A kind of ultra-high reflectivity optical scanning vibrating mirror and its preparation method

An optical scanning and reflectivity technology, applied in the field of scanning galvanometers, can solve problems affecting system scanning speed and repeat positioning accuracy, changing laser spots, affecting the quality of galvanometers, etc., to reduce vulcanization and oxidation effects, improve flatness, Effect of improving adhesion and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments

[0042] Such as figure 1 As shown, the schematic cross-sectional shape of the high-reflectivity optical scanning galvanometer of the present invention is shown. The sectional shape of the galvanometer of the present invention can be elliptical or octagonal with an axisymmetric structure.

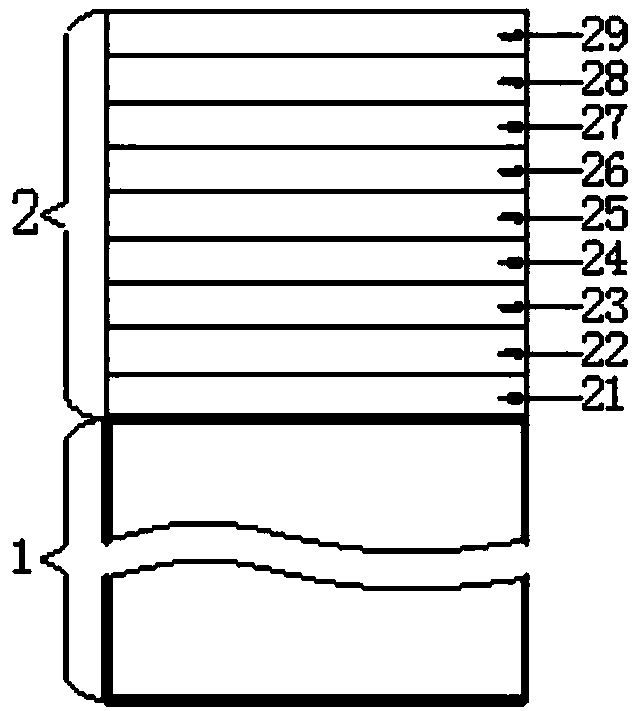

[0043] Such as figure 2 As shown, an ultra-high reflectivity optical scanning vibrating mirror, the optical scanning vibrating mirror is composed of a glass substrate layer and a high-reflection film deposited and plated on the glass substrate layer;

[0044] Below Nb 2 o 5 The film layer can also be replaced by TiO 2 、 Ta 2 o 5 or ZrO 2 .

[0045] The high-reflection film is composed of 9 film layers, and the 9 film layers are in order from near to far from the glass substrate layer: the first Al with a thickness of 98-100nm 2 o 3 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com