Patents

Literature

54results about How to "No strong irritating smell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

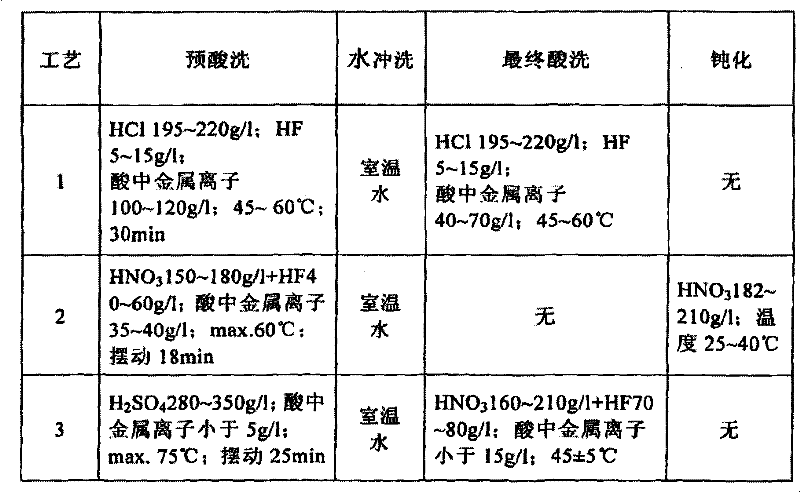

Novel stainless steel acid-washing passivation liquid

ActiveCN102653868AReduce pollutionLow running costMetallic material coating processesHydrofluoric acidAcid washing

The invention relates to a novel stainless steel acid-washing passivation liquid which comprises inorganic acid, penetrant, oxidant and corrosion inhibitor. The stainless steel acid-washing passivation liquid does not generate violent pungent odor or yellow acid mist in the application process, thereby avoiding hurting the skin, reducing the air pollution and lowering the cost. The stainless steel acid-washing passivation liquid is easy to use: the stainless steel acid-washing passivation liquid is poured into a tank, and soaks the stainless steel at normal temperature without heating; and the washing speed is about 50% higher than those of the acid-washing passivation liquid (paste) in the existing market and the acid-washing passivation liquid containing nitric acid and hydrofluoric acid, and the washing quantity is as 3.2 times or so as the like products in the market. The novel stainless steel acid-washing passivation liquid can complete oil removal, derusting, descaling and acid-washing passivation at one time. The residual liquid after use can be treated by a conventional treatment method, and can also be used for treating dyeing waste water; and the treated dyeing waste water is clear and transparent and achieves the reclamation standard. Thus, the stainless steel acid-washing passivation liquid has the advantages of environment protection and water resource saving, and can recycle water.

Owner:王福平

Environment-friendly polyurethane water shutoff material and preparation method thereof

The invention belongs to the field of high polymer materials and particularly relates to an environment-friendly polyurethane water shutoff material. The environment-friendly polyurethane water shutoff material is prepared from a polyurethane prepolymer and an additive, wherein the polyurethane prepolymer is prepared from the following raw materials: polyethylene-polypropylene glycol a (functionality: 3-4 and hydroxyl value: 300-500), polyethylene-polypropylene glycol b (functionality: 2-3 and hydroxyl value: 200-400), polyethylene-polypropylene glycol c (functionality: 2-3 and hydroxyl value: 100-200), a water remover and isocyanate; the additive is prepared from the following raw materials: a plasticizing agent, a diluent, a flame retardant, a catalyst and a surfactant. When being injected to a hole or crack, the polyurethane water shutoff material is diffused and solidified in the crack to generate foam with certain strength; molecules of a gel contain a great number of polar groups, so that the environment-friendly polyurethane water shutoff material is high in bonding strength and capable of shutting off the crack, thus playing the water shutoff and consolidation effects. The invention also provides a preparation method of the environment-friendly polyurethane water shutoff material. The preparation method is reasonable in process and easy for industrial production.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

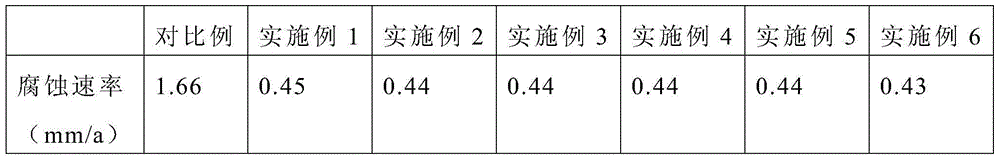

Stainless steel pickling passivator and preparation method thereof

InactiveCN107012472AAvoid harmGood for healthMetallic material coating processesFatty alcoholMaterials science

The invention discloses a stainless steel pickling passivator and a preparation method thereof. The stainless steel pickling passivator comprises citric acid, hydrochloric acid, formic acid, fatty alcohol-polyoxyethylene ether, polyethyleneimine, epoxy octyl stearate, thiosemicarbazide, epoxy chloropropane, hydrogen peroxide, a penetrating agent, a corrosion inhibitor, a thickening agent, an inorganic filler and a viscosity modifier. The preparation method comprises the steps of firstly adding part of raw materials such as the fatty alcohol-polyoxyethylene ether and the like into the hydrochloric acid sequentially, and uniformly stirring the raw materials to obtain a mixed solution I; then sequentially adding part of the raw materials such as the hydrogen peroxide into mixed acid liquor of the citric acid and the formic acid, and uniformly stirring the raw materials to obtain a mixed solution II; then mixing the mixed solution I and the mixed solution II, and adding the inorganic filler into the mixture; and finally adding the penetrating agent, the corrosion inhibitor, the thickening agent and the viscosity modifier sequentially into the mixture, and uniformly mixing the mixture to obtain the finished product. According to the stainless steel pickling passivator and the preparation method thereof, the stainless steel pickling passivator is good in passivation effect, not prone to damage the surface of stainless steel, environment-friendly and simple to prepare and does not cause harm to human bodies and environment.

Owner:合肥协耀玻璃制品有限公司

Bare steel rust layer conversion agent for terrestrial environment

InactiveCN104831263ANo strong irritating smellNo irritating smellMetallic material coating processesNitrateSulfate

The invention discloses a bare steel rust layer conversion agent for a terrestrial environment. The rust layer conversion agent comprises the following components in percentage by weight: 0.5-5 percent of sodium tripolyphosphate, 0.1-3 percent of copper sulfate, 0.1-2 percent of manganous nitrate, 0.1-2 percent of nickel sulfate, 0.1-2 percent of phytic acid and the balance of water. The rust layer conversion agent disclosed by the invention has excellent rust liquid sagging resistance, and after the conversion agent is sprayed onto the surface of a weather-resistant bare steel sample of which oxide scale is removed, formation of a stable rust layer is promoted, and the rust layer has excellent anticorrosive performance and is suitable for coating of bare steel.

Owner:武汉钢铁有限公司

Stainless steel passivation liquid and passivation technology thereof

InactiveCN106939420AAvoid harmNo harmMetallic material coating processesAcetic anhydrideSand blasting

The invention discloses stainless steel passivation liquid and a passivation technology thereof. The stainless steel passivation liquid comprises, by weight, 40-50 parts of inorganic acid, 5-15 parts of hydrogen peroxide, 8-12 parts of cyclohexanol, 4-8 parts of 2-ethylhexyl epoxystearate, 4-6 parts of acetic anhydride, 2-4 parts of polyethyleneimine, 3-5 parts of carbomer resin, 2-4 parts of a penetrating agent, 1-3 parts of corrosion inhibitor and 10-20 parts of organic filler. The passivation technology of the stainless steel passivation liquid comprises polishing and rust removal, surface oil removal, first-time water washing, sand blasting, acid pickling passivation, second-time water washing and surface drying. The stainless steel passivation liquid is little in perniciousness, good in passivation effect and not prone to generating corrosive damage on a stainless steel product. The passivation technology is simple, operation is easy, the production cost is low, pollution to the environment is weak, and the standard of green and environment friendliness is met.

Owner:合肥协耀玻璃制品有限公司

Surface treatment agent capable of generating brown stable rust layer

InactiveCN107903785ANo strong irritating smellNo strong strong irritating smellAnti-corrosive paintsMetallic material coating processesAlcoholNitrite

The invention discloses a surface treatment agent capable of generating a brown stable rust layer. The surface treatment agent is prepared from the following ingredients in percentage by mass: 30 to 35 percent of alcohol-soluble phenolic aldehyde varnish, 20 to 25 percent of NiSO4, 2 to 5 percent of CuSO4, 2 to 3 percent of sodium tungstate, 2 to 5 percent of trisodium orthophosphate, 5 to 10 percent of NaHSO3 and 28 to 33 percent of diluting solvents. The surface treatment agent is suitable for bare steel coating; after bare steel is coated with the surface treatment agent, a brown uniform and stable rust layer is generated on the surface; the long-time effective rust liquid flowing and hanging prevention and anti-corrosion performance is realized; in addition, the used surface treatmentagent does not have the strong pungent smell; chromium and nitrite are not contained; safety and environment protection are realized.

Owner:武汉钢铁有限公司

Hot rolled plate hydrochloric acid pickling corrosion inhibition accelerator

The invention provides a hot rolled plate hydrochloric acid pickling corrosion inhibition accelerator in which the compositions and weight percentages thereof are as follows: the weight percentage of surface active agent TX-10 that is octyl phenol polyethylene glycol (10) ether is 5% to 10%, the weight percentage of carboxylic cellulose salt is 5% to 10%, and the weight percentage of stannous salt reducing agent is 80% to 90%; the weight percentage of surface active agent TX-10 that is octyl phenol polyethylene glycol (10) ether is 5% to 10%, the weight percentage of carboxylic cellulose salt is 5% to 10%, and the weight percentage of stannous salt reducing agent is 85% to 90%. The composition weight percentage concentration range of corrosion inhibition accelerator in pickling working fluid keeps between 0.5% and 1%. The hot rolled plate hydrochloric acid pickling corrosion inhibition accelerator in the invention has not only good corrosion inhibition performance but also good acceleration performance, and still has good corrosion inhibition and acceleration performances within a certain range of pickling temperature and hydrochloric acid concentration.

Owner:武钢集团有限公司

Nail-protecting and antibacterial nail polish

InactiveCN105878085ARaw materials are easy to getSimple methodCosmetic preparationsToilet preparationsCelluloseStiphra robusta

The invention discloses a nail-protecting and antibacterial nail polish including the following components, by weight: 25-30 parts of olive oil, 15-20 parts of avocado extract liquid, 3-8 parts of garden balsam powder, 3-8 parts of coconut shell powder, 1-5 parts of pearl powder, 1-2 parts of a pigment, 10-20 parts of butyl acetate, and 15-20 parts of nitro-cellulose. The nail-protecting nail polish employs easy-to-obtain raw materials, is easy to prepare, is low in cost, is convenient to use, has no intensive pungent smell after use, and is low in damage on nails.

Owner:王萍

Bare steel rust layer transforming agent for salt-contained environment

InactiveCN104928664AGood adhesionPromote passivationMetallic material coating processesSulfatePhosphate

The invention provides a bare steel rust layer transforming agent for a salt-contained environment. The rust laser transforming agent comprises the following components in percentage by weight: 0.1-3% of titanyl sulfate, 0.5-5% of zinc dihydrogen phosphate, 0.1-3% of sodium pyrophosphate, 0.1-2% of tannic acid, 0.1-3% of copper sulfate, and the balance of water. The rust layer transforming agent has excellent rust liquid sagging prevention; after the rust layer transforming agent is sprayed on the surface of a weather-resistant steel bare sample with removed scales, the formation of a stable rust layer is accelerated; the rust layer is excellent in corrosion resistance; and the rust layer transforming agent is suitable for coating bare steels.

Owner:武汉钢铁有限公司

Chromium-containing treating fluid for stabilization of bare steel rust layer

InactiveCN104928665AImprove corrosion resistanceImproved sag performanceMetallic material coating processesAcetic acidSodium bichromate

The invention provides chromium-containing treating fluid for stabilization of a bare steel rust layer. The chromium-containing treating fluid is composed of, by weight, 0.5%-5% of sodium bichromate, 0.1%-3% of NaHSO3, 0.1%-2% of FeSO4, 0.1%-2% of FeCl3, 0.1%-1% of acetic acid, 0.1%-0.5% of triethanolamine, and the balance water. The chromium-containing treating fluid has good performance of preventing sagging of rust fluid; after the chromium-containing treating fluid is sprayed on the surface of a weathering resistant steel plain sample with oxide scale being removed, formation of a stable rust layer is promoted, and the rust layer has good corrosion resistance and is suitable for coating of bare steel.

Owner:武汉钢铁有限公司

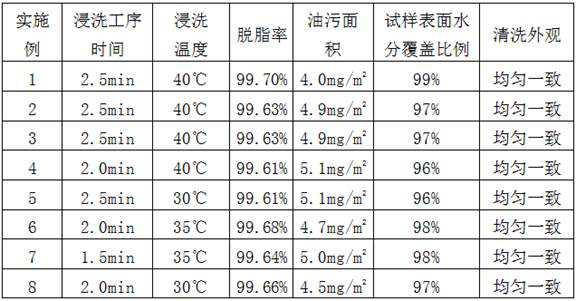

Cleaning agent for treating steel plate after annealing and before tin plating

The invention discloses a cleaning agent for treating a steel sheet after and before tin plating. The cleaning agent comprises the components, by weight: 70-80% of sodium hydroxide, 10-20% of trisodium orthophosphate, 3-7% of n-tetradecyl polyoxyethylene ether, 3-7% of sodium oleate, and 2-6% of triethanolamine. While in use, the cleaning agent for treating the steel plate after annealing and before tin plating is added into water to form a cleaning solution according to the weight percentage of 3-5%, a cold rolled steel sheet after annealing and before tin plating is cleaned in the cleaning solution at the temperature of 70-85 DEG C. The cleaning product for treating the steel sheet after annealing and before tin plating has no strong irritating smell, can be added into water of a cleaning stage before tin plating, is convenient and easy to use, and has good cleaning effect and cleaning efficiency of 99% or more. The steel sheet after cleaning has excellent rust resistance, and residues on the steel sheet surface are less than 6 mg / m<2>. The cleaning agent also has relatively good buffering capability of pH value, and still has good cleaning performance at certain cleaning temperature and certain concentration ranges.

Owner:武汉钢铁有限公司

Electrostatic spraying anti-rust oil free of barium and sulfonate

InactiveCN103911206ANo strong irritating smellImprove rust resistanceLubricant compositionSulfonateSarcosine

The invention discloses electrostatic spraying anti-rust oil free of barium and sulfonate. The electrostatic spraying anti-rust oil is characterized by comprising the following components by weight percent: 80-90% of No.15 machine oil, 2-10% of zinc naphthenate, 1-6% of N-oleoyl sarcosine octadecylamine, 2-10% of dodecenylsuccinic acid, and 1-5% of 2,6-butylated hydroxytoluene. The anti-rust oil disclosed by the invention is free of a strong pungent smell, does not contain barium or sulfonate, is healthy and environment-friendly, and has excellent anti-rust property, stable performance and good lubricating property.

Owner:武汉钢铁有限公司

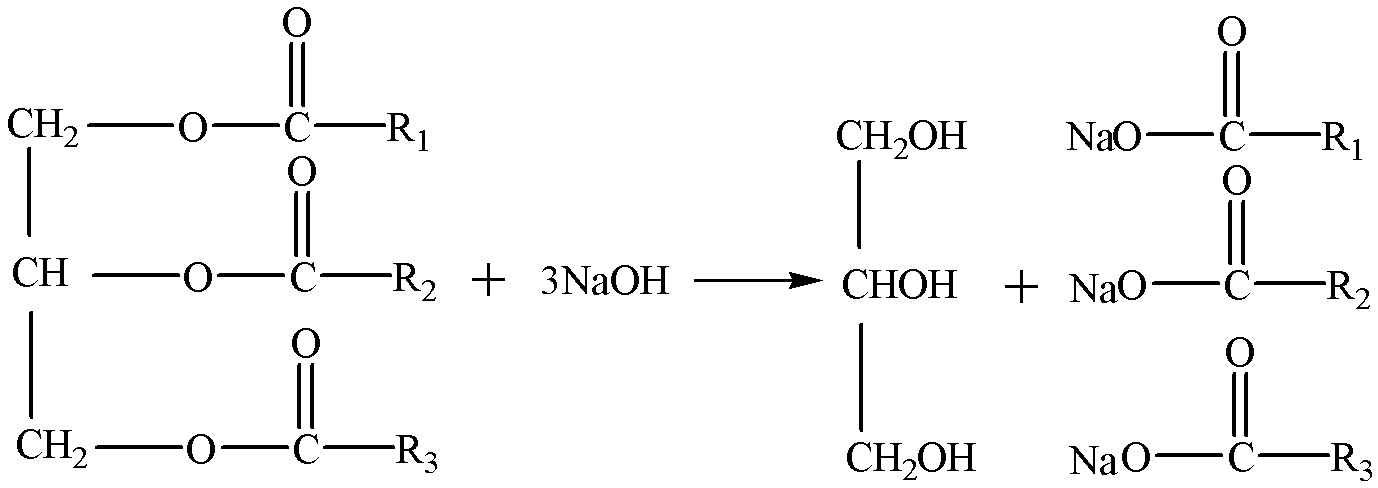

Preparation method of benzo [e] [1, 3] oxazine-2, 4-diketone

ActiveCN114195730ANo strong irritating smellLow priceOrganic chemistryDiketoneSimple Organic Compounds

The invention relates to a preparation method of benzo [e] [1, 3] oxazine-2, 4-diketone, and belongs to the technical field of organic compounds. According to the preparation method, under the alkaline condition, 2-hydroxybenzamide and (Boc) 2O react in a solvent under the action of a catalyst, and benzo [e] [1, 3] oxazine-2, 4-diketone is obtained. A carbonylation cyclization reagent di-tert-butyl dicarbonate ester (Boc) 2O is adopted, and the reagent has no strong pungent smell, has no toxic effect on a human body, is low in price and is not limited to transportation and use. (Boc) 2O can be used as a relatively good protective reagent. Under the anhydrous condition, the compound can react with 2-hydroxybenzamide with weak nucleophilicity under the action of a catalyst (N, N-dimethyl pyridine). The preparation method is simple to operate, the purity of the obtained product reaches 98% or above, the yield reaches 80%, and the preparation method is suitable for industrial production.

Owner:苏州天马医药集团天吉生物制药有限公司

Cleaning agent for rust-proof cold-rolled steel sheets before annealing

The invention discloses a cleaning agent for rust-proof cold-rolled steel sheets before annealing. The cleaning agent comprises the following components by weight percent: 30-40% of sodium hydroxide, 20-30% of sodium carbonate, 10-20% of trisodium phosphate, 10-20% of sodium benzoate, 2-7% of ethylene diamine tetraacetic acid and 3-8% of n-tetradecyl polyoxyethylene ether. When the cleaning agent is used, the cleaning agent is added to water according to a weight percent of 3-5% to prepare cleaning solution and the cold-rolled steel sheets before annealing are cleaned in the cleaning solution at 70-85 DEG C. The cleaning agent has the beneficial effects that the cleaning agent does not have strong pungent smell, can be directly added to cleaning section water before recrystallization annealing of the cold-rolled steel sheets, is convenient and easy to use, has good cleaning effects, has high cleaning efficiency being above 99%, has excellent rust-proof property, is suitable for cleaning the cold-rolled steel sheets, alloying galvanized sheets, hot galvanized sheets and the like and enables the rust-proof period of the steel sheets in the middle process to be over 15 days.

Owner:武汉钢铁有限公司

Barium-free and sulfonate-free electrostatic spraying anti-rust oil

InactiveCN103911206BNo strong irritating smellImprove rust resistanceLubricant compositionSarcosineButylated hydroxytoluene

Owner:武汉钢铁有限公司

Preparation method of water reducer used for electronic ceramic spray granulation slurry

The invention discloses a preparation method of a water reducer used for electronic ceramic spray granulation slurry. The method comprises steps of: 1) weighing 7.0-7.2% of acrylic acid, 10.2-10.8% of concentrated aqueous ammonia, 1.02-1.07% of a hydrogen dioxide solution, 79.0-79.5% of water, 1.9-2.1% of isopropanol and 0.0021-0.0023% of hydroquinone according to a molar ratio; 2) adding the acrylic acid into a reactor, and adding a portion of the concreted aqueous ammonia to obtain a neutralized solution; 3) adding the isopropanol, the water, and a portion of the hydrogen dioxide solution into the neutralized solution, stirring uniformly, heating to 60-65 DEG C, then adding dropwise the rest of the hydrogen dioxide solution, and heating to 90-94 DEG C after the addition of the hydrogen dioxide solution is finished, and maintaining the temperature to obtain a polymerization solution; and 4) after the temperature of the polymerization solution is lowered to 20-25 DEG C, adding the hydroquinone dropwise under stirring, then adding dropwise the rest of the concentrated aqueous ammonia, and stirring uniformly after the addition of the concentrated aqueous ammonia is finished to obtain the water reducer used for the electronic ceramic spray granulation slurry. The water reducer prepared by the method is strong in dispersion force.

Owner:CHINA XD ELECTRIC CO LTD

Brightener for PSA electrotinning insoluble anode system and application

The invention discloses a brightener for a PSA electrotinning insoluble anode system and application. The brightener comprises a main brightening agent, a dispersing agent, an antioxidant and a complexing agent; the main brightening agent comprises imidazoline and 3-alkyl-4-amino-5-mercapto-1, 2, 4-s-triazole; and the dispersing agent comprises polyethylene glycol and alkyl amide polyoxyethylene ether. According to the brightener for the PSA electrotinning insoluble anode system, a plating solution can be stable, no strong pungent smell exists during electroplating, high-current-density tinning can be allowed, and the brightener is suitable for continuous and rapid tinning of plates, strips and wires; and when 3%-5% of the brightener is added into the electroplating solution of the PSA electrotinning insoluble anode system for electroplating, plating grains are uniform and refined, a plating is bright, tin ions in the electroplating solution are not prone to being oxidized, and the corrosion resistance of the plating is excellent.

Owner:BAOSHAN IRON & STEEL CO LTD

Electronic soldering flux

InactiveCN108393611ASolder joints are full and smoothNo strong irritating smellWelding/cutting media/materialsSoldering mediaOrganic solventAntioxidant

The invention discloses one type of electronic soldering flux. The electronic soldering flux comprises the following raw materials, by weight, 13 parts to 33 parts of rosin, 11 parts to 19 parts of citric acid, 8 parts to 16 parts of hydrochloric acid, 2 parts to 6 parts of filmogen, 1.5 parts to 3.5 parts of antioxidants, 6 parts to 14 parts of organic solvent, and 0.5 part of deionized water. The electronic soldering flux is full and smooth in welding spot, non-toxic and free of strong pungent smell, basically causes no pollution to the environment, and is safe to operate and remarkable in reoxidation resistance during welding, and the quality of welding is improved.

Owner:SUZHOU RUINAIJIE ELECTRONICS SCI & TECH NEW MATERIAL

Automobile coating surface conditioning pretreatment normal-temperature degreasing agent and degreasing method thereof

The invention discloses a normal-temperature degreasing agent for the pre-conditioning treatment of automobile painting surface and a degreasing method thereof. 50%, complexing agent 10-20%, non-ionic surfactant 1-5%, anionic surfactant 1-5%, stabilizer 2-6%. The degreasing method is to heat the desalted water working solution to 20-35° C., add different percentages of the normal temperature degreasing agent, and degrease the automobile steel plate through three processes of spraying, soaking and water washing. The invention has excellent cleaning performance, can adapt to a faster automobile coating production line, and effectively solves the problem of unclean cleaning of the steel plate surface.

Owner:武汉钢铁有限公司

Surface treatment agent capable of generating red stable rust layer

InactiveCN108004535ANo strong irritating smellNo strong strong irritating smellAnti-corrosive paintsMetallic material coating processesNickel phosphateSolvent

The invention discloses a surface treatment agent capable of generating a red stable rust layer. The surface treatment agent comprises the following components in percentage by mass: 20-30% of alcohol-soluble phenolic aldehyde varnish, 2-5% of nickel phosphate, 2-5% of sodium tungstate, 2-3% of sodium silicate, 5-10% of Fe(OH)3, 30-35% of Fe2O3 and 23-33% of one or more dilution solvents. The surface treatment agent disclosed by the invention is suitable for bare steel coating; after bare steel is coated with the surface treatment agent, the red uniform stable rust layer is generated on the surface of the bare steel, and has the long-term effective properties of rust liquid sagging prevention and corrosion prevention; and the adopted surface treatment agent has no strong irritating odor, contains no chromium and nitrite, and is safe and environmentally friendly.

Owner:武汉钢铁有限公司

Medium-temperature degreasing agent for automobile coating surface conditioning pretreatment and degreasing method thereof

The invention discloses a medium-temperature degreasing agent for pre-treatment of automobile painting surface adjustment and a degreasing method thereof. The medium-temperature degreasing agent is prepared by mixing the following components in weight percent: 30-50% of strong alkali, 30-50% of soluble phosphate 50%, complexing agent 10-20%, surfactant 2-6% and stabilizer 2-10%. The degreasing method is to heat the desalted water working solution to 40-55° C., add different percentages of the normal temperature degreasing agent, and degrease the automobile steel plate through three processes of spraying, soaking and water washing. The invention has excellent cleaning performance, can adapt to a faster automobile coating production line, and effectively solves the problem of unclean cleaning of the steel plate surface.

Owner:武汉钢铁有限公司

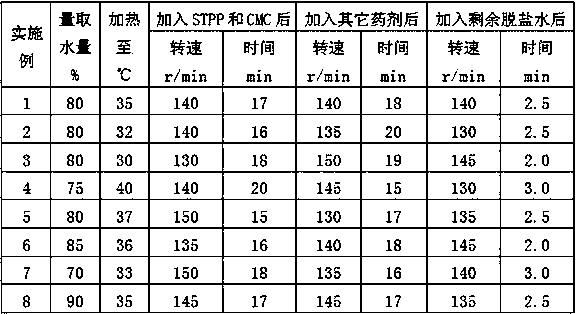

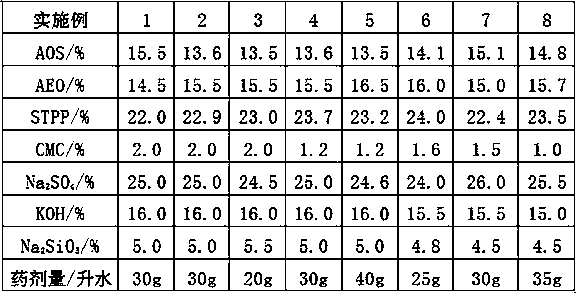

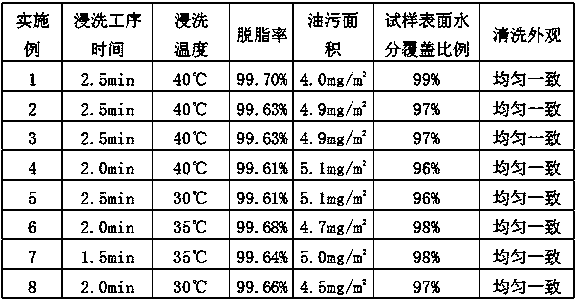

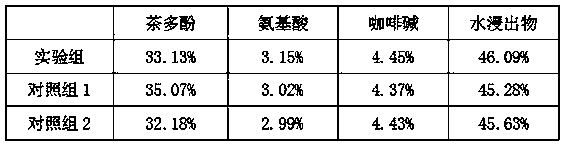

Degreasing agent for cleaning oil stains on surface of steel and preparation method thereof

The invention discloses a degreasing agent for cleaning oil stains on the surface of steel and a preparation method thereof. Medicaments are added in water; and the medicaments comprises the followingcomponents in percentage by weight: 13.5-15.5% of alpha-olefin sodium sulfonate, 14.5-16.5% of fatty alcohol-polyoxyethylene ether, 22-24% of pentasodium phosphate, 1-2% of carboxymethylcellulose, 24-26% of sodium sulfate, 15-16% of potassium hydroxide, and 4.5-5.5% of sodium silicate. The degreasing agent is compounded by AEO and AOS, can achieve an efficient decontamination effect, and is excellent in oil stain and other inroagnic impurity removing effect. The degreasing agent is efficient in steel plate cleaning effect, can meet quick production requirements in modern coating workshops, contains no chromium, nitrite and strong irritating smell, is low in component poison, green and environment-friendly, and can be widely applied to cleaning of the oil stains on the surface of the steel.

Owner:TANGSHAN IRON & STEEL GROUP +1

High temperature corrosion and high humidity corrosion resisting agent coating surface of bare steel, and preparation method of high temperature corrosion and high humidity corrosion resisting agent

InactiveCN105908173AExcellent anti-rust fluid sag performanceGood corrosion resistanceMetallic material coating processesSodium silicateSodium triphosphate

The invention discloses a high temperature corrosion and high humidity corrosion resisting agent coating the surface of bare steel, and a preparation method of the high temperature corrosion and high humidity corrosion resisting agent. The acid rain corrosion resisting agent includes, by weight, 0.3%-2% of sodium tripolyphosphate, 0.3%-2% of copper sulfate, 0.1%-1% of sodium tungstate, 0.1%-1% of hexafluorozirconic acid, 0.1%-1% of phytic acid, 0.1%-1% of sodium silicate, and the balance water. The high temperature corrosion and high humidity corrosion resisting agent can be prepared by evenly mixing the sodium tripolyphosphate, the copper sulfate, the sodium tungstate, the hexafluorozirconic acid, the phytic acid, the sodium silicate and water. The high temperature corrosion and high humidity corrosion resisting agent coating the surface of the bare steel is free of strong irritating odor and chrome, and has excellent rust liquid sagging prevention performance. After the high temperature corrosion and high humidity corrosion resisting agent coating the surface of the bare steel is sprayed to the surface of a bare weather-resistant steel sample with oxide skin removed, a rust layer has excellent corrosion resistance.

Owner:武汉钢铁有限公司

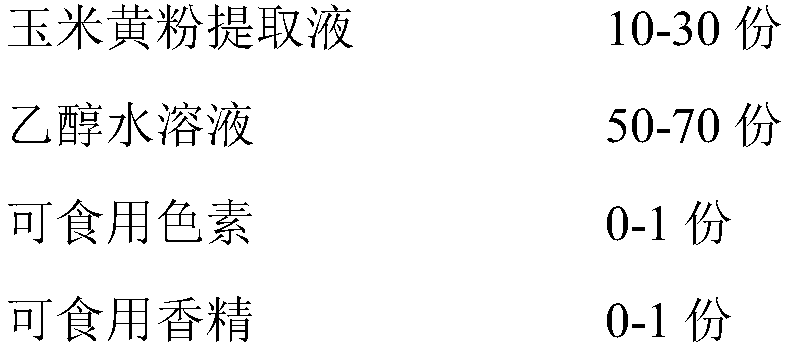

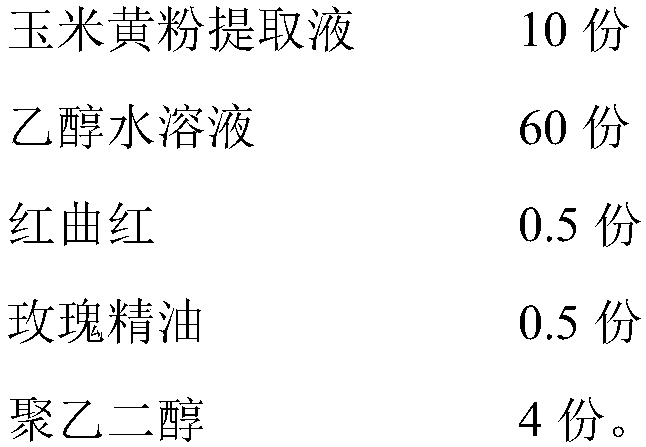

an edible nail polish

InactiveCN105726419BNo strong irritating smellNo irritating smellCosmetic preparationsToilet preparationsHuman bodySide effect

The invention relates to edible, safe and toxicity-free nail polish. The nail polish is prepared from, by weight, 10-30 parts of a maize yellow powder extracting solution, 50-70 parts of an ethanol water solution, 0-1 part of edible food coloring, 0-1 part of edible essence and 4-6 parts of edible plasticizer. The problem that existing nail polish in the market takes a toxic chemical reagent as a main raw material is solved, and the natural and toxicity-free nail polish is prepared from maize yellow powder extract as the main raw material, has no irritation or toxic or side effects on the human body and can be suitable for being used by special people groups such as children and pregnant women.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Hot rolled plate hydrochloric acid pickling corrosion inhibition accelerator

InactiveCN101586243BNo strong irritating smellReduce pickling temperaturePolyethylene glycolSurface-active agents

The invention provides a hot rolled plate hydrochloric acid pickling corrosion inhibition accelerator in which the compositions and weight percentages thereof are as follows: the weight percentage of surface active agent TX-10 that is octyl phenol polyethylene glycol (10) ether is 5% to 10%, the weight percentage of carboxylic cellulose salt is 5% to 10%, and the weight percentage of stannous saltreducing agent is 80% to 90%; the weight percentage of surface active agent TX-10 that is octyl phenol polyethylene glycol (10) ether is 5% to 10%, the weight percentage of carboxylic cellulose saltis 5% to 10%, and the weight percentage of stannous salt reducing agent is 85% to 90%. The composition weight percentage concentration range of corrosion inhibition accelerator in pickling working fluid keeps between 0.5% and 1%. The hot rolled plate hydrochloric acid pickling corrosion inhibition accelerator in the invention has not only good corrosion inhibition performance but also good acceleration performance, and still has good corrosion inhibition and acceleration performances within a certain range of pickling temperature and hydrochloric acid concentration.

Owner:武钢集团有限公司

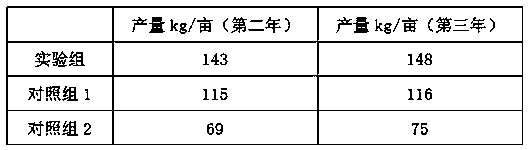

Special fertilizer for high-density planting tea garden and fertilizing method thereof

InactiveCN111116262APromote wound healingPromote germinationFertilising methodsOrganic fertiliser preparationEcological environmentNutrition

The invention belongs to the technical field of fertilizers, and particularly relates to a special fertilizer for a high-density tea garden and a fertilizing method thereof. The fertilizer is composedof a liquid chitosan compound fertilizer and a liquid water-soluble fertilizer. The fertilizer provided by the invention can promote wound healing of tea tree branches after Taiwan cradling, can promote roots of the tea trees to germinate new branches after Taiwan cradling and can provide the nutritional requirements of high-density planting tea garden production. The fertilizer provided by the invention is scientific in proportioning, has higher water solubility, can be used for supplementing tea tree nutrition through water-fertilizer integrated drip irrigation in a tea garden, and is highin fertilizer utilization rate and small in application amount; the prepared fertilizer has no strong pungent smell, nutrition is supplemented according to the growth requirement characteristics of tea trees, medium trace elements and amino acid required by the tea trees are supplemented, and after the fertilizer provided by the invention is used for a long time, the disease resistance and insectresistance of the tea trees can be improved; tea garden soil can be improved, and the soil micro-ecological environment required by tea tree growth is improved; and tea tree root activity is improved,and tea tree root germination is promoted.

Owner:SHANDONG INST OF POMOLOGY

Degreasing agent for oil stain cleaning on steel surface and preparation method thereof

The invention discloses a degreasing agent for cleaning oil stains on the surface of steel and a preparation method thereof. Medicaments are added in water; and the medicaments comprises the followingcomponents in percentage by weight: 13.5-15.5% of alpha-olefin sodium sulfonate, 14.5-16.5% of fatty alcohol-polyoxyethylene ether, 22-24% of pentasodium phosphate, 1-2% of carboxymethylcellulose, 24-26% of sodium sulfate, 15-16% of potassium hydroxide, and 4.5-5.5% of sodium silicate. The degreasing agent is compounded by AEO and AOS, can achieve an efficient decontamination effect, and is excellent in oil stain and other inroagnic impurity removing effect. The degreasing agent is efficient in steel plate cleaning effect, can meet quick production requirements in modern coating workshops, contains no chromium, nitrite and strong irritating smell, is low in component poison, green and environment-friendly, and can be widely applied to cleaning of the oil stains on the surface of the steel.

Owner:TANGSHAN IRON & STEEL GROUP +1

Manufacturing method of ceramic flute

InactiveCN110372327AImprove anti-agingImprove corrosion resistanceWind musical instrumentsClaywaresFluteKiln

The invention discloses a manufacturing method of ceramic flute. The manufacturing method comprises the following steps that S1, ceramic mud is refined; S2, a vacuum ceramic pipe extrusion device is used for producing a flute green body; S3, a straightening and drying device is used for straightening and drying the flute ciao green body for molding; S4, the formed flute green body is trimmed; S5,the trimmed flute green body is subjected to hole digging manually or by a hole digging device, and a blow hole, a film hole and sound holes are manufactured; S6, the flute green body with dug holes is subjected to firing at 800-1100 DEG C, and the firing time is 5-8 hours; S7, the qualified fired flute green body is selected and glazed so that the product can be more perfect; S8, after the glazeis applied, kiln placing is performed, and a kiln and a bracket are used for hanging the flute green body to which the glaze is applied on the bracket for high-temperature firing; the firing temperature is 1100-1350 DEG C, and the firing time is 8-12 hours; S9, after the completion of the firing, qualified products are selected for sound checking; and S10, the qualified products are packaged and shipped after the sound checking is completed.

Owner:查金塘

Wet leveling agent for bell-type annealing secondary cold-rolled tin-plated extremely thin sheet

InactiveCN104141137BNo strong irritating smellDoes not affect the operating environmentThin slabSarcosine

The invention discloses a wet leveling agent for bell-type annealing secondary cold-rolled tin-plated extremely thin plate. The wet leveling agent is composed of the following components by weight percentage: triethanolamine: 20-30%, dodecenyl Succinic acid: 5-10%, N-oleoyl sarcosine octadecylamine: 10-20%, polyacrylamide: 10-15%, octylphenol polyoxyethylene (10) ether: 15-25%, Ethylenediaminetetraacetic acid: 5-10%, sodium gluconate: 5-10%. The wet leveling agent of the present invention has the advantages of stable performance, good rust resistance and cleaning performance, no strong irritating smell, and no influence on the operating environment.

Owner:武汉钢铁有限公司

Fish-scaling-resistance acid pickling additive used for cold-rolled glassed steel

The invention discloses a fish-scaling-resistance acid pickling additive used for cold-rolled glassed steel. The fish-scaling-resistance acid pickling additive is characterized in that the additive comprises, by weight, 50-70 percent of octylphenol polyoxyethylene (10) ether, 10-25 percent of hexamethylenetetramine, 10-20 percent of normal butanol and 5-20 percent of sodium benzoate. The additive has the advantages that an acid pickling solution can be stablized, the applicable hydrochloric acid concentration range and the acid pickling temperature range are wide, no strong pungent smell exists, and the operation environment is not affected.

Owner:武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of benzo [e] [1, 3] oxazine-2, 4-diketone Preparation method of benzo [e] [1, 3] oxazine-2, 4-diketone](https://images-eureka.patsnap.com/patent_img/72fbee1e-356f-4978-bd9f-28d0b2d2ffab/HDA0003357820070000011.png)

![Preparation method of benzo [e] [1, 3] oxazine-2, 4-diketone Preparation method of benzo [e] [1, 3] oxazine-2, 4-diketone](https://images-eureka.patsnap.com/patent_img/72fbee1e-356f-4978-bd9f-28d0b2d2ffab/HDA0003357820070000021.png)

![Preparation method of benzo [e] [1, 3] oxazine-2, 4-diketone Preparation method of benzo [e] [1, 3] oxazine-2, 4-diketone](https://images-eureka.patsnap.com/patent_img/72fbee1e-356f-4978-bd9f-28d0b2d2ffab/BDA0003357820060000011.png)