Bare steel rust layer transforming agent for salt-contained environment

A rust layer conversion agent and bare steel technology, which is applied in the coating process of metal materials, etc., to achieve the effect of excellent anti-rust liquid sag performance and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

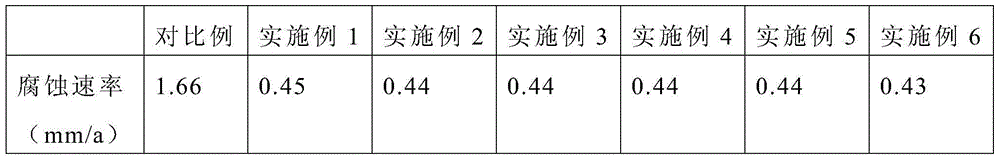

Examples

Embodiment 1

[0012] A bare steel rust conversion agent used in saline environment, its components by weight percent, titanium oxysulfate accounted for 0.1%, zinc dihydrogen phosphate accounted for 5%, sodium pyrophosphate accounted for 0.1%, tannic acid accounted for 2%, copper sulfate 0.1%, water 92.7%.

Embodiment 2

[0014] A bare steel rust conversion agent used in saline environment, its components by weight percent, titanium oxysulfate accounted for 3%, zinc dihydrogen phosphate accounted for 0.5%, sodium pyrophosphate accounted for 3%, tannic acid accounted for 0.1%, copper sulfate 3%, water 90.4%.

Embodiment 3

[0016] A bare steel rust conversion agent used in saline environment, its components by weight percentage, titanium oxysulfate accounted for 1%, zinc dihydrogen phosphate accounted for 1.5%, sodium pyrophosphate accounted for 2.5%, tannic acid accounted for 0.5%, copper sulfate 2%, water 92.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com