Bicomponent oily polyurethane primer with low VOC (volatile organic compounds)

An oil-based polyurethane, two-component technology, applied in the field of coatings, can solve the problems that oil-based paints cannot be completely replaced, water-based wood paints are immature, etc., and achieve the effects of improved construction and storage stability, suitable construction viscosity, and excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A two-component low-VOC oily polyurethane primer, characterized in that it comprises component A, component B and diluent, and the ratio of parts by weight of component A to component B is 2:1;

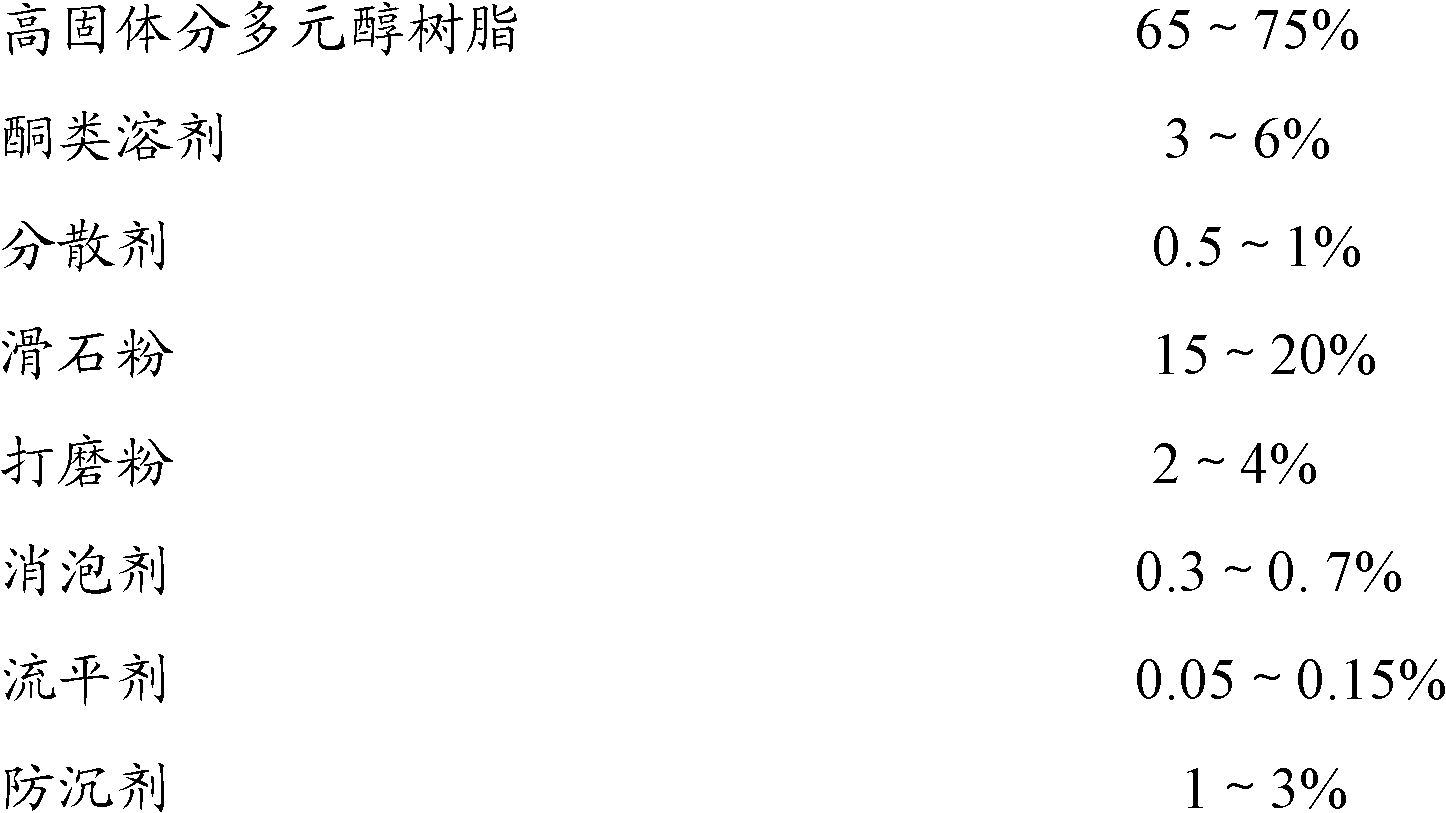

[0047] Wherein, the first component includes the following raw materials calculated by weight percentage:

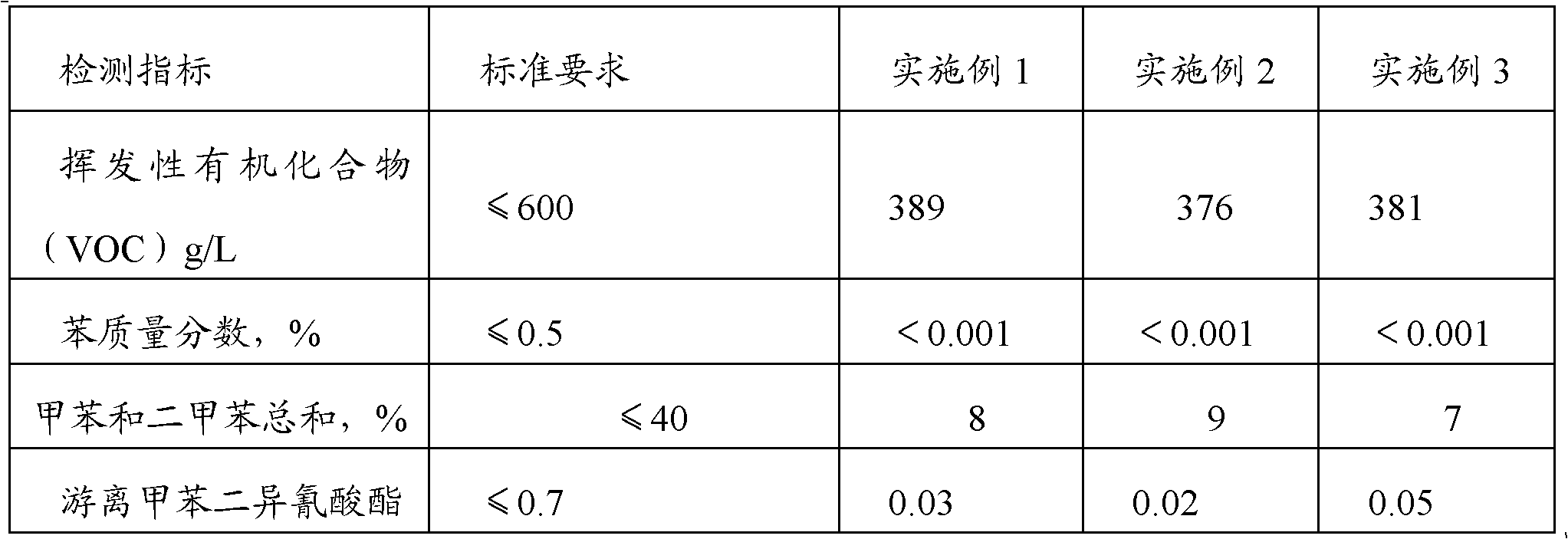

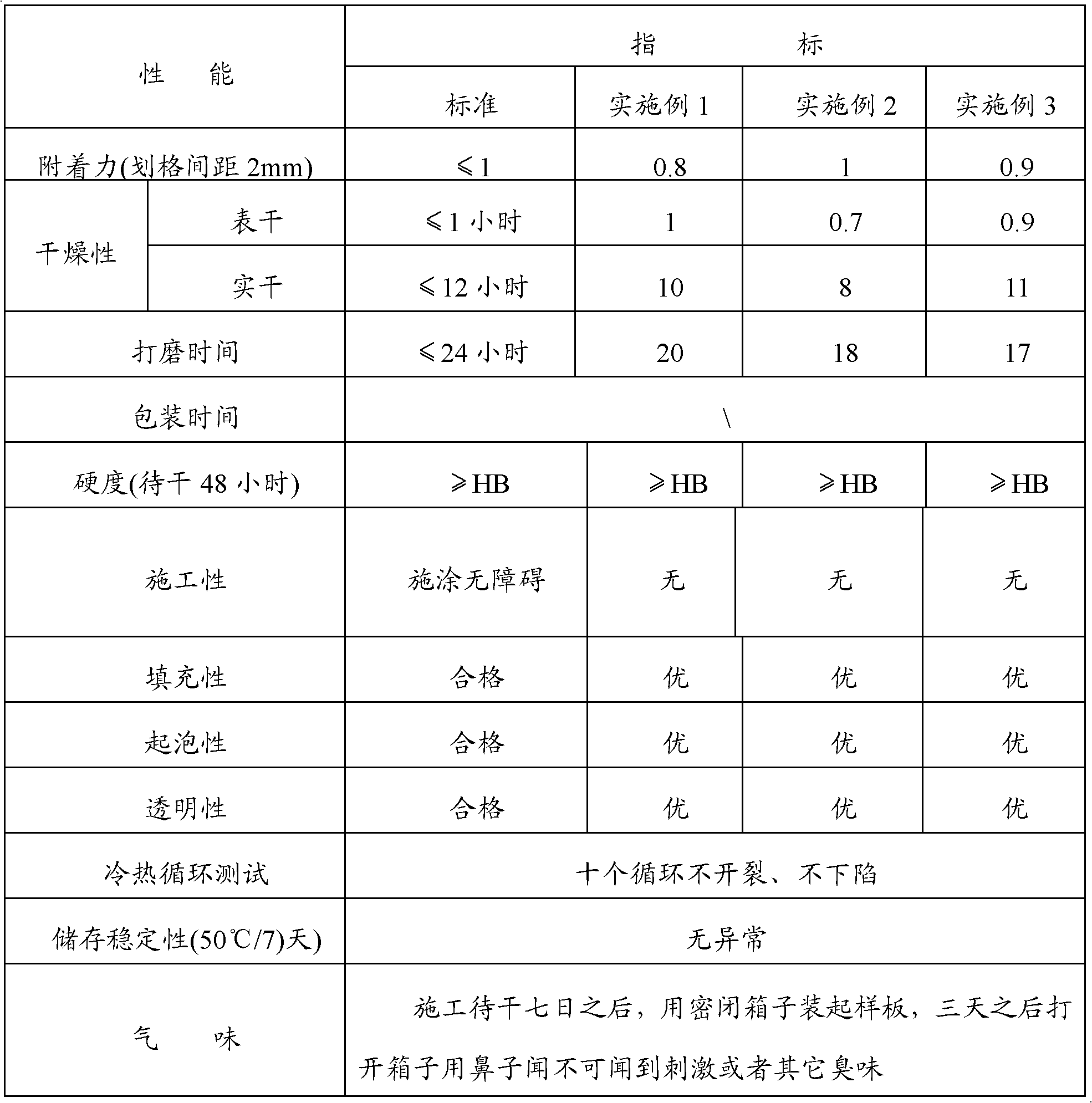

[0048] High solid polyol resin 67.2%, ketone solvent 6%, dispersant 1%, grinding powder 4%, talcum powder 20%, defoamer 0.65%, leveling agent 0.15%, anti-settling agent 1%; The solid content of component A is 76%.

[0049] The B component has a solid content of 48%, and includes the following raw materials calculated by weight percentage: 50% of toluene diisocyanate trimer, 30% of toluene diisocyanate adduct, and 20% of solvent.

[0050] Described diluent comprises following raw material calculated by weight percentage:

[0051] Ethyl acetate (EAC) 10%, n-butyl acetate (BAC) 85%, propylene glycol monomethyl ether propionate (PMP) 5%.

[0052] The method for preparing t...

Embodiment 2

[0061] A two-component low-VOC oily polyurethane primer, characterized in that it comprises component A, component B and diluent, and the ratio of parts by weight of component A to component B is 2:1;

[0062] Wherein, the first component includes the following raw materials calculated by weight percentage:

[0063] High solid polyol resin 75%, ketone solvent 5%, dispersant 0.5%, grinding powder 2.8%, talcum powder 16%, defoamer 0.35%, leveling agent 0.05%, anti-settling agent 0.3%; The solid content of component A is 78%.

[0064] The B component has a solid content of 50%, and includes the following raw materials calculated by weight percentage: 60% of toluene diisocyanate trimer, 20% of toluene diisocyanate adduct, and 20% of solvent.

[0065] Described diluent comprises following raw material calculated by weight percentage:

[0066] Ethyl acetate (EAC) 20%, n-butyl acetate (BAC) 70%, propylene glycol monomethyl ether propionate (PMP) 10%.

[0067] The method for prepar...

Embodiment 3

[0076] A two-component low-VOC oily polyurethane primer, characterized in that it comprises component A, component B and diluent, and the ratio of parts by weight of component A to component B is 2:1;

[0077] Wherein, the first component includes the following raw materials calculated by weight percentage:

[0078] High solid polyol resin 75%, ketone solvent 3%, dispersant 1%, grinding powder 2%, talcum powder 18%, defoamer 0.5%, leveling agent 0.1%, anti-settling agent 0.4%; The solid content of A component is 80%.

[0079] The B component has a solid content of 52%, and includes the following raw materials calculated by weight percentage: 65% of toluene diisocyanate trimer, 25% of toluene diisocyanate adduct, and 10% of solvent.

[0080] Described diluent comprises following raw material calculated by weight percentage:

[0081] Ethyl acetate (EAC) 15%, n-butyl acetate (BAC) 77%, propylene glycol monomethyl ether propionate (PMP) 8%.

[0082] The method for preparing the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com