High-solid multifunctional quick-drying intermediate coating composition and purpose thereof

A multi-functional, fast-drying technology used in coatings to solve problems such as poor adhesion, slow initial drying of intermediate coatings, and low gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

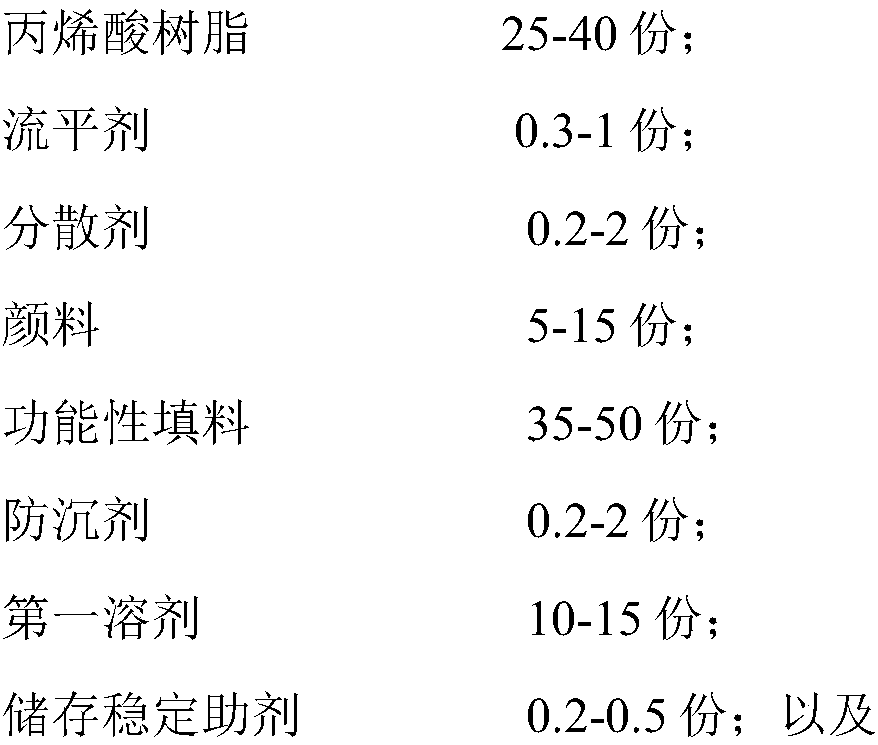

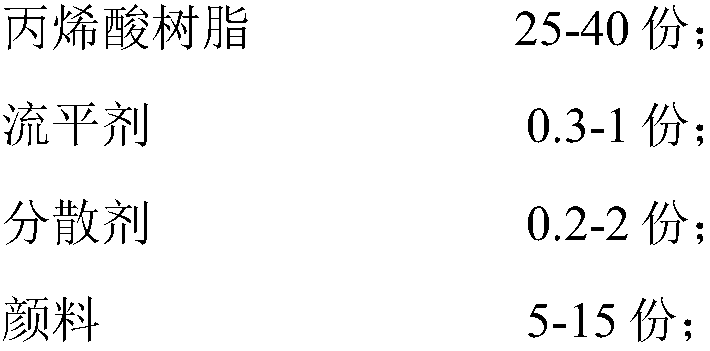

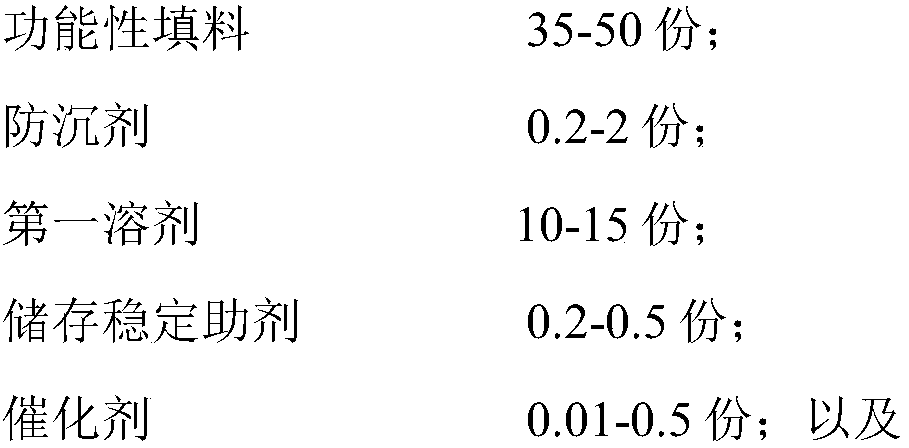

Method used

Image

Examples

Embodiment 1

[0095] In a container with a stirrer, add 3.9 parts of butyl acetate, 5 parts of 3-methoxybutyl propionate, 0.2 parts -DISPERSANT-163 dispersant, 35 parts of Uracron CY 430E-70 acrylic resin, stir at 800 rpm for 15 minutes, then slowly add 4.1 parts of TIPAQUE CR-97 titanium dioxide, hydrogen anthracene advanced pigment carbon black C311 carbon under stirring at 500-600 rpm 0.9 parts of black, 20 parts of talcum powder, 25 parts of barium sulfate, 0.2 parts of BENTONE 38, stir at 800 rpm for 20 minutes, sand mill until the fineness is less than 30 microns, then slowly add 0.3 parts of BYK 358N acrylate under stirring at 500-600 rpm Leveling agent, 0.02 parts of dibutyltin dilaurate, 0.5 parts of DeuAdd DVP additive, 4.88 parts of butyl acetate, stir evenly, and filter through a 100-micron filter to obtain a mid-coat;

[0096] Under the protection of nitrogen, add 30 parts of butyl acetate, 10 parts of ethyl acetate, and 5 parts of methyl amyl ketone, stir well, use a moisture...

Embodiment 2

[0100] In a container with a stirrer, add 4 parts butyl acetate, 3 parts butyl 3-methoxypropionate, 2 parts -DISPERSANT-110 dispersant, 33.8 parts of Joncryl RPD 950-B Polyol acrylic resin, stirred at 800 rpm for 15 minutes, then slowly added 14.96 parts of titanium dioxide R-972, 0.04 parts of MITSUBISHI CARBONBLACK MA-220 carbon black under stirring at 500-600 rpm , 15 parts of talcum powder, 20 parts of calcium carbonate, 2 parts of DEURHEO 201P, stirred at 800 rpm for 20 minutes, sanded until the fineness is less than 30 microns, and then slowly added 0.5 parts of BYK3560 silicone leveling agent under stirring at 500-600 rpm, 0.5 parts of EFKA-3772 fluorine-modified acrylate leveling agent, 0.5 parts of Borchi Kat24, 0.5 parts of BYK 410 anti-sag additive, 0.2 parts of dimethylethanolamine, 3 parts of ethyl acetate, stir well, use a 100 micron filter Filter to obtain middle coating;

[0101] Under the protection of nitrogen, add 10 parts of butyl acetate, 25 parts of eth...

Embodiment 3

[0105] In a container with a stirrer, add 4 parts butyl acetate, 3 parts butyl 3-methoxypropionate, 0.5 parts PU 4010 dispersant, 25 parts of Macrynal SM 2810 75 BAC acrylic resin, stirred at 800 rpm for 15 minutes, then slowly added 7.96 parts of titanium dioxide R-972, 0.04 parts of MITSUBISHI CARBON BLACK MA-220 carbon black, 20 1 part of talcum powder, 20 parts of calcium carbonate, 10 parts of barium sulfate, 0.5 part of BENTONE SD-2, stirred at 800 rpm for 20 minutes, sanded until the fineness is less than 30 microns, and then slowly added 5 parts of Setal 1615 under stirring at 500-600 rpm SS-75 polyester resin, 0.3 parts of EFKA-3777 fluorine-modified acrylate leveling agent, 0.5 parts of Borchi Kat22, 0.2 parts of dimethylethanolamine, 3 parts of ethyl acetate, stirred evenly, and filtered with a 100 micron filter to obtain Intermediate coating;

[0106] Under nitrogen protection, add 25 parts of butyl acetate, 10 parts of ethyl acetate, 15 parts of S-100# solvent oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com