Preparation method of fiber reinforced composite silica sol shell for investment casting

A fiber-reinforced composite and investment casting technology, which is applied to casting molding equipment, molds, and mold components, can solve the problems of high residual strength and low wet strength, reduce residual strength, improve production efficiency, and reduce mold. Effect of shell residual strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

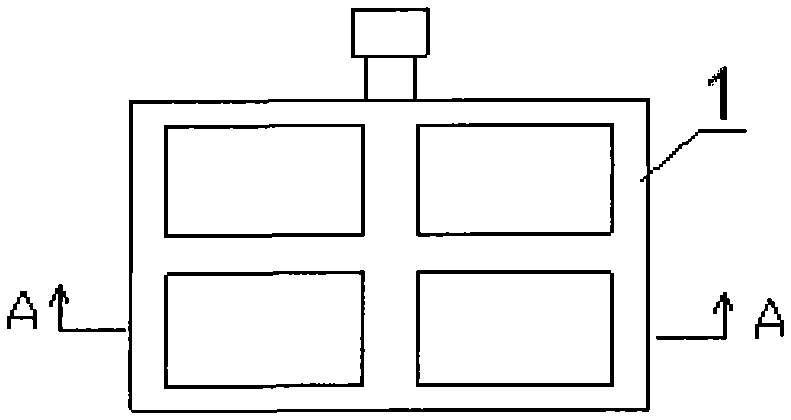

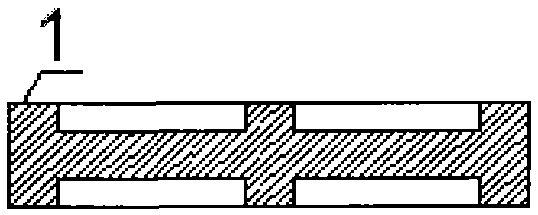

Image

Examples

Embodiment approach 1

[0041] Embodiment 1, the preparation method of the fiber-reinforced composite silica sol mold shell for investment casting of the present invention includes the following steps in sequence: the following mass may also be referred to as weight. The following "h" can also be replaced by "hour".

[0042] 1), preparation of the surface coating, according to the mass ratio of the refractory powder zirconium powder and the silica sol in the surface coating as 3.2:1, add the zirconium powder into the silica sol, stir evenly, and add an appropriate amount of wetting agent and Defoamer, after continuous stirring for later use;

[0043] 2) Surface layer shell preparation, after cleaning the surface of the wax pattern with a wax pattern cleaning solution, immerse the wax pattern in the coating prepared in step 1 for 20-30 seconds, after taking it out, sprinkle sand and dry it to obtain the surface layer pattern;

[0044] 3), the preparation of the transition layer coating and the mold she...

Embodiment approach 2

[0054] Embodiment 2, the preparation method of the fiber-reinforced composite silica sol shell for investment casting of the present invention includes the following steps in sequence:

[0055] 1) Preparation of the surface coating, according to the mass ratio of the refractory powder zircon powder and the silica sol in the surface coating being 2.8:1, adding the zircon powder into the silica sol, stirring evenly, and adding an appropriate amount of wetting agent and Defoamer, after continuous stirring for later use;

[0056] 2) Surface layer shell preparation, after cleaning the surface of the wax pattern with a wax pattern cleaning solution, immerse the wax pattern in the coating prepared in step 1 for 20-30 seconds, after taking it out, sprinkle sand and dry it to obtain the surface layer pattern;

[0057] 3), the preparation of the transition layer coating and the mold shell, according to the mass ratio of the refractory powder mullite powder in the transition layer coatin...

Embodiment approach 3

[0067] Embodiment 3, the preparation method of the fiber-reinforced composite silica sol shell for investment casting of the present invention includes the following steps in sequence:

[0068] 1) Preparation of the surface coating, according to the mass ratio of the refractory powder zircon powder and silica sol in the surface coating to 3.4:1, add the zircon powder into the silica sol, stir evenly, and add an appropriate amount of wetting agent and Defoamer, after continuous stirring for later use;

[0069] 2) Surface layer shell preparation, after cleaning the surface of the wax pattern with a wax pattern cleaning solution, immerse the wax pattern in the coating prepared in step 1 for 20-30 seconds, after taking it out, sprinkle sand and dry it to obtain the surface layer pattern;

[0070] 3), the preparation of the transition layer coating and the mold shell, according to the mass ratio of the refractory powder mullite powder in the transition layer coating to the silica s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com