Halogen-free flame-retardant solvent-free double-curing ink composition and preparation method thereof

An ink composition, dual-curing technology, applied in inks, household appliances, applications, etc., can solve problems such as non-compliance with the requirements for flame retardant use of electronic materials, increased thermal expansion coefficient of ink cured products, and reduced thermal deformation temperature of ink cured products. , to achieve the effect of ensuring thermal stability, reducing viscosity, and reducing fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

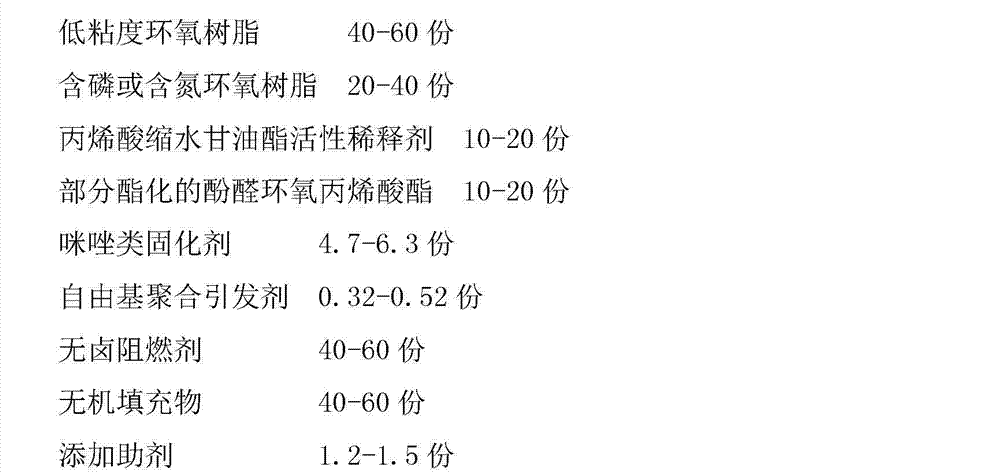

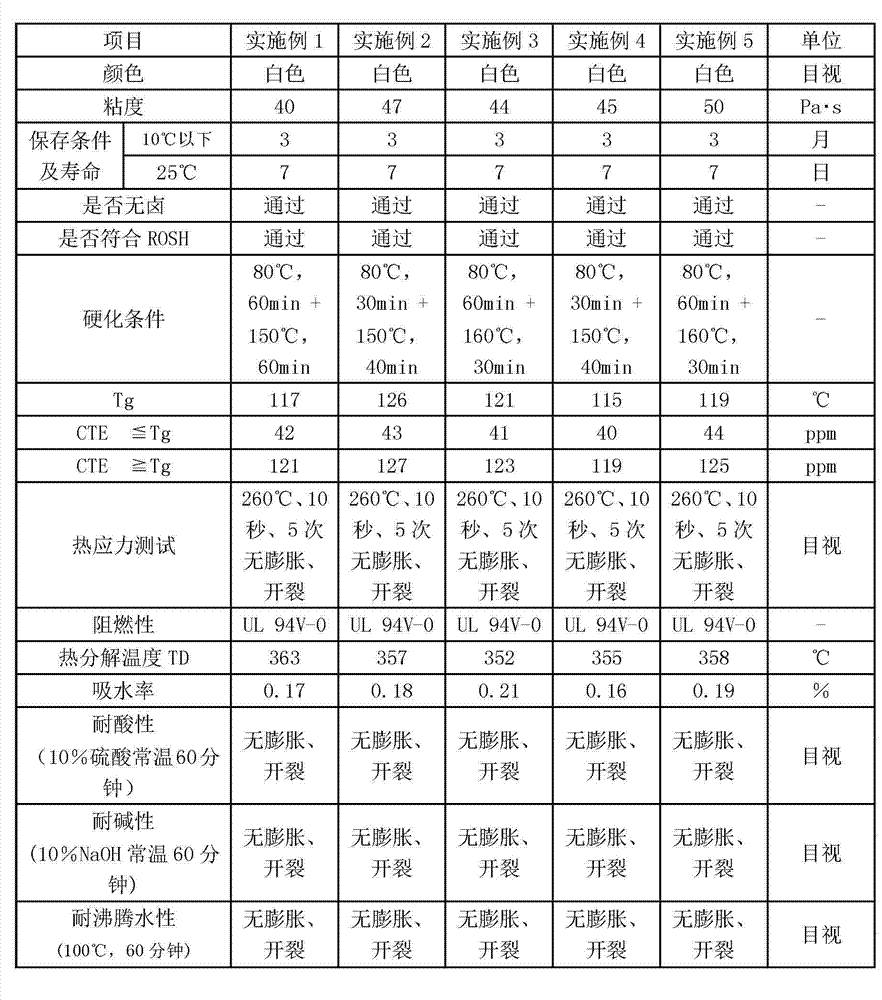

[0030] Example 1: Accurately weigh 24g of low-viscosity bisphenol A glycidyl ether, 26g of low-viscosity bisphenol F-type glycidyl ether, 10g of allyl glycidyl ether, 10g of low-viscosity hydantoin epoxy resin, and phosphatized bisphenol A Epoxy resin 10g, glycidyl methacrylate 10g, partially methacrylated (esterification rate 20%) phenol novolac epoxy resin 10g, 2-11 alkyl imidazole (C11Z) 4.7g, diphenyl peroxide Acyl (BPO) 0.34g, aluminum hydroxide 40g, magnesium hydroxide 20g, calcium carbonate 40g, defoamer 1g, after the above materials are uniformly dispersed in the pre-disperser, transferred to the three-roll mill for grinding, after 17 grinding Finally, test the viscosity of the ink to meet the index requirements, stop the grinding, then stir evenly in the disperser, filter to remove the coarser powder particles, and fill it to obtain a uniform and fine ink product. The product performance is shown in Table 1.

Embodiment 2

[0032] Accurately weigh 20g of low-viscosity bisphenol A glycidyl ether, 15g of low-viscosity bisphenol F glycidyl ether, 10g of low-viscosity allyl glycidyl ether, 10g of hydantoin epoxy resin, phosphating novolak epoxy resin (P%= 2.5%) 10g, glycidyl methacrylate 15g, partially methacrylated (esterification rate 38%) o-cresol novolac epoxy resin 20g, 1-nitrile ethyl-2-ethyl-4-methyl Imidazole (2E4MZ-CN) 6.2g, dibenzoyl peroxide (BPO) 0.32g, aluminum hydroxide 30g, calcium carbonate 50g, phenoxypolyphosphazene (SPB) 20g, defoamer 1g, put the above materials in After uniform dispersion in the pre-disperser, transfer to a three-roll mill for grinding. After 19 grindings, test the viscosity of the ink and meet the index requirements. Stop grinding, then stir evenly in the disperser, filter to remove coarse powder particles, pour Packed to get uniform and delicate ink products. The product performance is shown in Table 1.

Embodiment 3

[0034] Accurately weigh 20g of low-viscosity bisphenol A glycidyl ether, 15g of low-viscosity bisphenol F glycidyl ether, 5g of allyl glycidyl ether, 20g of low-viscosity hydantoin epoxy resin, phosphating phenol novolac epoxy resin (P% =2.8%) 20g, glycidyl methacrylate 10g, partially methacrylated (esterification rate 27%) bisphenol A novolak epoxy resin 10g, 2,4-diamino-6-[2'- Methylimidazolyl-(1')]-ethyl-s-triazine (2MZ-A) 5.8g, azobisisobutylcyanide (AIBN) 0.45g, aluminum hydroxide 30g, calcium carbonate 60g, melamine polyphosphate Salt (MPP) 10g, defoamer 1.2g, after the above materials are uniformly dispersed in the pre-disperser, transfer to the three-roll mill for grinding, after 16 grinding, test the viscosity of the ink, and stop the grinding, and then Stir evenly in a disperser, filter to remove coarse powder particles, and fill to obtain a uniform and fine ink product. The product performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com