Low-VOC (volatile organic compound) super-curing repairing varnish and preparation method thereof

A varnish, curing resin technology, applied in the direction of paint, coating, anti-corrosion coating containing biocide, can solve the problems of poor fullness, dry paint film, difficult to consumers, etc., to reduce the content of VOC, paint film Bright, GST-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1, a kind of fluorine modified acrylic resin

[0052] The fluorine-modified resin is made from the following raw materials in parts by weight:

[0053] 24 parts of xylene, 14 parts of butyl acetate, 40 parts of methyl methacrylate, 20 parts of butyl acrylate, 8 parts of methacrylic acid, 45 parts of hydroxybutyl acrylate, 23 parts of vinyl tertiary carbonate, acetoacetic acid methacrylate 6 parts of ethyl ester, 45 parts of dodecafluoroheptyl methacrylate, 8 parts of tert-butyl peroxybenzoate, 4 parts of mercaptoethanol;

[0054] The preparation method of the fluorine-modified acrylic resin:

[0055] S1. Put the four-neck flask in a constant temperature and constant speed magnetic stirring oil bath, add xylene and butyl acetate to the four-necked flask, raise the temperature of the constant temperature and constant speed magnetic stirring oil bath to 116°C, and adjust the speed to 350r / min ;

[0056] S2, then methyl methacrylate, butyl acrylate, methacryli...

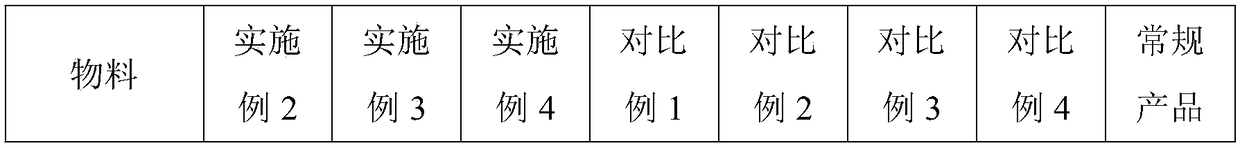

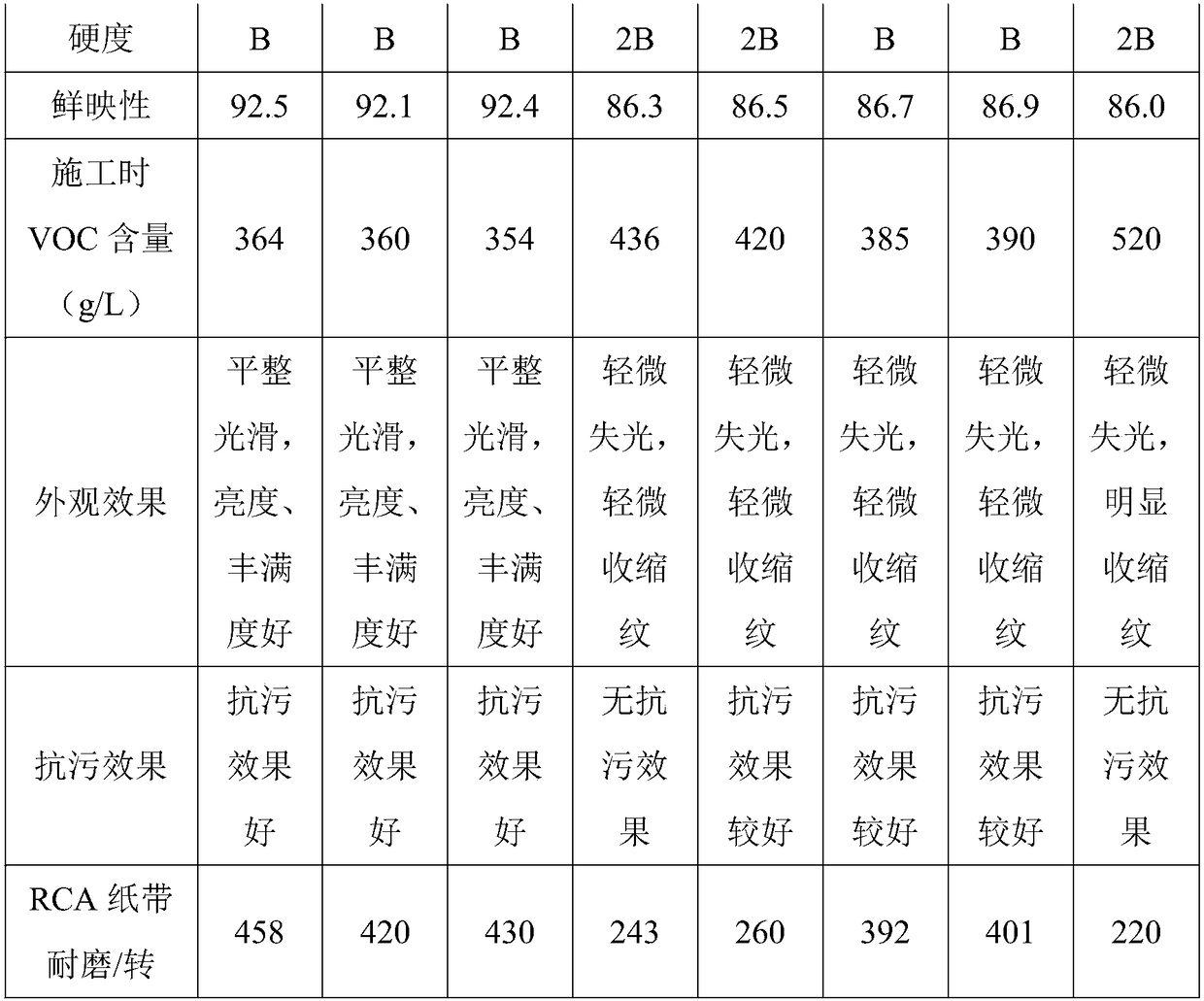

Embodiment 2

[0059] Embodiment 2, a kind of low-VOC super-cured repair varnish

[0060] The super-cured repair varnish of described low VOC is formulated by the weight ratio of A component and B component by 2:1;

[0061] Described A component is made up of the raw material of following parts by weight:

[0062] 58.8 parts of polyol supercured resin, 20 parts of fluorine-modified acrylic resin, 1.2 parts of hyperbranched polyester polyol resin, 20 parts of solvent, 0.5 part of AFCONA 3700, 0.05 part of dibutyltin dilaurate; Ester, isobutyl acetate and propylene glycol methyl ether acetate are composed of 5:6:9 by volume;

[0063] The B component consists of the following raw materials in parts by weight:

[0064] Covestro 60 parts of N3900, 5 parts of xylene, 35 parts of n-butyl acetate.

[0065] Preparation:

[0066] Step 1, preparation of component A:

[0067] Put the solvent into the container, then put in polyol super-curable resin, fluorine-modified acrylic resin and hyperbranc...

Embodiment 3

[0071] Embodiment 3, a kind of low-VOC super-cured repair varnish

[0072] The super-cured repair varnish of described low VOC is formulated by the weight ratio of A component and B component by 2:1;

[0073] Described A component is made up of the raw material of following parts by weight:

[0074] 50 parts of polyol supercured resin, 15 parts of fluorine-modified acrylic resin, 1 part of hyperbranched polyester polyol resin, 16 parts of solvent, 0.1 part of AFCONA 3700, 0.01 part of dibutyltin dilaurate; Ester, isobutyl acetate and propylene glycol methyl ether acetate are composed of 4:4:6 by volume;

[0075] The B component consists of the following raw materials in parts by weight:

[0076] Covestro 53 parts of N3900, 3 parts of xylene, 32 parts of n-butyl acetate;

[0077] The preparation method is similar to Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com