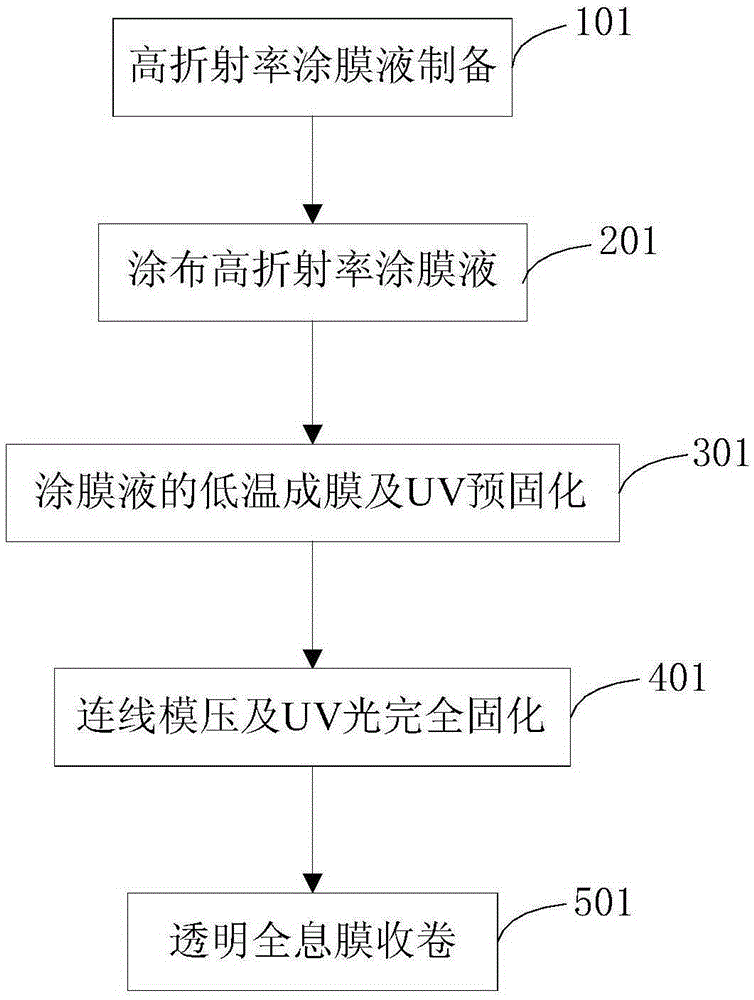

A production process of transparent holographic film with high refractive index

A technology with high refractive index and production process, which is applied in the field of high refractive index transparent holographic film production process, can solve the problems of restricting the research and application of transparent holographic film, diffraction pattern interference, and difficult control of uniformity, so as to avoid the structure and function. Capacitance and matching issues, reducing equipment costs and labor costs, streamlining equipment and the effect of occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

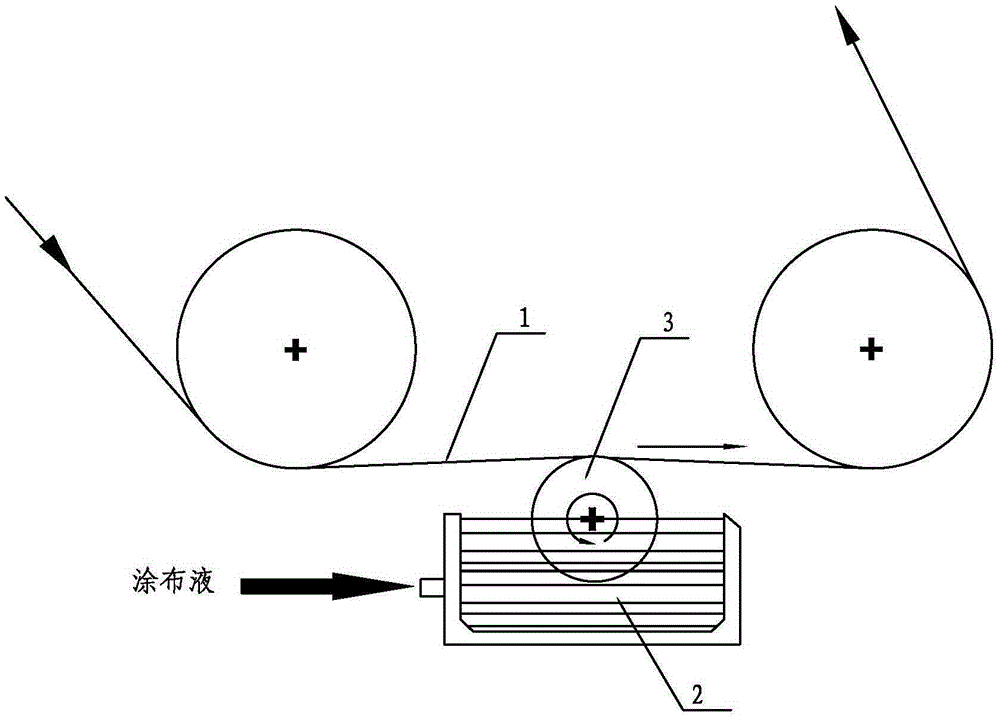

Method used

Image

Examples

Embodiment 2~4

[0063] The basic flow of the high-refractive index transparent holographic film production process described in Examples 2-4 is the same as that of Example 1, the difference mainly lies in the different proportions of components in the high-refractive index coating liquid, as shown in Table 1.

[0064] Table 1: Components and proportioning relationship of the high-refractive-index coating solutions of Examples 1-4:

[0065] serial number butanone Epoxy resin E-40 Ethylenediamine Precursor solution ZnS volume fraction Refractive index of coating solution Transmittance of coating liquid Example 1 70 16 8 6 2% 1.47 91% Example 2 66 16 3 15 5% 1.5 90% Example 3 48 16 6 30 10% 1.55 88% Example 4 40 16 8 45 15% 1.60 86%

[0066] Theoretical value of refractive index: the refractive index of epoxy resin is 1.45, and the refractive index of zinc sulfide is 2.45.

[0067] Can draw from the experimental data of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com