Preparation method of quaternary ammonium salt and quaternary phosphonium salt cationic core-shell emulsion polymer

A technology of emulsion polymer and quaternary phosphonium salt, which is applied in coatings, anti-corrosion coatings, conductive coatings, etc., can solve the problems of general adhesion, poor waterproof performance and aging resistance of coatings, and achieve good sagging and good mechanical properties Performance and mechanical properties, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

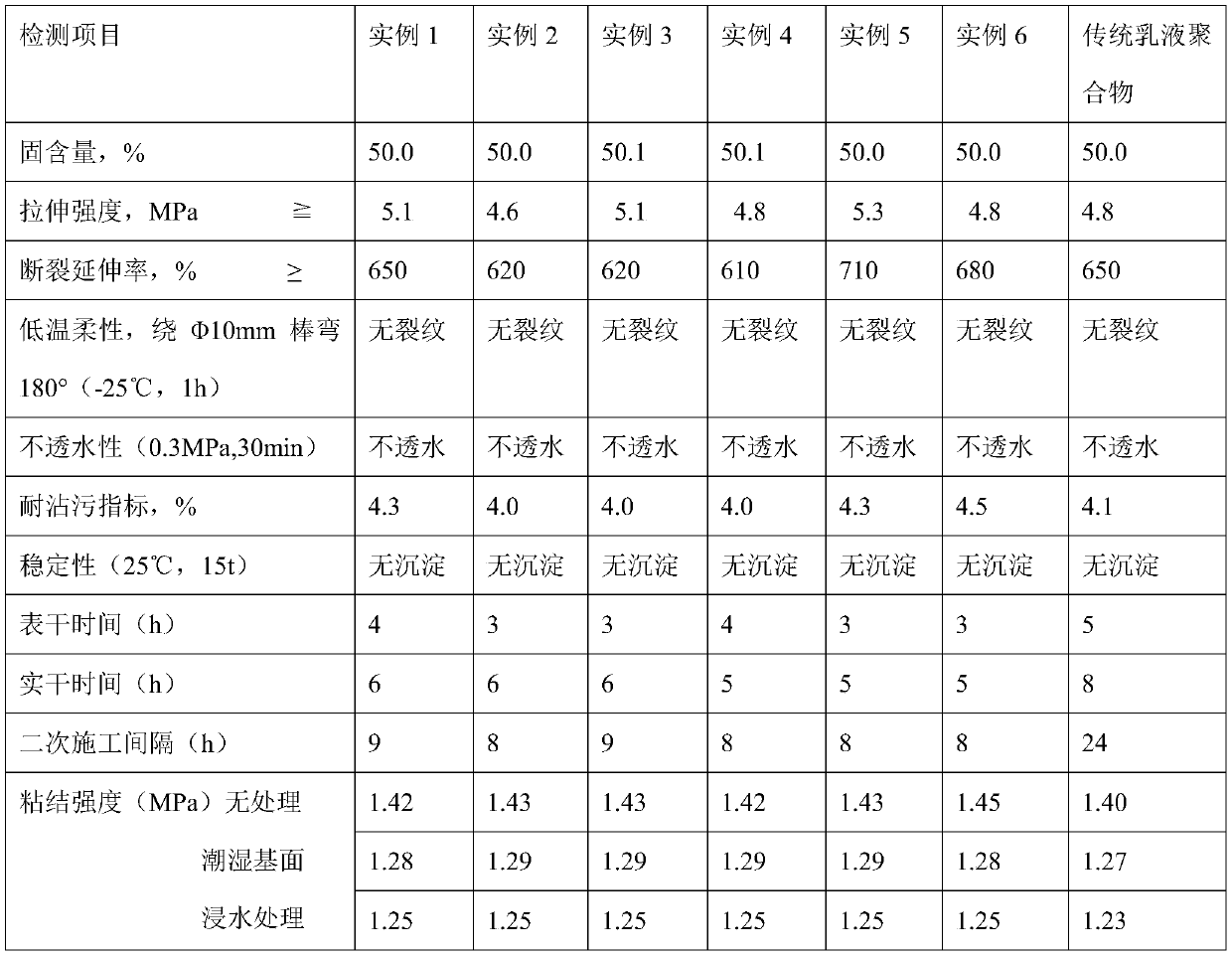

Examples

example 1

[0050] A method for preparing a quaternary ammonium salt quaternary phosphonium salt cationic core-shell emulsion polymer, which is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and the components and process parameters are as follows:

[0051] Combination of tetrabutylphosphine acetate and tetramethylammonium fluoride with a mass ratio of 1:1: 4.2

[0052] 1-Phenylvinylboronic acid: 13.8 parts

[0053] Dicyclohexyl peroxydicarbonate: 0.25 parts

[0054] Sodium hypophosphite: 0.45 parts

[0055] Composition of tetrabutylphosphine fluoride and benzyltrimethylammonium bromide with a mass ratio of 1:1: 8 parts

[0056] Isooctyl acrylate: 241 parts

[0057] 1-Phenylvinylboronic acid: 200 parts

[0058] Dimethyl azobisisobutyrate: 4 parts

[0059] Hydroxyethyl Phthalic Anhydride Dimethacrylate: 4 parts

[0060] Triisopropanolamine: 1.8 parts

[0061] Ammonia: 1.2 parts

[0062] Composition of 2,2,2-trifluoroethyl methacrylat...

example 2

[0070] A method for preparing a quaternary ammonium salt quaternary phosphonium salt cationic core-shell emulsion polymer, which is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and the components and process parameters are as follows:

[0071] Combination of tetrabutylphosphine acetate and tetramethylammonium fluoride with a mass ratio of 1:1: 4.2

[0072] 1-Phenylvinylboronic acid: 13.8 parts

[0073] Dicyclohexyl peroxydicarbonate: 0.25 parts

[0074] Sodium hypophosphite: 0.45 parts

[0075] Composition of tetrabutylphosphine fluoride and benzyltrimethylammonium bromide with a mass ratio of 1:1: 8 parts

[0076] Isooctyl acrylate: 241 parts

[0077] Composition of 1-allyl-4-fluorobenzene and 4-methoxy-2-vinylaniline with a mass ratio of 2:1: 200 parts

[0078] Dimethyl azobisisobutyrate: 4 parts

[0079] Hydroxyethyl Phthalic Anhydride Dimethacrylate: 4 parts

[0080] Triisopropanolamine: 1.7 parts

[0081] Ammonia: ...

example 3

[0090] A method for preparing a quaternary ammonium salt quaternary phosphonium salt cationic core-shell emulsion polymer, which is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and the components and process parameters are as follows:

[0091] Combination of tetrabutylphosphine acetate and tetramethylammonium fluoride with a mass ratio of 1:1: 4.2

[0092] 1-Phenylvinylboronic acid: 13.8 parts

[0093] Dicyclohexyl peroxydicarbonate: 0.25 parts

[0094] Sodium hypophosphite: 0.45 parts

[0095] Composition of tetrabutylphosphine fluoride and benzyltrimethylammonium bromide with a mass ratio of 1:1: 8 parts

[0096] Composition of ethyl acrylate and isooctyl acrylate with a mass ratio of 2:1: 240 parts

[0097] 1-Phenylvinylboronic acid: 200 parts

[0098] Composition of azobisisobutyronitrile and azobisisoheptanonitrile with a mass ratio of 1:4: 4 parts

[0099] Hydroxyethyl Phthalic Anhydride Dimethacrylate: 4 parts

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com