Patents

Literature

47results about How to "Improved sag performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

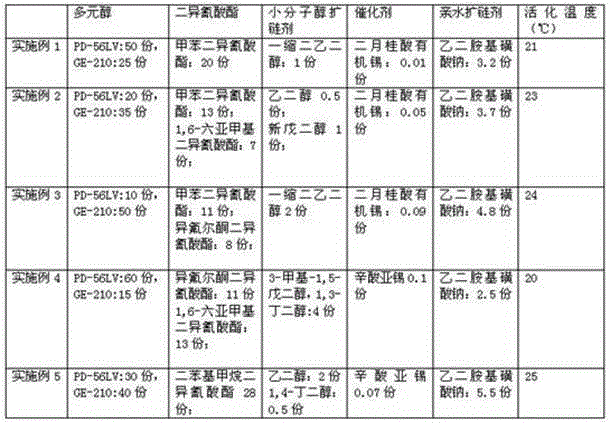

Low-molding-temperature waterborne polyurethane adhesive and preparation method thereof

ActiveCN104031596AImproved sag performanceReduce lossNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

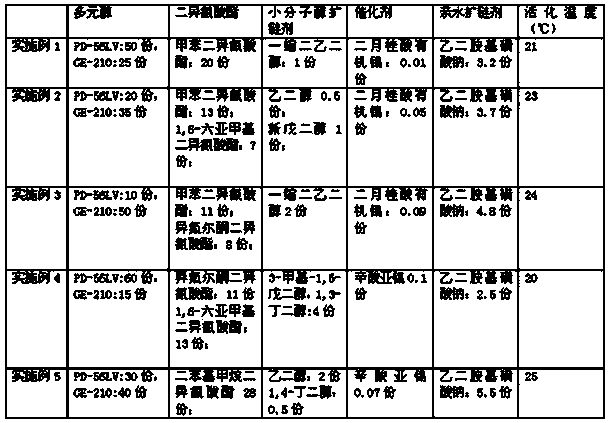

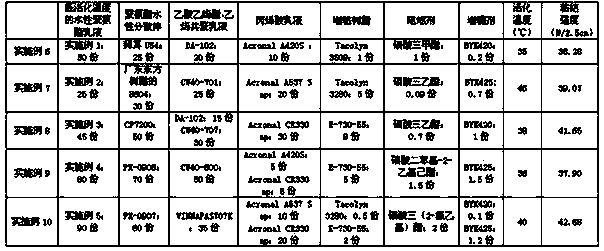

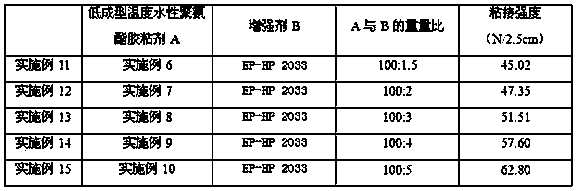

The invention discloses a low-molding-temperature waterborne polyurethane adhesive and a preparation method thereof. The low-molding-temperature waterborne polyurethane adhesive is prepared by matching a waterborne polyurethane dispersion, ethylene-vinyl acetate (EVA) emulsion, acrylic emulsion and the like based on low-activation-temperature waterborne polyurethane emulsion, wherein the low-activation-temperature waterborne polyurethane emulsion mainly consists of polyhydric alcohols, diisocyanate, a small molecule alcohol chain extender, a catalyst and a hydrophilic chain extender and has the activation temperature of less than 25 DEG C; the low-molding-temperature waterborne polyurethane adhesive prepared based on the low-activation-temperature waterborne polyurethane emulsion has the activation temperature of 30-60 DEG C, is high in bonding strength, is water-based emulsion, does not contain organic solvents or volatile organic compounds, is green and environment-friendly and can well meet the service requirements of adhesives for automobile roofs. The low-molding-temperature waterborne polyurethane adhesive also can be matched with a certain amount of enhancers, the bonding strength of colloid at the later stage is effectively improved, and the heat resistance of the roof at the later molding stage is guaranteed.

Owner:重庆中科力泰高分子材料有限公司

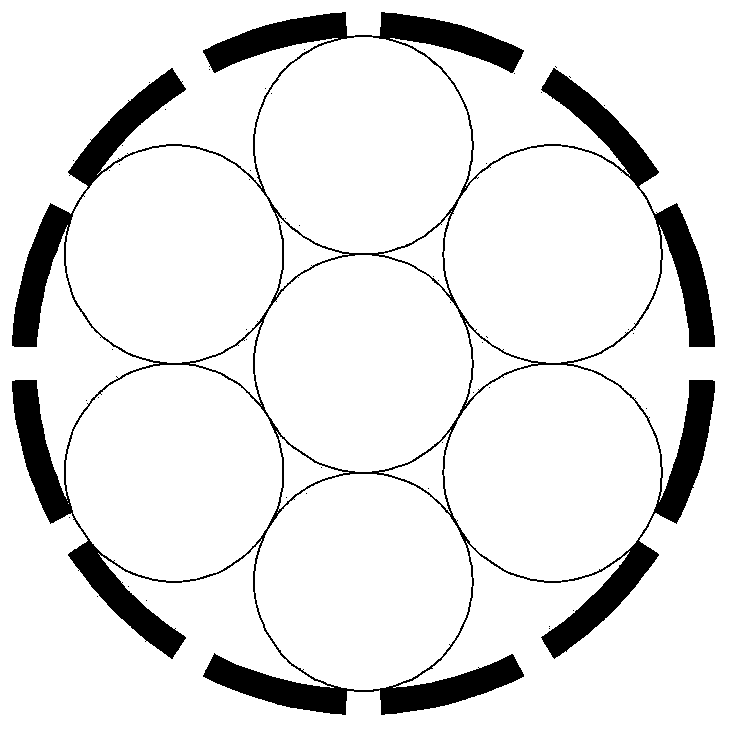

Grapheme-nanomaterial-based conductive wire

ActiveCN103700440AReduce lossRaise the draw-to-weight ratioMaterial nanotechnologyNon-insulated conductorsFiberCarrying capacity

The invention provides a grapheme-nanomaterial-based conductive wire, belongs to the technical field of conductive wires for overhead transmission lines, and solves the problems that improvement on the conductivity of aluminum and copper and other conventional metal materials is limited and the transmission capacity of an overhead transmission line is limited. The grapheme-nanomaterial-based conductive wire comprises two structures as follows: 1, the grapheme-nanomaterial-based conductive wire comprises an inner layer and an outer layer, wherein the inner layer is formed by twisting monofilaments of steel or carbon fiber, nanotube monofilaments of a grapheme nanomaterial or composite monofilaments, and the outer layer is formed by twisting arc grapheme nanomaterial sheets; 2, the grapheme-nanomaterial-based conductive wire is formed by twisting circular linear nanotube monofilaments of the grapheme nanomaterial or the composite monofilaments, wherein the monofilament are tightly adhered to one another to form a regular tubular structure, circular cross sections of the composite monofilaments are made of a carbon fiber composite material, and the grapheme nanomaterial is filled into the circular cross sections. The grapheme-nanomaterial-based conductive wire can effectively reduce the line loss and improve the transmission power of the overhead transmission line, and has an allowable current-carrying capacity which is 10 times as that of an ordinary wire under the same external conditions.

Owner:CHINA ELECTRIC POWER RES INST +1

Epoxy-modified sulfonic waterborne polyurethane emulsion and preparing method and application thereof

InactiveCN105131243AImprove hydrolysis resistanceImprove performancePolyurea/polyurethane coatingsEpoxyPolyurethane adhesive

The invention discloses an epoxy-modified sulfonic waterborne polyurethane emulsion and a preparing method and application thereof. The sulfonic waterborne polyurethane emulsion is prepared from, by weight, 70-80 parts of polyhydric alcohol, 10-15 parts of diisocyanate, 1-2 parts of small molecular alcohol chain extender, 0.01-0.05 part of organobismuth and / or organotin catalyst, 2.5-3.5 parts of hydrophilic chain extender and 5-15 parts of epoxy resin. The formula is simple, blending stability is high, the hydrolysis resistance of a waterborne polyurethane adhesive is improved, and the epoxy-modified sulfonic waterborne polyurethane emulsion can be used for preparing 3D furniture paint-free blister adhesives and has the advantages of low use temperature, high adhesion strength, high temperature resistance and the like.

Owner:重庆中科力泰高分子材料有限公司

Micro powder reinforced polyurethane-based high-strength waterproof heat preservation and decoration integrated material and preparation method thereof

InactiveCN106431087AImprove performanceRealize the utilization of solid wastePolyurea/polyurethane coatingsSlurryUltimate tensile strength

The invention relates to a micro powder reinforced polyurethane-based high-strength waterproof heat preservation and decoration integrated material and a preparation method thereof. According to the material, polyurethane is adopted as matrix resin, a large number of micro powder particles and multiple compounding agents are added, grinding is carried out, foaming is controlled, and the closed-cell material is prepared. Coatings or rolls or plates or blocks can be manufactured by means of brushing or spraying or pouring. The material can be manufactured to be red, yellow, blue, black, white and other colors by adjusting a coloring agent. The material has the comprehensive advantages of being efficient, waterproof, good in heat preservation performance and decoration effect, high in strength, good in corrosion resistance, resistant to inflaming and the like. The coatings are tightly bonded with a substrate, and the surface is smooth. The material has good toughness as the rolls and can be used for waterproofness and heat preservation of newly-built or existing buildings, tunnels, underground facilities and the like. The material serves as the plates, sand particles can be bonded to the surface of damp-dry slurry to obtain various building plates with a stone grain decoration effect. The material is extremely low in cost and has good market prospects.

Owner:SOUTHEAST UNIV +1

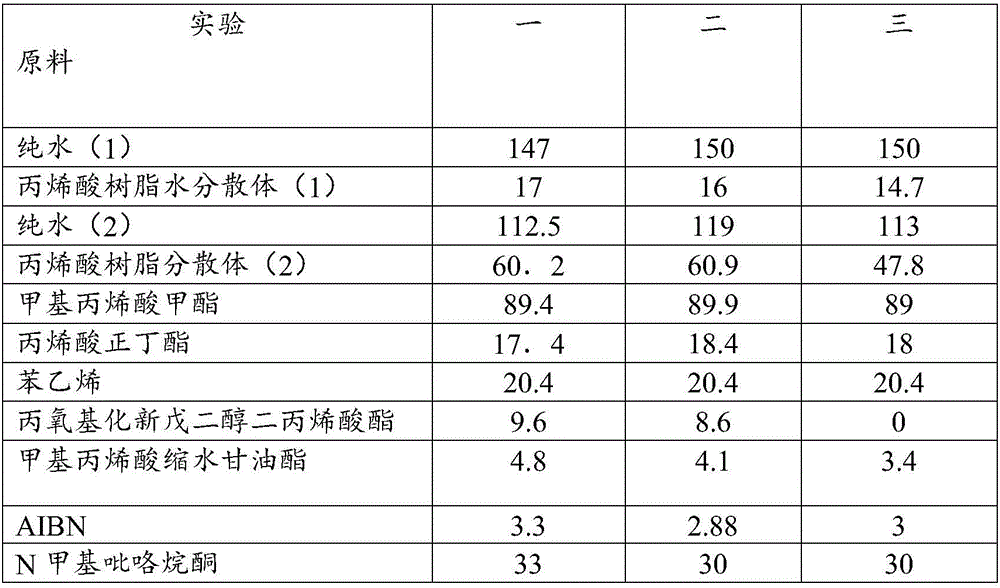

Microgel aqueous acrylic acid shell-core resin emulsion and preparation method thereof

The invention belongs to the field of aqueous coatings, and relates to a microgel aqueous acrylic acid shell-core resin emulsion. The resin emulsion is prepared through a reaction of 13-16 parts of an acrylic acid resin water dispersion (with the solid content of 28-34%), 18-21 parts of a vinyl monomer, 20.5-27.6 parts of an acrylic acid and acrylate monomer, 0.3-0.6 parts of an initiator, 5-6 parts of an organic solvent and 49-53 parts of water. The microgel resin emulsion is added to an aqueous coating, so the sagging property of a paint film is obviously improved, a good anti-sagging effect is reached, the thickness of the paint film in closed angles or edges and other difficult coating positions of a coated member is obviously increased, and the corrosion resistance of the surface of the coated member is improved. The nanometer-level aqueous acrylic acid emulsion with the particle size being smaller than 150nm is produced through the method, can be added to the aqueous coating without thickening the coating, and facilitates maintenance of high construction solid content.

Owner:LANGFANG JINHUILI INDAL PAINT

Bare steel rust layer conversion agent for terrestrial environment

InactiveCN104831263ANo strong irritating smellNo irritating smellMetallic material coating processesNitrateSulfate

The invention discloses a bare steel rust layer conversion agent for a terrestrial environment. The rust layer conversion agent comprises the following components in percentage by weight: 0.5-5 percent of sodium tripolyphosphate, 0.1-3 percent of copper sulfate, 0.1-2 percent of manganous nitrate, 0.1-2 percent of nickel sulfate, 0.1-2 percent of phytic acid and the balance of water. The rust layer conversion agent disclosed by the invention has excellent rust liquid sagging resistance, and after the conversion agent is sprayed onto the surface of a weather-resistant bare steel sample of which oxide scale is removed, formation of a stable rust layer is promoted, and the rust layer has excellent anticorrosive performance and is suitable for coating of bare steel.

Owner:武汉钢铁有限公司

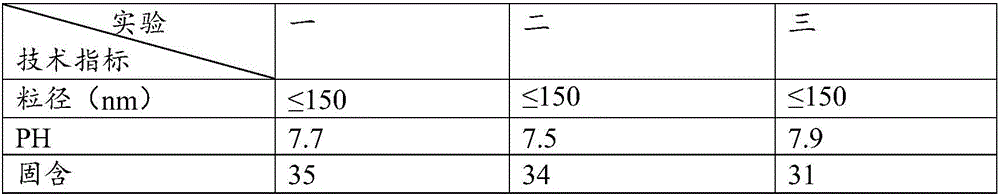

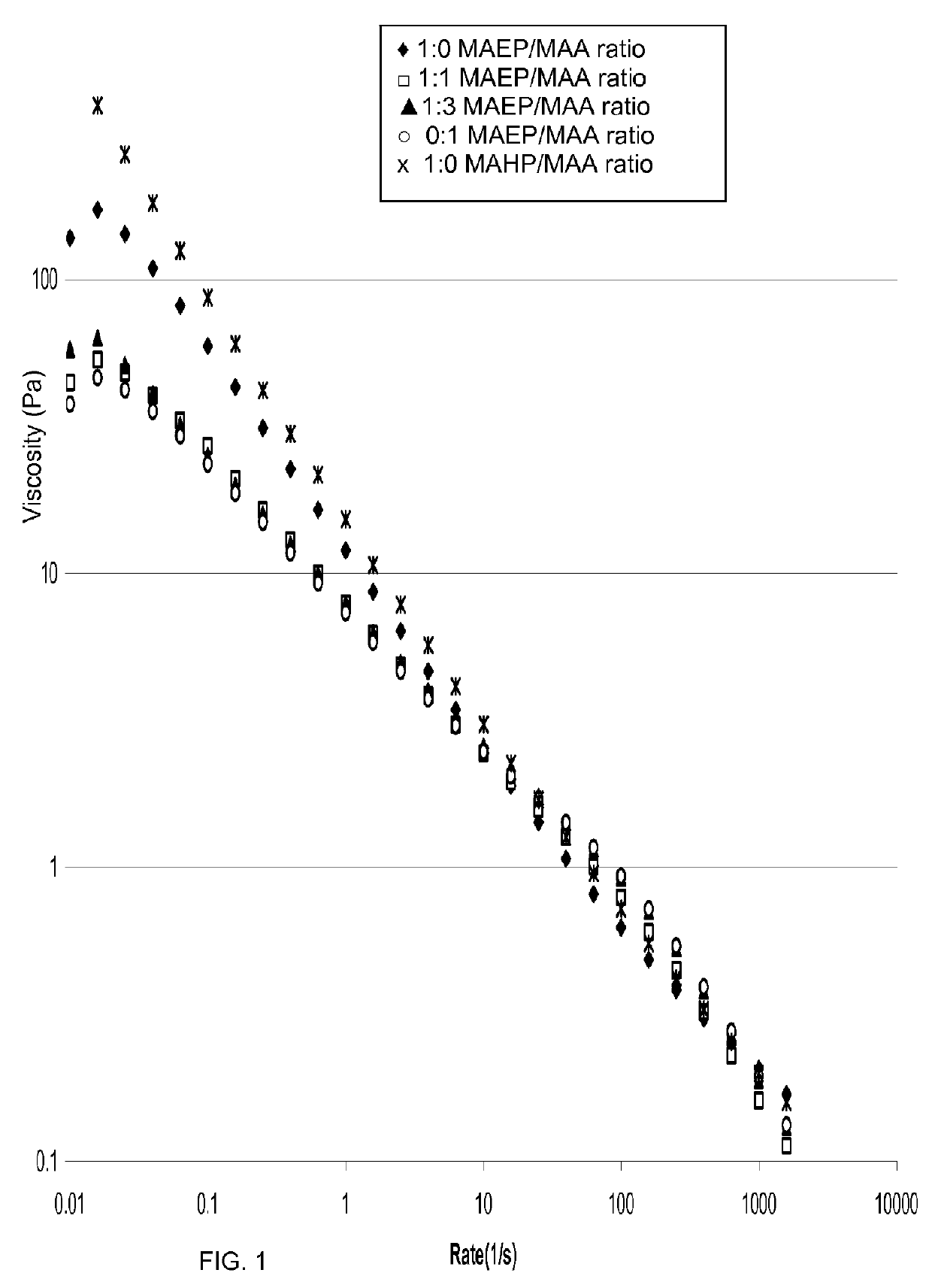

Compositions with pH responsive copolymer containing MAEP and/or MAHP and method for using same

ActiveUS9228041B2Improved sag performanceReduce glossCosmetic preparationsHair cosmeticsPersonal careHydraulic fracturing

Disclosed is a pH responsive polymer made with mono-[2-(methacryloyloxy)ethyl]phthalate and / or mono-[2-(methacryloyloxy)ethyl hexahydro]phthalate. Also disclosed is an aqueous coating composition including at least one latex polymer derived from at least one monomer copolymerized or blended with alkali swellable acrylate copolymer. Also provided is an aqueous coating composition including at least one latex polymer derived from at least one monomer blended with alkali swellable acrylate copolymer, at least one pigment, and water. Also provided is a method of preparing an aqueous coating composition such as a latex paint including the above components. Also provided are methods of preparing mono-[2-(methacryloyloxy)ethyl]phthalate. Also provided are compositions and methods using the polymer in hydraulic fracturing, personal care and or home and industrial cleaners.

Owner:RHODIA OPERATIONS SAS

Anti-slip heat insulation and sound isolation environment-friendly ground coating and preparation method thereof

InactiveCN108384390AImprove thermal insulation performanceImprove corrosion resistanceEpoxy resin coatingsPolyester coatingsCorrosion resistantEnvironmental resistance

The invention discloses anti-slip heat insulation and sound isolation environment-friendly ground coating and a preparation method thereof. The coating is prepared from the following raw materials inparts by weight: 90 to 100 parts of modified composite resin, 7 to 11 parts of sound insulation additives, 8 to 14 parts of heat insulation fillers, 6 to 10 parts of anti-slip additives, 20 to 30 parts of property enhancing resin, 2 to 4 parts of desinsectization and sterilization extraction liquid, 10 to 20 parts of mixed dibasic acid ester, 15 to 20 parts of propylene glycol methyl ether acetate, 3 to 5 parts of titanium dioxide, 0.5 to 1.5 parts of anti-settling agents, 1 to 2 parts of film forming agents, 0.4 to 0.8 part of anti-foaming agents, 0.8 to 1.4 parts of leveling agents and 2 to4 parts of dispersing agents. The coating is used as ground coating; the surface is fine; the leveling performance and the touch sense are excellent; the heat insulation and sound isolation performance is good; the anti-slip, friction resistant and anti-corrosion performance is good; meanwhile, the raw material ingredients are safe and reliable; no toxin and no harm exist; the raw materials can beeasily obtained; the cost is lower; the process is simple and clear; the operation is easy; the industrial production can be realized; higher practical value and good application prospects are realized.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

Surface treatment agent capable of generating brown stable rust layer

InactiveCN107903785ANo strong irritating smellNo strong strong irritating smellAnti-corrosive paintsMetallic material coating processesAlcoholNitrite

The invention discloses a surface treatment agent capable of generating a brown stable rust layer. The surface treatment agent is prepared from the following ingredients in percentage by mass: 30 to 35 percent of alcohol-soluble phenolic aldehyde varnish, 20 to 25 percent of NiSO4, 2 to 5 percent of CuSO4, 2 to 3 percent of sodium tungstate, 2 to 5 percent of trisodium orthophosphate, 5 to 10 percent of NaHSO3 and 28 to 33 percent of diluting solvents. The surface treatment agent is suitable for bare steel coating; after bare steel is coated with the surface treatment agent, a brown uniform and stable rust layer is generated on the surface; the long-time effective rust liquid flowing and hanging prevention and anti-corrosion performance is realized; in addition, the used surface treatmentagent does not have the strong pungent smell; chromium and nitrite are not contained; safety and environment protection are realized.

Owner:武汉钢铁有限公司

Concrete surface retarder and application method thereof

InactiveCN112299741AReduce labor intensitySimple and fast operationCeramic shaping apparatusPolymer sciencePolymer chemistry

The invention discloses a concrete surface retarder and an application method thereof, and belongs to the technical field of cement concrete retarders, the concrete surface retarder comprises at leastone cement retarding active component, the active component is dispersed in water, and the concrete surface retarder is environmentally friendly and belongs to an aqueous environmental protection product. The concrete surface retarder comprises one or more cement retarding active components, deionized water, a rheological additive, a humectant, an antifreezing agent, a preservative, an antirust agent, a pigment or dye coloring agent and a filler.

Owner:天津富乐佳科技有限公司

Dry plastering technology

InactiveCN105272113ASolve powder dropSolve problems such as dehydrationCeramicwareCelluloseFoaming agent

The invention provides a dry plastering technology. The dry plastering technology comprises the following steps that solid materials and water are blended into ardealite mortar, wherein the solid materials are prepared from, by weight, 600-700 parts of ardealite, 300-400 parts of aggregates, 0.2-1.5 parts of redispersible latex powder, 0.2-0.3 part of a foaming agent, 1-1.5 parts of cellulose ether, 2 parts of a water reducing agent and 1-1.5 parts of a retarder; the ardealite mortar is painted on a base layer to be plastered. The dry plastering technology has the advantages of saving water, time and labor and the like.

Owner:GUIZHOU TENGFENG TECH CO LTD

Polyethylene with a high vinyl content and with a low MFR

ActiveUS11286315B2Easy to processImprove liquidityPlastic/resin/waxes insulatorsPolymer sciencePower cable

The invention relates to a polyethylene having a melt flow rate at (2.16) kg loading (MFR2), determined according to method ISO1133-1:2011, which MFR2 is A g / 10 min and A1≤A≤A2; wherein A1 is (0.5) and A2 is (1.70), and containing a total amount of vinyl groups which is B vinyl groups per (1000) carbon atoms, and B1≤B, wherein B1 is (0.45), determined according to method ASTM D6248-98, a polymer composition, an article being e.g. a cable, e.g. a power cable, and processes for producing a polyethylene, a polymer composition and an article, and an article; useful in different end applications, such as wire and cable (W&C) applications.

Owner:BOREALIS AG

Bare steel rust layer transforming agent for salt-contained environment

InactiveCN104928664AGood adhesionPromote passivationMetallic material coating processesSulfatePhosphate

The invention provides a bare steel rust layer transforming agent for a salt-contained environment. The rust laser transforming agent comprises the following components in percentage by weight: 0.1-3% of titanyl sulfate, 0.5-5% of zinc dihydrogen phosphate, 0.1-3% of sodium pyrophosphate, 0.1-2% of tannic acid, 0.1-3% of copper sulfate, and the balance of water. The rust layer transforming agent has excellent rust liquid sagging prevention; after the rust layer transforming agent is sprayed on the surface of a weather-resistant steel bare sample with removed scales, the formation of a stable rust layer is accelerated; the rust layer is excellent in corrosion resistance; and the rust layer transforming agent is suitable for coating bare steels.

Owner:武汉钢铁有限公司

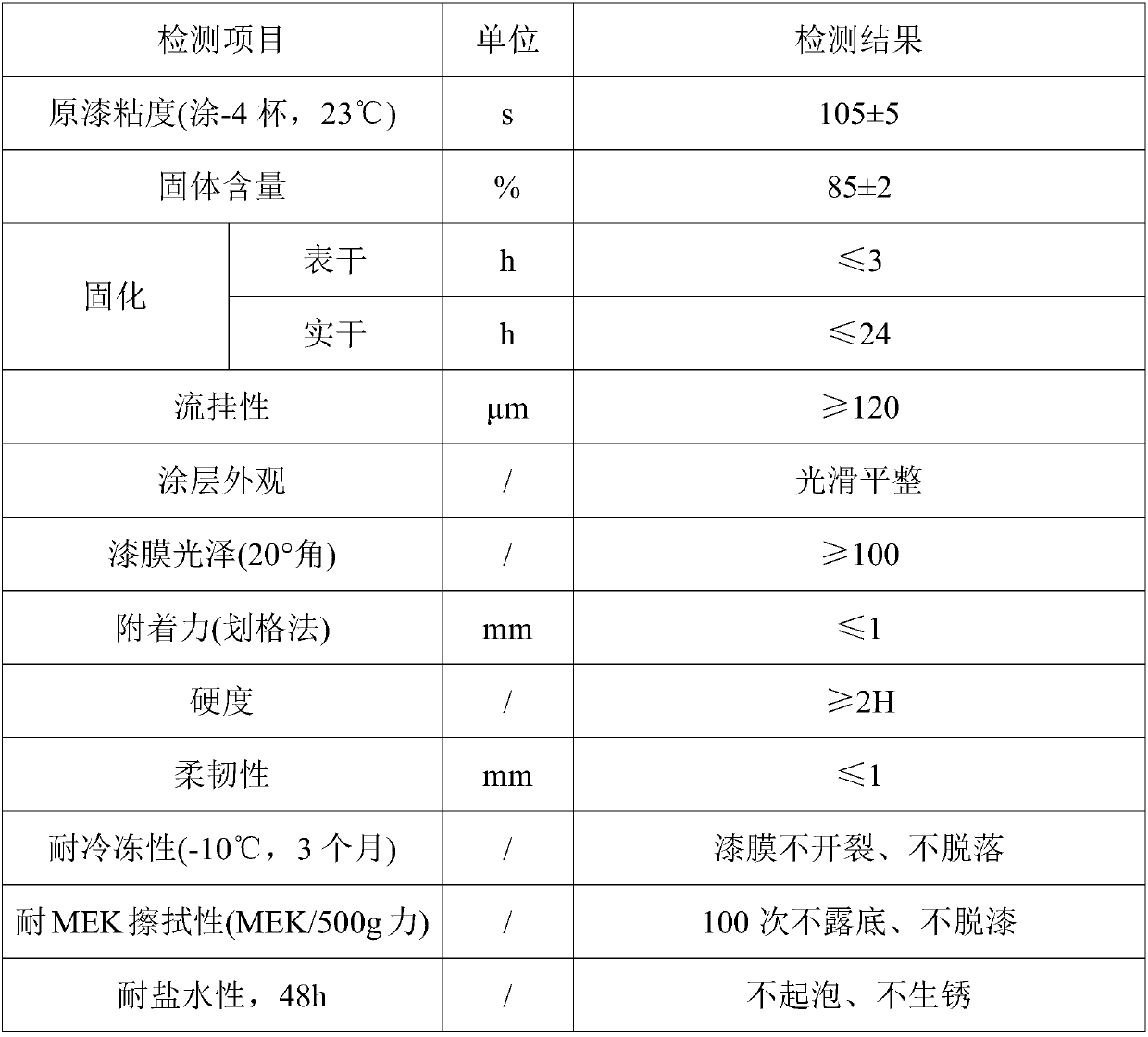

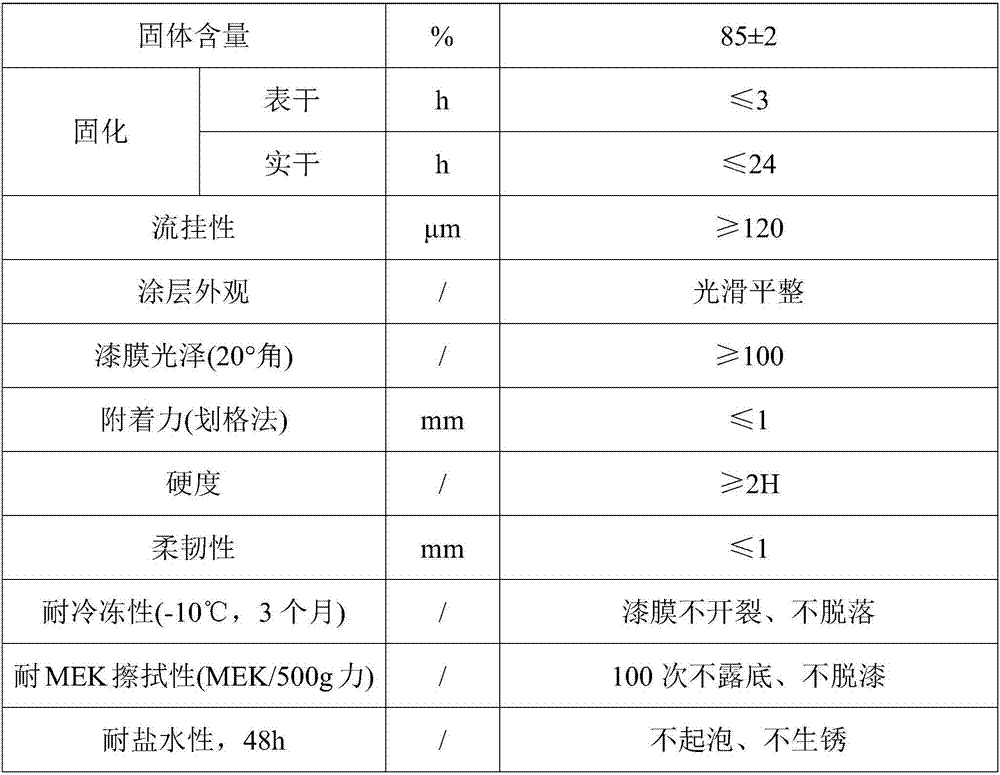

Water-based metallic heavy-duty anticorrosion epoxy interior finish paint for containers and method for preparing water-based metallic heavy-duty anticorrosion epoxy interior finish paint

InactiveCN107177276AEasy constructionImproved sag performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

The invention relates to water-based metallic heavy-duty anticorrosion epoxy interior finish paint for containers. The water-based metallic heavy-duty anticorrosion epoxy interior finish paint comprises water-based epoxy resin, UV (ultraviolet) absorbents, light stabilizers, pH (potential of hydrogen) regulators, 0.1-0.5 part of wetting and dispersing agents, deionized water, adhesion promoters, coalescing agents and water-based aliphatic amine curing agents. The water-based metallic heavy-duty anticorrosion epoxy interior finish paint has the advantages of excellent construction performance, high metal adhesive strength, extremely low irritation, zero VOC (volatile organic compound) emission and environmental friendliness.

Owner:HUIZHOU CITY HUIYANG DISTRICT JIATAI PAINT CO LTD

Chromium-containing treating fluid for stabilization of bare steel rust layer

InactiveCN104928665AImprove corrosion resistanceImproved sag performanceMetallic material coating processesAcetic acidSodium bichromate

The invention provides chromium-containing treating fluid for stabilization of a bare steel rust layer. The chromium-containing treating fluid is composed of, by weight, 0.5%-5% of sodium bichromate, 0.1%-3% of NaHSO3, 0.1%-2% of FeSO4, 0.1%-2% of FeCl3, 0.1%-1% of acetic acid, 0.1%-0.5% of triethanolamine, and the balance water. The chromium-containing treating fluid has good performance of preventing sagging of rust fluid; after the chromium-containing treating fluid is sprayed on the surface of a weathering resistant steel plain sample with oxide scale being removed, formation of a stable rust layer is promoted, and the rust layer has good corrosion resistance and is suitable for coating of bare steel.

Owner:武汉钢铁有限公司

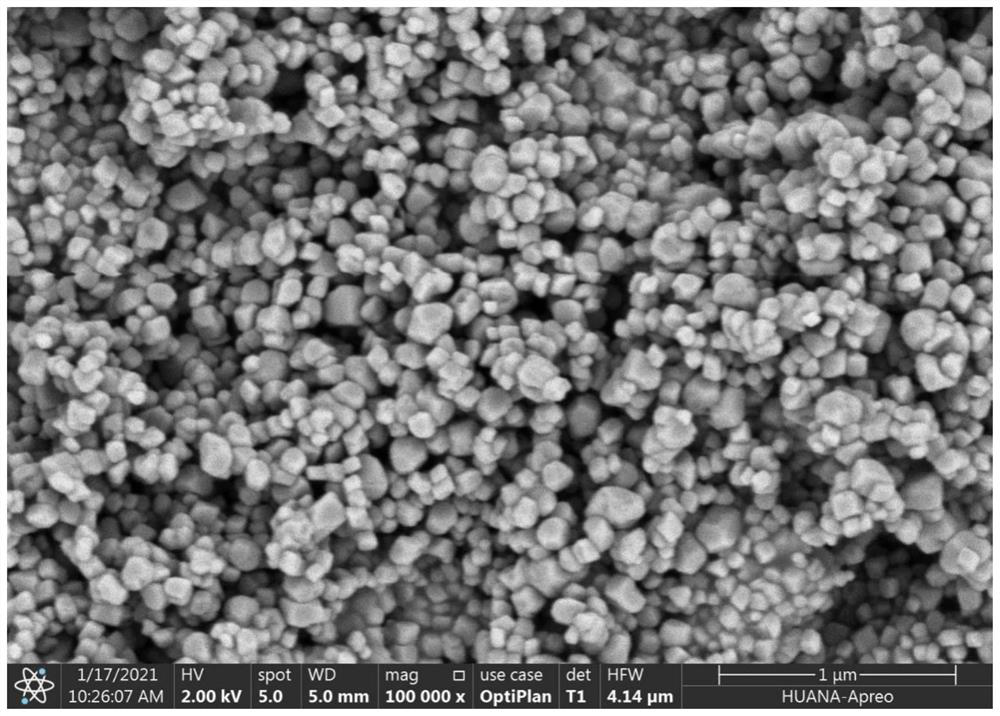

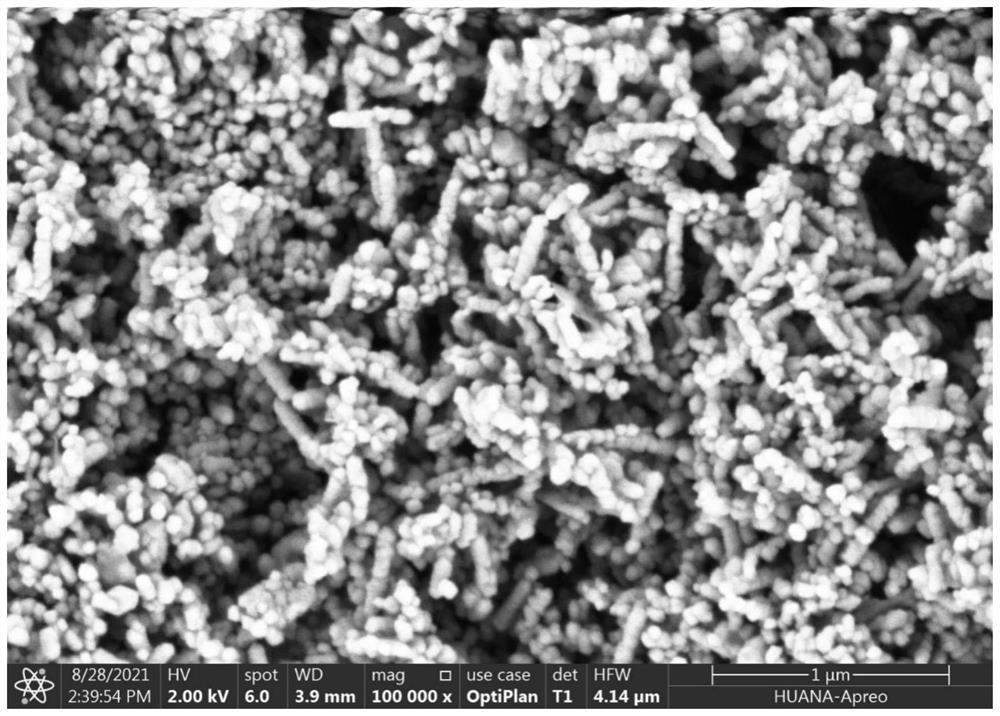

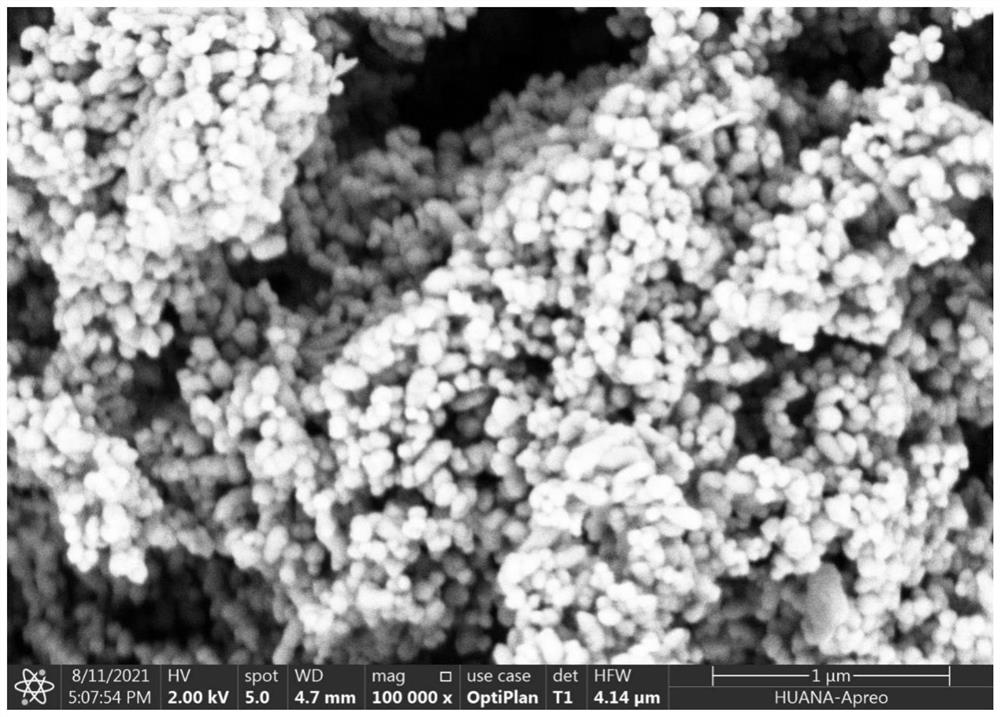

Preparation method of nano calcium carbonate for anti-sagging PVC plastifying paste

PendingCN113980491AImprove impact resistanceGood dispersionPigment treatment with macromolecular organic compoundsPigment physical treatmentActive agentAlkylphenol

The invention discloses a preparation method of nano calcium carbonate for anti-sagging PVC (polyvinyl chloride) plastifying paste. The method comprises the following steps of: pretreating suspension liquid by using a phosphoric acid compound; compounding the pretreated suspension liquid into a surfactant by using fatty acid saponification liquid, polyethylene glycol, fatty acid methyl ester sodium sulfonate and alkylphenol polyoxyethylene ether phosphate monoester to obtain a modified nano calcium carbonate suspension; and finally, carrying out filter pressing, drying and sieving to obtain the anti-sagging nano calcium carbonate for the PVC plastifying paste. According to the method, after the PVC accelerating paste is filled with the nano calcium carbonate, the nano calcium carbonate has relatively good sagging performance, flowability, viscoelasticity, dispersity, impact resistance and stability, and the nano calcium carbonate can be used as an excellent automobile chassis filler.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

High-stability waterborne epoxy resin coating for woodware

InactiveCN107936756AIncreased dispersionImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsParaffin waxFreeze-drying

The invention discloses a high-stability waterborne epoxy resin coating for woodware. The coating comprises an A component and a B component, wherein the A component comprises the following raw materials in parts by weight: 80-120 parts of bisphenol A type epoxy resin, 10-22 parts of waterborne polyurethane emulsion, 40-50 parts of filler, 4-8 parts of composite dispersant, 2-4 parts of stearic acid, 4-7 parts of polyethylene glycol, 2-5 parts of defoamer, 3-4 parts of wetting agent, and 2-4 parts of leveling agent; the B component comprises the following raw materials in parts by weight: 10-18 parts of waterborne curing agent, 2-4 parts of ethylene glycol butyl ether acetate, 4-6 parts of 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate), and 30-50 parts of deionized water; and thecomposite dispersant is prepared by the following process: mixing dichloronated polyethylene glycol, sodium hydroxide, tetrabutylammonium bromide, and p-aminophenol to obtain a mixture, performing heating and stirring on the mixture, and performing heating and stirring continuously; performing cooling, then adding gelatin, liquid paraffin and water, and performing uniform stirring; and performingcooling to room temperature, and then performing freeze drying, so as to obtain the composite dispersant.

Owner:合肥林邦门业有限公司

High-stability wood door water-based epoxy resin coating

InactiveCN107955489AImprove dispersion stabilityImprove adhesionEpoxy resin coatingsWater basedEpoxy

The invention discloses a high-stability wood door water-based epoxy resin coating which comprises first materials and second materials. The first materials comprise, by weight, 70-110 parts of main materials, 2-8 parts of aluminum nitride, 1-5 parts of melamine resin, 1-4 parts of magnesium hydroxide, 2-6 parts of expanded perlite, 1-4 parts of diatomite, 1-4 parts of mica powder, 0.5-1.2 parts of zinc oxide, 2-6 parts of composite dispersing agents, 3-7 parts of plasticizers, 1-2 parts of defoaming agents, 1-2 parts of wetting agents and 1-2 parts of leveling agents. The second comprise, byweight, 5-9 parts of aminoethyl piperazine, 1-3 parts of propanediol butyl ether, 2-4 parts of 2, 2, 4-trimethyl-1, 3-pentanediol diisobutyl acid ester and 20-40 parts of deionized water. According tothe high-stability wood door water-based epoxy resin coating, adhesive force between the coating and a coating substrate is good, toughness and hardness can be balanced, mechanical properties are excellent, and the dispersion stability of the coating is good when the coating stands for a long time.

Owner:合肥林邦门业有限公司

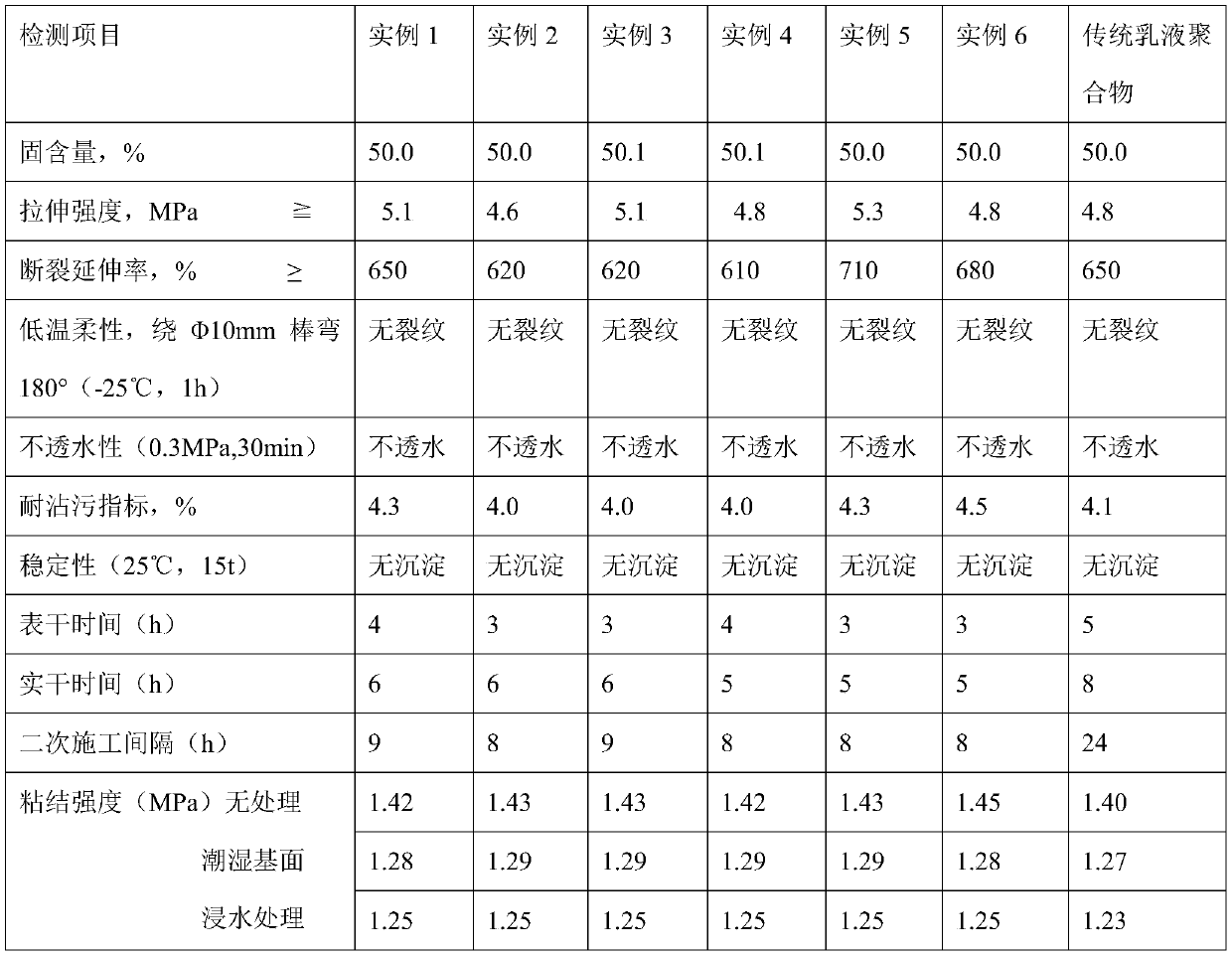

Preparation method of quaternary ammonium salt and quaternary phosphonium salt cationic core-shell emulsion polymer

ActiveCN110627963ASmall expansion coefficientGood mechanical and mechanical propertiesAnti-corrosive paintsElectrically-conductive paintsEmulsionMechanical construction

The invention discloses a preparation method of a quaternary ammonium salt and quaternary phosphonium salt cationic core-shell emulsion polymer. A cation strong hydrophilic monomer and a benzene ringrigid hydrophobic monomer are used as raw materials, in an emulsification reaction system, a high-molecular polymer waterproof coating is prepared by a series of processes such as dispersion and emulsification, constant-temperature polymerization, pH adjustment and the like. The strong hydrophilic effect enhances the adhesion force with a matrix, the rigid benzene ring provides good mechanical properties and mechanical properties, the film forming hardness and the tensile strength are enhanced, and the cross-linking agent reticular combination effect significantly improves the mechanical properties and adhesion force between polymers. The waterproof coating is more environment-friendly than an oily waterproof coating, has stronger binding force to the cement surface than an anionic waterproof coating, and has a better and more durable waterproof effect; the waterproof coating disclosed by the invention is simple in preparation method, adjustable in viscosity, good in sagging property,convenient for secondary construction and suitable for large-area mechanical construction.

Owner:HUBEI UNIV OF TECH

Plant protein liquid for bakery and preparation method of plant protein liquid

The invention relates to a plant protein liquid for bakery and a preparation method of the plant protein liquid. The plant protein liquid is prepared from the following raw materials in parts by weight: 190-194 parts of sunflower seed oil, 70-72 parts of pea protein powder, 17-20 parts of glucose, 6-7 parts of maltodextrin, 4-5 parts of starch and 817-821 parts of water. The preparation method comprises the following steps: S1, selecting raw materials in the proportion for later use; S2, putting the raw materials into an emulsion tank, and performing uniform stirring; S3, filtering the raw materials through a 40-mesh screen, introducing the mixture into a homogenizer, and performing homogenizing; S4, performing precooking, namely heating the homogenized raw materials through a sterilizer,and discharging the materials; and S5, filling the precooked protein liquid, and performing high-temperature high-pressure sterilization to obtain the plant protein liquid. The preparation method is simple in steps and convenient to operate; and the plant protein liquid prepared by the method is uniform in concentration and has the characteristics of excellent viscosity, good sagging performance and more coating amount. A coating with uniform color and relatively good brightness can be formed on the surface layer after the plant protein liquid is sprayed or brushed onto the surface layer of abakery product and is baked, and the preservation period of bakery can be prolonged.

Owner:佳顺食品(烟台)有限公司

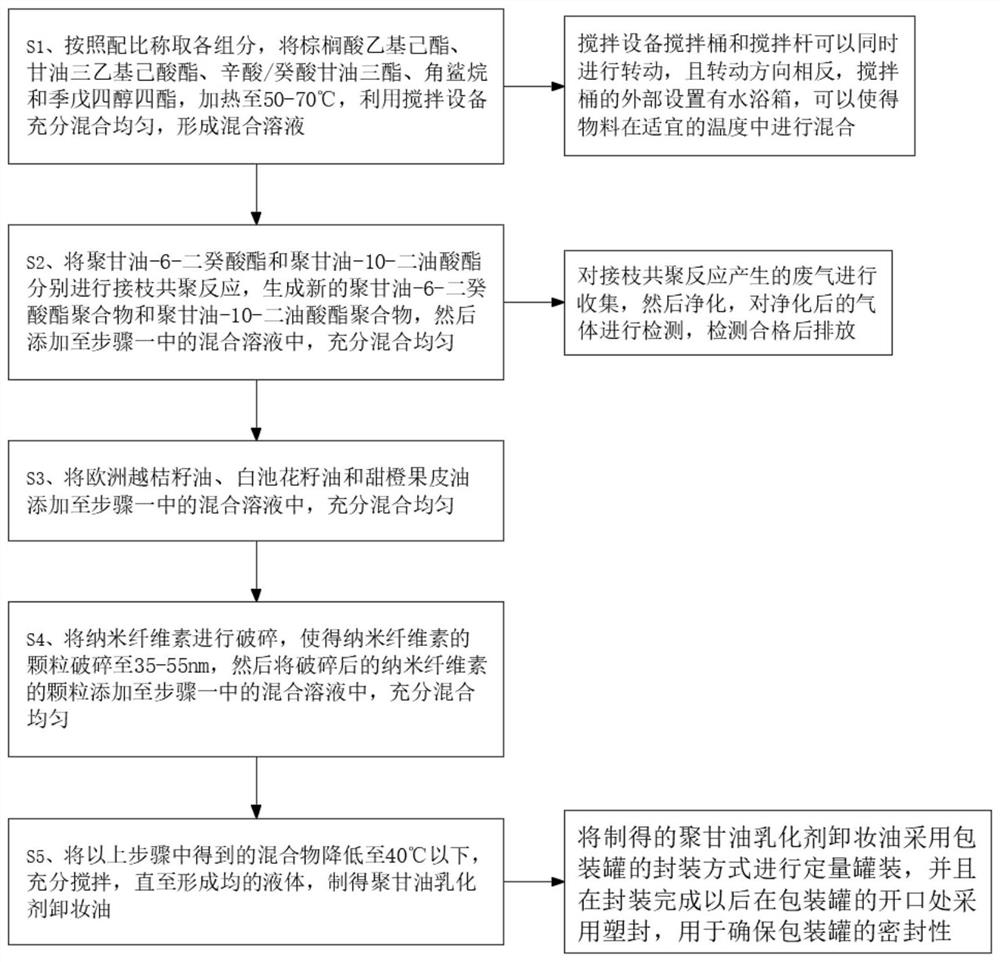

Cleansing oil of polyglycerol emulsifier and preparation method of cleansing oil

PendingCN114129463AGood emulsifying effectHigh affinityCosmetic preparationsMake-upEthylhexyl palmitateMeadowfoam seed oil

The invention discloses cleansing oil of a polyglycerol emulsifier, which is prepared from ethylhexyl palmitate, polyglycerol-6-dicaprate, glyceryl triethyl hexanoate, polyglycerol-10-dioleate, caprylic / capric triglyceride, vaccinium myrtillus seed oil, meadowfoam seed oil, sweet orange peel oil, squalane, pentaerythritol tetraester and nano cellulose. The polyglycerol emulsifier cleansing oil is prepared from the following components in parts by mass: 35 to 55 parts of ethylhexyl palmitate, 5 to 10 parts of polyglycerol-6-dicaprate, 4 to 6 parts of glycerol triethyl hexanoate, 15 to 21 parts of polyglycerol-10-dioleate, 6 to 8 parts of caprylic / capric triglyceride, 4 to 6 parts of vaccinium myrtillus seed oil, 8 to 10 parts of meadowfoam seed oil, 4 to 6 parts of sweet orange peel oil and 5 to 25 parts of squalane. When the makeup removing oil is used, the makeup removing oil using the polyglycerol emulsifier can have a good makeup removing effect, is mild and does not irritate eyes and skin, and the makeup removing oil is good in affinity, easy to clean and convenient to use.

Owner:前研化妆品科技(上海)有限公司

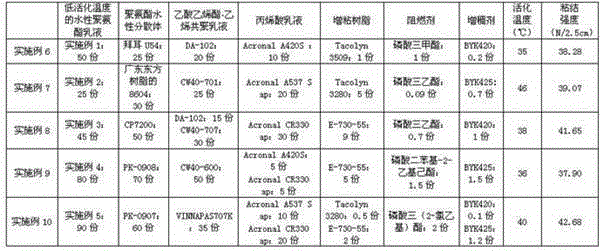

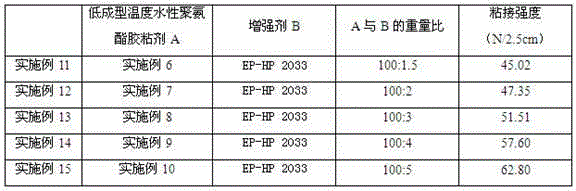

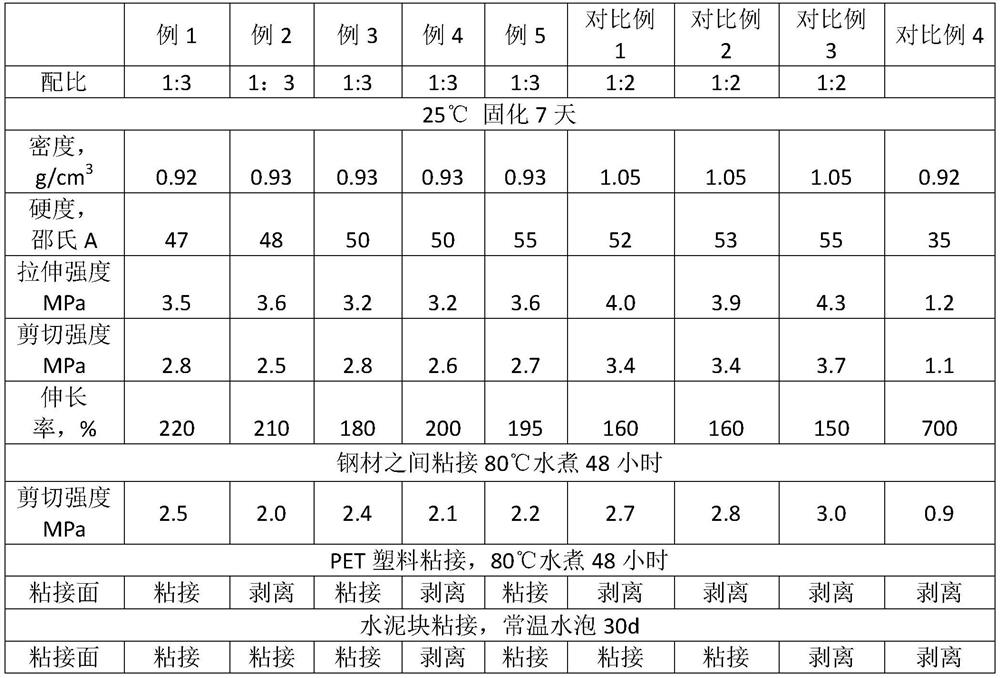

A kind of low molding temperature water-based polyurethane adhesive and preparation method thereof

ActiveCN104031596BImproved sag performanceReduce lossNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolyurethane dispersion

The invention discloses a low molding temperature water-based polyurethane adhesive and a preparation method thereof. The low molding temperature water-based polyurethane adhesive of the present invention is prepared based on a water-based polyurethane emulsion with a low activation temperature and combined with an aqueous polyurethane dispersion, EVA emulsion, and acrylic emulsion. The water-based polyurethane emulsion with a low activation temperature is mainly composed of polyol, Composed of diisocyanate, small molecule alcohol chain extender, catalyst and hydrophilic chain extender, its activation temperature is below 25°C, and the low molding temperature waterborne polyurethane adhesive prepared based on the low activation temperature waterborne polyurethane emulsion has an activation temperature of 30°C -60℃, high bonding strength, water-based emulsion, no organic solvent, 0VOC, green and environmental protection, can well meet the requirements of adhesives for car roofs. The low molding temperature water-based polyurethane adhesive of the present invention can also be used in conjunction with a certain amount of reinforcing agent, which effectively improves the bonding strength of the colloid in the later stage and ensures the heat resistance of the ceiling in the later stage of molding.

Owner:重庆中科力泰高分子材料有限公司

Surface treatment agent capable of generating red stable rust layer

InactiveCN108004535ANo strong irritating smellNo strong strong irritating smellAnti-corrosive paintsMetallic material coating processesNickel phosphateSolvent

The invention discloses a surface treatment agent capable of generating a red stable rust layer. The surface treatment agent comprises the following components in percentage by mass: 20-30% of alcohol-soluble phenolic aldehyde varnish, 2-5% of nickel phosphate, 2-5% of sodium tungstate, 2-3% of sodium silicate, 5-10% of Fe(OH)3, 30-35% of Fe2O3 and 23-33% of one or more dilution solvents. The surface treatment agent disclosed by the invention is suitable for bare steel coating; after bare steel is coated with the surface treatment agent, the red uniform stable rust layer is generated on the surface of the bare steel, and has the long-term effective properties of rust liquid sagging prevention and corrosion prevention; and the adopted surface treatment agent has no strong irritating odor, contains no chromium and nitrite, and is safe and environmentally friendly.

Owner:武汉钢铁有限公司

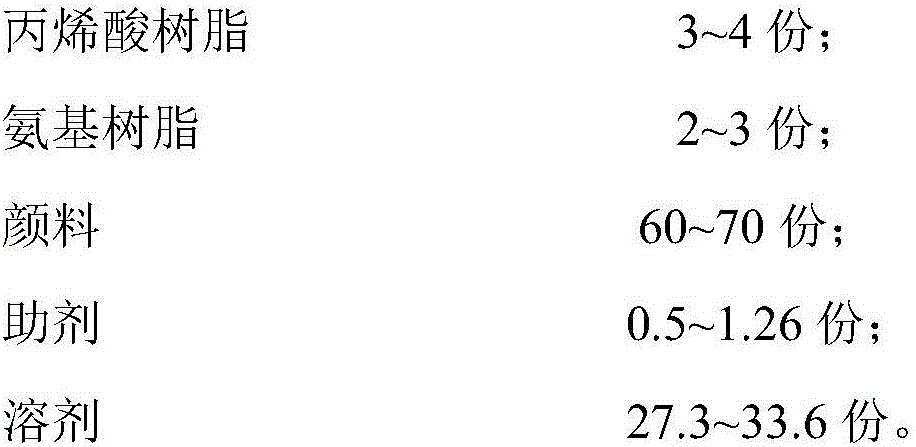

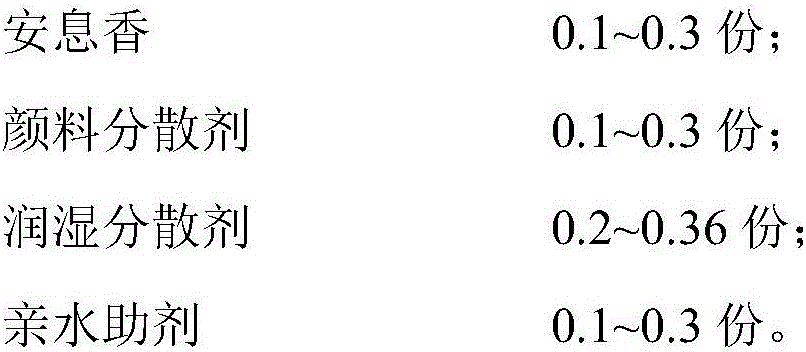

Hydrophilic primer surfacer and preparation method thereof

InactiveCN105713466AImprove surface tension and water solubilityImprove compatibilityCoatingsSolventChemistry

The invention provides a hydrophilic intermediate paint, which is characterized by comprising the following components in parts by weight: 3-4 parts of acrylic resin; 2-3 parts of amino resin; 60-70 parts of pigment; 0.5-1.26 parts of auxiliary agent parts; solvent 27.3 to 33.6 parts. The present invention also provides a preparation method of the hydrophilic mid-coat paint. The hydrophilic mid-coat paint preparation method and the mid-coat paint product of the present invention use acrylic resin and amino resin as reaction main bodies, and are equipped with pigments and fillers. The hydrophilic auxiliary agent can effectively solve the sag phenomenon caused by the incompatibility of water and oil, thereby solving the defects that occur when the oily mid-paint is matched with the water-based topcoat; the preparation method of the invention has a simple process and is suitable for industrial production.

Owner:LANGFANG NIPPON PAINT

Tensile fire resistant cable

InactiveCN108231240ARaise the draw-to-weight ratioReduce lossInsulated cablesDetails of conductive coresFiberLow smoke zero halogen

The invention belongs to the technical field wires and cables, and specifically relates to a tensile fire resistant cable. The tensile fire resistant cable comprises an internal conductor, a shieldinglayer coated outside the conductor and an insulating layer coated outside the shielding layer, wherein the conductor is stranded by carbon fiber monofilaments and nanotube monofilaments of a graphenenano material; the shielding layer is a graphene-rubber composite layer prepared by compositing graphene and rubber; the insulating layer is externally coated with a fireproof layer; and the fireproof layer is made of a 90-degree high-flame-retardant low-smoke halogen-free polyolefin material. The cable adopts the graphene nano material to serve as a force bearing part or a conductive part of thewire, so that the conductivity and the tensile capacity of the cable can be significantly improved; and the cable adopts the 90-degree high-flame-retardant low-smoke halogen-free polyolefin to serveas the fire-proof layer, so that the overall structure is simpler, thereby being simpler in overall structure, and playing an excellent effect of fire protection and heat insulation.

Owner:XIAN RENKE ELECTRONICS TECH CO LTD

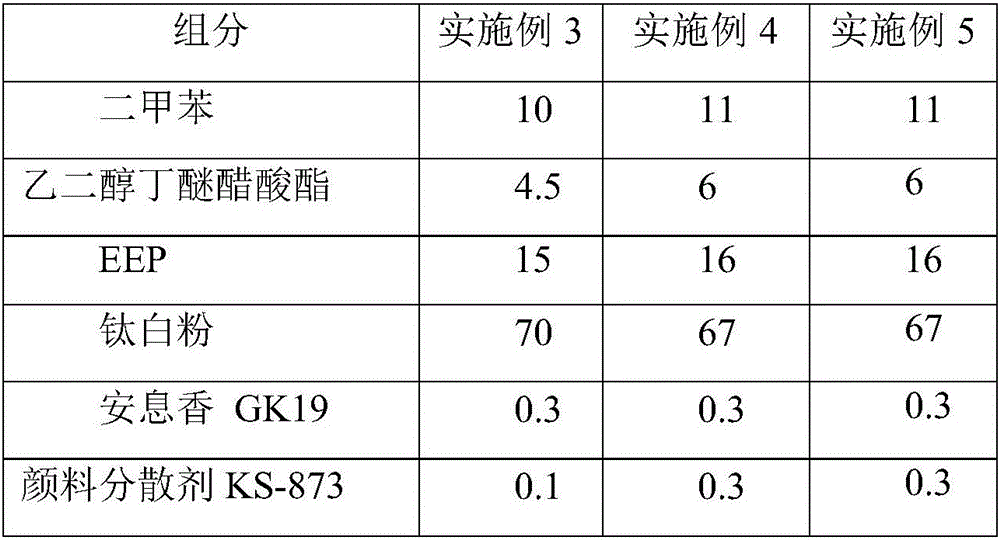

Processing method of electronegative multilayer OPC drum

InactiveCN111085417AImprove thixotropyControl UniformityPretreated surfacesCoatingsAcrylic resinPhysical chemistry

The invention discloses a processing method of an electronegative multilayer OPC drum. The processing method comprises the following steps that S1, a dispersing agent, an anti-settling agent and titanium dioxide are taken, a mixture containing one or more of phenolic resin, acrylic resin and nylon resin is added to an alcohol solution, and a charge blocking layer material solution is prepared; S2,a charge generating layer material solution and a charge transmission layer material solution are prepared; S3, pretreatment is carried out on a pixel pipe, and successively the surface of the pixelpipe is subjected to coating in sequence, so that a charge blocking layer, a charge generating layer and a charge transmission layer are sequentially formed on the surface of the pixel pipe from inside to outside; and S4, stepped baking is carried out on the pixel pipe, then the pixel pipe is taken out for aging, and the finished OPC drum is obtained. According to the processing method of the electronegative multilayer OPC drum, modification is carried out on the charge blocking layer material arranged on the OPC drum in a coating manner, and the thixotropic property of the material solution is improved, so that the good sagging property is achieved when the coating thickness is relatively thick, and the uniformity of the subsequent coating is guaranteed when the thickness of the charge blocking layer is increased.

Owner:苏州恒久光电科技股份有限公司 +1

High temperature corrosion and high humidity corrosion resisting agent coating surface of bare steel, and preparation method of high temperature corrosion and high humidity corrosion resisting agent

InactiveCN105908173AExcellent anti-rust fluid sag performanceGood corrosion resistanceMetallic material coating processesSodium silicateSodium triphosphate

The invention discloses a high temperature corrosion and high humidity corrosion resisting agent coating the surface of bare steel, and a preparation method of the high temperature corrosion and high humidity corrosion resisting agent. The acid rain corrosion resisting agent includes, by weight, 0.3%-2% of sodium tripolyphosphate, 0.3%-2% of copper sulfate, 0.1%-1% of sodium tungstate, 0.1%-1% of hexafluorozirconic acid, 0.1%-1% of phytic acid, 0.1%-1% of sodium silicate, and the balance water. The high temperature corrosion and high humidity corrosion resisting agent can be prepared by evenly mixing the sodium tripolyphosphate, the copper sulfate, the sodium tungstate, the hexafluorozirconic acid, the phytic acid, the sodium silicate and water. The high temperature corrosion and high humidity corrosion resisting agent coating the surface of the bare steel is free of strong irritating odor and chrome, and has excellent rust liquid sagging prevention performance. After the high temperature corrosion and high humidity corrosion resisting agent coating the surface of the bare steel is sprayed to the surface of a bare weather-resistant steel sample with oxide skin removed, a rust layer has excellent corrosion resistance.

Owner:武汉钢铁有限公司

Highly anticorrosive epoxy coating and preparation method thereof

InactiveCN108976979AEasy constructionImproved sag performanceAnti-corrosive paintsEpoxy resin coatingsFatty amineMetal

The invention relates to the field of coatings and in particular discloses a highly anticorrosive epoxy coating. The highly anticorrosive epoxy coating is composed of the following raw materials: aqueous epoxy resin, a UV (Ultraviolet) absorbent, a light stabilizer, a pH adjuster, wetting dispersant 0.1-0.5 part, deionized water, a coalescing agent and an aqueous fatty amine curing agent. The highly anticorrosive paint has good construction performance, strong adhesion to metal, extremely low irritation and no emission of VOC (Volatile Organic Compounds), and is environment-friendly.

Owner:牛宝芬

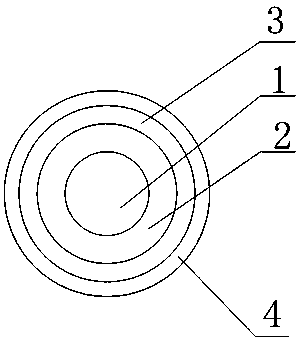

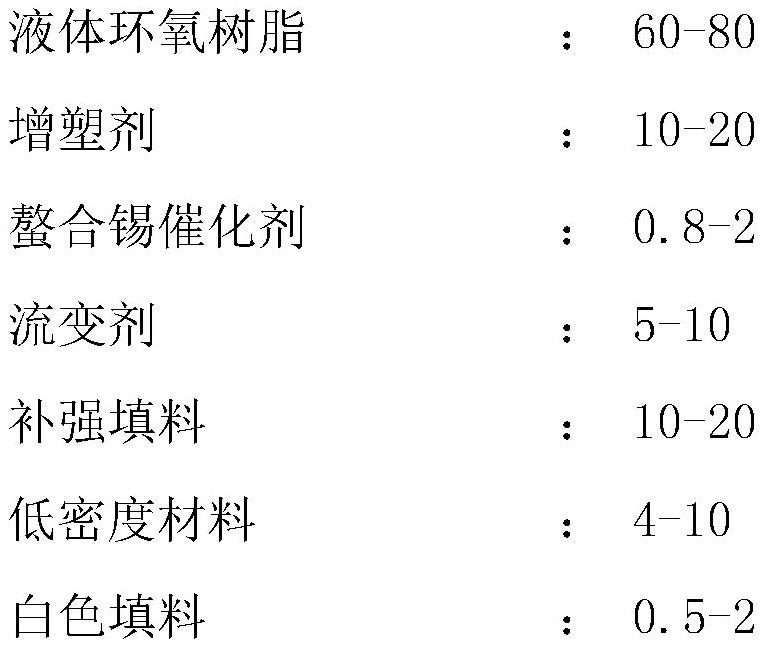

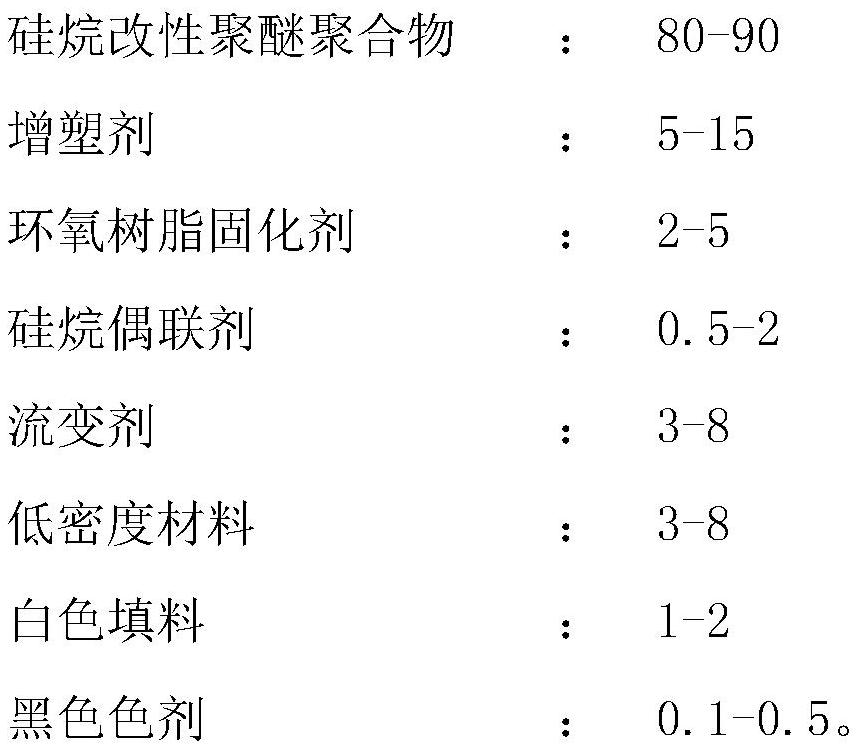

Low-density waterproof elastic two-component sealant

PendingCN112341974AHigh strengthGood adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention discloses a low-density waterproof elastic two-component sealant. A component A is composed of liquid epoxy resin with excellent bonding strength, a component B is composed of silane modified polyether with excellent elongation ability, and the ratio of the component A to the component B is 1: 3. The high strength, adhesive strength and water resistance of the liquid epoxy resin areutilized, the high elongation of the silane modified polyether polymer is matched to form a brand-new elastic sealant, the bridging effect of the silane coupling agent is utilized to improve the strength of the sealant again, the chemical adsorption reaction on the surface of the silane coupling agent is utilized to improve the adhesive strength, the density of the sealant is reduced by utilizingthe low-density filler, so that the sealant can be strongly bonded without primer, and is outstanding in water resistance, moderate in viscosity, high in sagging performance and extremely convenient and easy to construct; and the sealant is high in water-resistant adhesion, low in density and high in thixotropy.

Owner:DALIAN KAIHUA NEW TECH ENG

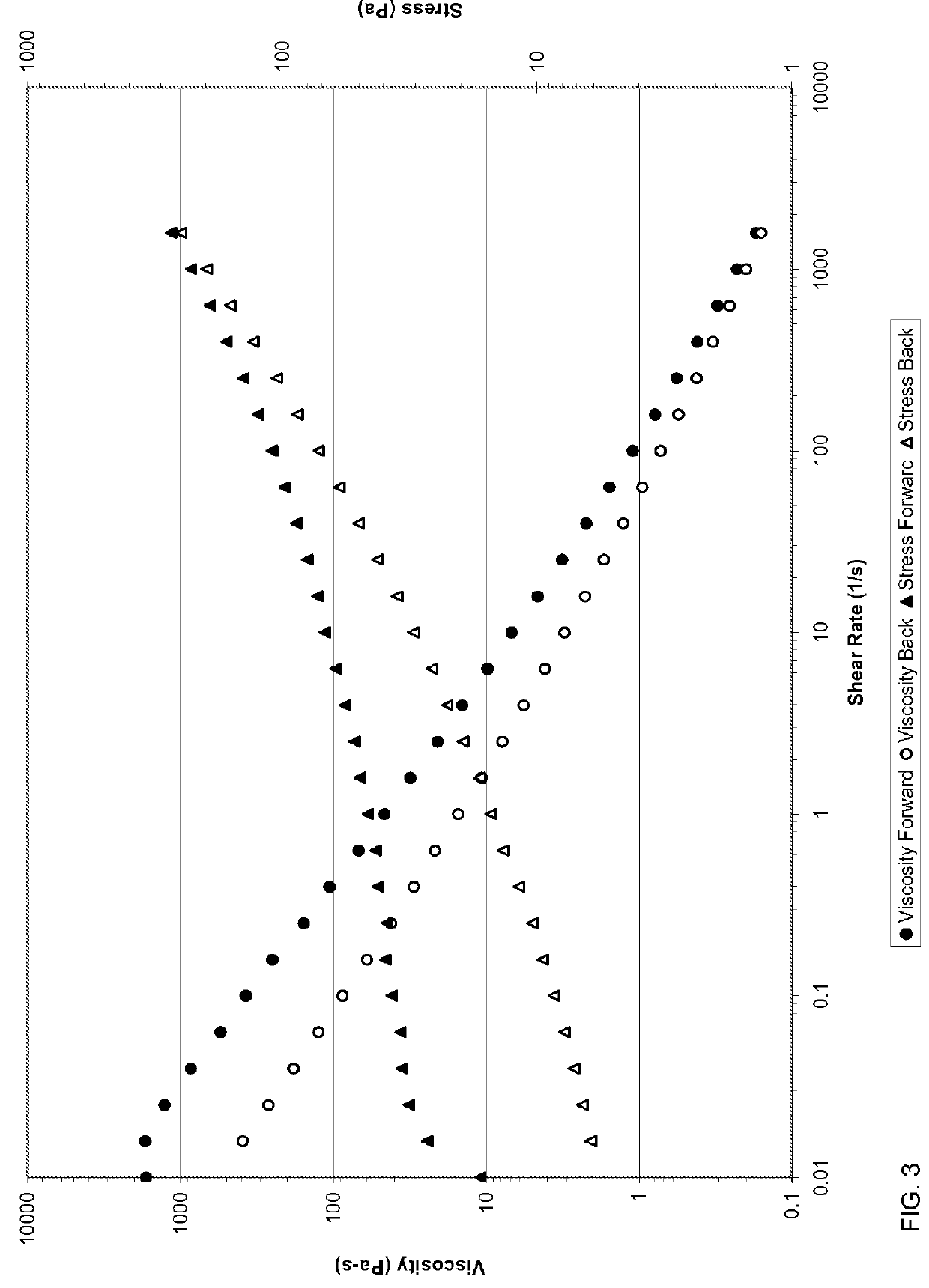

Vinyl chloride resin aggregate particles, process for producing same, and glove obtained using same

InactiveUS20140237702A1Improved sag performanceNon-infiltrating propertyGlovesSynthetic resin layered productsPolymer sciencePhthalic acid

The present invention provides: vinyl chloride-based resin aggregate particles that can be produced through a heat treatment while inhibiting scale formation within a vessel for the heat treatment and that provide a plastisol with non-infiltrating property and a satisfactory sagging property; a process for producing the particles; and a glove obtained using the particles. The vinyl chloride-based resin aggregate particles of the present invention are characterized in that the aggregate particles have a mean volume particle diameter of 10 to 60 μm, the percentage of particles having a particle diameter of 10 to 60 μm is at least 50 vol. %, and a plastisol containing 100 weight parts of the aggregate particles and 160 weight parts of di-2-ethylhexyl phthalate satisfies the relationship 3≦η70 / η40≦1000 where η40 is the viscosity at a shear rate of 1 s−1 of the plastisol that has been retained at 40° C. for 10 minutes and η70 is the viscosity at a shear rate of 1 s−1 of the plastisol that has been warmed from 40° C. at 10° C. / min. and retained at 70° C. for 3 minutes. The vinyl chloride-based resin aggregated particles are obtained by flocculating a vinyl chloride-based resin through a two-stage heat treatment consisting of a primary heat treatment and a secondary heat treatment.

Owner:KANEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com