Device and method for preparing fiber-reinforced silica sol composite shell by air laying

A fiber reinforced, silica sol technology, applied in the direction of core, mold, mold composition, etc., can solve the problems of uneven mixing of fibers, uneven distribution of fibers, and reduced strength, so as to improve the filling ability, and the operation is simple and easy. line, the effect of improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

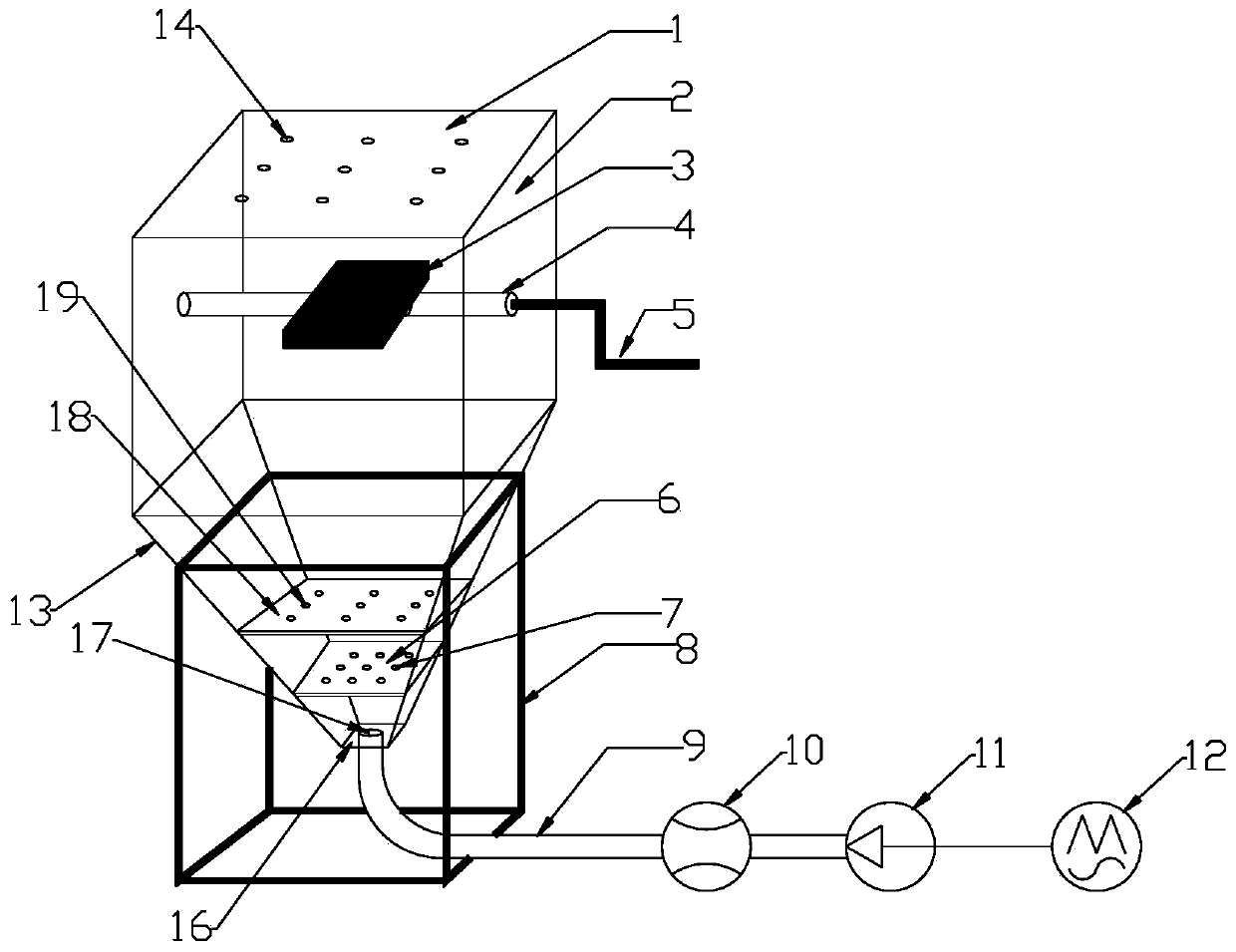

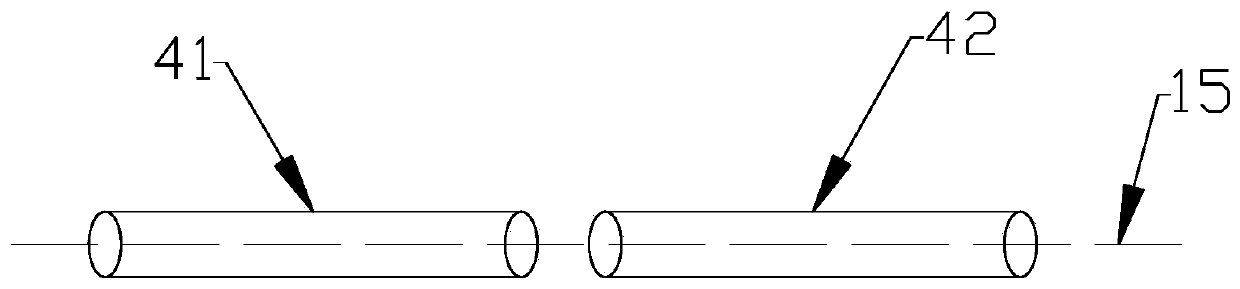

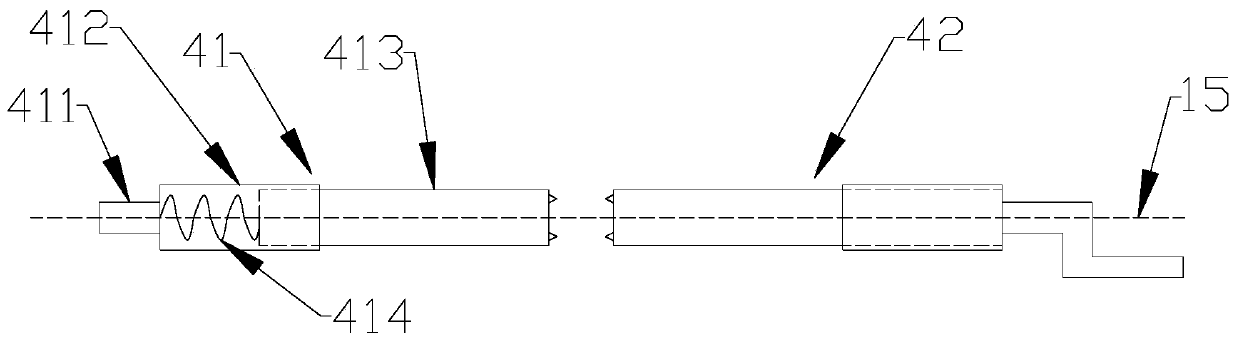

[0050] The device for preparing fiber-reinforced silica sol composite shells by airflow laying in this embodiment includes a fiber laying chamber 2, a fiber storage chamber 13, an air supply unit and a support 8; the fiber laying chamber 2 is composed of four side vertical plates It is in the shape of a hollow cube formed with an upper bottom surface exhaust hole plate 1, and the upper bottom surface exhaust hole plate 1 is provided with an exhaust hole 14, and the fiber laying chamber 2 is equipped with a container for carrying the molded shell sample 3. Rotating shaft; the fiber storage chamber 13 is a hollow inverted quadrangular truss shape made up of four side panels and a lower bottom surface air intake hole plate 16, a fiber storage rack 6 is installed in the fiber storage chamber 13, the The fiber storage rack 6 is provided with an airflow air guide hole 7; the fiber laying room 2 is located directly above the fiber storage room 13, and the side length of the side plate...

Embodiment 2

[0056]The method for preparing fiber-reinforced silica sol composite shells by using the device for preparing fiber-reinforced silica sol composite shells by airflow laying in Example 1, the device for preparing fiber-reinforced silica sol composite shells by airflow laying includes fiber laying chamber 2, fiber Storage chamber 13, air supply unit and support 8; the fiber laying chamber 2 is a hollow cube shape composed of four side vertical plates and an upper bottom exhaust hole plate 1, and the upper bottom surface exhaust hole plate 1 There is an exhaust hole 14 on the top, and a rotating shaft for carrying the shell sample 3 is installed in the fiber laying room 2; It is composed of a hollow inverted square prism shape, and a fiber storage rack 6 is installed in the fiber storage room 13, and an airflow air guide hole 7 is opened on the fiber storage room 13; the fiber laying room 2 is located at the fiber Right above the storage chamber 13, the side lengths of the side r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com