Hydrophilic primer surfacer and preparation method thereof

A hydrophilic and painting technology, applied in the direction of coating, etc., can solve the problems of unstable spraying effect, complicated wettability technology, high cost investment, etc., to improve matching, solve the problem of leaving marks and sagging, and improve The effect of sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

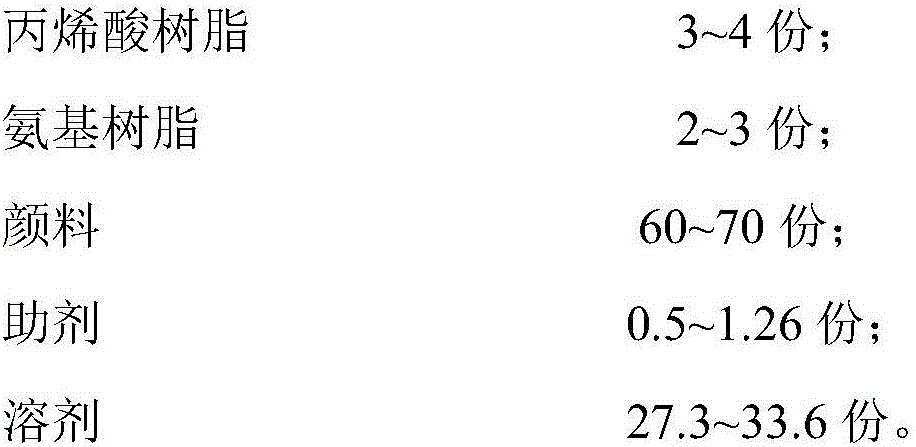

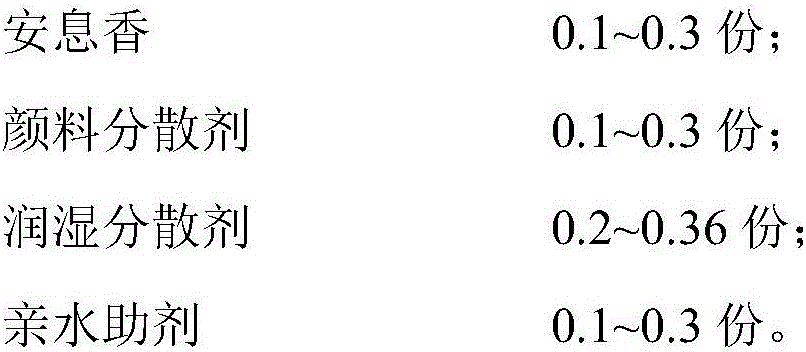

Method used

Image

Examples

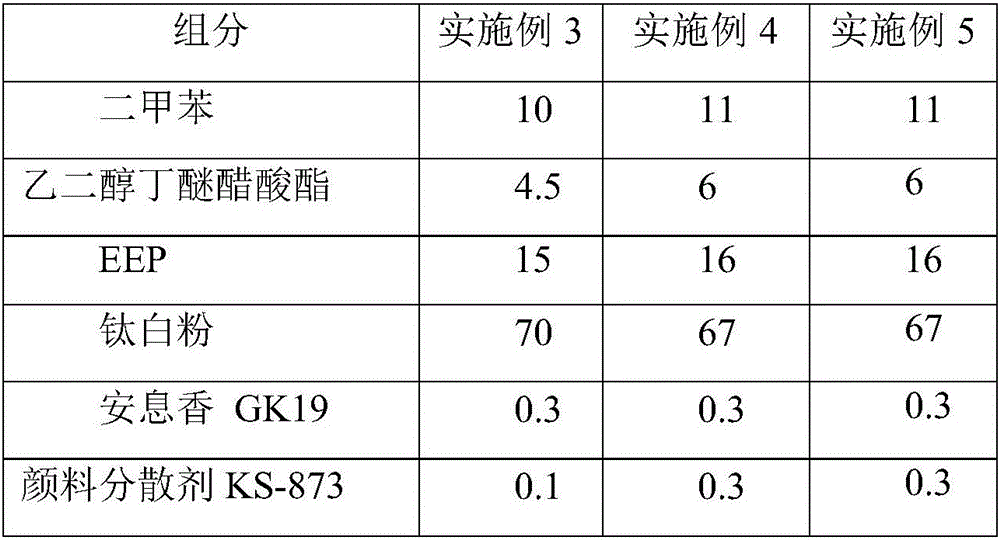

Embodiment 3

[0067] The preparation method of the hydrophilic intermediate paint of embodiment 3 may further comprise the steps:

[0068] Step 1: Soak 70 parts of titanium dioxide pigment with 10 parts of xylene solvent, 4.5 parts of ethylene glycol butyl ether acetate, and 15 parts of EEP for 2 hours, then add 3 parts of acrylic resin PRS-1015 and 0.1 part of pigment to disperse under stirring Agent KS-873 continues to stir for 20 minutes before sanding, the fineness is less than 5um;

[0069] Step 2: filtering the material obtained in step 1 after sand grinding;

[0070] Step 3: After filtering, add 3 parts of amino resin 20SE under stirring;

[0071] Step 4: Continue to add 0.16 parts of wetting and dispersing agent BYK161, 0.15 parts of wetting and dispersing agent BYK182, and 0.3 parts of benzoin GK19 under stirring state, then sand mill, the fineness is less than 5um, and finally add 0.1 part of hydrophilic additive BYK3560;

[0072] Step 5: Add 0.15 parts of DBE (dibasic acid este...

Embodiment 4

[0075] The preparation method of the hydrophilic intermediate paint of embodiment 4 may further comprise the steps:

[0076] Step 1: soak 67 parts of titanium dioxide pigment with 11 parts of xylene solvent, 6 parts of ethylene glycol butyl ether acetate, and 16 parts of EEP for 2 hours, then add 4 parts of acrylic resin and 0.3 parts of pigment dispersant to continue stirring Sanding after 20 minutes, the fineness is less than 5um;

[0077] Step 2: filtering the material obtained in step 1 after sand grinding;

[0078] Step 3: After filtering, add 2 parts of amino resin under stirring state;

[0079] Step 4: Continue to add 0.16 parts of wetting and dispersing agent BYK161, 0.2 parts of wetting and dispersing agent BYK182, and 0.3 parts of benzoin GK19 under stirring state, then sand mill, the fineness is less than 5um, and finally add 0.2 parts of hydrophilic additive BYK3560;

[0080] Step 5: adding 0.2 parts of DBE (dibasic acid ester), 0.2 parts of S-100 solvent, and 0....

Embodiment 5

[0083] The preparation method of the hydrophilic intermediate paint in Example 5 is the same as that in Example 4, and will not be repeated here.

[0084] The performance parameters of the hydrophilic intermediate coatings prepared in Examples 1 to 5 are shown in Table 3 below:

[0085] Table 3: Comparison table of performance parameters of hydrophilic medium paint

[0086] performance parameters

Example 1

Example 2

Example 3

Example 4

Example 5

Surface tension (dry film)

65

67

69

73

75

Water flow length (CM)

0

0

2

5

6

[0087] The solvent used in the present invention provides the solubility of raw materials for the hydrophilic medium paint of the present invention; benzoin is an anti-pinhole auxiliary agent, which can effectively prevent shrinkage; Flexibility; amino resin provides the crosslinking density of the hydrophilic medium paint of the present invention; the remaining components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com