Filler compound and copper clad laminate made of same

A technology of copper-clad laminates and compositions, which is applied in the field of copper-clad laminates, can solve the problems of narrow use range and no fluidity of resin composites, and solve the problem of dispersion, wide use range, and reduce expansion The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

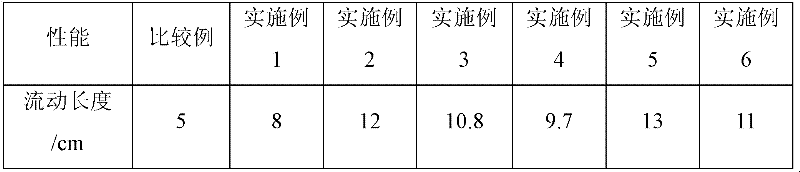

Examples

Embodiment 1

[0027] (1) Use silane coupling agent (Shin-Etsu Chemical, product name KBM403) with epoxy group to 20 parts by weight spherical silica (Toyota Tsusho, SOC2, D50=0.5um) and 80 parts by weight spherical silica (Tongda Wei Peng Electric Co., Ltd., D50=3um) for surface treatment, the amount of treatment agent is 5% of the total weight of spherical silica, then add butanone solution, after high-speed grinding, prepare a filler composition with a solid content of 70% .

[0028] (2) 100 parts by weight of brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19%, product name DER530), 24 parts by weight of novolak resin (Nippon Qunrong, hydroxyl equivalent 105, product name TD2090), 0.05 parts by weight 2-methylimidazole, the filler composition prepared by 100 parts by weight, be dissolved in ethylene glycol monobutyl ether solvent, be mixed with the glue of 70wt%, impregnate glass fiber cloth then, pass through After heating and drying, a prep...

Embodiment 2

[0030] (1) Use silane coupling agent (Shin-Etsu Chemical, product name KBM403) with epoxy group to 30 parts by weight spherical silica (Toyota Tsusho, SOC2, D50=0.5um) and 70 parts by weight spherical silica (Tongda Wei Peng Electric Co., Ltd., D50=3um) for surface treatment, the amount of treatment agent is 5% of the total weight of spherical silica, then add butanone solution, after high-speed grinding, prepare a filler composition with a solid content of 70% .

[0031] (2) 100 parts by weight of brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19%, product name DER530), 24 parts by weight of novolak resin (Nippon Qunrong, hydroxyl equivalent 105, product name TD2090), 0.05 parts by weight 2-methylimidazole, the filler composition prepared by 100 parts by weight, be dissolved in ethylene glycol monobutyl ether solvent, be mixed with the glue of 70wt%, impregnate glass fiber cloth then, pass through After heating and drying, a prep...

Embodiment 3

[0033](1) Use silane coupling agent (Shin-Etsu Chemical, product name KBM403) with epoxy group to 40 parts by weight spherical silica (Toyota Tsusho, SOC2, D50=0.5um) and 60 parts by weight spherical silica (Tongda Wei Peng Electric Co., Ltd., D50=3um) for surface treatment, the amount of treatment agent is 5% of the total weight of spherical silica, then add butanone solution, after high-speed grinding, prepare a filler composition with a solid content of 70% .

[0034] (2) 100 parts by weight of brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19%, product name DER530), 24 parts by weight of novolak resin (Nippon Qunrong, hydroxyl equivalent 105, product name TD2090), 0.05 parts by weight 2-methylimidazole, the filler composition prepared by 100 parts by weight, be dissolved in ethylene glycol monobutyl ether solvent, be mixed with the glue of 70wt%, impregnate glass fiber cloth then, pass through After heating and drying, a prepr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com