Production process of compound transparent holographic film

A production process and composite technology, applied in the direction of layered products, copy/marking methods, printing, etc., can solve the problems of restricting the research and application of transparent holographic films, diffraction pattern interference, and difficulty in controlling uniformity. Functional compatibility and matching issues, reducing equipment and labor costs, and the effect of reducing equipment and footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

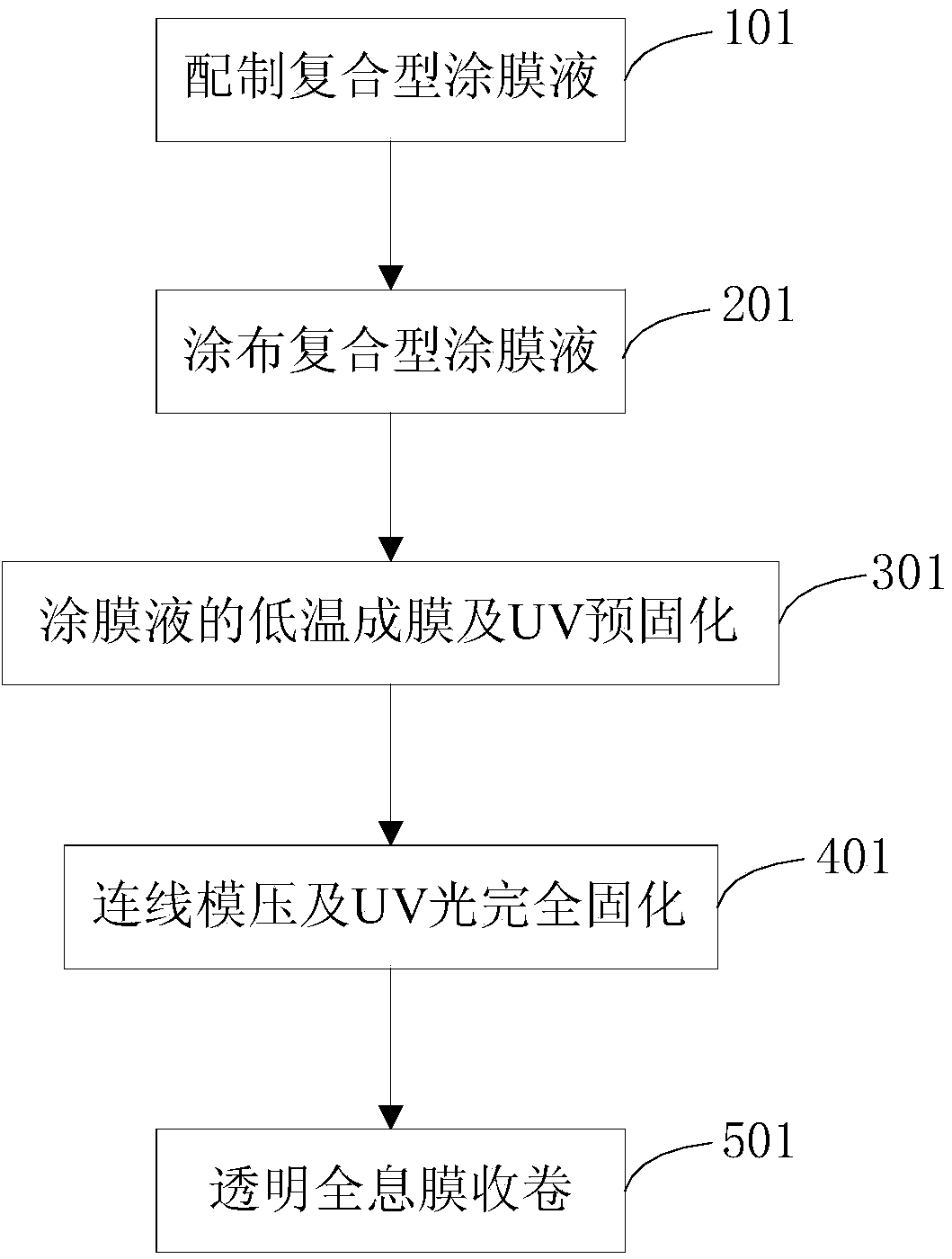

[0044] A composite transparent holographic film production process, such as figure 1 shown, including the following steps:

[0045] Step 101, preparation of composite coating solution:

[0046] 1) Preparation of nanomaterial dispersion: use tetrahydrofuran as solvent and ammonium polyacrylate as dispersant, weigh titanium dioxide with an average particle size of 40nm and add it to tetrahydrofuran, use 6KW power ultrasonic wave, and oscillate at 80KHz for 4 minutes to make a uniform Dispersion system; Ultrasonic power, frequency and oscillation time can be adjusted according to actual needs, generally use 6-8KW power, 80-100KHz ultrasonic oscillation for 4-8 min;

[0047] Dispersion liquid component and content (weight part) proportioning are as follows:

[0048] Tetrahydrofuran 56.7

[0049] Ammonium polyacrylate 32.4

[0050] Nano Titanium Dioxide 10

[0051] The above ratio relationship can make nano-titanium dioxide uniformly dispersed without sedimentation for 48 hour...

Embodiment 2~5

[0068] The basic production process of the composite transparent holographic film described in Examples 2 to 5 is the same as that of Example 1, the difference mainly lies in the different components and volume fractions of the composite coating solution, as shown in Table 1.

[0069] Table 1: Components and proportioning relationship of the composite coating solution of Examples 1-5:

[0070] serial number Nanomaterials (average particle size) Dispersion ratio Polyurethane solution ratio Volume fraction of nanomaterials Composite coating liquid refractive index Composite coating solution light transmittance Example 1 Titanium dioxide (40nm) 8 40 2% 1.56 92% Example 2 Titanium dioxide (50nm) 20 40 5% 1.57 90% Example 3 Zinc oxide (60nm) 40 40 10% 1.63 88% Example 4 Zinc sulfide (50nm) 60 40 15% 1.7 85% Example 5 Cadmium sulfide (60nm) 40 40 10% 1.63 88%

[0071] From the experimental data of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com