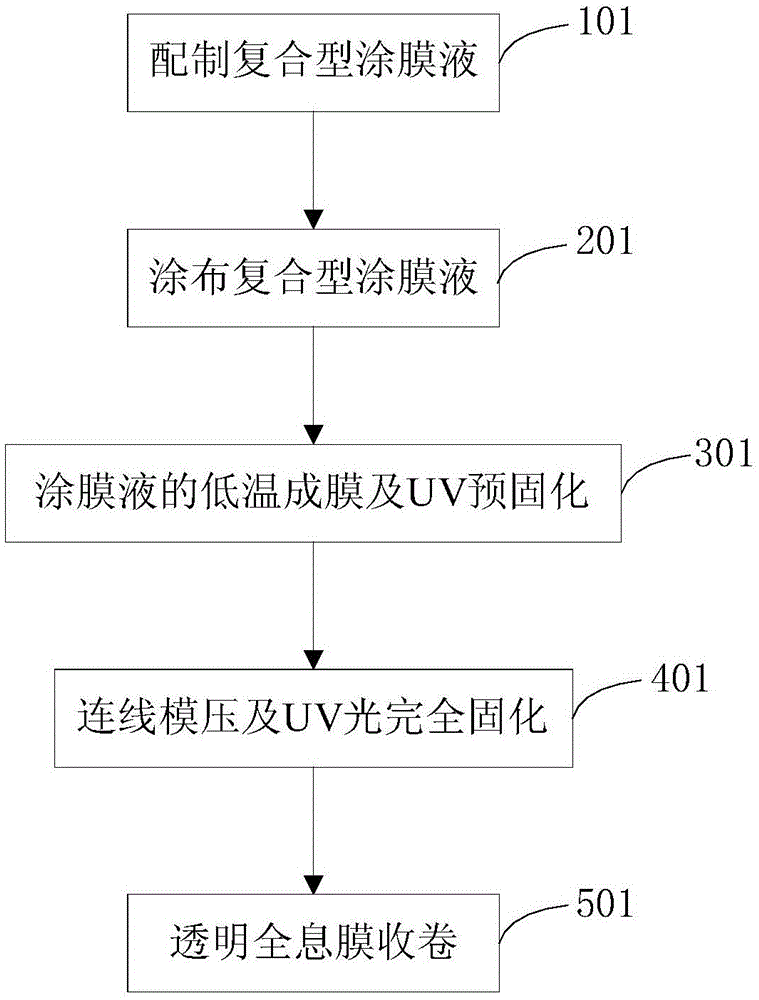

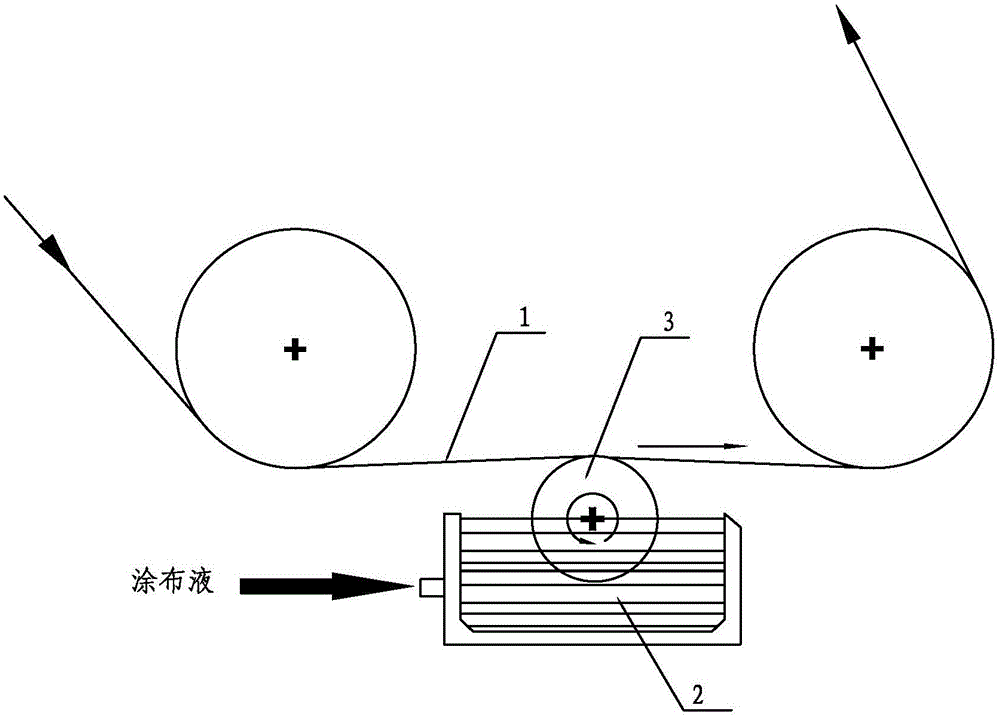

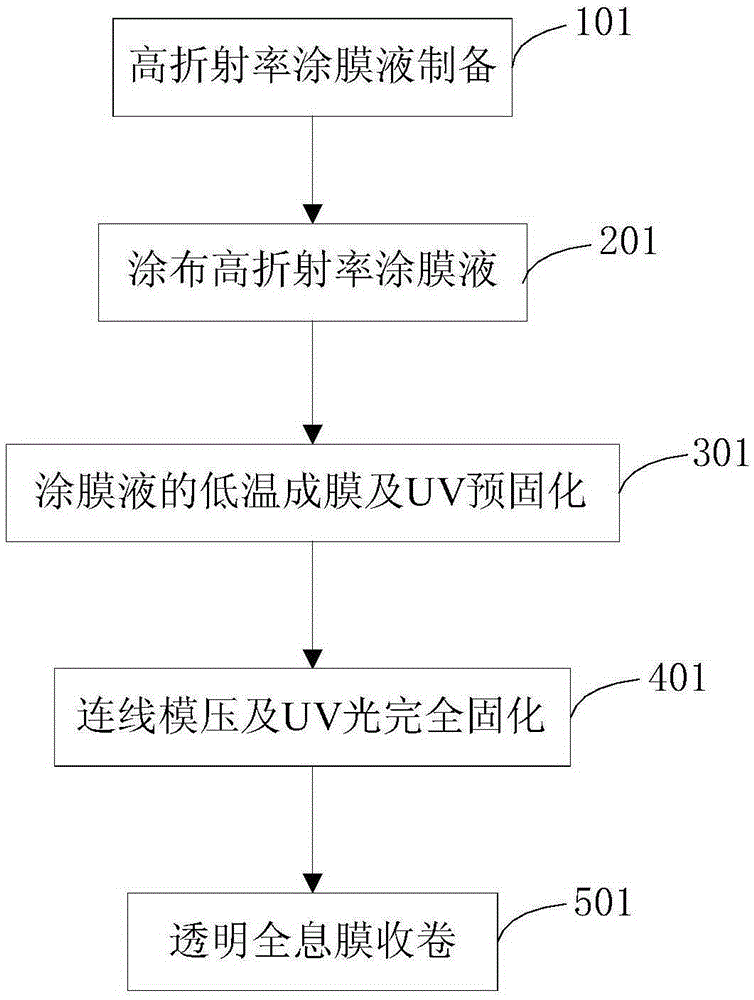

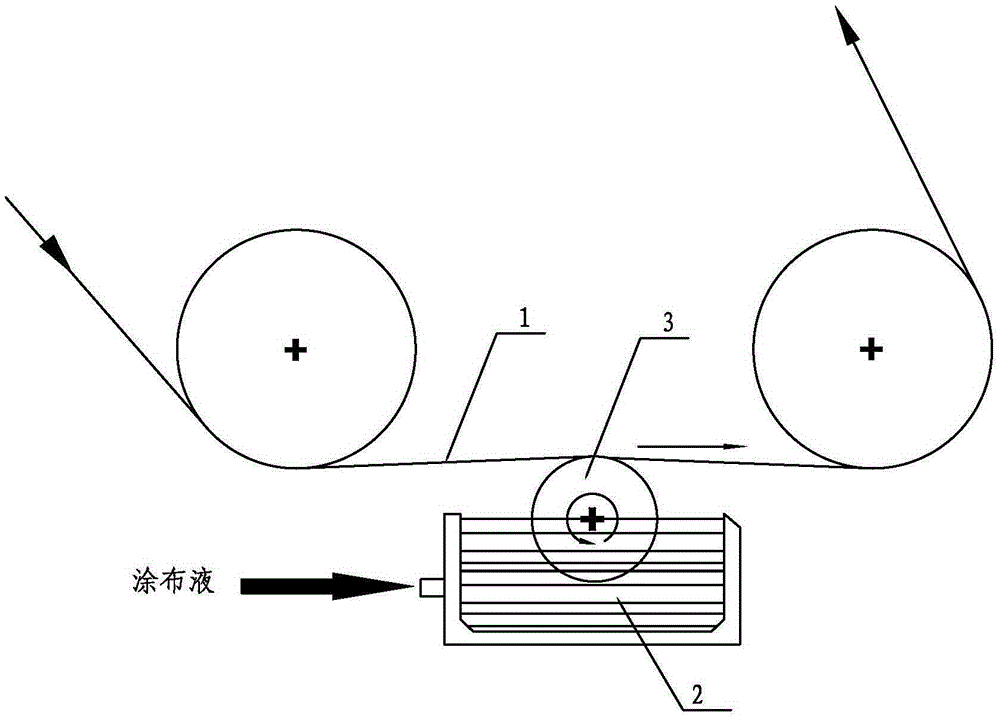

Production process of compound transparent holographic film

ActiveCN104029513AHigh refractive indexHigh transparencyLamination ancillary operationsDuplicating/marking methodsInformation layerImage contrast

The invention discloses a production process of a compound transparent holographic film, and belongs to the technical field of laser anti-counterfeit. The production process comprises the preparation of compound film coating liquid, the coating of the compound film coating liquid, the low-temperature film formation and UV pre-curing of the film coating liquid, the wired mold pressing and UV light full curing, and the rolling of the transparent holographic film; and the production process combines an information layer with a medium layer as a whole through the compound film coating liquid to form a compound coating layer, so that the prepared transparent holographic film has such characteristics as high refraction index, high transparency and signal-to-noise ratio, excellent wear and ageing resistance and obvious holographic image contrast, the technical bottlenecks of difficult tracking and difficult positioning due to small contrast in a traditional transparent holographic image are broken through, the random positioning of a transparent holographic pattern in a certificate is really achieved, and the comprehensive anti-fake effect of transparent hologram is enhanced.

Owner:ZHEJIANG JINGHUA LASER TECH CO LTD

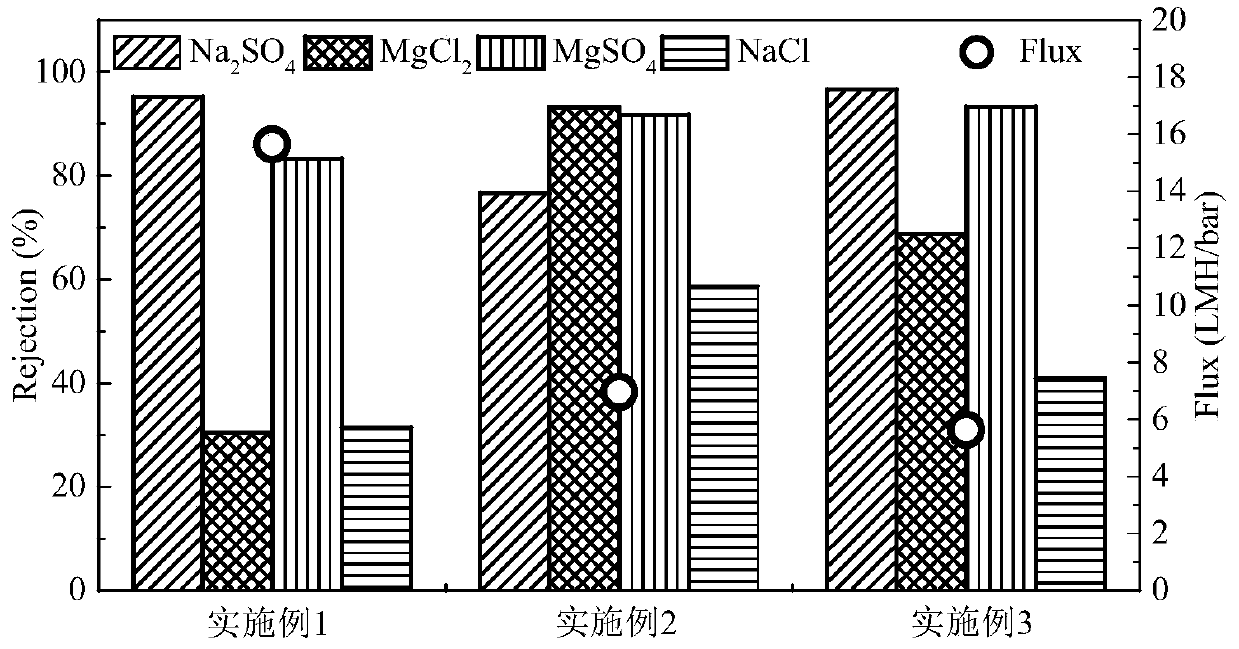

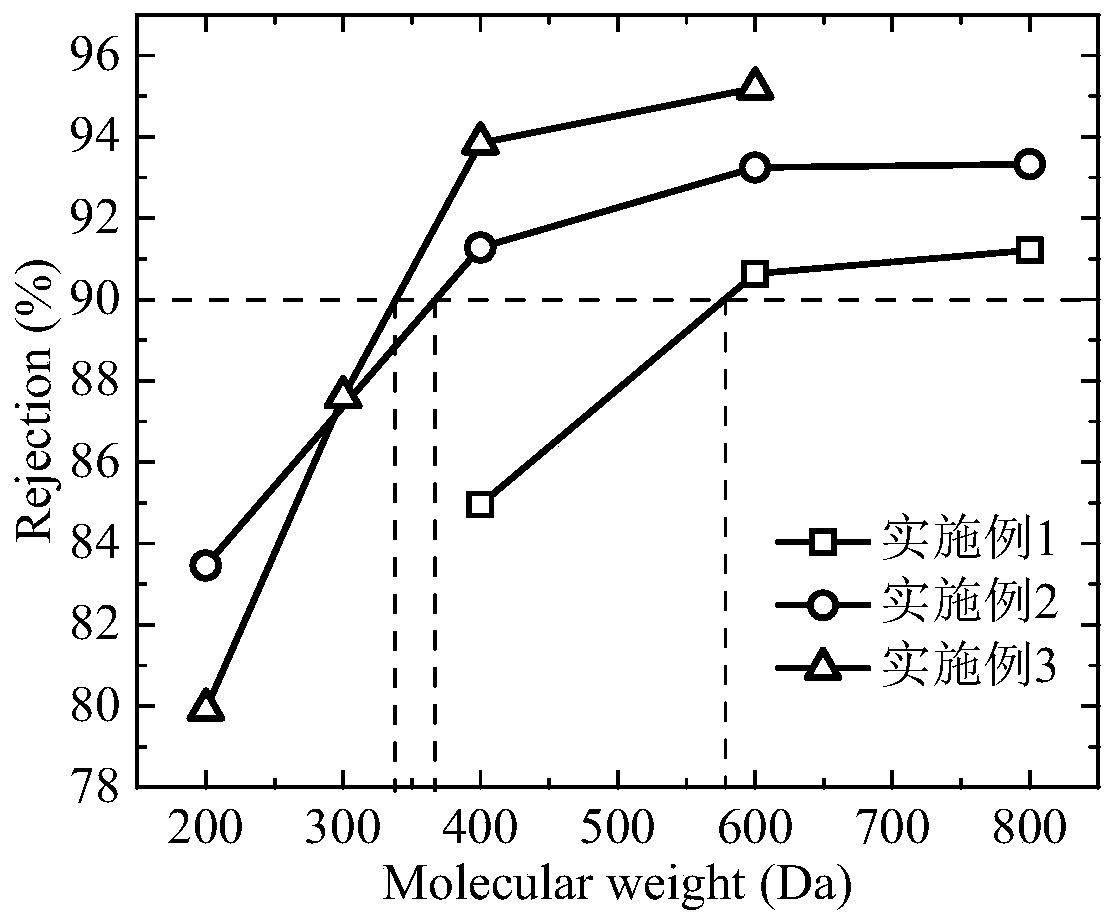

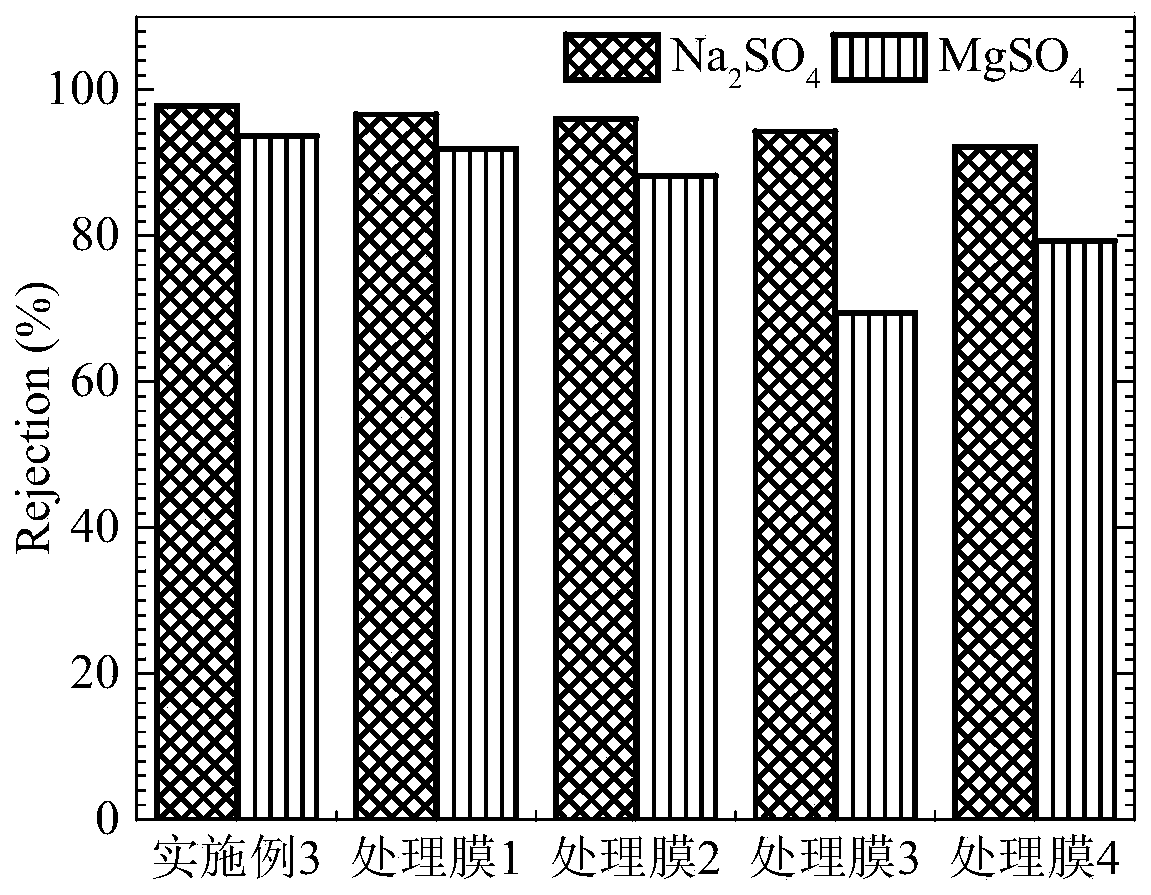

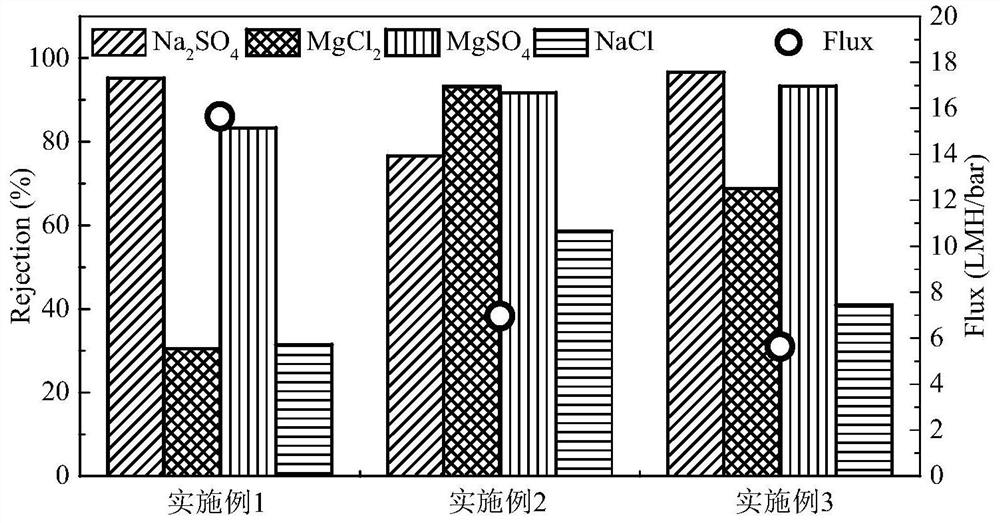

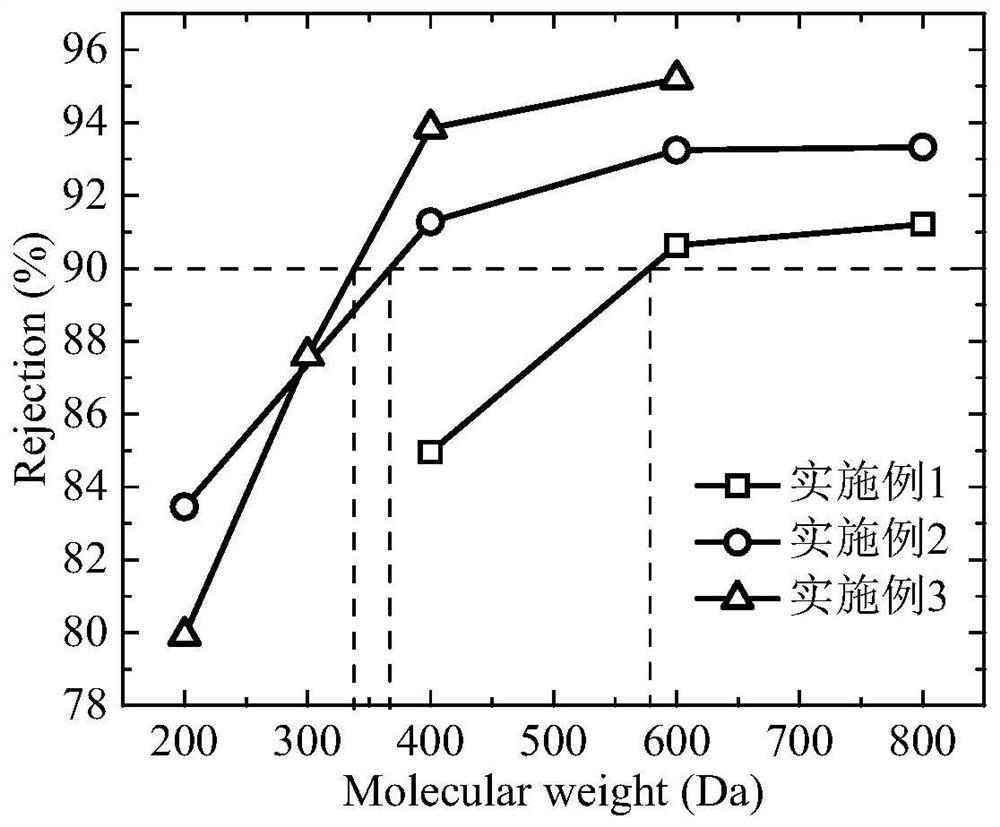

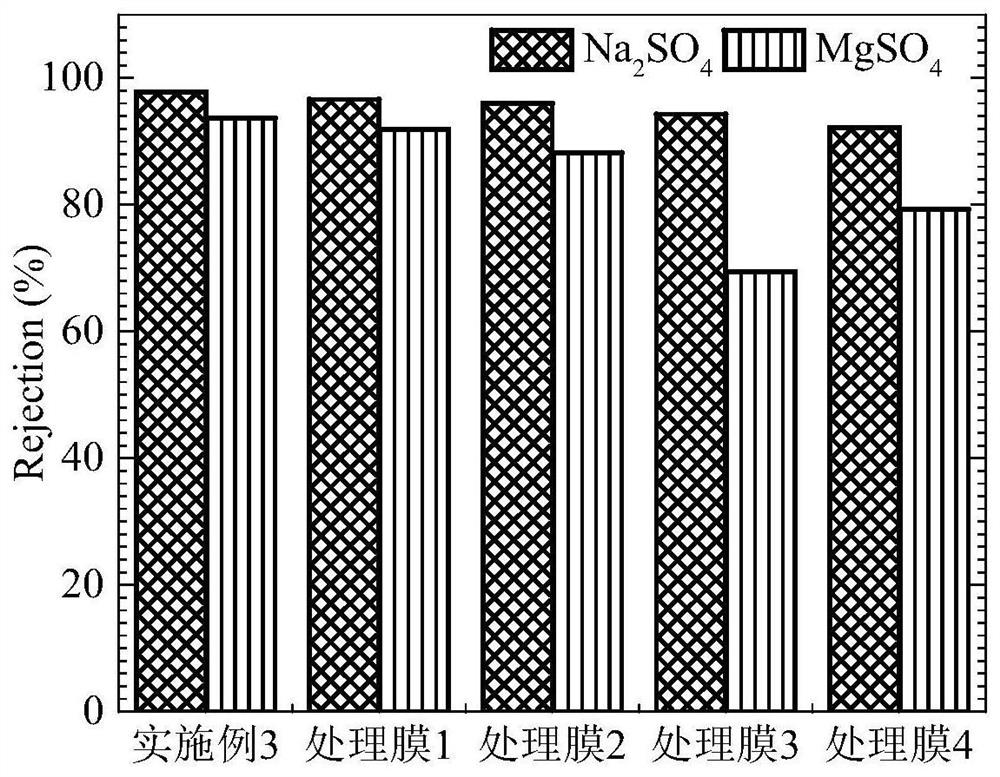

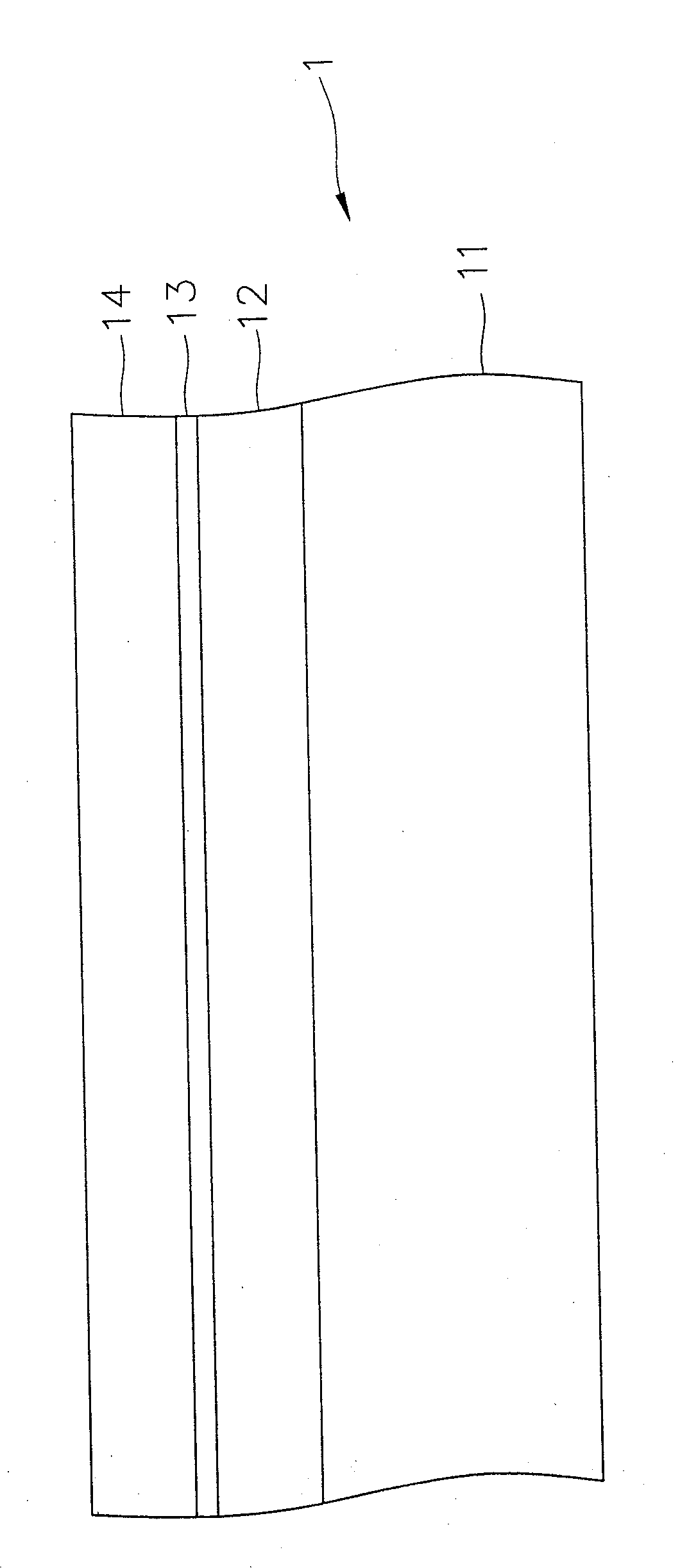

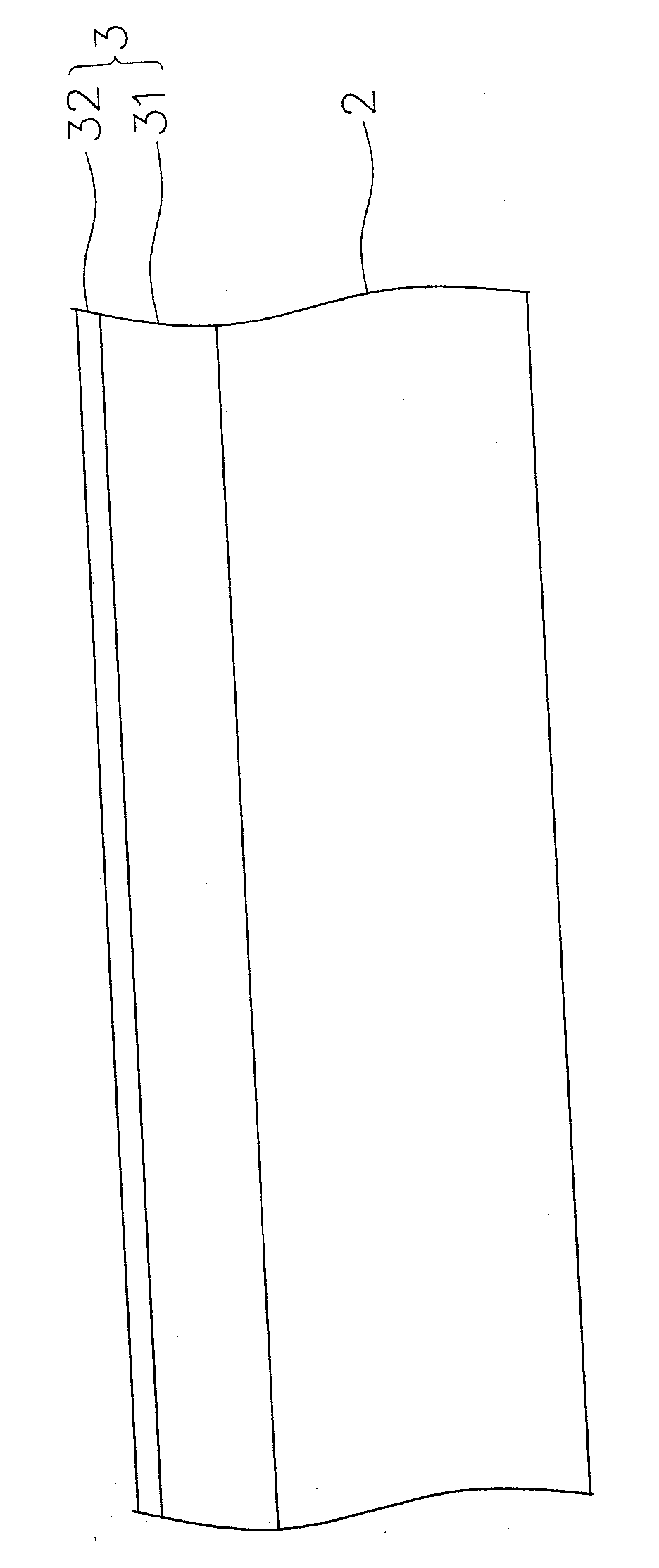

Mussel bionic auxiliary polyelectrolyte layer-by-layer self-assembled nanofiltration membrane and application thereof

ActiveCN111437741AImprove hydrophilicityHigh retention rateReverse osmosisWater/sewage treatment bu osmosis/dialysisPolystyreneEngineering

The invention discloses a mussel bionic auxiliary polyelectrolyte layer-by-layer self-assembled nanofiltration membrane and application thereof. The nanofiltration membrane is prepared by circularly coating and modifying the surface of a base membrane with a polydopamine / polyethyleneimine mixed solution and a polyanion electrolyte solution for 1-3 times by virtue of a layer-by-layer self-assemblytechnology, and finally carrying out cross-linking reaction. Polydopamine and polyethyleneimine with high hydrophilicity are adopted, both may form a covalent bond, a stable coating is formed on the surface of the membrane; after performing coating modification, coating modification is carried out by adopting sodium polystyrenesulfonate with negative electricity, sodium polystyrenesulfonate and positively charged polyethyleneimine can be subjected to electrostatic adsorption, and benzene rings in molecules of sodium polystyrenesulfonate and benzene rings in molecules of polydopamine have a pi-pi stacking effect so that the stability of the coating is improved, coating is more uniform, and the prepared nanofiltration membrane is good in hydrophilicity, high in rejection rate, high in pollution resistance and high in chemical stability.

Owner:SUN YAT SEN UNIV

Composite modified ceramic shell and preparation method thereof

InactiveCN109128037AHigh strengthImprove cooling effectFoundry mouldsFoundry coresFiberConnection - action

The invention relates to the fields of directional solidification and investment casting, in particular to a zirconia fiber and graphite powder composite modified ceramic shell and a preparation method thereof. According to the preparation method, by adjusting technological parameters, good connection action of a duplication wax pattern surface of a surface layer and a transition layer is ensured;by adding zirconium oxide fibers and graphite powder into a back layer, the strength and heat dispersion of the shell are improved; after sizing, stuccoing and drying are conducted many times, dewaxing and sintering are conducted to prepare the shell. The characteristics that the strength of the zirconium oxide fibers is high, and the zirconium oxide fibers keep in a fiber condition at a high temperature are utilized, and the high-temperature strength of the shell can be remarkably improved; when alloy liquid is cooled, due to the high heat conductivity of the graphite powder, the heat dispersing speed of the shell is effectively improved, and the production requirements of the ceramic shell are well met.

Owner:JIANGSU UNIV

Production process of transparent holographic film with high refractive index

ActiveCN104029512AHigh refractive indexHigh transparencyLamination ancillary operationsDuplicating/marking methodsInformation layerImage contrast

The invention discloses a production process of a transparent holographic film with high refractive index, and belongs to the technical field of laser anti-counterfeit. The process comprises the steps of preparation of film coating liquid with high refractive index, coating of the film coating liquid with high refractive index, low-temperature film formation and UV precuring of the film coating liquid, wired mold pressing, UV light complete curing and rolling of the transparent holographic film. The production process combines an information layer with a medium layer through the film coating liquid with high refractive index to form a composite coating layer, so that the prepared transparent holographic film has such characteristics as high refractive index, high transparency and signal-to-noise ratio, excellent wear resistance and ageing resistance and obvious holographic image contrast, the technical bottlenecks of difficult tracking and difficult positioning caused by small contrast in traditional transparent holographic images are broken through, the random positioning of the transparent holographic images in certificates is truly realized, and the transparent holographic comprehensive anti-counterfeiting effect is promoted.

Owner:ZHEJIANG JINGHUA LASER TECH CO LTD

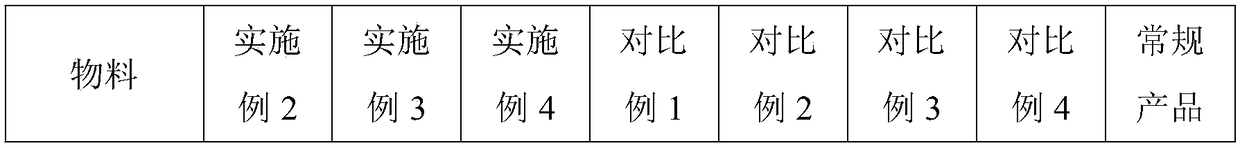

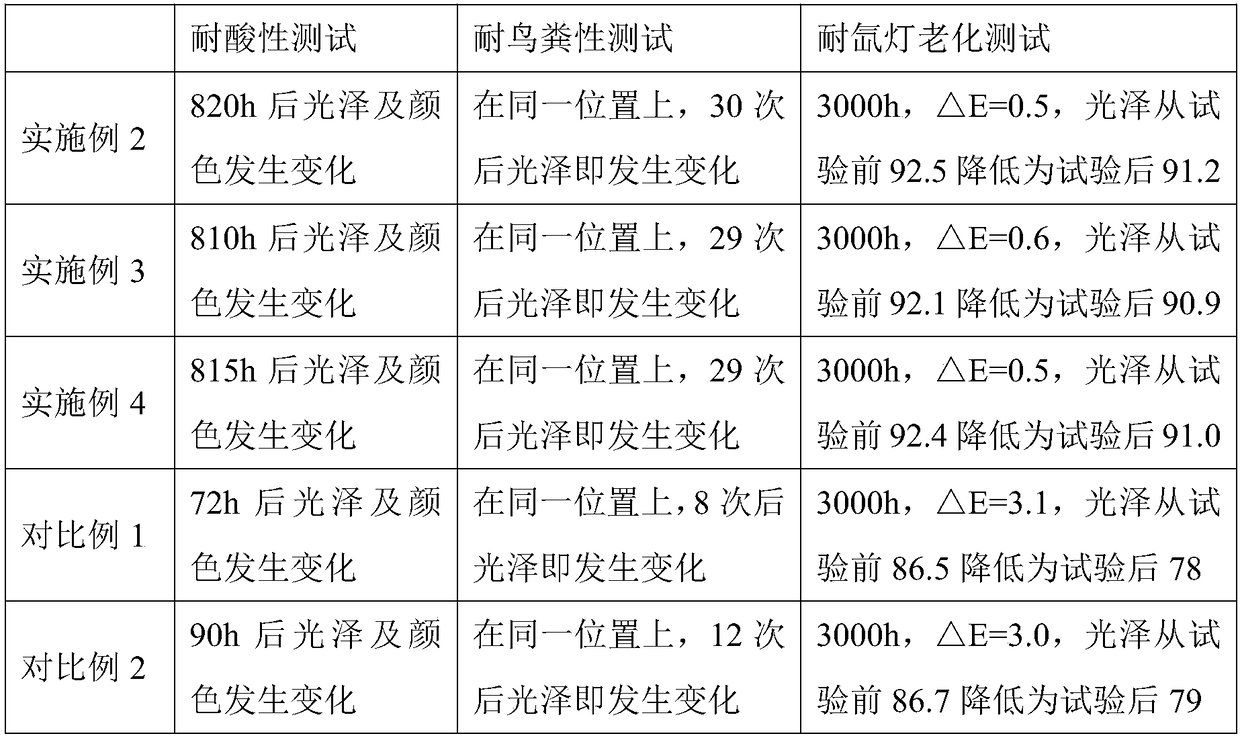

Low-VOC (volatile organic compound) super-curing repairing varnish and preparation method thereof

ActiveCN108276886AHigh hardnessReduce VOC contentAntifouling/underwater paintsPaints with biocidesSolventN-Butyl acetate

The invention belongs to the technical field of chemical coatings, and particularly relates to low-VOC (volatile organic compound) super-curing repairing varnish and a preparation method thereof. Thelow-VOC super-curing repairing varnish provided by the invention is mainly prepared from a component A and a component B; the component A is mainly prepared from polyol super-curing resin, fluoro-modified acrylic resin, overbranched polyester polyol resin, a solvent, a leveling agent and an organic tin dryer; the component B is mainly prepared from low-viscosity aliphatic polyisocyanate, xylene and n-butyl acetate. The low-VOC super-curing repairing varnish provided by the invention can reduce the VOC content using use of coating and relieve the environmental pollution; furthermore, the low-VOC super-curing repairing varnish also has the advantages of formation of a bright varnish film, high fullness, high hardness, scratching resistance, aging resistance, straining resistance and the likein a use process.

Owner:GUANGDONG YATU CHEM

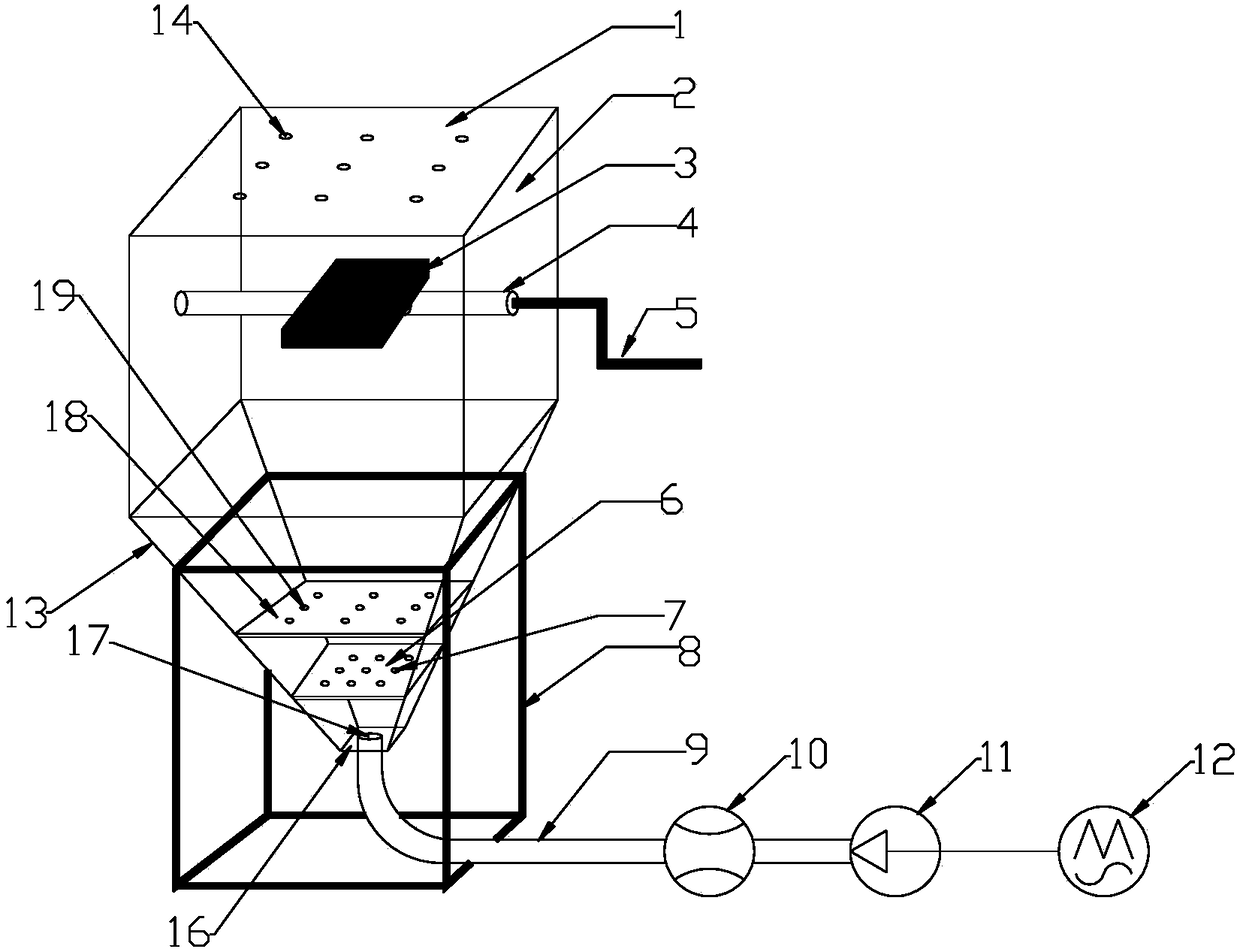

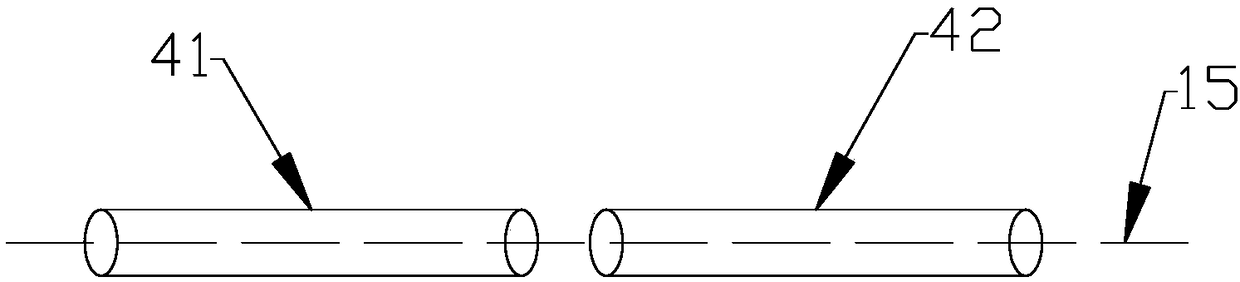

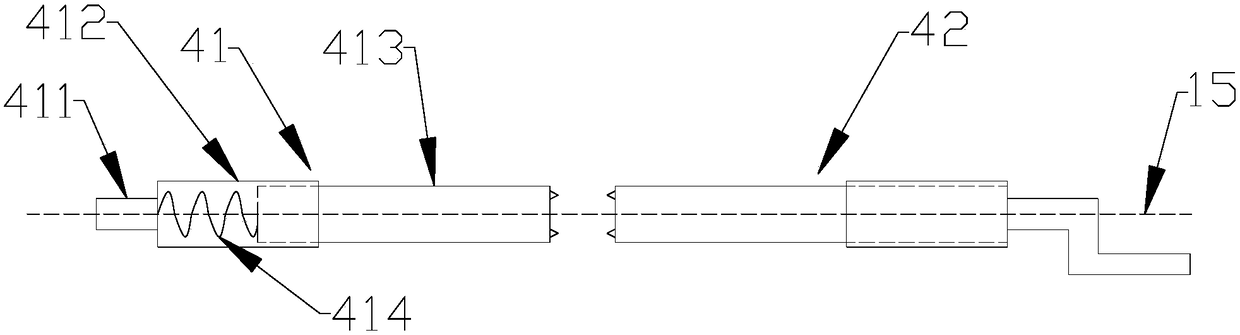

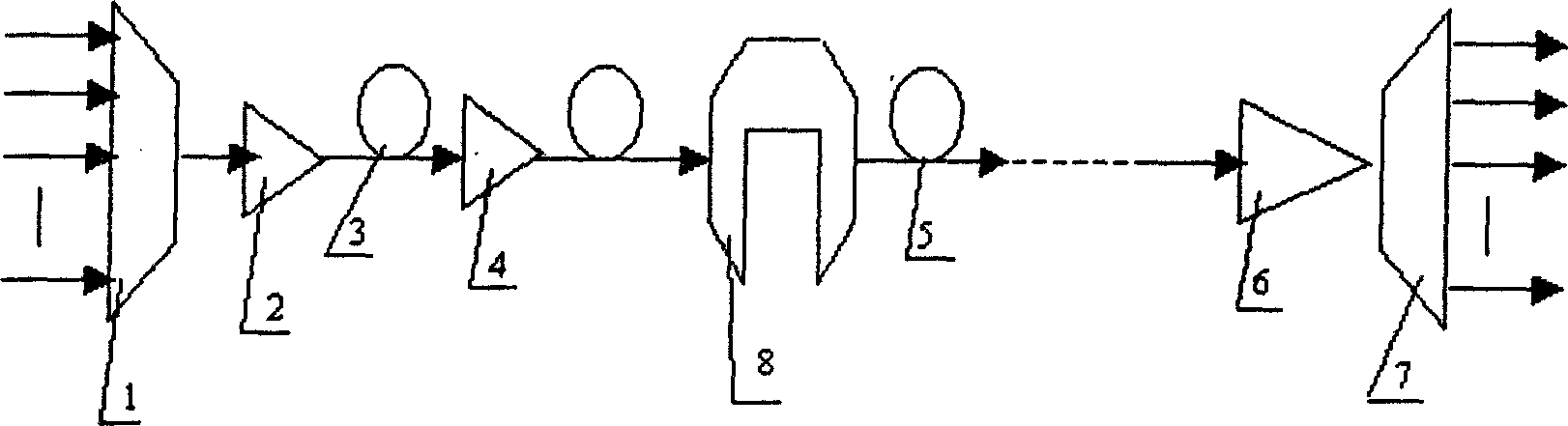

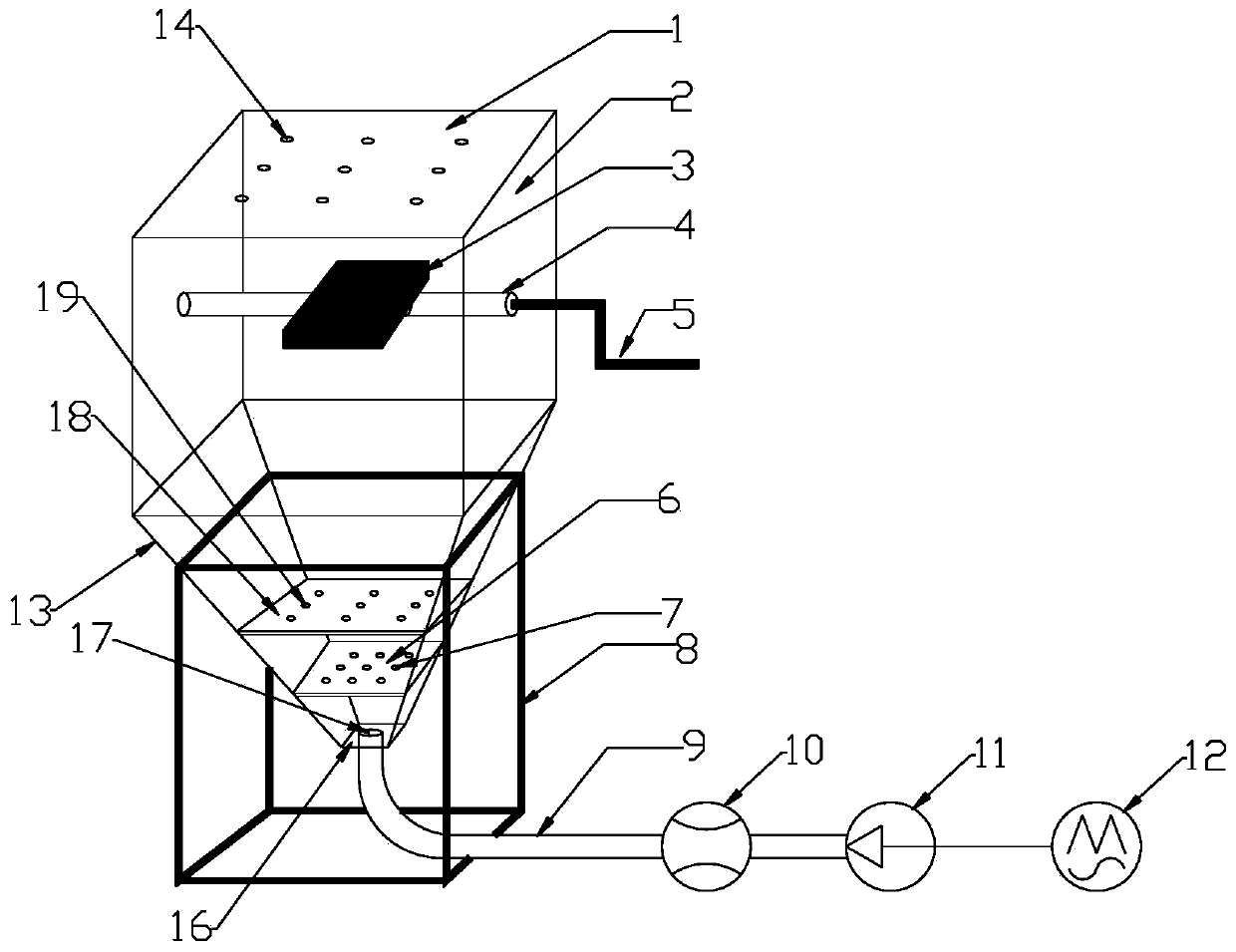

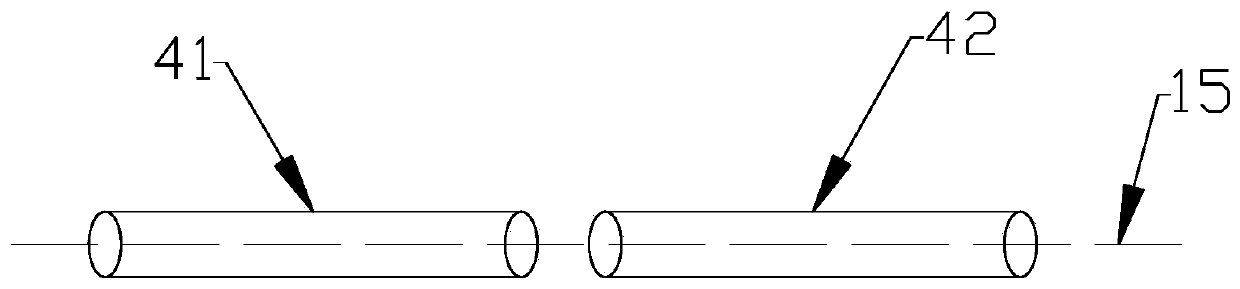

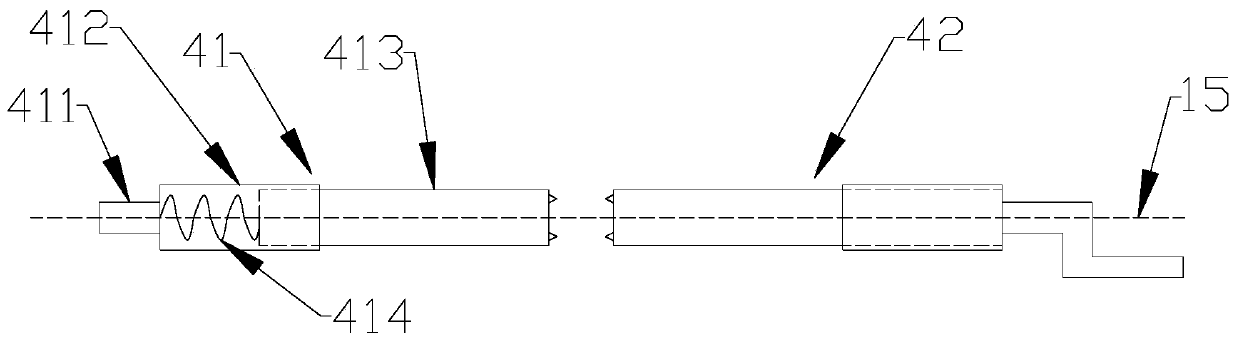

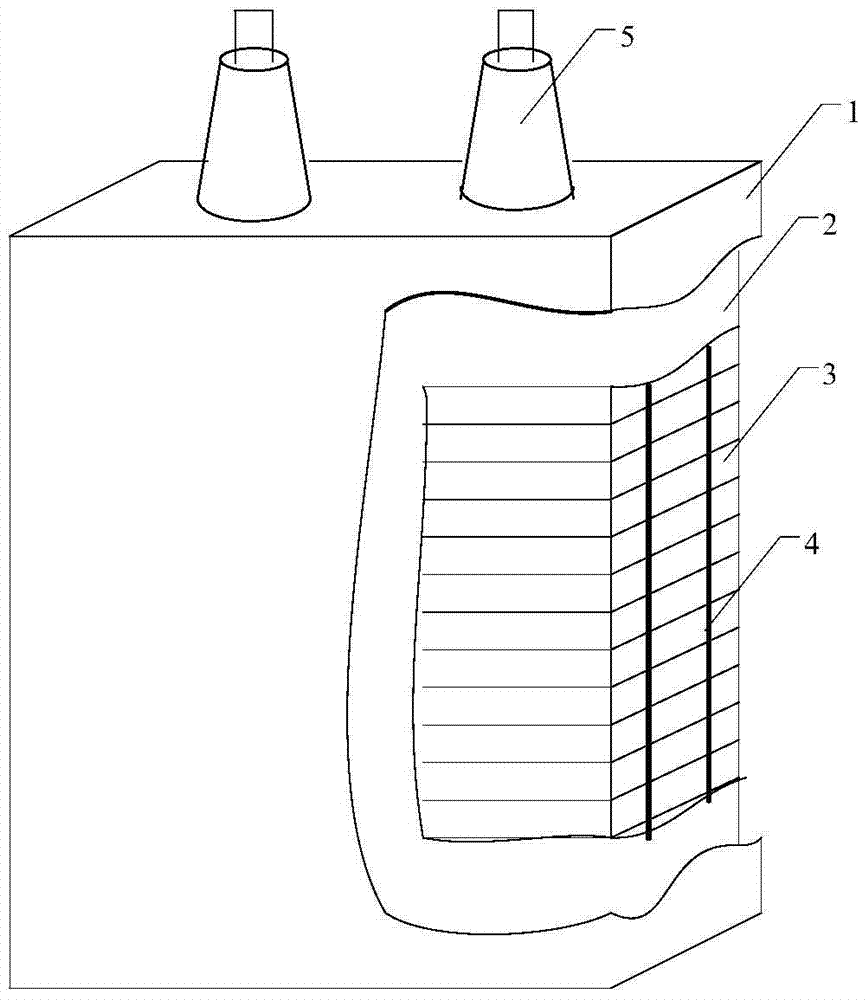

Device and method for preparing fiber reinforced silica sol composite shell through airflow laying

InactiveCN108213344AConsistent performanceImprove air permeabilityFoundry mouldsFoundry coresDiameter ratioAirflow

The invention discloses a device and a method for preparing a fiber reinforced silica sol composite shell through airflow laying. The device comprises a fiber laying chamber, a fiber storage chamber,an air supply unit and a support, wherein the fiber laying chamber is a hollow cube and is composed of four side vertical plates and an upper bottom surface exhaust hole plate and an upper bottom surface exhaust hole plate, and an exhaust hole is formed in the upper bottom surface exhaust hole plate; a rotating shaft used for bearing the shell sample is installed in the fiber laying chamber; the fiber storage chamber is of a hollow inverted quadrangular frustum shape formed by four side plates and a lower bottom surface air inlet plate, a fiber storage rack is arranged in the fiber storage chamber, and airflow guide holes are formed in the fiber storage rack; and the fiber spreading chamber is located right above the fiber storage chamber, the side length of the side vertical plate of thefiber spreading chamber is equal to the side length of the side plate of the fiber storage chamber, and the four side vertical plates and the four side plates are fixedly connected in a one-to-one correspondence manner. According to the device and the method, the fibers can be uniformly distributed in the shell, the fibers can be laid on the shell in a quantitative mode, so that the performance ofthe prepared shell is consistent, and the fiber with the large length-diameter ratio can also be added into the shell.

Owner:INNER MONGOLIA UNIV OF TECH

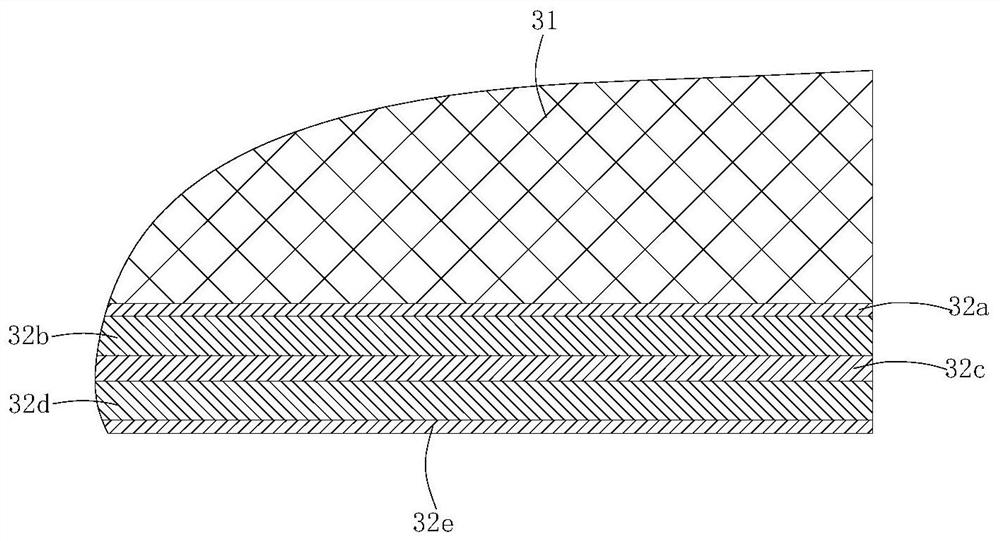

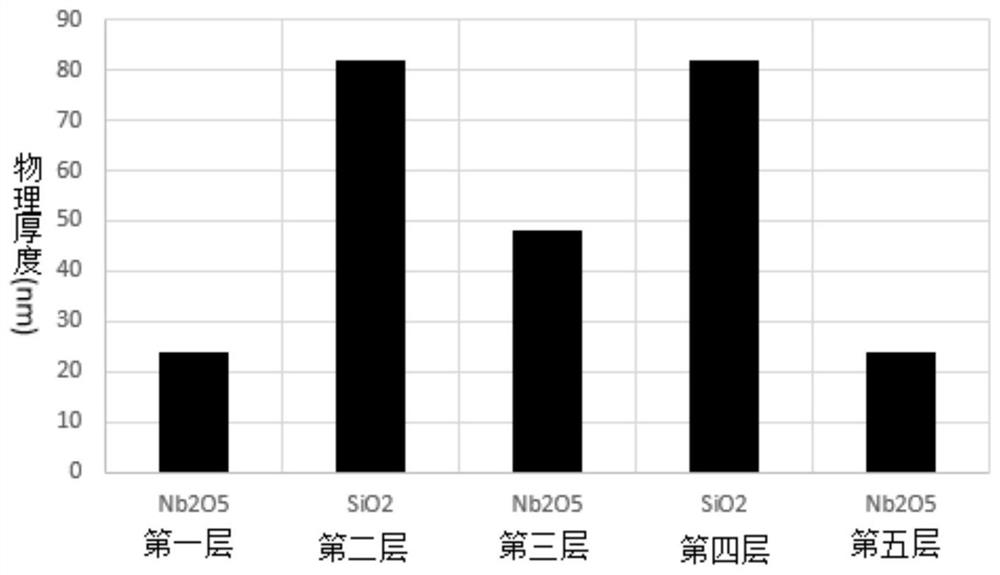

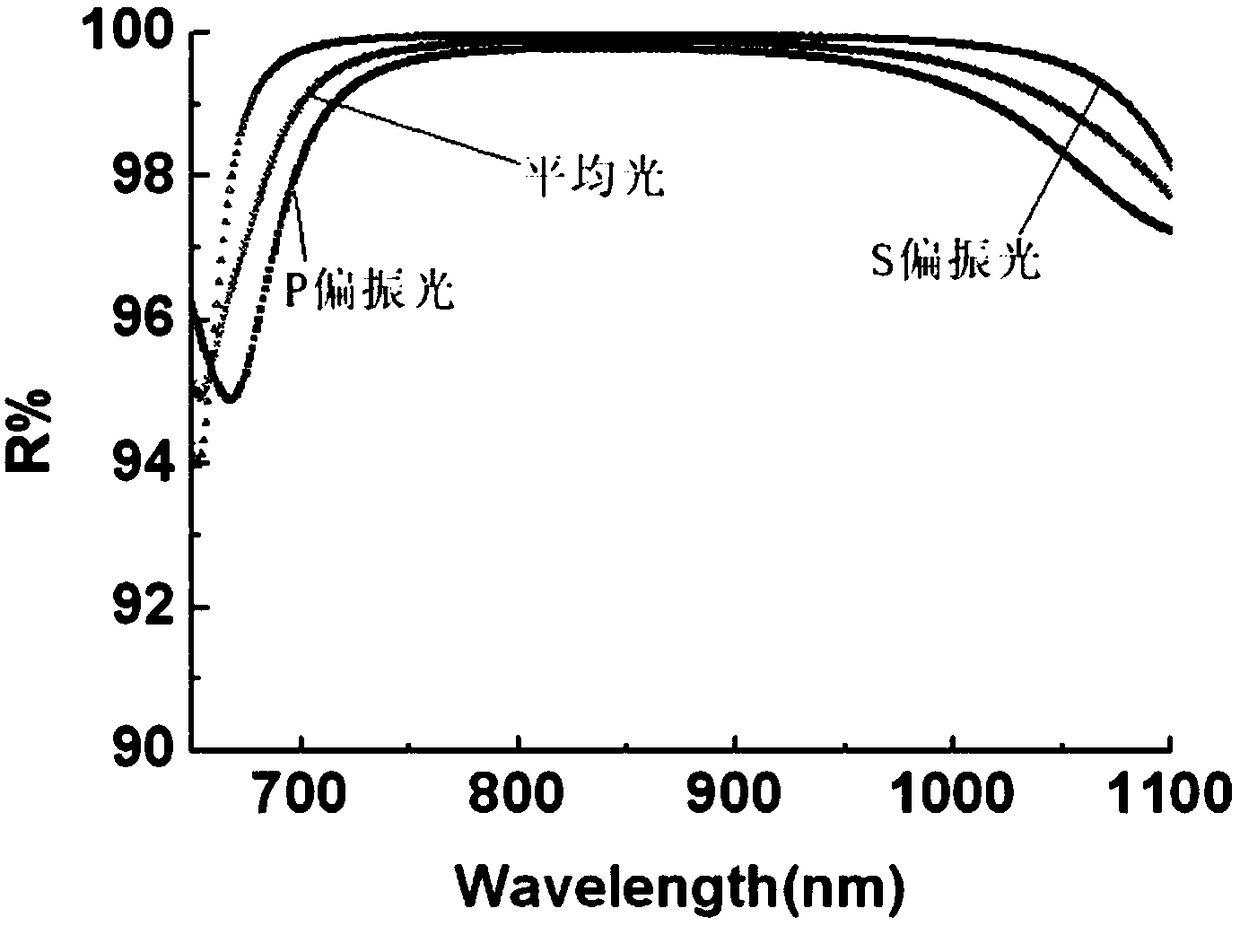

Anti-blue-ray and high-transmittance coated front plate and anti-blue-ray solar cell module

PendingCN111925129ALow mass production costReduce manufacturing costPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention provides an anti-blue-light and high-transmittance coated front plate which comprises float glass, a first film structure is arranged on the float glass, the first film structure comprises a plurality of high-refractive-index film layers and at least one low-refractive-index film layer, a coating material used by the high-refractive-index film layers is Nb2O5, and a coating materialused by the low-refractive-index film layers is SiO2. The invention further provides an anti-blue-ray solar cell module which comprises the front plate, an adhesive film for packaging, a solar cell chip, a photovoltaic junction box and an aluminum alloy auxiliary frame, the front plate adopts the anti-blue-light and high-transmittance coated front plate, and the first film structure of the anti-blue-light and high-transmittance coated front plate is located at the position close to one side of the solar cell chip relative to the float glass. According to the anti-blue-ray solar cell module, the sunlight transmission rate reaches up to 90% or above in the whole sunlight spectrum range, and the prepared anti-blue-ray solar cell module is thick in color, free of chromatic aberration, capableof achieving multi-angle and large-angle observation and stable in color.

Owner:ANHUI TIANZHU GREEN ENERGY SCI & TECH

Precision casting silica sol shell preparation process

InactiveCN112589052AImprove high temperature strengthDoes not affect breathabilityFoundry mouldsFoundry coresPhysical chemistryEngineering

The invention relates to a precision casting silica sol shell preparation process. The process comprises a three-layer semi-preparation process of a surface layer, a transition layer, a back layer anda slurry sealing layer, so that the number of coating layers can be reduced, and the shell preparation period can be obviously shortened; and meanwhile, silica sol and zircon powder are adopted as surface layer slurry, 80-120-mesh mullite sand is spread, and transition layer slurry is prepared from silica sol and mullite powder according to the mass ratio of 1:(3.4-3.6). The shell prepared by combining the mesh number of the mullite sand, the slurry viscosity, temperature and humidity control and the like has excellent high-temperature strength without influencing the air permeability, and the process can be used for preparing shells of various products, and is low in cost. According to the process, the surface layer slurry is prepared from silica sol, zircon powder, a wetting agent and adefoaming agent, the mass ratio of the silica sol to the zircon powder is 1:(2.8-3.0), and the viscosity is 35-45 seconds; and the transition layer slurry is prepared from silica sol and mullite powder according to the mass ratio of 1:(3.4-3.6), and the viscosity is 28-35 seconds.

Owner:杨开发

Preparation method of fiber reinforced composite silica sol shell for investment casting

InactiveCN103962506BImprove wet strengthImprove filling abilityFoundry mouldsFoundry coresResidual strengthMass ratio

The invention relates to a preparation method of a fiber reinforced compound silica sol shell for investment casting, which aims to solve the problem that a shell preparedin the prior art is low in humidity and strength, and comprises the sequential steps as follows: 1), surface layer coating preparation; 2), surface layer shell preparation; 3) transition layer coating and shell preparation; 4) back layer coating preparation, that is, adding mullite powder into silica sol according to the mass ratio of (2.2-3.0):1 of the fireproof mullite powder to the silica sol in the back layer coating, so that paste-shaped coating is obtained, and agitating; adding polypropylene fiber which is 0.4 percent-2.0 percent of the fireproof mullite powder in mass in the back layer coating into the agitated paste-shaped coating, enabling the polypropylene fiber to uniformly disperse, adding the silica sol once again so as to lower the mass ratio of the mullite powder to the silicon sol to (1.1-1.5):1, and continuously agitating the mixture for 2 h for stand-by application; selecting the polypropylene fiber with the diameter of Phi 30 mum-Phi 50 mum and length of 2mm-6mm; 5) back layer shell preparation; 6) slurry sealing; 7) calcination, cooling and tapping off. The preparation method has the advantages that the shell is high in humidity and strength, and low in shell residual strength; the high-temperature air permeability is not affected after the fiber is burned at a high temperature; the effect of improving metal liquid mold-filling capacity to a certain degree is achieved; the number of coating and smearing layers is decreased; the production efficiency is improved.

Owner:INNER MONGOLIA UNIV OF TECH

Coating liquid with high refractive index for transparent holographic film and preparation method thereof

The invention discloses a coating liquid with high refractive index for a transparent holographic film and a preparation method thereof. The coating liquid with high refractive index comprises a nanomaterial precursor, butanone, ethanediamine and epoxy resin E-40, wherein the nanomaterial precursor comprises butanone, an acetic acid zinc salt, sodium sulfide and methyl butyl cellulose. The preparation method of the coating liquid with the high refractive index is that the nanomaterial is subjected to in-situ synthesis in the precursor of organic resin or resin, and the prepared coating liquid has the characteristics of high refractive index and high light transmittance.

Owner:ZHEJIANG JINGHUA LASER TECH CO LTD

Anti-corrosion polysiloxane finish paint

InactiveCN103342962AImprove mechanical properties and weather resistanceGood gloss and color retentionAnti-corrosive paintsSolventChemistry

The invention provides an anti-corrosion polysiloxane finish paint which is prepared from siloxane resin, amino silane, polyamine, a pigment, filler, gaseous silicon, an antioxidant and a solvent in parts by weight. A paint film of the anti-corrosion polysiloxane finish paint has superior gloss retention and color retention and long service and protection period and meets the needs of people; the corrosion resistance and the chemical resistance are superior, and the paint film has good physical and mechanical performance, high drying speed and high construction efficiency and is stain-resistant and easy to clean. An intermediate paint is not required to be coated during paint construction, so that the number of coatings is reduced, the construction time is shortened, and the construction efficiency is improved; the anti-corrosion polysiloxane finish paint is low in VOC (Volatile Organic Compounds) content, contains no isocyanate, has small smell and has the characteristics of safety, health and environmental friendliness.

Owner:TIANCHANG JULONG TRAVEL PAINT

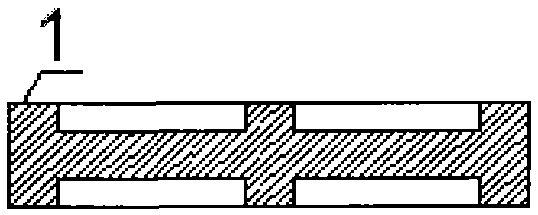

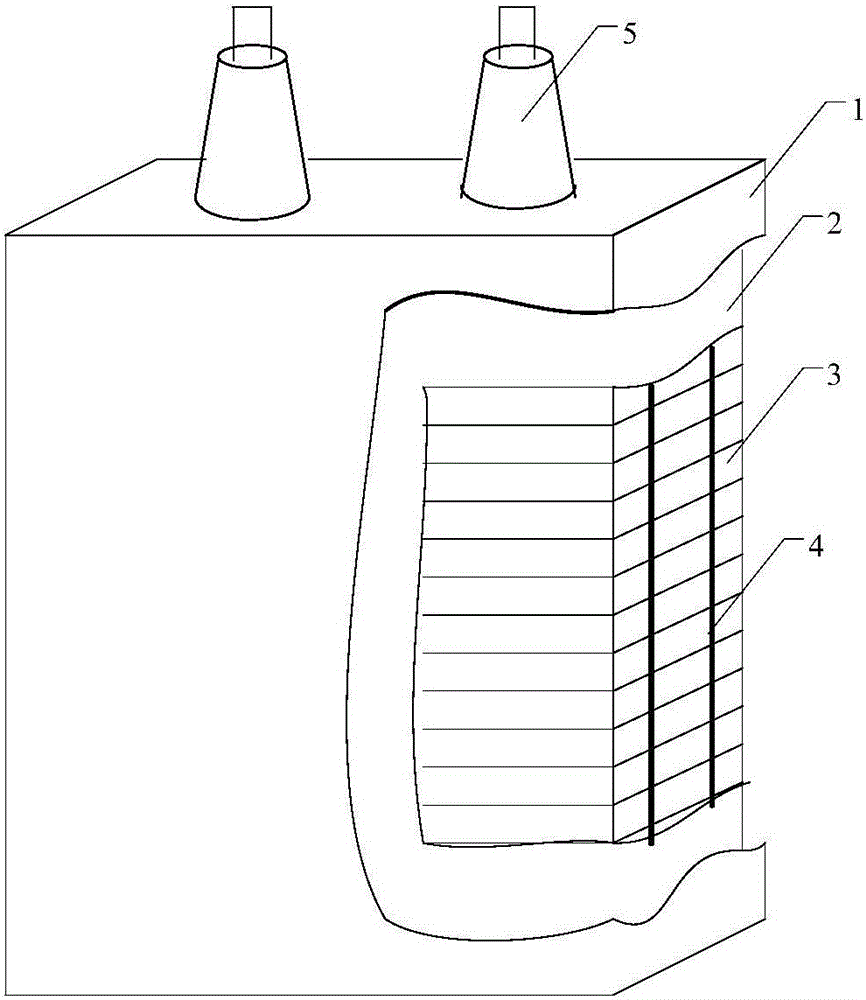

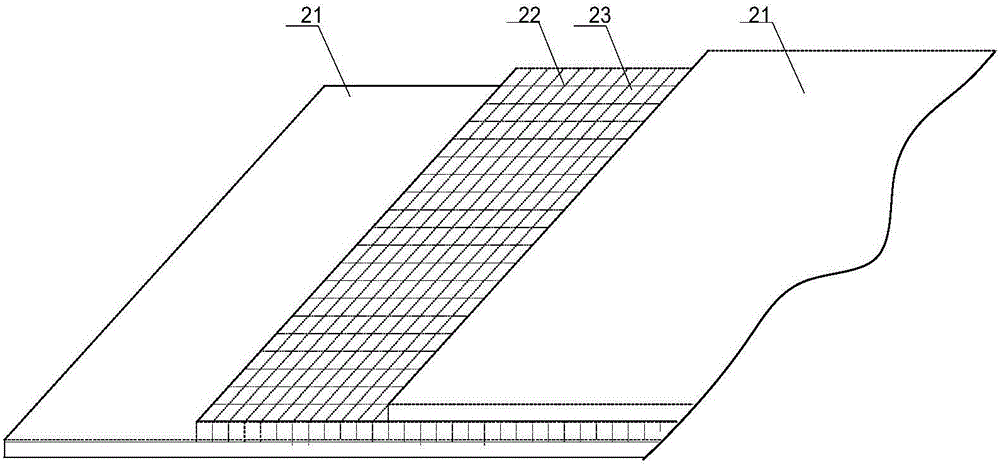

Mute power capacitor

InactiveCN105140026AStrengthen structural features and functional effectsReduce the number of coating layersCapacitorsExternal encapsulating structureEngineering

A mute power capacitor of the present invention comprises a shell, a core and a core encapsulating film which are arranged in the shell, outgoing line terminals fixed outside the shell, and core leading-out wires. The encapsulating film is wrapped on the exterior of the core and is composed of two layers of basement films, a netted skeleton layer clamped between the two layers of basement films and the plastic damping grease filled in the gaps between the two layers of basement films and the netted skeleton layer. By compositing the two layers of basement films and the plastic damping grease, a practical and convenient core external encapsulating structure is provided, so that the core can be fastened very well, a lead wire structure can be protected, the insulation between the core and the shell can be satisfied, and the structure characteristic and the effect of the mute power capacitor can be enhanced by the arrangement of the two layers of basement films, and the product technological process is simplified. By utilizing the plastic damping grease as the receptor, the operation noise of the power capacitor can be reduced effectively, thereby realizing a mute effect. Meanwhile, the damping grease is formed by compositing the special high-molecular materials of good electrical insulating property, so that the insulation effect is enhanced, and the suitable range and the voltage resistant grade of a product are improved.

Owner:CHINA XD ELECTRIC CO LTD

High-solid-content PU (polyurethane) matte varnish and preparation method thereof

ActiveCN105255357ASolve the technical problem of poor storage stabilityHigh solid content in constructionPolyurea/polyurethane coatingsLacquerDiluent

The invention relates to high-solid-content PU (polyurethane) matte varnish and a preparation method thereof. The matte varnish is prepared from a component A, a component B and an environment-friendly diluent. The matte varnish has the benefits as follows: the problem of poorer storage stability under low viscosity is effectively solved, meanwhile, by means of low system viscosity, the VOC (volatile organic compound) content of construction is further reduced, the purpose of consumption tax exemption is achieved, besides, the usage of a solvent and the number of coating layers of the varnish can be greatly reduced due to the high solid content of the construction, accordingly, the cost reduction is facilitated, and raw materials are saved; a paint film has high hardness and is scratch-resistant, and the grade of wood lacquer is improved.

Owner:SKSHU PAINT

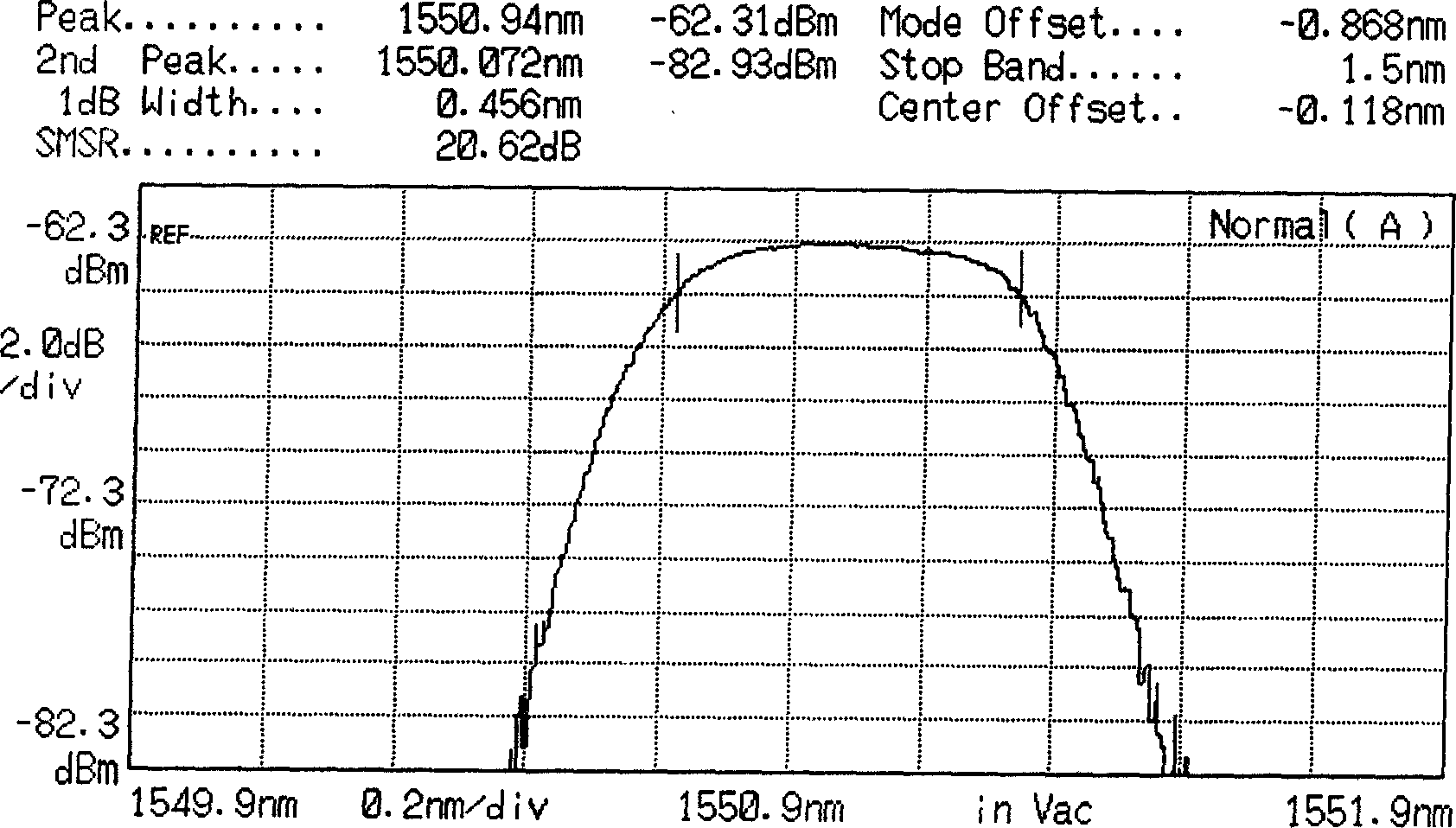

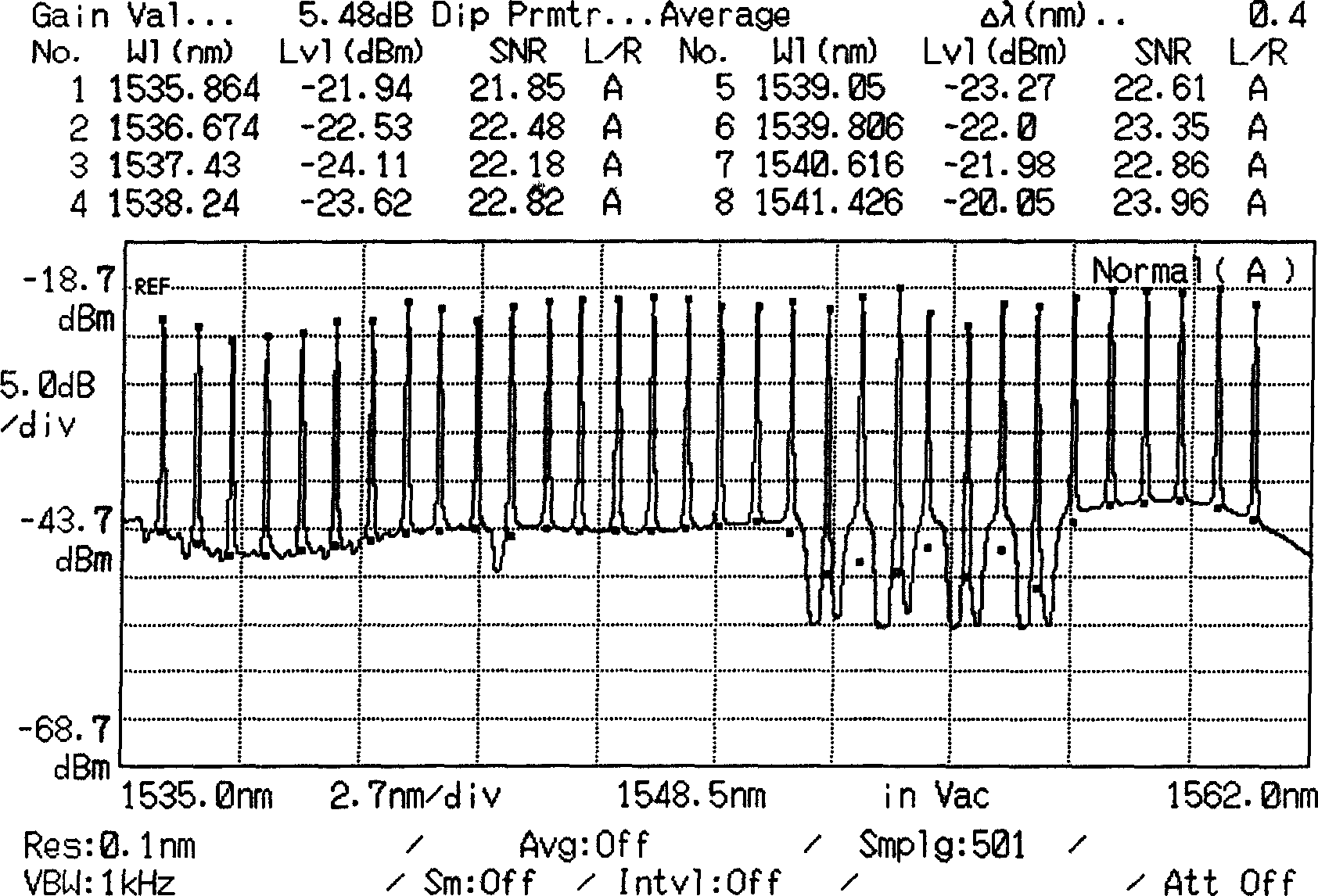

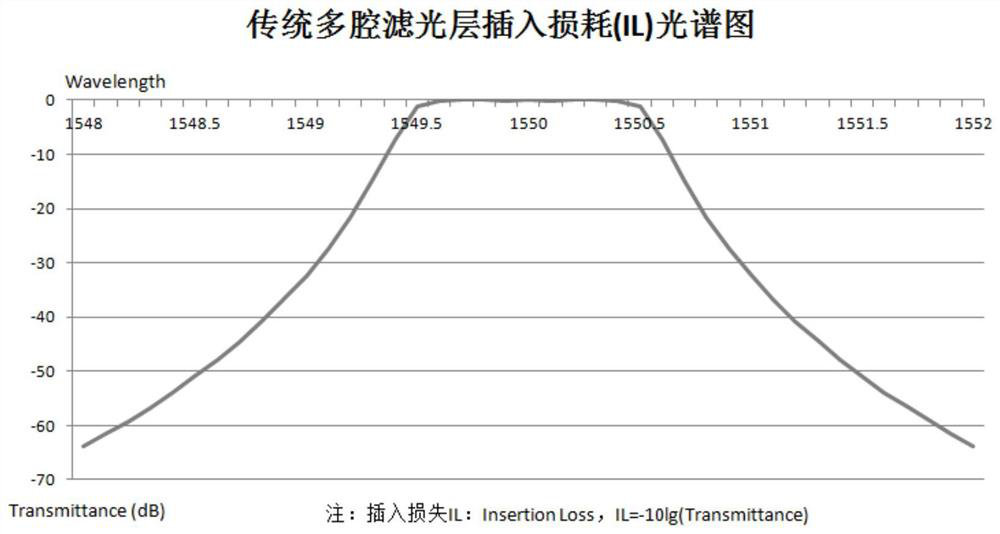

Method for improving transmission quality of WDM system signal

InactiveCN1531237AImprove transmission qualityReduce the number of coating layersOptical filtersWavelength-division multiplex systemsSpectral widthLight guide

A method promoting signal transmission quality for WDM, on optical demultiplexer in the system -1dB spectra width are controlled at -0.35nm, and >0.2nm. The optical demultiplexer is the demultiplex part of the output terminal demultiplexer or optical add / drop mutiplexer. Particularly the demultiplexer between the 0.2 nm -0.35 nm can be selected; ether before the ordinary optical demultiplexer of terminal station or before the demultiplex part of optical add / drop multiplexer of optical add / drop multiplex station adds a 50GHz optical comb filter applied to spectralwave 80 DWDM system to compress spectral width of pass band in the optical demultiplexer. Or the terminal station selects the array light guide wave separator or filter plate type light wave separateor of which the central wavelength is modulated to the side and a filter plate is connected inseries at its each demultiplex channel, through modulating the wavelength in central of filter plate implements the compression for superposition light spectrum width.

Owner:FENGHUO COMM SCI & TECH CO LTD

A composite transparent holographic film production process

ActiveCN104029513BHigh refractive indexHigh transparencyLamination ancillary operationsDuplicating/marking methodsInformation layerImage contrast

The invention discloses a production process of a compound transparent holographic film, and belongs to the technical field of laser anti-counterfeit. The production process comprises the preparation of compound film coating liquid, the coating of the compound film coating liquid, the low-temperature film formation and UV pre-curing of the film coating liquid, the wired mold pressing and UV light full curing, and the rolling of the transparent holographic film; and the production process combines an information layer with a medium layer as a whole through the compound film coating liquid to form a compound coating layer, so that the prepared transparent holographic film has such characteristics as high refraction index, high transparency and signal-to-noise ratio, excellent wear and ageing resistance and obvious holographic image contrast, the technical bottlenecks of difficult tracking and difficult positioning due to small contrast in a traditional transparent holographic image are broken through, the random positioning of a transparent holographic pattern in a certificate is really achieved, and the comprehensive anti-fake effect of transparent hologram is enhanced.

Owner:ZHEJIANG JINGHUA LASER TECH CO LTD

Device and method for preparing fiber-reinforced silica sol composite shell by air laying

InactiveCN108213344BEvenly distributedConsistent performanceFoundry mouldsFoundry coresDiameter ratioEngineering

The invention discloses a device and a method for preparing a fiber reinforced silica sol composite shell through airflow laying. The device comprises a fiber laying chamber, a fiber storage chamber,an air supply unit and a support, wherein the fiber laying chamber is a hollow cube and is composed of four side vertical plates and an upper bottom surface exhaust hole plate and an upper bottom surface exhaust hole plate, and an exhaust hole is formed in the upper bottom surface exhaust hole plate; a rotating shaft used for bearing the shell sample is installed in the fiber laying chamber; the fiber storage chamber is of a hollow inverted quadrangular frustum shape formed by four side plates and a lower bottom surface air inlet plate, a fiber storage rack is arranged in the fiber storage chamber, and airflow guide holes are formed in the fiber storage rack; and the fiber spreading chamber is located right above the fiber storage chamber, the side length of the side vertical plate of thefiber spreading chamber is equal to the side length of the side plate of the fiber storage chamber, and the four side vertical plates and the four side plates are fixedly connected in a one-to-one correspondence manner. According to the device and the method, the fibers can be uniformly distributed in the shell, the fibers can be laid on the shell in a quantitative mode, so that the performance ofthe prepared shell is consistent, and the fiber with the large length-diameter ratio can also be added into the shell.

Owner:INNER MONGOLIA UNIV OF TECH

A silent power capacitor

InactiveCN105140026BGuaranteed uniformityGuaranteed insulation performanceCapacitorsNetwork structureEngineering

A silent power capacitor of the present invention comprises a casing, a core and a core encapsulation film arranged in the casing, an outlet terminal fixed outside the casing, and core lead wires; the core is coated with an encapsulation film; the encapsulation The membrane is composed of two base films and a network skeleton layer sandwiched therein, and the space between the two base films and the network skeleton layer is filled with plastic damping grease. Through the compounding of two layers of base film and plastic damping grease, a practical and convenient core outsourcing structure is provided, which can not only fasten the core and protect the lead wire structure well, but also satisfy the insulation between the core and the shell, and due to the double The setting of the base film can strengthen its structural characteristics and effect, reduce the number of coating layers, and simplify the product process; use plastic damping grease as the receptor, effectively reduce the operating noise of the power capacitor, and achieve a quiet effect; at the same time, because the damping grease is composed of Composite with special polymer materials with good electrical insulation, which enhances the insulation effect and improves the scope of application and withstand voltage level of the product.

Owner:CHINA XD ELECTRIC CO LTD

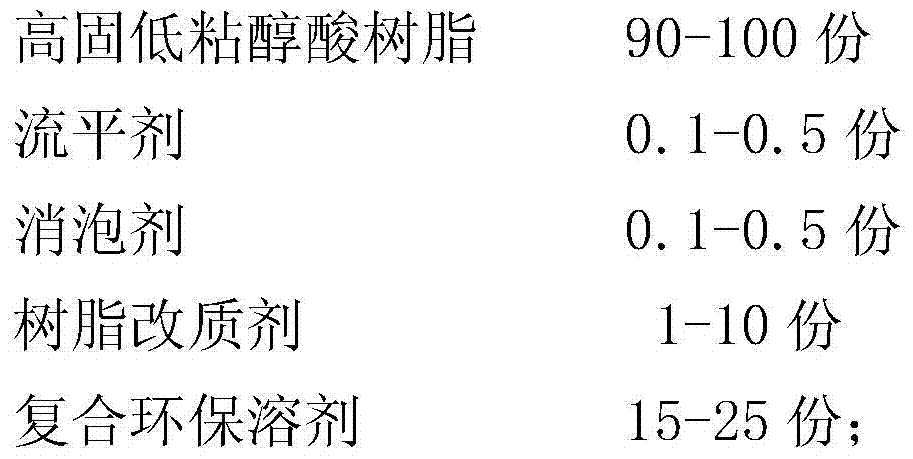

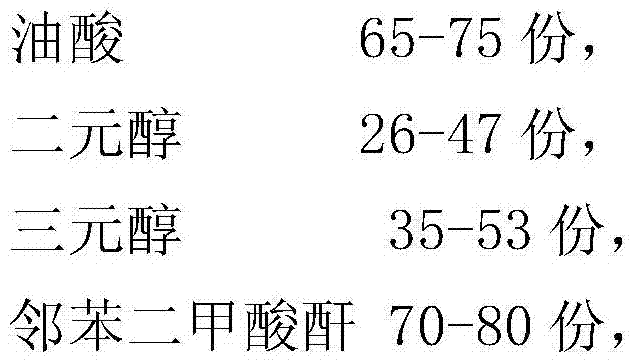

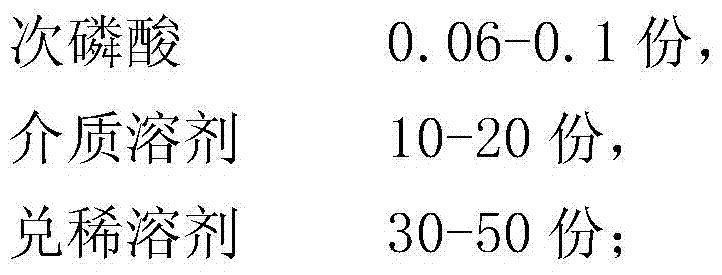

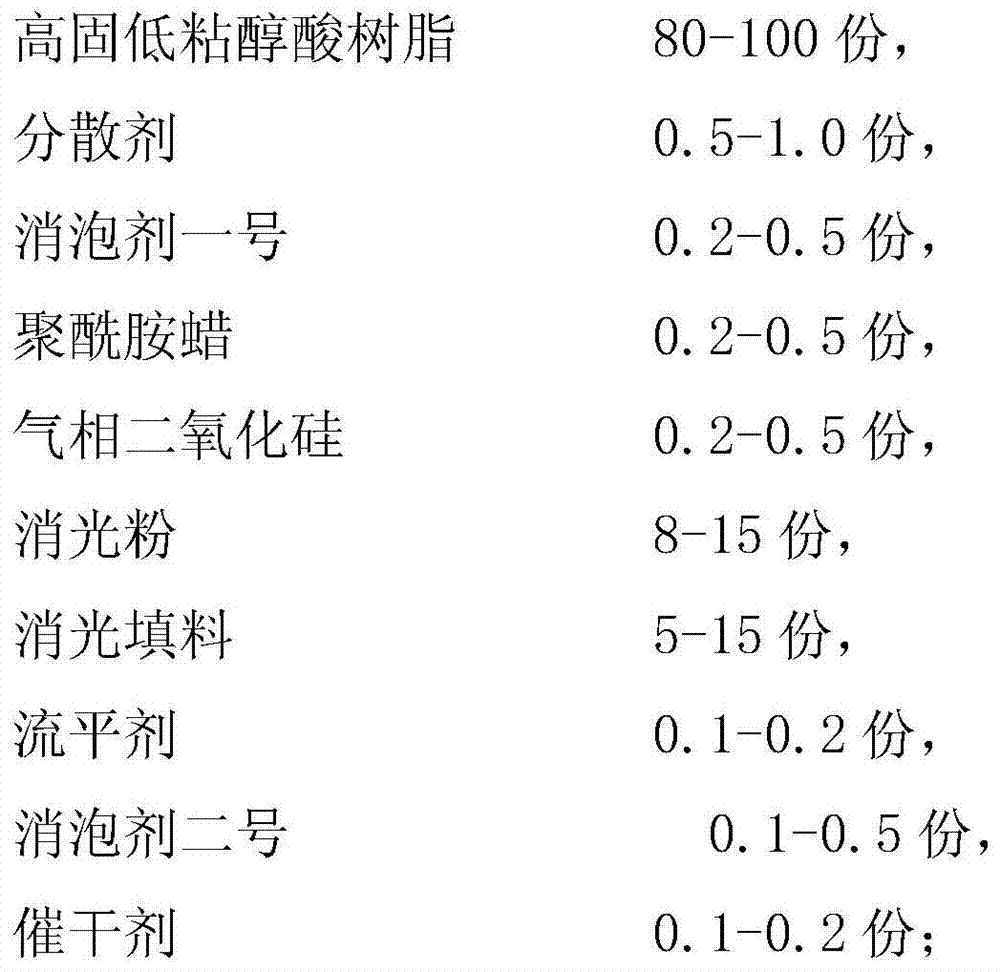

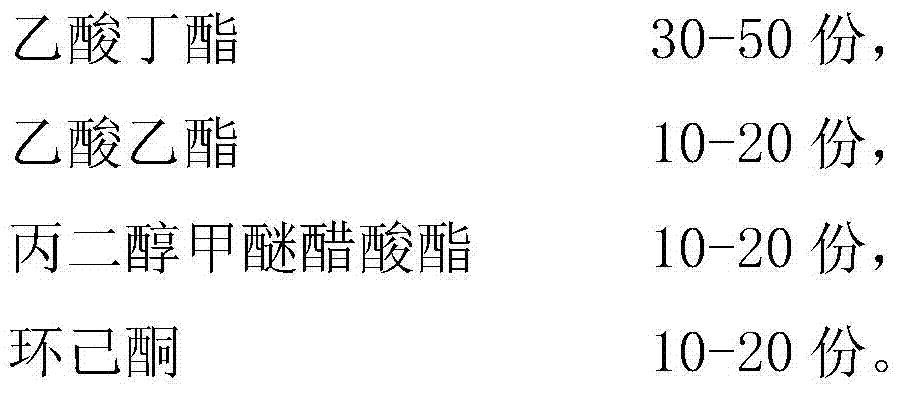

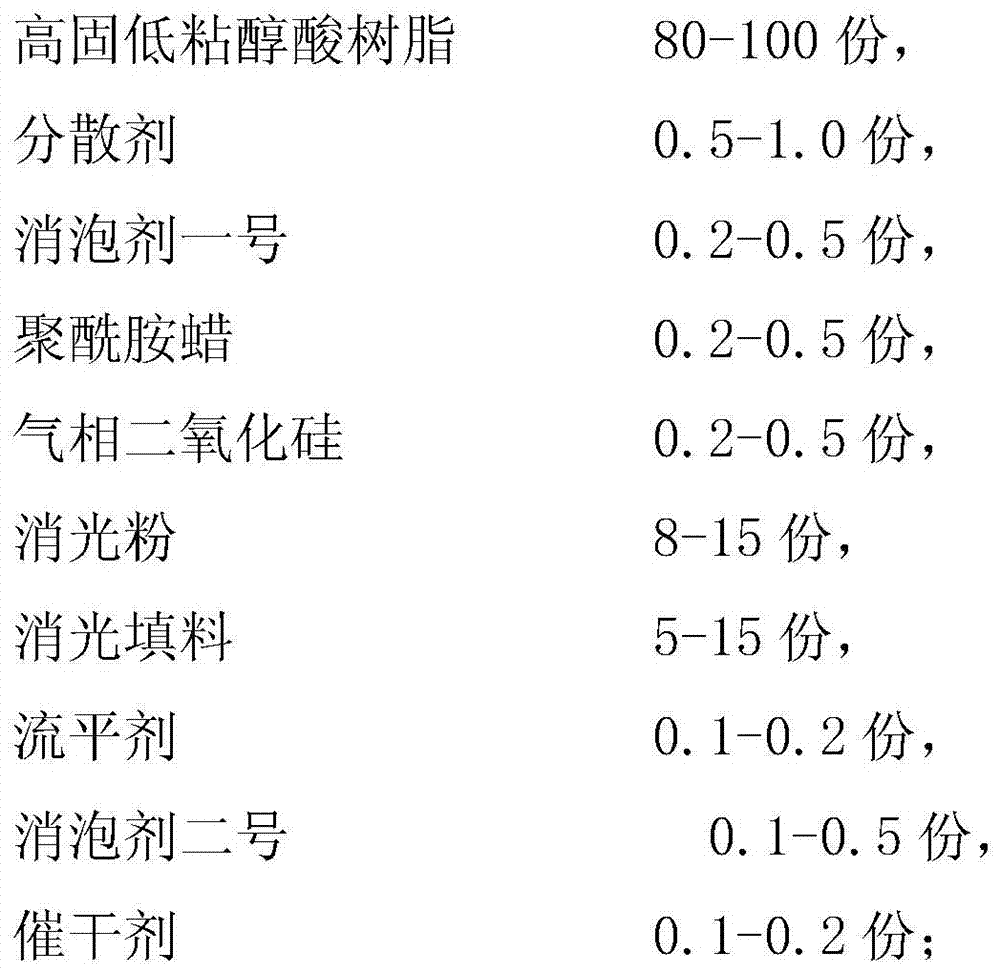

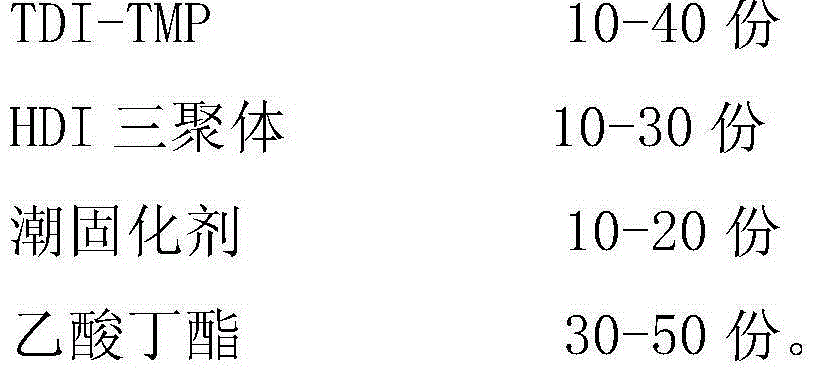

Low voc polyurethane gloss varnish

The invention relates to low-VOC polyurethane high-light varnish and a preparation method therefor. The low-VOC polyurethane high-light varnish is prepared from components A and B in a ratio of 1: (0.6-1). The component A is prepared from the following materials in parts by weight: 90-100 parts of high-solid low-viscosity alkyd resin, 0.1-0.5 part of a flatting agent, 0.1-0.5 part of a defoamer, 1-10 parts of a resin modifier and 15-25 parts of a composite environmental-friendly solvent; the component B is prepared from the following materials in parts by weight: 50-70 parts of TDI-TMP, 10-30 parts of a HDI tripolymer and 20-40 parts of butyl acetate. The low-VOC polyurethane high-light varnish provided by the invention has the benefits that the low-VOC polyurethane high-light varnish can be used for reducing the content of VOC during coating construction, so that the varnish not only is environmental-friendly, but also achieves a consumption tax-free purpose; as the solid content in construction is high, the number of coating layers of paint can be reduced, so that the cost is lowered and the raw materials are saved; the film is bright, the fullness is high and the grade of wood lacquer is improved.

Owner:SKSHU PAINT

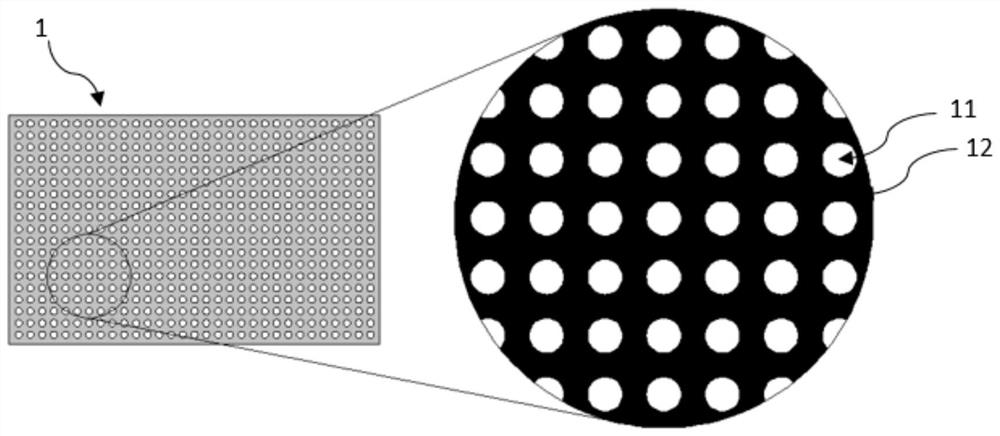

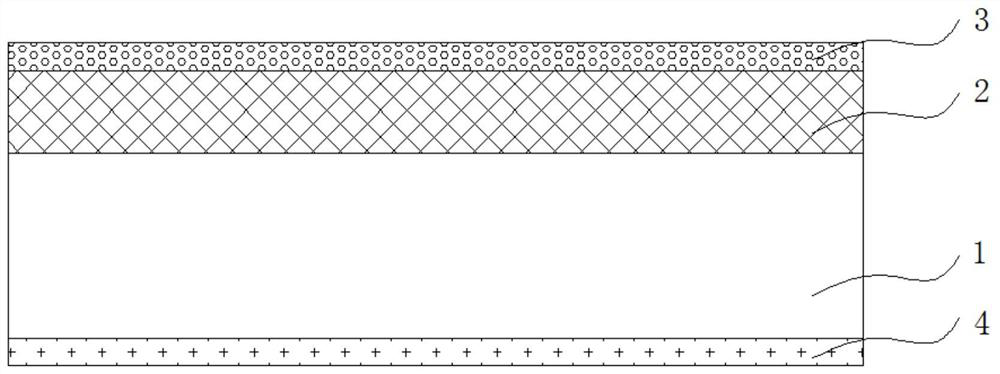

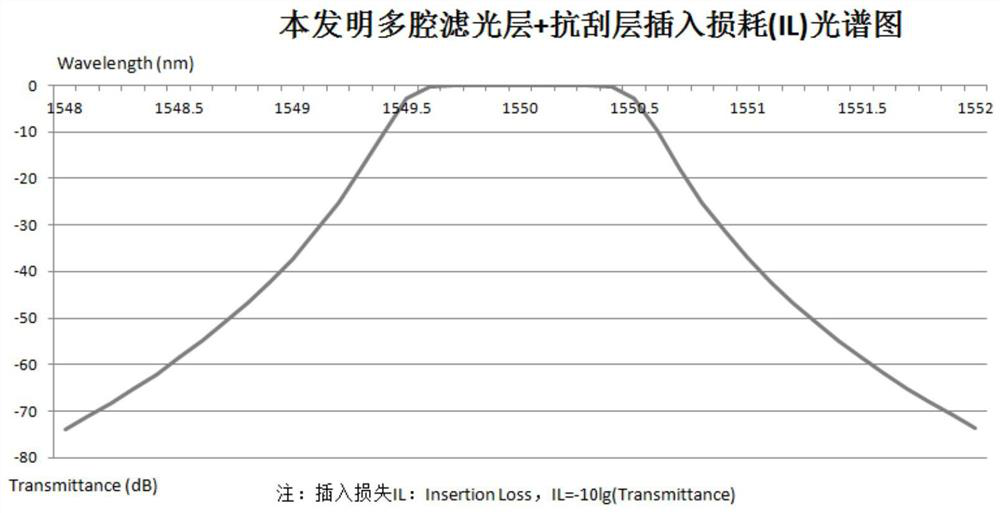

Intensive optical wave multiplexing optical filter

InactiveCN112099124AReduce the number of coating layersAvoid damageOptical light guidesEngineeringLight filter

The invention discloses an intensive optical wave multiplexing optical filter, which comprises a substrate, and an optical filter layer and an anti-radiation layer which respectively cover two opposite surfaces of the substrate, and is characterized in that the surface, opposite to the substrate, of the optical filter layer is also provided with an anti-scraping layer, so that the optical filter layer can be prevented from being damaged due to friction when polishing operation is required subsequently, and the yield of the optical filter is ensured; meanwhile, the first dielectric sub-layer forming the filter layer is made of silicon hydride, so that the total layer number of the filter layer is reduced to be not more than 84, and the layer thickness is not more than 20 [mu] m. Compared with the prior art, the thickness of the filter layer is greatly reduced, and light loss, light path disruption and stress accumulation caused by over-thickness of the filter layer are effectively inhibited; and the overall manufacturing cost is reduced.

Owner:GUANGZHOU JIAHE PHOTOELECTRIC TECH CO LTD

A self-assembled nanofiltration membrane of mussel biomimetic assisted polyelectrolyte layer and its application

ActiveCN111437741BImprove hydrophilicityHigh retention rateReverse osmosisWater/sewage treatment bu osmosis/dialysisPolymer sciencePolystyrene

The invention discloses a mussel bionic assisted polyelectrolyte layer-by-layer self-assembly nanofiltration membrane and application thereof. The nanofiltration membrane of the present invention uses a mixed solution of polydopamine / polyethyleneimine and a polyanion electrolyte solution, and undergoes layer-by-layer self-assembly technology to cyclically coat and modify the surface of the base membrane for 1 to 3 times, and finally undergoes a cross-linking reaction. After preparation; due to the use of highly hydrophilic polydopamine and polyethyleneimine, the two can form a covalent bond and form a stable coating on the surface of the membrane. After the coating is modified, the negatively charged Sodium polystyrene sulfonate is used for coating modification, sodium polystyrene sulfonate can be electrostatically adsorbed with positively charged polyethyleneimine, and the benzene ring in its molecule and the benzene ring in polydopamine molecule have π‑ The π stacking effect improves the stability of the coating, and the coating is more uniform, so that the prepared nanofiltration membrane has good hydrophilicity, high rejection rate, high pollution resistance and high chemical stability.

Owner:SUN YAT SEN UNIV

Optical recording media for writing only once

InactiveCN100580783CReduce manufacturing costIncrease productivityRecord information storageRecording layersAlloyRecording layer

The invention relates to a write-once-only optical record medium, which comprises a baseplate and a film coated on the baseplate. The coated film comprises a record layer and a reflecting layer connected with the record layer. The record layer primarily contains germanium, antimony and silicon or the mixture of any two elements of germanium, antimony and silicon. The reflecting layer primarily contains aluminium, copper, silver and aurum or alloy consisting of two elements of aluminium, copper, silver and aurum. When a writing and recording laser emit to the coated film, local material constituents change and react at the interface area of the record layer and the reflect layer, thus forming a record point as a digital signal source. As the record layer is made of inorganic materials which can grow by adopting the direct current sputtering technology, and the manufacturing process of products is minimized, the production cost is significantly reduced, and the production efficiency is improved.

Owner:CHINA STEEL

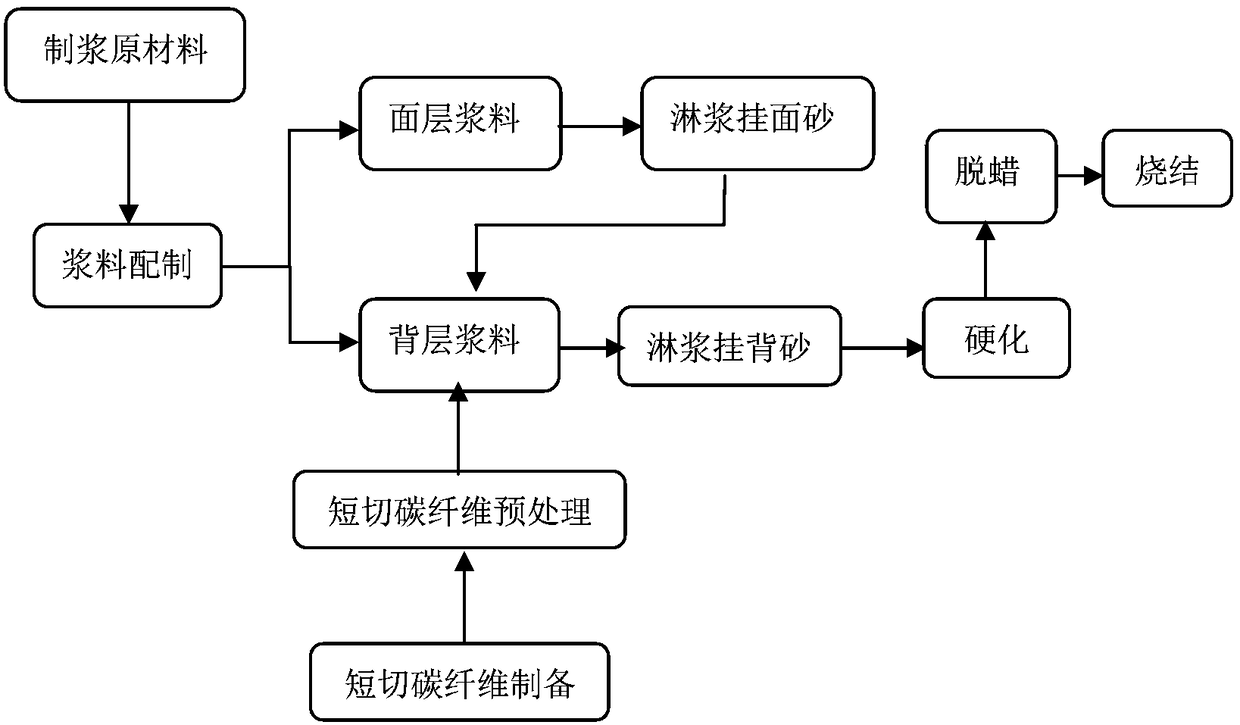

A kind of preparation method of special-shaped section chopped carbon fiber modified ceramic mold shell

The invention relates to the field of precision casting of high-temperature alloy vacuum furnaces, in particular to a method for preparing a modified ceramic mold shell through special-shaped cross section short carbon fibers. The mold shell is a compound shell and comprises a surface layer and a back layer modified by adding the special-shaped cross section short carbon fibers. The method comprises the preparation steps that surface layer slurry and back layer slurry are prepared correspondingly; the short carbon fibers which are evenly scattered in advance are added into the back layer slurry; the surface layer is coated with the surface layer slurry, the back layer is coated with the back layer slurry, and sand is sprayed to the surface layer and the back layer; the slurry coating and sand spraying operations are conducted repeatedly till a preset number of layers is met; the surface layer slurry is used for slurry sealing, and the mold shell is dewaxed; and the mold shell is cooled in a furnace after being roasted. According to the mold shell prepared through the method, the fibers are scattered evenly and are not likely to be pulled out and lose efficacy, the strength of the mold shell is improved, the thickness of the mold shell is reduced, the heat dissipation performance of the mold shell is enhanced, the performance requirements for thin walls and high strength are met, and the yield of single-crystal blades is increased.

Owner:JIANGSU UNIV +1

Coating method of sugar-coated tablets

ActiveCN112641746AReduce the number of coating layersReduce dosageInorganic non-active ingredientsPharmaceutical product form changeCoated tabletsPhysical chemistry

The embodiment of the invention provides a coating method of sugar-coated tablets. The coating method comprises the following steps: step 1, coating an isolation layer; step 2, coating a powder coat layer: controlling the temperature to be 40-50 DEG C, adding mixed slurry according to the amount of 20-40 ml / kg of plain tablets, and enabling the mixed slurry to be uniformly attached to the surface of each tablet; adding a small amount of talcum powder to enable the talcum powder to be uniformly attached to the surface of each tablet, blowing hot air for 2-5 minutes after all the tablets are scattered, coating the next powder coat layer after full drying, and repeating the operation for 5-15 times until edges and corners of all the tablets disappear; step 3, coating a sugar coating layer; step 4, coating a colored layer; and step 5, polishing: scattering 2 / 3 of a part of Chinese insect wax powder into the tablets, slowly scattering the rest 1 / 3 of Chinese insect wax powder after the surfaces of the Chinese insect wax powder are bright, and rotating a coating pan until the surfaces of all the tablets are bright. The method is high in efficiency and low in pollution in the manufacturing process, and the manufactured tablets are not prone to color fading and moisture absorption.

Owner:重庆市药研院制药有限公司

High-solid polyurethane matt varnish and preparation method thereof

ActiveCN105255357BLow VOC contentReduce dosagePolyurea/polyurethane coatingsEnvironmental resistanceLacquer

The invention relates to high-solid-content PU (polyurethane) matte varnish and a preparation method thereof. The matte varnish is prepared from a component A, a component B and an environment-friendly diluent. The matte varnish has the benefits as follows: the problem of poorer storage stability under low viscosity is effectively solved, meanwhile, by means of low system viscosity, the VOC (volatile organic compound) content of construction is further reduced, the purpose of consumption tax exemption is achieved, besides, the usage of a solvent and the number of coating layers of the varnish can be greatly reduced due to the high solid content of the construction, accordingly, the cost reduction is facilitated, and raw materials are saved; a paint film has high hardness and is scratch-resistant, and the grade of wood lacquer is improved.

Owner:SKSHU PAINT

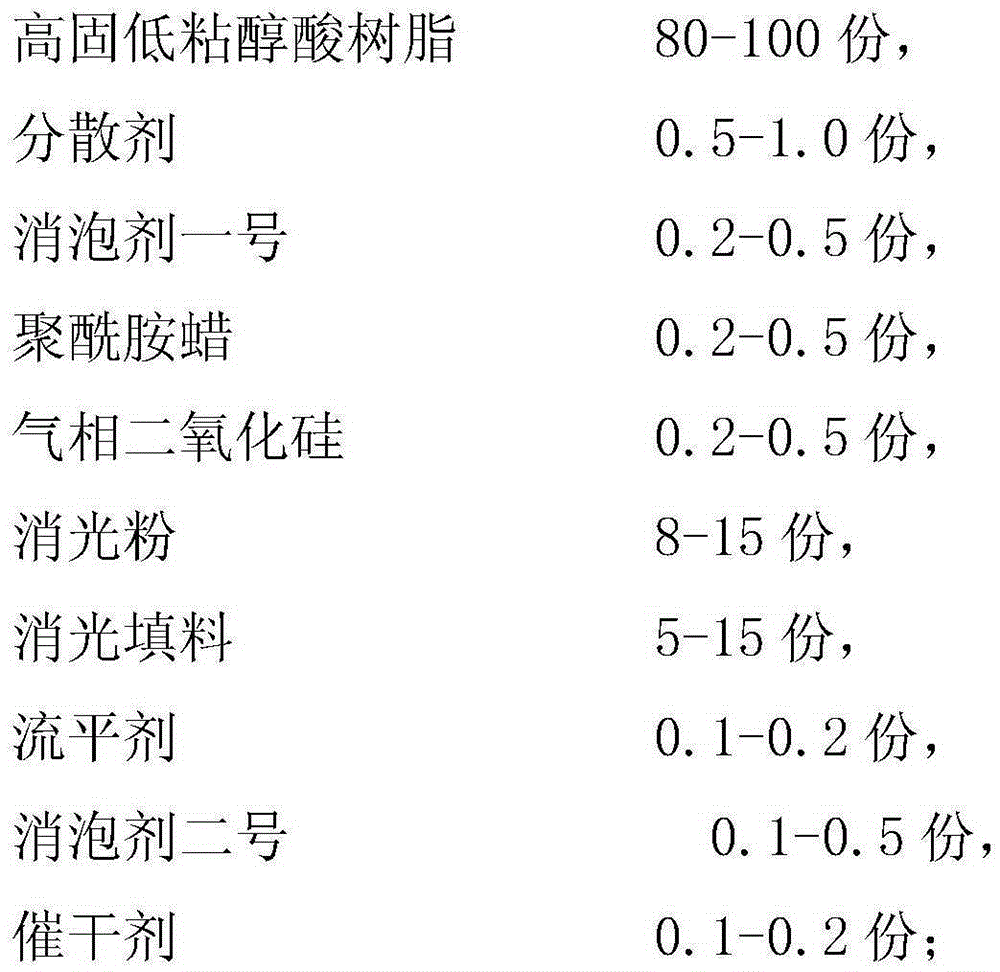

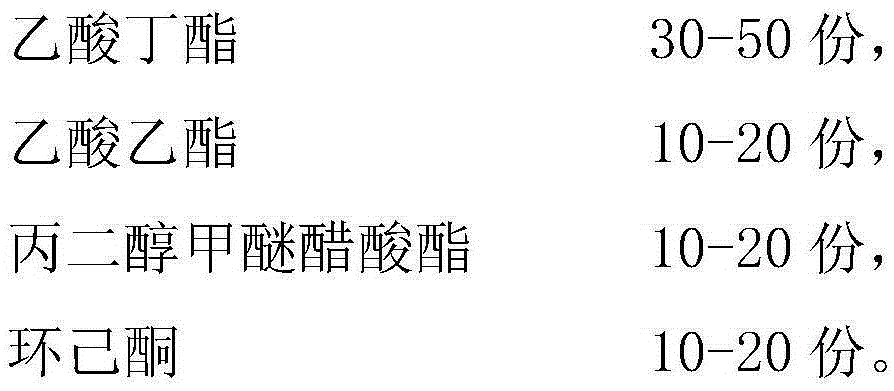

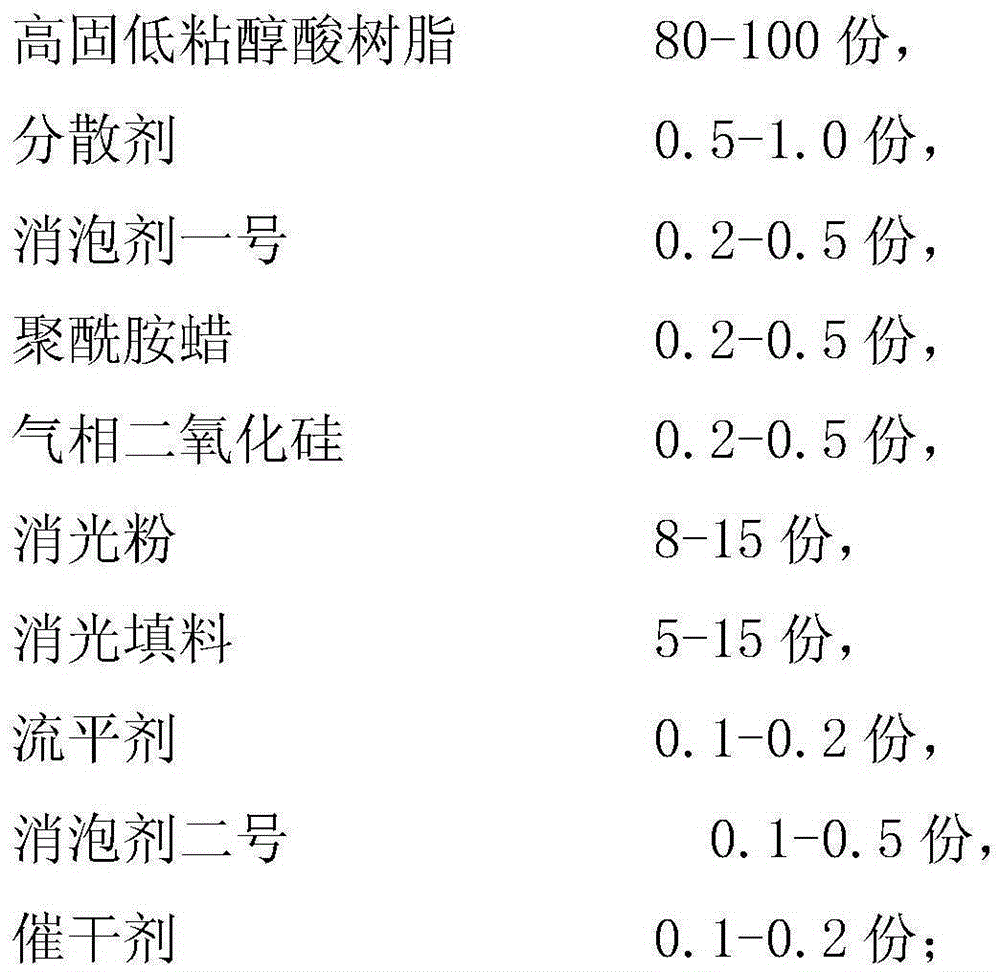

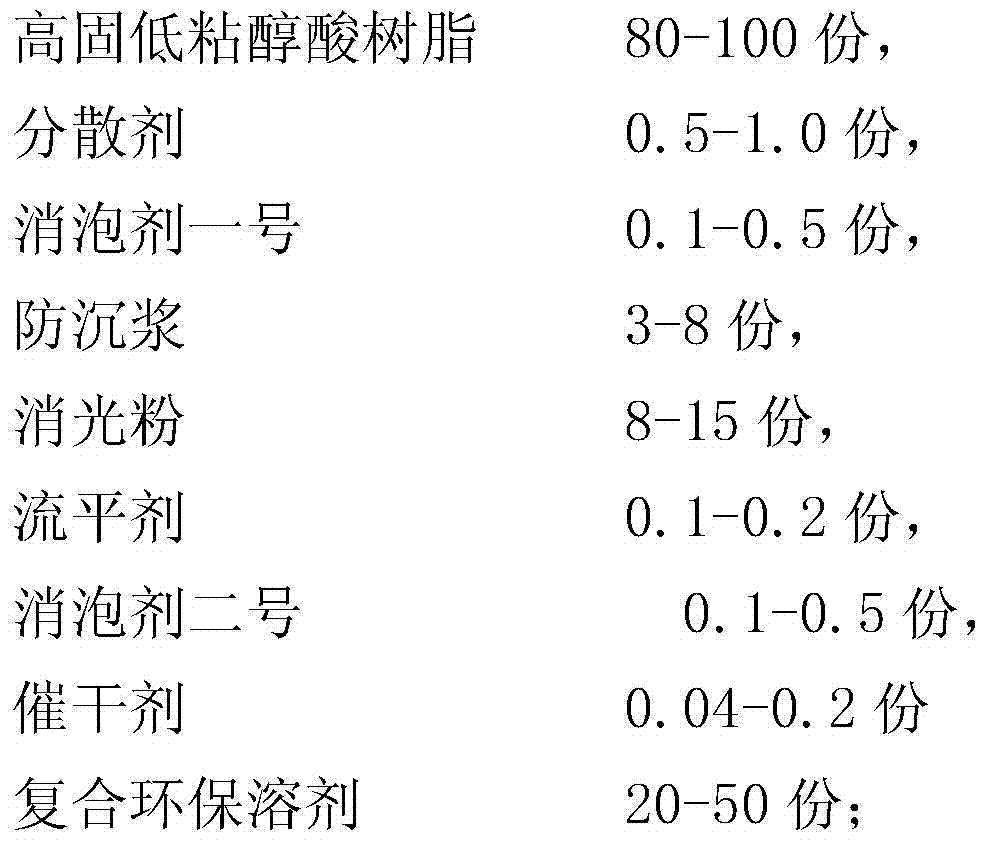

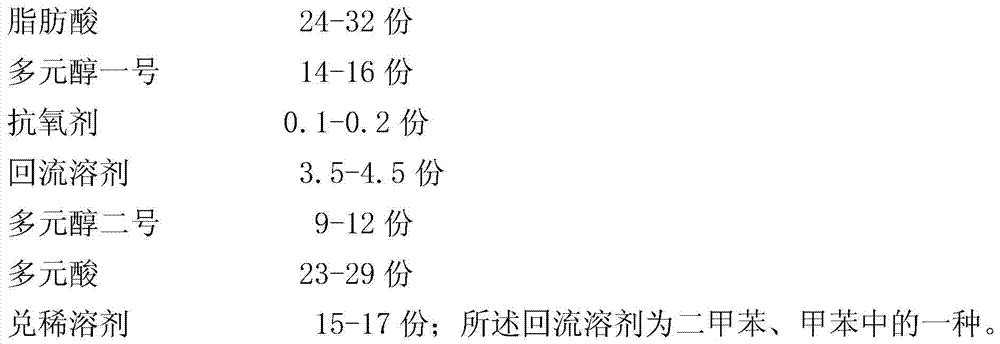

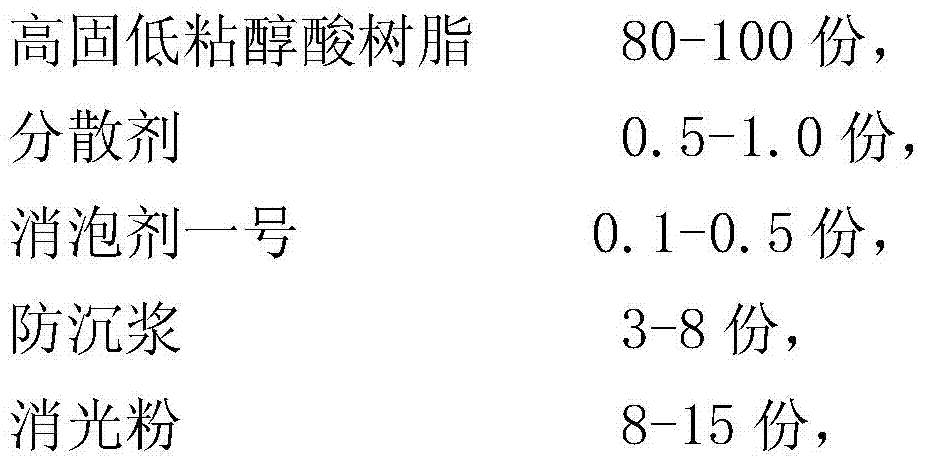

Low-voc polyurethane matte varnish and preparation method thereof

ActiveCN105255356BLow VOC contentReduce the number of coating layersPolyurea/polyurethane coatingsAcetic acidLacquer

The invention relates to a low-VOC polyurethane matt varnish and a preparation method thereof. It is prepared from components A and B at a ratio of 1:0.8-1.2. A is composed of the following components: high-solid and low-viscosity alkyd resin, dispersant , defoamer No. 1, anti-settling slurry, matting powder, leveling agent, defoamer No. 2, drier, composite environmental protection solvent; B is composed of the following components: TDI trimer, HDI trimer, acetic acid butyl ester. The beneficial effects of the present invention are as follows: it can reduce the VOC content during coating construction and achieve the purpose of exempting consumption tax; it can reduce the number of coating layers of paint, so it helps to reduce costs and save raw materials; the paint film is smooth and transparent, and improves the quality of woodenware The grade of paint.

Owner:SKSHU PAINT

A kind of high-refractive-index coating liquid for transparent holographic film and preparation method thereof

ActiveCN104031525BHigh refractive indexHigh light transmittanceEpoxy resin coatingsEpoxyRefractive index

The invention discloses a high-refractive-index coating liquid for transparent holographic film and a preparation method thereof. The high-refractive-index coating liquid comprises nanomaterial precursor, methyl ethyl ketone, ethylenediamine and epoxy resin E-40, Wherein, the nanomaterial precursors include methyl ethyl ketone, zinc acetate dihydrate, sodium sulfide nonahydrate and methylbutyl cellulose, and the method for preparing the high-refractive index coating liquid is in situ in an organic resin or a resin precursor. Synthesize nanomaterials, and the obtained coating liquid has the characteristics of high refractive index and high light transmittance.

Owner:ZHEJIANG JINGHUA LASER TECH CO LTD

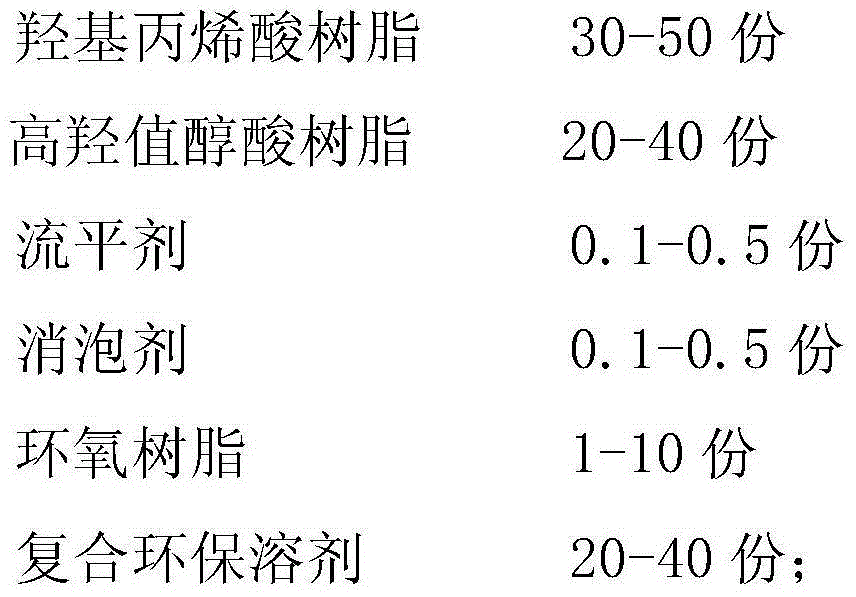

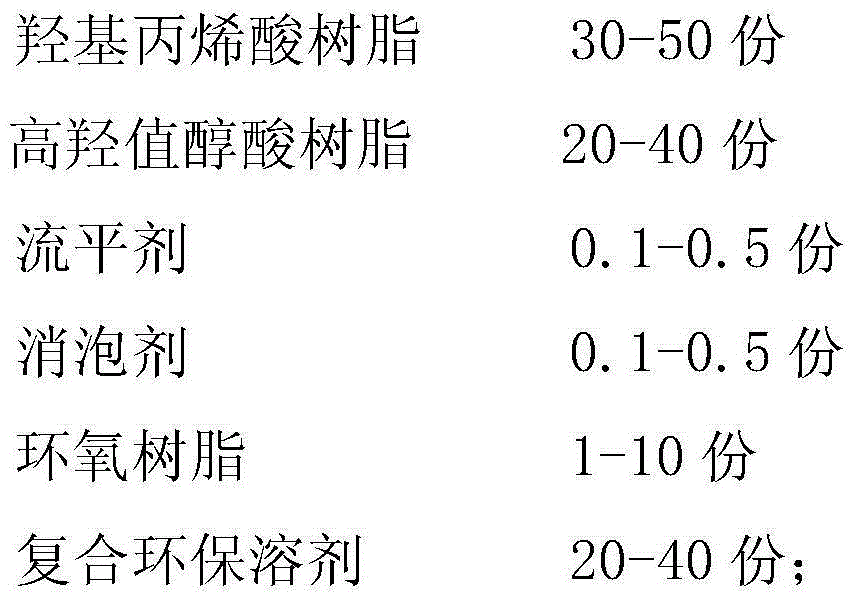

Anti-scratch PU bright floor paint and preparation method thereof

ActiveCN103450794BImprove scratch resistanceLow transparencyPolyurea/polyurethane coatingsEnvironmental resistanceEpoxy

The invention relates to a scratch resistant PU (Poly Urethane) floor varnish and a preparation method thereof. The scratch resistant PU floor varnish is prepared from a first ingredient and a second ingredient at weight ratio of (0.8-1.2):(0.8-1.2), wherein the first ingredient is prepared from the following raw materials in parts by weight: 30-50 parts of hydroxy acrylic resin, 20-40 parts of high-hydroxyl number alkyd resin, 0.1-0.5 part of leveling agent, 0.1-0.5 part of antifoaming agent, 1-10 parts of epoxy resin, and 20-40 parts of composite environment-friendly solvent, and the second ingredient is prepared from the following raw materials in parts by weight: 10-40 parts of TDI-TMP, 10-30 parts of HDI (Hexamethylene Diisocyanate) tripolymer, 10-20 parts of moisture curing agent, and 30-50 parts of butyl acetate. By adopting the scratch resistant PU floor varnish disclosed by the invention, the scratch resistance of the varnish surface on the floor is obviously improved, while the other performances of transparency, storage stability and the like are rarely influenced; simultaneously the varnish film is uniform, smooth, and good in adhesion force; the number of the varnish coating layers can be reduced, therefore the cost is reduced; in addition, fracture is unlikely to form to influence the beautiful appearance of the floor.

Owner:SKSHU PAINT

A production process of transparent holographic film with high refractive index

ActiveCN104029512BHigh refractive indexHigh transparencyLamination ancillary operationsDuplicating/marking methodsInformation layerRefractive index

Owner:ZHEJIANG JINGHUA LASER TECH CO LTD

A kind of ultra-high reflectivity optical scanning vibrating mirror and its preparation method

ActiveCN105824119BHigh bandwidthIncrease the angleVacuum evaporation coatingSputtering coatingResonance angleRefractive index

The invention relates to an optical scanning galvanometer of super high reflectivity, which is composed of a glass substrate layer and a highly-reflective film deposited and plated on the glass substrate layer. The highly-reflective film is composed of nine film layers, which are sequentially, according to the distance from the glass substrate layer from small to large, a first Al2O3 film layer, an Ag film layer, a second Al2O3 film layer, a first SiO2 film layer, a first high-refractivity material film layer, a second SiO2 film layer, a second high-refractivity material film layer, a third SiO2 film layer, and a third high-refractivity material film layer. The beneficial effects are as follows: the reflection bandwidth and resonance angle are increased greatly while the number of coating layers is reduced; the reflection bandwidth with the reflectivity higher than 99% is up to 300nm; and the effective resonance angle can be 0-80 degrees.

Owner:SANMING FOCTEK PHOTONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com