Acid epoxy high-temperature curing type coating varnish for automobile exterior coating and preparation method thereof

A high-temperature curing, overcoating varnish technology, applied in coatings, polyester coatings, etc., can solve problems such as damage, corrosion, weak chemical structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0067] Reference example 1: the synthetic preparation of the thermosetting acrylic resin that the total acid value that the present invention uses is 120-140:

[0068] The acid value comes from the introduction of maleic anhydride monomer.

[0069] 1) The distribution of raw materials used in resin synthesis is shown in the table below.

[0070] raw material name

parts by weight

153.1

48.1

131.3

105.0

Solvent: trimethylbenzene

178.0

Solvent: ethyl 3-ethoxypropionate

210

55

total

890.5

[0071] 2) In a four-necked flask equipped with a stirrer, a thermometer, a condenser, a water separator and a nitrogen device, add 110 parts by weight of styrene, n-butyl methacrylate, n-butyl acrylate, and trimethylbenzene according to the formula , Turn on and stir until uniform, and use jacket cooling to ke...

reference example 2

[0073] Reference example 2: the present invention uses the synthetic preparation of the thermosetting acrylic resin of epoxy value 2.0-4.0:

[0074] The epoxy value comes from the introduction of glycidyl methacrylate.

[0075] 1) The distribution of raw materials used in resin synthesis is shown in the table below.

[0076] raw material name

parts by weight

150

120

Isobutyl methacrylate

60

4-Hydroxybutyl Acrylate

30

30

210

Catalyst: di-tert-amyl peroxide

20

Solvent: trimethylbenzene

180

Solvent: Butanol

68

total

868

[0077] 2) In a four-necked flask equipped with a stirrer, a thermometer, a condenser, a water separator and a nitrogen device, add styrene, glycidyl methacrylate, and 2-hydroxyethyl methacrylate according to the formula in the above table. ester, n-butyl acrylat...

reference example 3

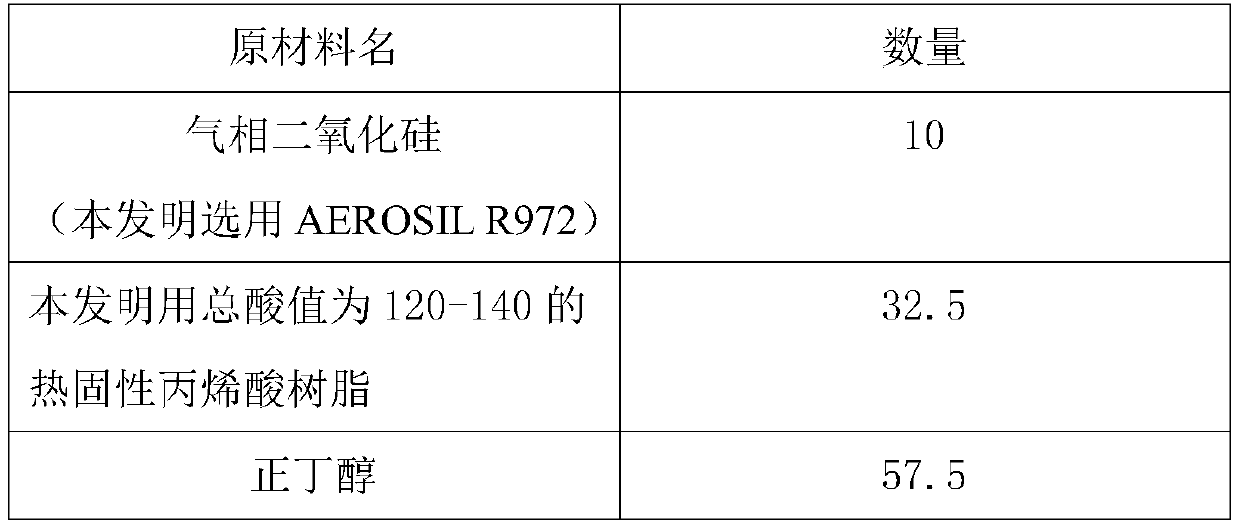

[0079] Reference example 3: the preparation of the anti-sagging additive containing fumed silica used in the present invention:

[0080] The gas phase silica is evenly dispersed into the resin through the dispersion equipment:

[0081] 1) See the table below for the weight ratio of raw materials

[0082]

[0083] 2) Put 60% glass beads of 1.0-1.4mm specification in a sealable container, then add the materials in Table 3, keep the total volume of glass beads and dispersion not exceeding 85% of the container volume, and seal it;

[0084] 3) Fix the sealed container in a high-speed shaker and shake it for more than 30 minutes, the speed is controlled at 500-700 times / min, until the fineness of the dispersion is less than 20 microns, and the anti-sag additive containing fumed silica is obtained .

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com