Patents

Literature

374 results about "Hydrogen dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integral catalyst for producing hydrogen dioxide solution as well as preparation and application thereof

InactiveCN101497040AImprove mass transfer efficiencyReduce internal mass transfer resistancePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesCatalyst activation/preparationActive componentHydrogenation reaction

The invention provides a monolithic catalyst for oxydol production and a preparation method thereof. The catalyst uses ceramic monolithic honeycomb or metal monolithic honeycomb as a substrate, one or more of Al2O3, SiO2, CaO, MgO, TiO2, ZrO2, La2O3, CeO2, Fe2O3 and Cr2O3 as a coating material, and noble metal palladium as an active component to be used in an anthraquinone hydrogenation reaction of oxydol production. The monolithic catalyst adopts a preparation method of fractional support so as to effectively control depth of impregnation of the active component. The monolithic catalyst used in the anthraquinone hydrogenation process has the advantages of high activity, good selectivity and 82.21kg (100 percent of H2O2) / mcat.h of space-time yield of the oxydol, which is over 3 times more than a commercial bead catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

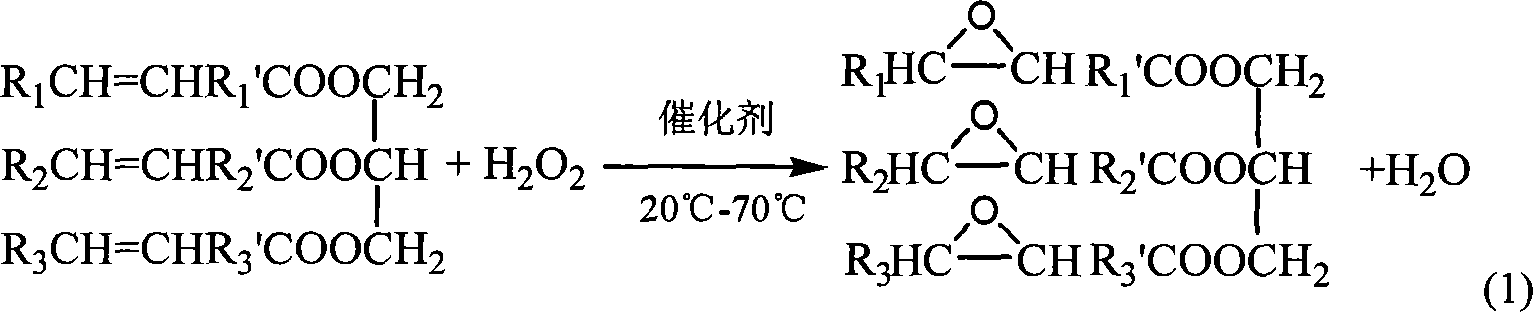

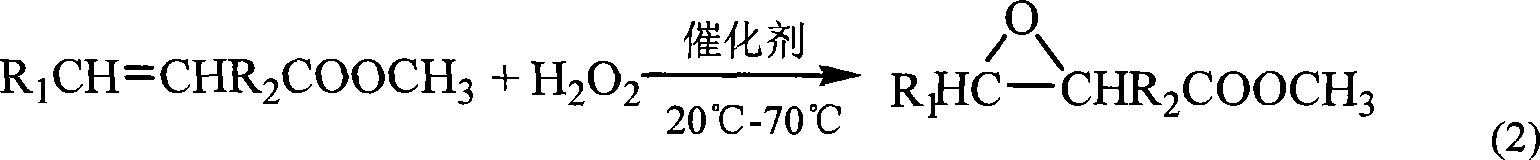

Method for preparing epoxidized soybean oil or epoxy fatty acid methyl(ethyl) ester by heteropolyacid liquid phase catalysis

InactiveCN101235021AReduce usageDisadvantages of Avoiding Recycling DifficultiesOrganic chemistryEpoxyHeteropoly acid

A heteropoly acid liquid-phase catalysis preparation method of epoxy soybean oil or epoxy fatty acid methyl ester (ethyl ester) belongs to liquid-phase catalysis oxidization technical field, which utilizes biomass soybean oil and unsaturated fatty acid methyl ester (ethyl ester) and uses solid heteropoly acid salt compound as catalyst, without carboxyl acid, protonic acid and solvent, to synthesize epoxy soybean oil or epoxy fatty acid methyl ester (ethyl ester) via hydrogen dioxide solution reaction, without acid waste water generation in epoxidation to protect environment. The epoxy soybean oil or epoxy fatty acid methyl ester (ethyl ester) can be used as plasticizer to be widely used in non-toxic polyvinyl chloride (PVC) product and transparent PVC product, as transparent bottle, transparent box, food and drug package, PVC medical blood bag and environment-friend uv-curing coating or the like.

Owner:JIANGNAN UNIV

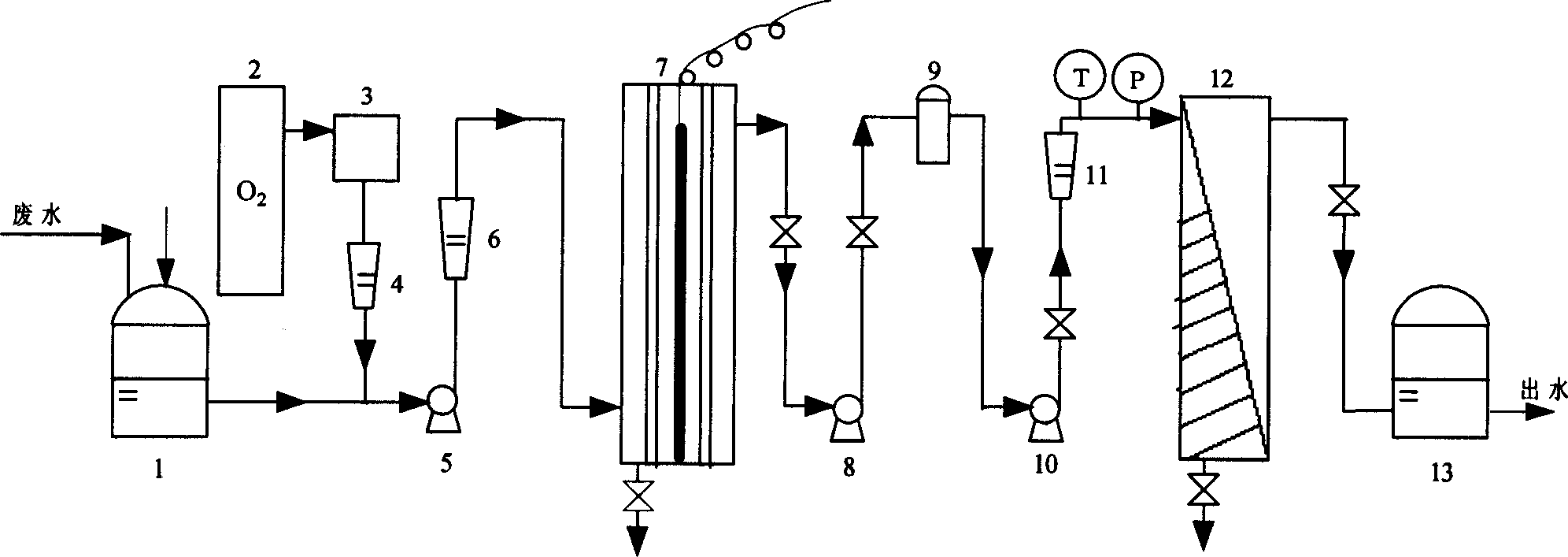

Photocatalytic oxidation reaction- membrane separation method for processing antibiotic industry waste water

InactiveCN1733624AEfficient removalRealize purification and reuseWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisChlorine dioxideUltraviolet lights

The invention relates to a treatment method for antibiotic pharmaceutical waste water integrated with photocatalyst oxidation reaction and membrane separation. Wherein, taking flocculations, coarse filter and adjust pH value to the waste water putting the water into photocatalyst oxidation reactor with particle titania as catalyst, ultraviolet light as light source and ozone, hydrogen dioxide or chlorine dioxide as oxidizer; degradating organic in water; forcing the waste water into membrane separator to catch most inorganic salt and organic of 97% removal ratio and 98% desalinization ratio and satisfy the recycle standard. This method has high efficiency and the yielding water is colourless and clear.

Owner:TIANJIN UNIV

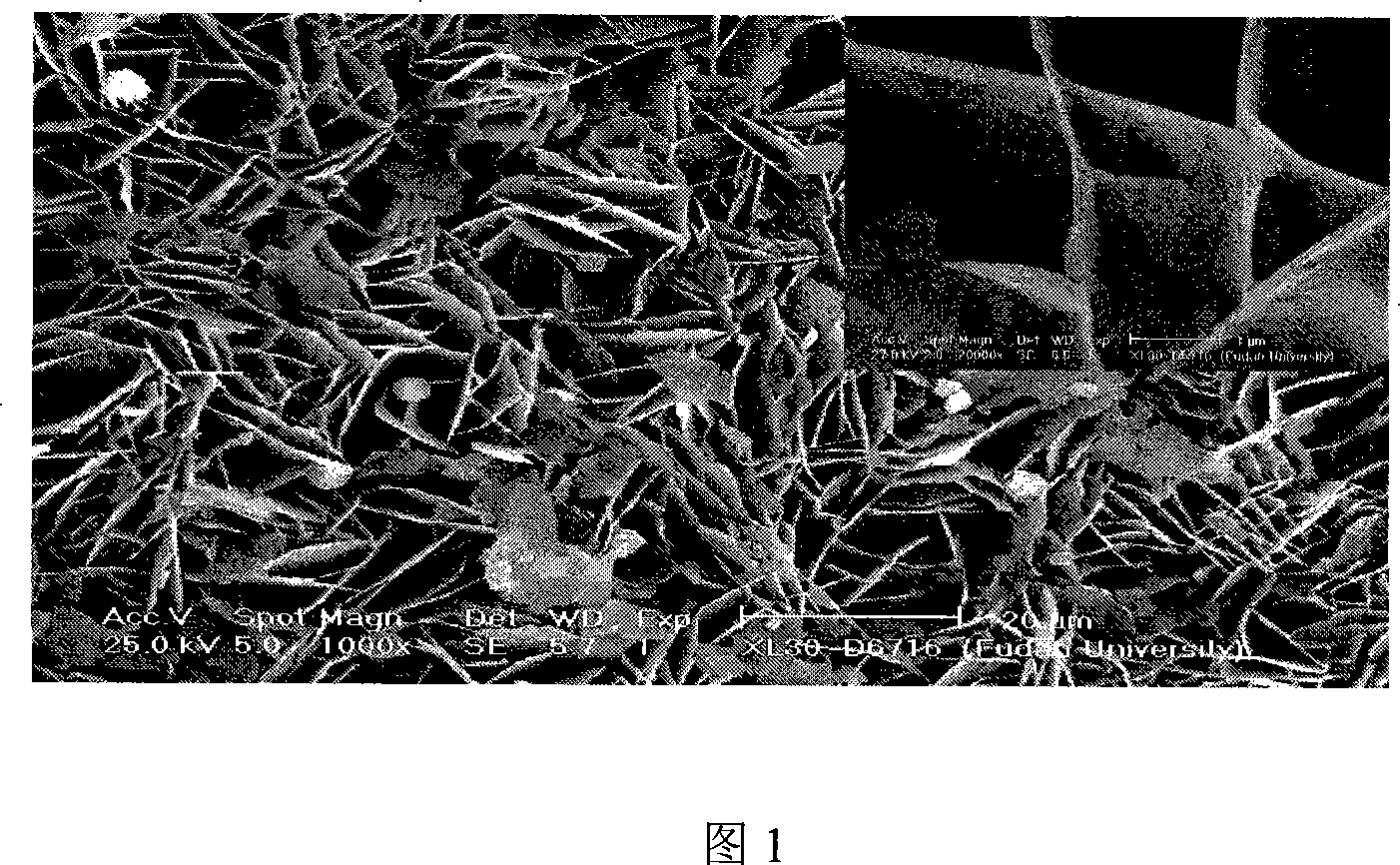

Method for catalyzing cyclone oxide to synthesizing lactone by using nano magnesium-base catalyst

InactiveCN101186601AHigh catalytic activityHigh selectivityPhysical/chemical process catalystsOrganic chemistryCyclohexanoneCatalytic oxidation

The invention relates to chemical technical field, in particular to a method for using magnesia catalyst to catalyze and oxidize cyclone to synthesize lactone. The invention uses some nanometer sheet magnesia compound as catalyst, uses mixture of cyanobenzene and 1, 4-dioxane at a certain proportion as solvent, at a special reaction temperature, to catalyze and oxidize cyclone to synthesize lactone compound. The invention uses commercial cyclopentanone, cyclohexanone and adamantaneketone as raw materials, at mild condition, to reach the total yield of lactone compound more than 90%. The invention uses hydrogen dioxide water solution as oxidant, to eliminate the environment pollution of traditional oxidation process as peroxyacid, to realize environment-friend catalysis conversion. The invention has low cost, which can be used for industrialized lactone compound production.

Owner:FUDAN UNIV

Method for preparing nano-crystal lithium-titanium composite oxide

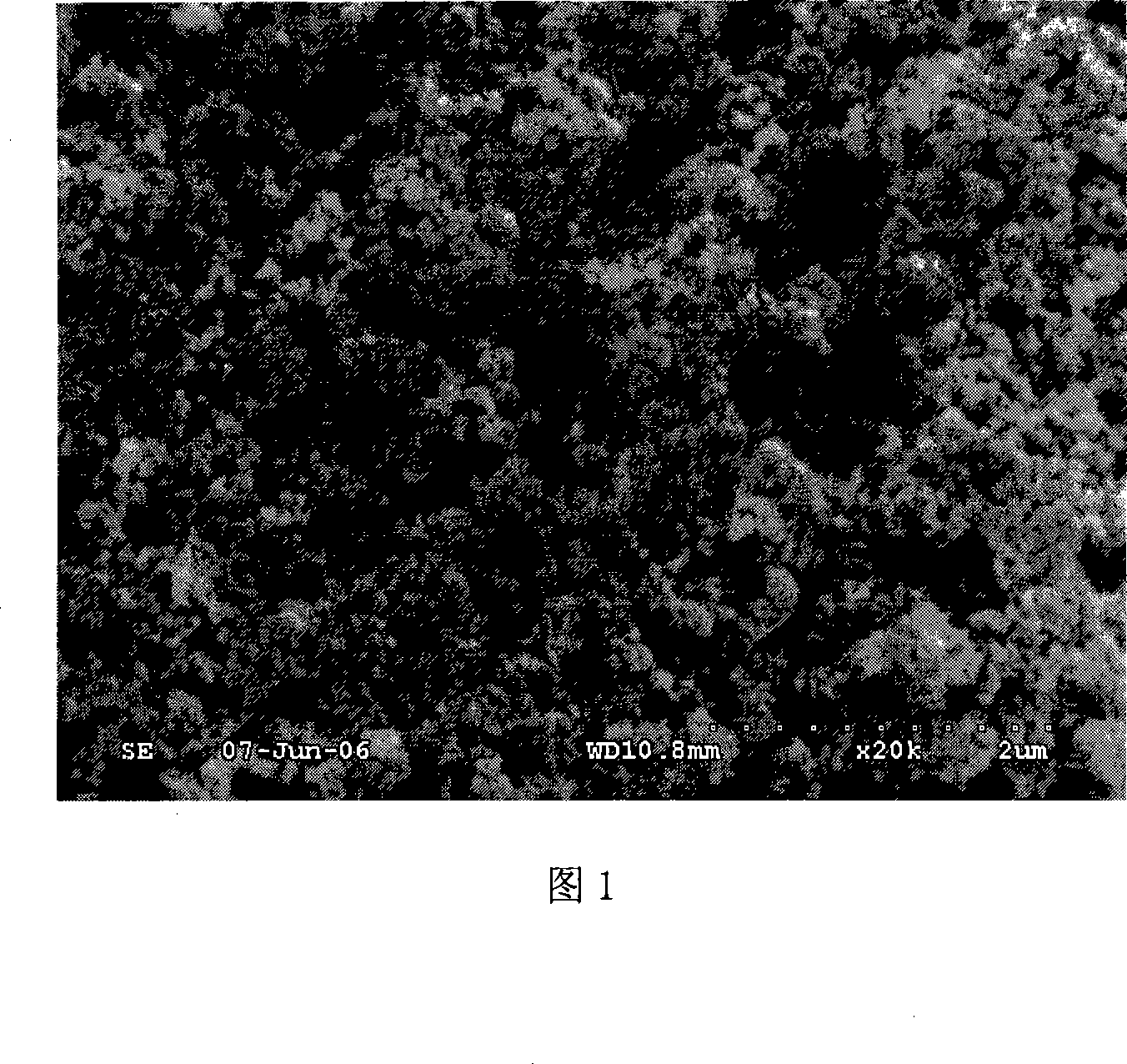

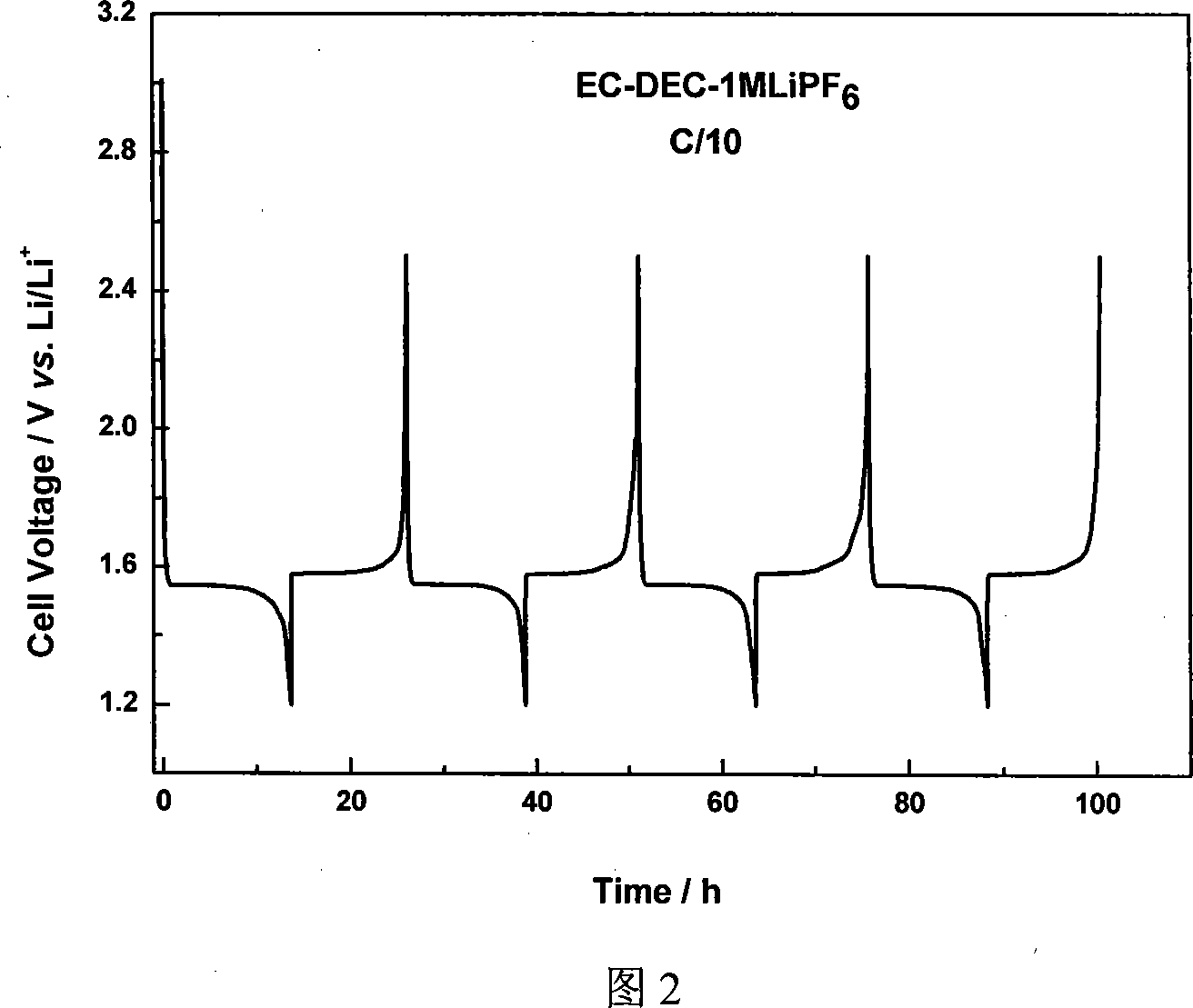

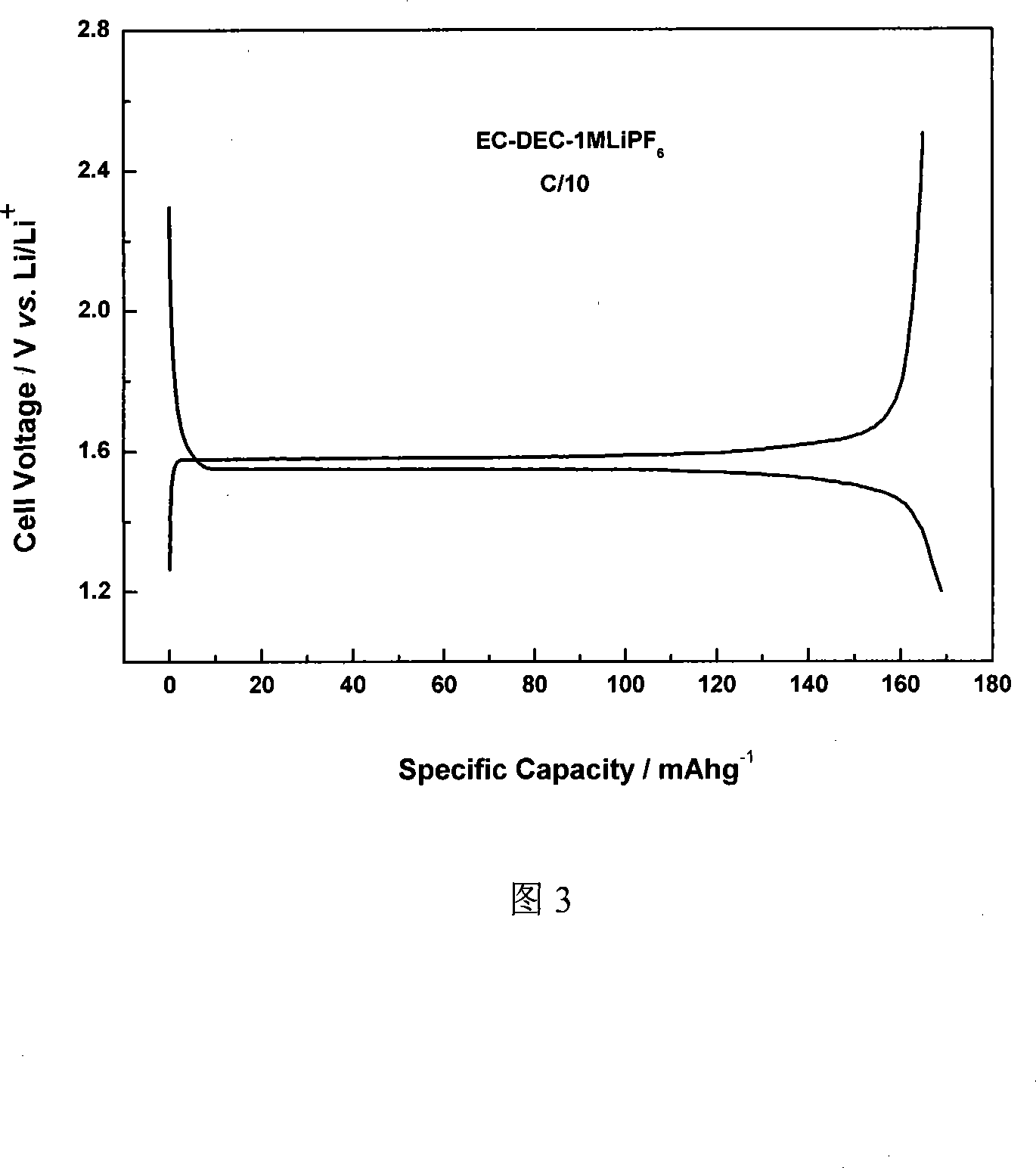

InactiveCN101058438ARich reservesReserves are cheapNanostructure manufactureCell electrodesCapacitanceWater baths

The invention discloses a making method of nanometer crystal Li-Ti composite oxide, which comprises the following steps: adopting titanium powder or titanium compound as raw material; blending the materials with 30% hydrogen peroxidate under low temperature; adding certain quantity of lithium salt solution and moulder; stirring evenly; reacting under water bath condition at 50-100 deg. c completely; drying the composite system directly to produce predecessor; proceeding heat disposal for the predecessor at 200-400 deg. c for 2-6h; heating to 600-1000 deg. c; sintering 8-36h; cooling; grinding; obtaining the nanometer crystal Li-Ti composite oxide with spinel structure and the content of Li4Ti5O12 over 90%; controlling the even grain size of the product between 15nm and 100nm and specific surface area between 10 and 100m2 / g due to different aperture shape of moulds, sintering time and temperatures; making the reversible specific capacity of the product over 160mAh / g under 0. 1C charging and discharging condition; keeping the capacity maintaining rate between 50% and 70% under discharging condition at 100deg. c as ideal negative electrode material of lithium ion dynamic battery and lithium ion super-capacitance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

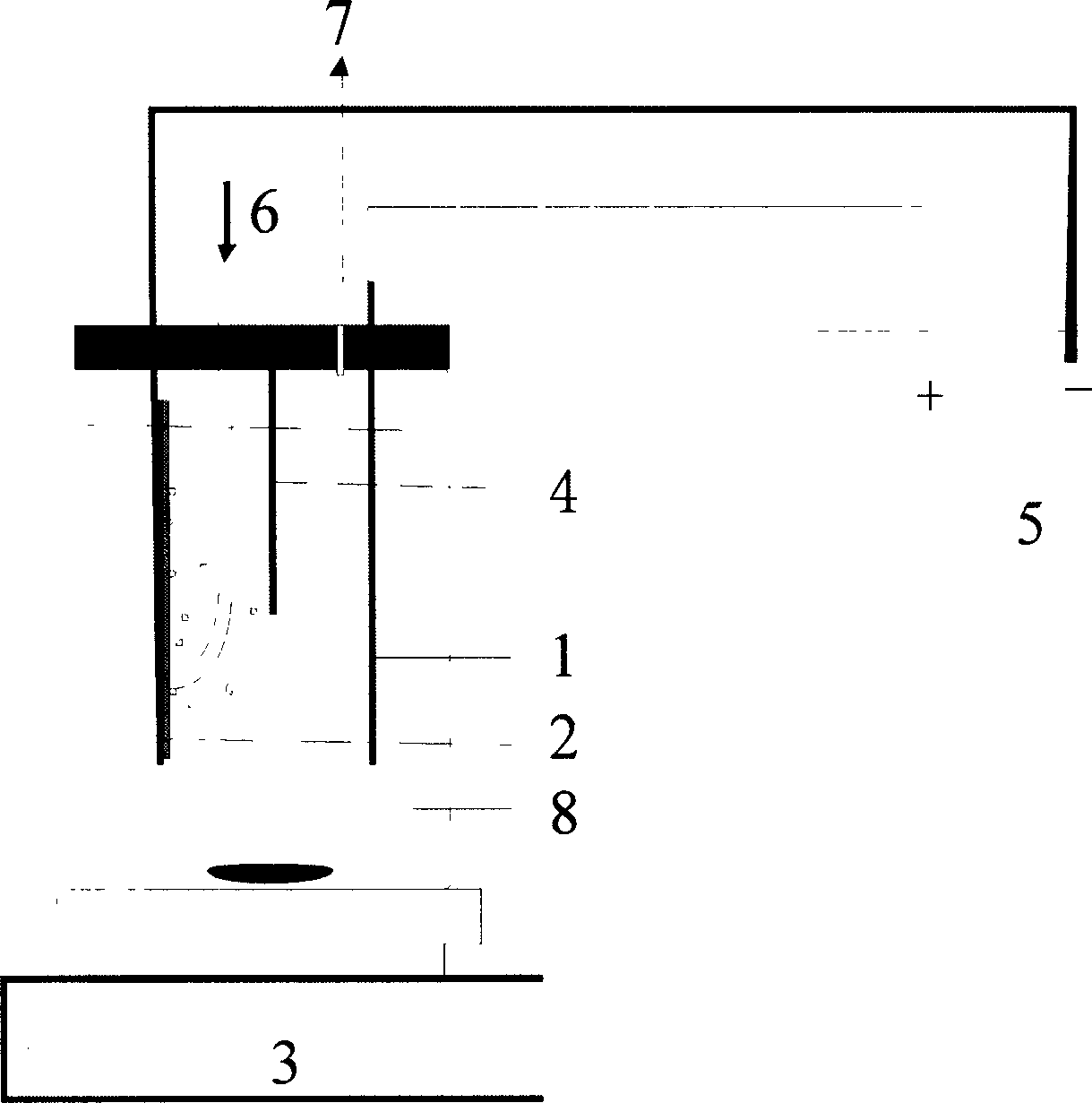

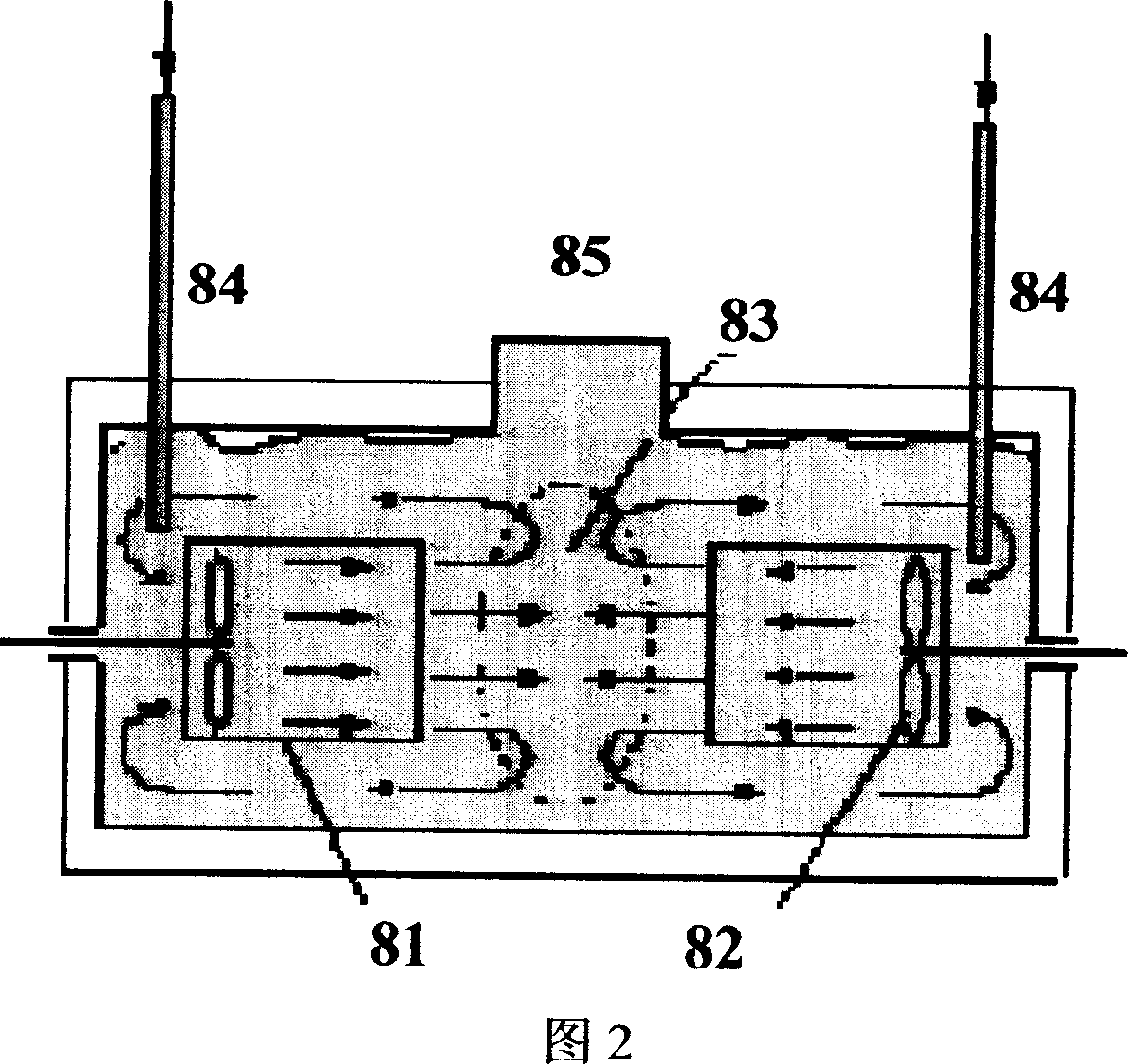

Method and apparatus for removing water organisms by utilizing inductive electric Fenton reaction

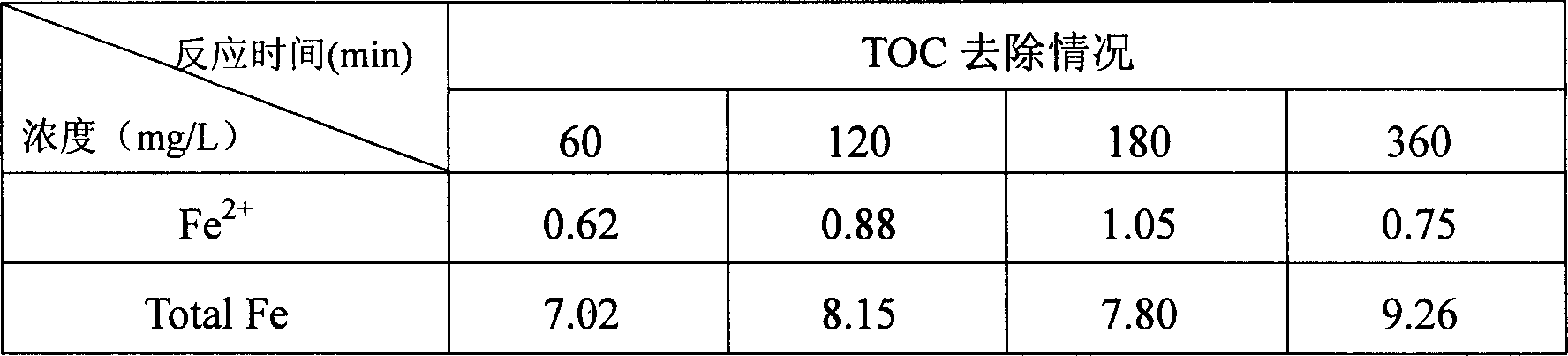

ActiveCN1789154AHigh removal rateGood mineralization removalWater/sewage treatment by electrochemical methodsFiberChemical reaction

The invention provides a faradic electrical FenDun method of removing the non-degradable organic matter in water, applying the faradic ferro-electricity to the electrical FenDun reaction, the ferrous iron ion dissolving out from the surface of iron electrode through oxidation-reduction reaction and electrochemical faradic reaction in electrolytic process and reacting with hydrogen dioxide generated on the cathode surface, that is FenDun reaction, generating hydroxyl free radical with high effect to degrade the organic matter in water. The invention also provides a device applying the faradic electrical FenDUN reaction to remove organic substance in water, which comprises: the reactor employing shape stable electrode as anode, employing activated charcoal fiber as cathode, putting the iron faradic electrode of certain area between the anode and cathode and venting a certain quantity of oxygen to the cathode surface. Adding organic wastewater with pH being about 3 into reactor and importing current flow for electrolysis to remove pollutant. The invention employs oxidation-reduction reaction and electrical chemical reaction to generate the ferrous iron ion gradually needed for FenDun reaction which reacts with the hydrogen dioxide generated by electrochemical reaction to generate the FenDUn reaction which generates the hydroxyl free radical with high effect to degrade the organic matter in water and realizes the purpose of removing pollutant.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Full-cotton woven fabric bioenzyme continuous destarch ungumming-bathing pretreatment process

The invention is a kind of fore process of biology enzyme continuous desizing, refinery-washing method for cotton textile, which belongs to textile front process field in printing and dyeing industry. It solves the problem that the water and electricity are consumed in a large amount, and goes against with the environment protection, the process reaches the best process effect. The process carries on boiled water heat process to cotton textile, and then through impregnating biology enzyme liquid, steamed biology enzyme desizing, refinery process water cleaning, then through impregnating hydrogen dioxide bleaching liquid, steaming bleaching process, water cleaning etc. processes. By using the process, the fore process effect is good, the desizing effect is good, the white rate is high, and it has good humidification, small harm to fiber, high quality, soft, the method process the colourity, pH value, COD value to degree far lower than the current process, it reduces the bear of waste water processing, it is advantage to protect the environment, the efficiency is high, the low labour intensity, energy saving, and water saving.

Owner:JIANGNAN UNIV

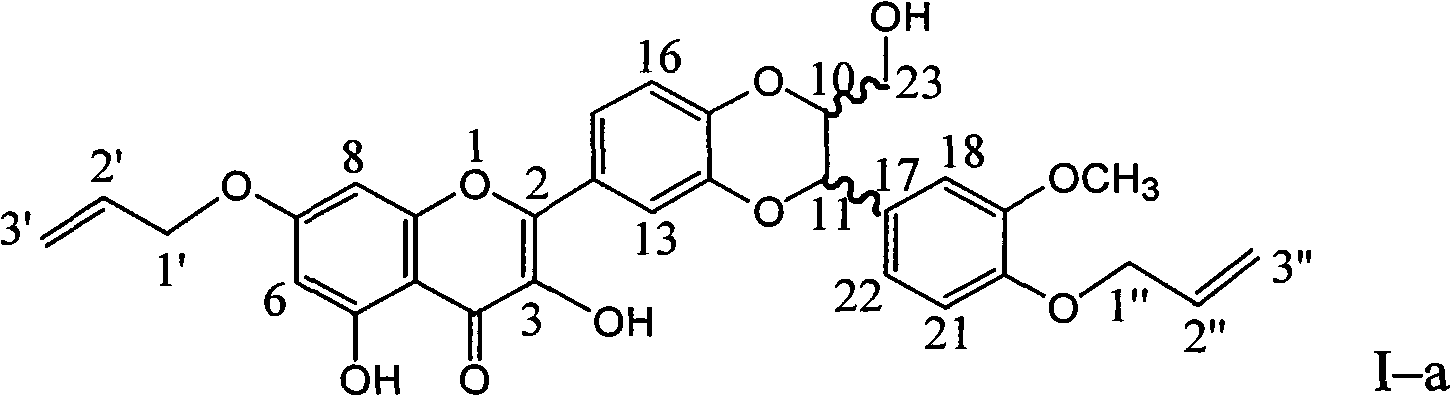

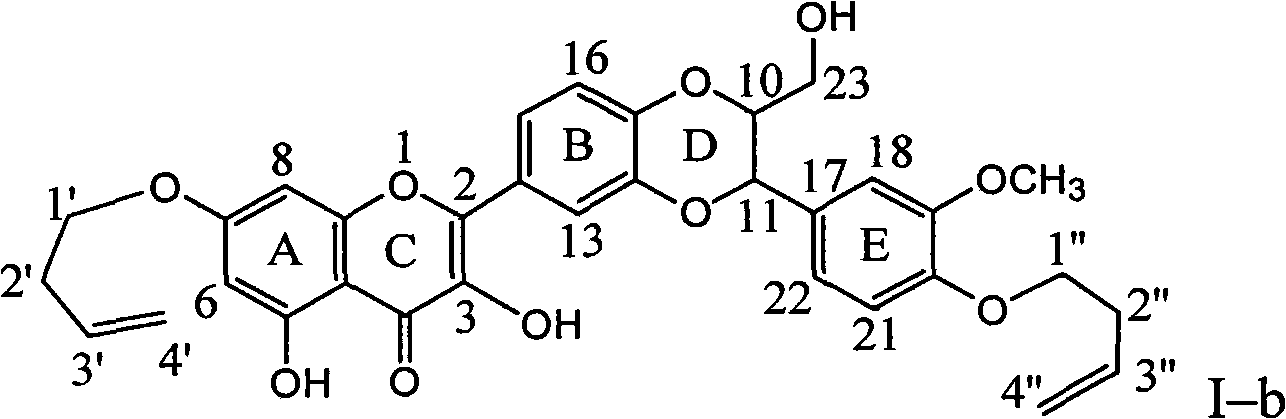

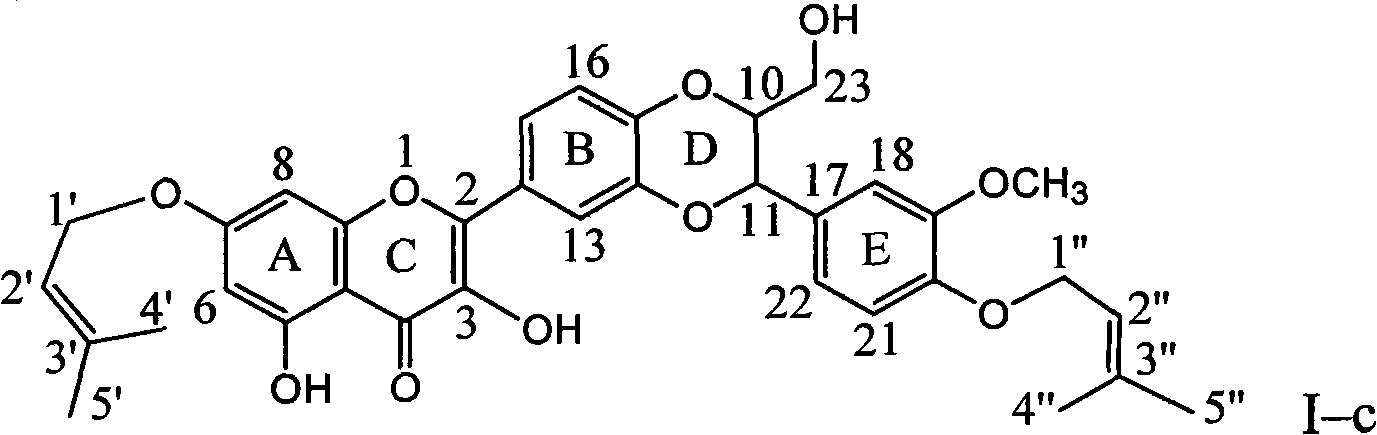

7 and 20 dehydro-silybin dialky ether and preparation method and medicine use thereof

InactiveCN101565419AStrong anti-lipid peroxidationProtects chelation abilityOrganic active ingredientsNervous disorderDiseaseSuperoxide

The invention relates to a 7 and 20 dehydro-silybin dialky ether and preparation method and medicine use thereof. The compounds are capable of obviously preventing the lipid superoxide induced by the free radical from being generated; effectively protecting the injury rat adrenal pheochromocytoma cells PC12 due to hydrogen dioxide, namely with oxidation resistance injury protection function on thePC12 cells which simulate the cranial nerves; preventing the brain cells and the cranial nerves from being oxidized and controlling the neurodegenerative diseases such as senile dementia. In addition, the compounds have strong chelation on the ferrous ion. The pharmacodynamics result shows that: the compounds are anticipated to prepare the medicine for controlling the neurodegenerative diseases.

Owner:DALI UNIV

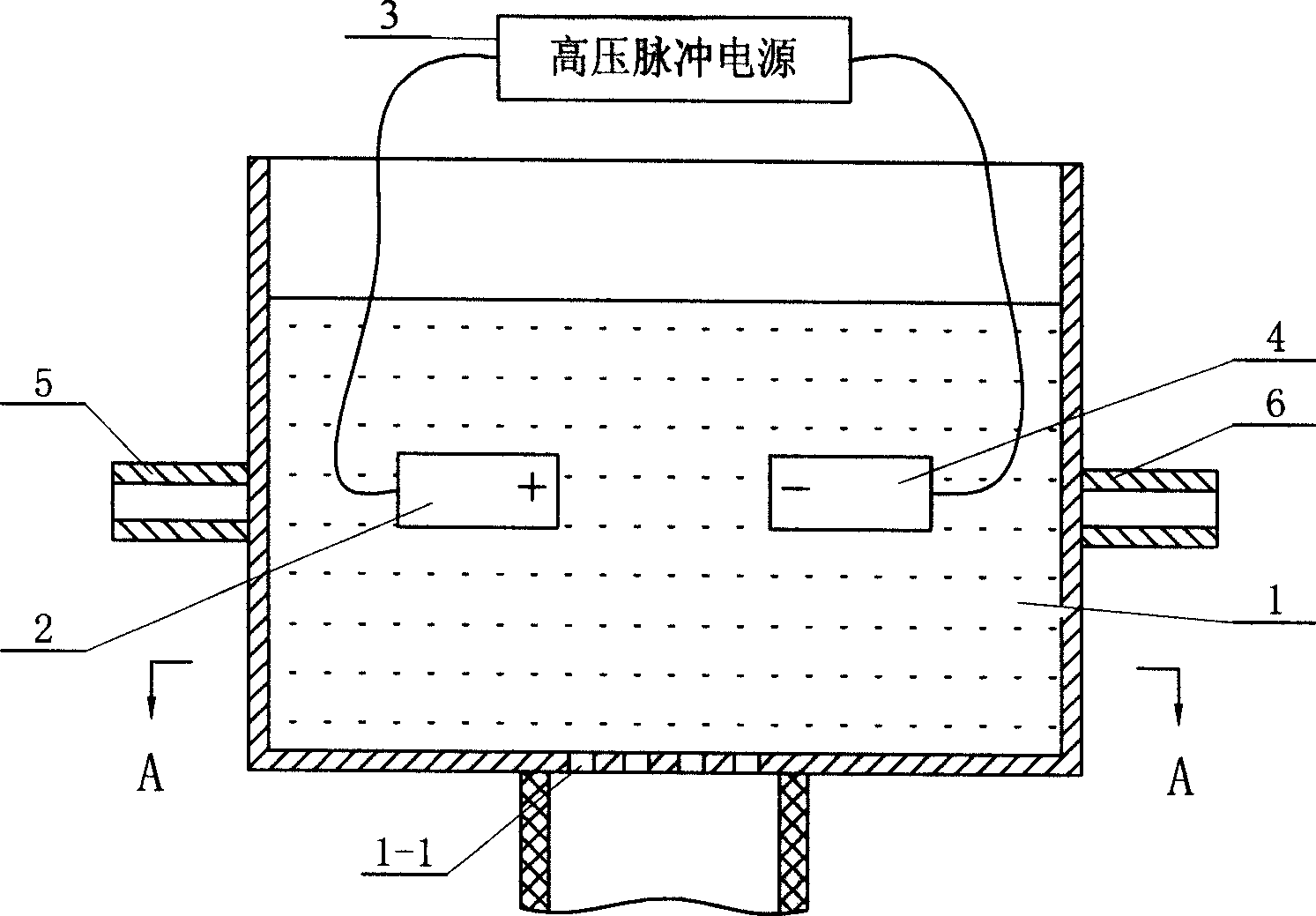

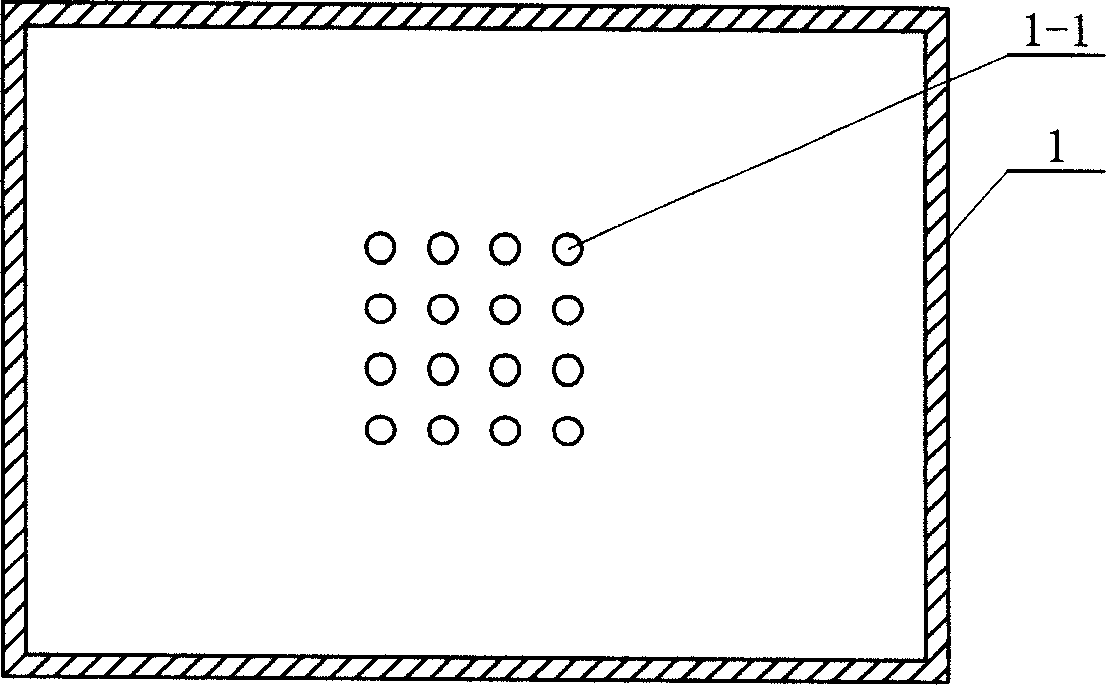

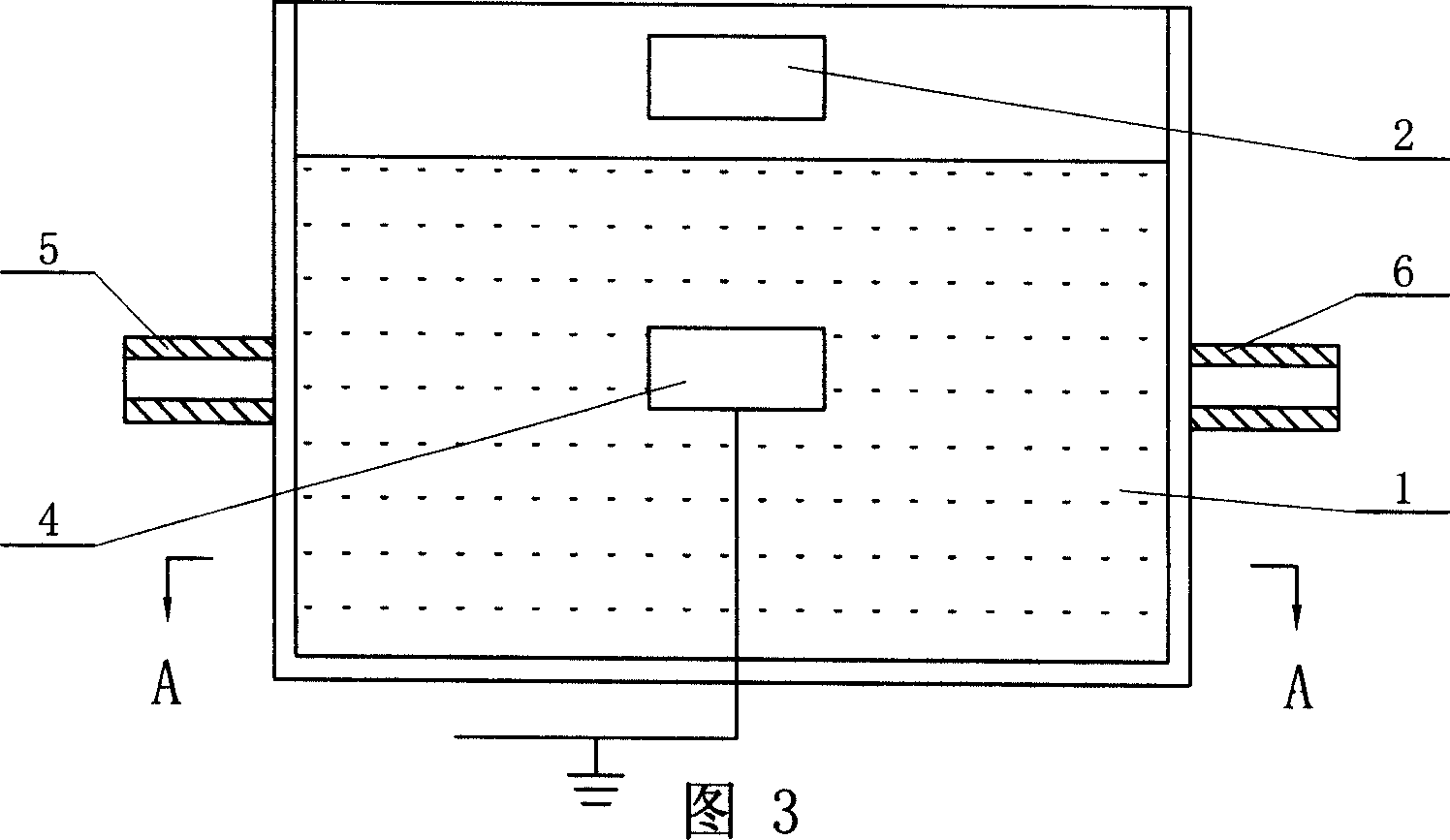

High-pressure pulse discharge catalytic oxidation method for removal of undegradable organic substances in water

InactiveCN1663916AImprove oxidation efficiencyImprove processing efficiencyWater/sewage treatment by electrochemical methodsWater/sewage treatment by magnetic/electric fieldsCatalytic oxidationOxygen

The invention discloses a method of removing the non-degradable organic substance in the water by catalyzed oxidation with high-voltage discharging, comprising applying the high-voltage pulse between the high voltage electrode 2 and earth electrode 4 in the reaction container with water by high voltage impulse power source 3, and at the same time adding oxygen, ozone, powdered activated carbon, transition metal oxide, hydrogen dioxide or transition metal ion to catalyze and oxygenize the organics. The process of removal of non-degradable organic is reinforced because of the existing of diverse catalyst and the efficiency of removal is greatly improved.

Owner:HARBIN INST OF TECH

Process for preparing magnesium alloy chemical conversion coating

ActiveCN1880503AEliminate hazardsImprove corrosion resistanceMetallic material coating processesSodium iodideFluohydric acid

The invention discloses a chemical transmission film preparing technology of magnesium alloy, which comprises the following steps: a. proceeding degreasing disposal for magnesium or magnesium alloy through sodium hydroxide or one or multiple hybrid solutions of sodium phosphate with sodium hydroxide, sodium carbonate and sodium silicate solution; b. proceeding acid cleaning disposal for degreased magnesium or magnesium alloy through hybrid solution of phosphoric acid and sodium phosphate; c. proceeding activating disposal for acid cleaned magnesium or magnesium alloy through hybrid solution of fluohydric acid and sodium phosphate; d proceeding chemical synthesizing disposal for activated magnesium or magnesium alloy through composite solution of calcium nitrate hydrate, sodium nitrite, sodium iodide and hydrogen dioxide solution; e. packing hole of synthetic magnesium or magnesium alloy through deionized water. The invention doesn't utilize chromic composition, which eliminates danger for environment.

Owner:靖江市华信科技创业园有限公司

Method for preparing carbon nanotube supported nanometer hydrated ruthenium oxide

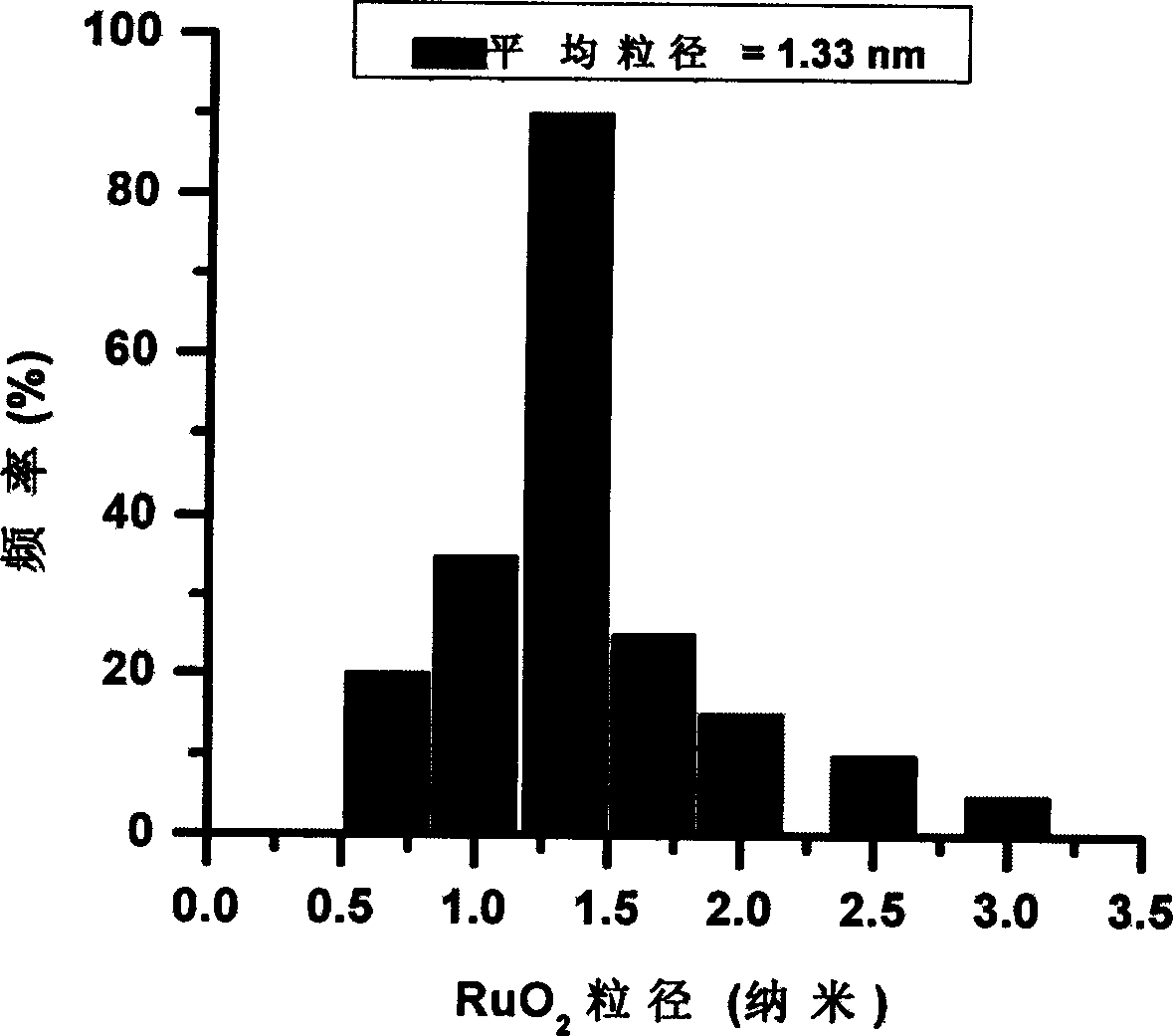

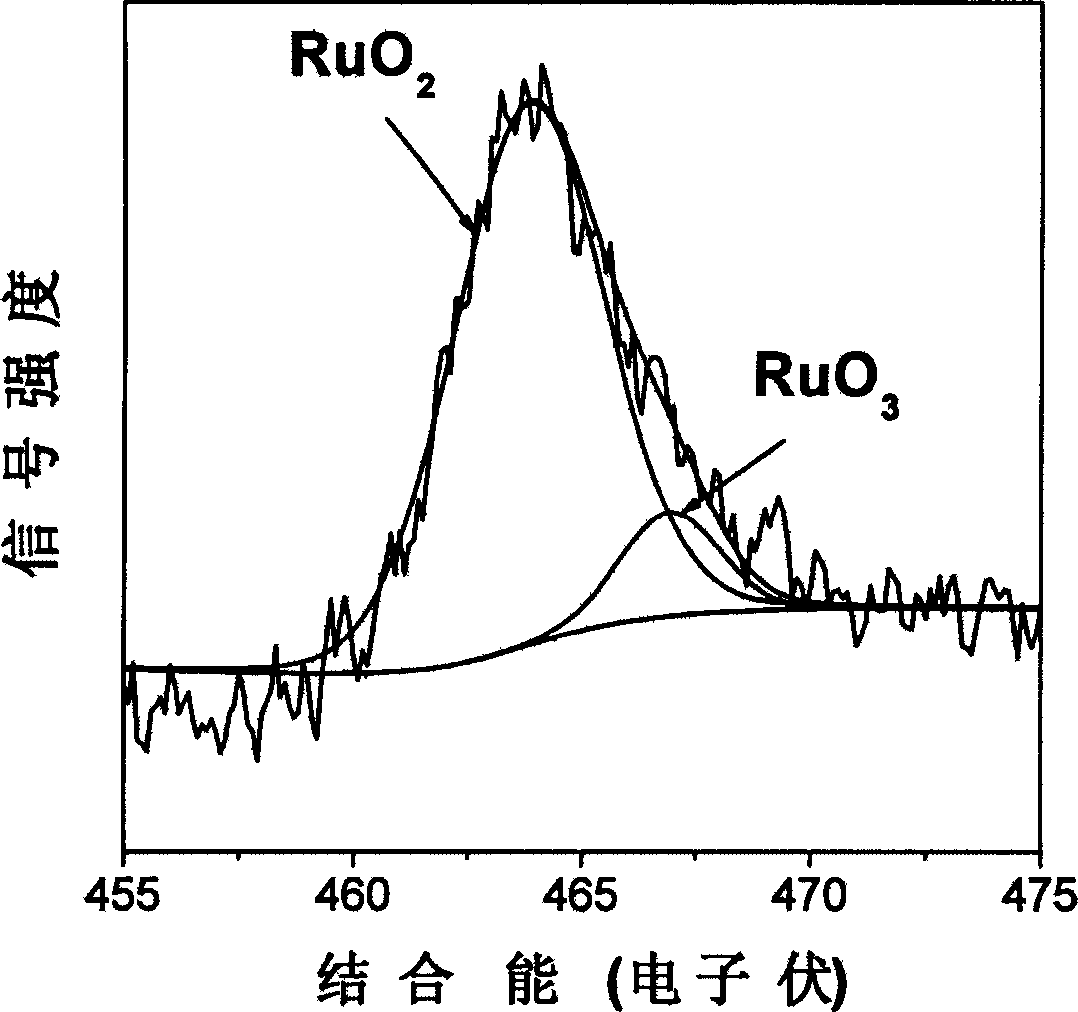

InactiveCN1806914AAvoid influenceMild preparation conditionsCatalyst carriersCatalyst activation/preparationCapacitanceAlcohol

The invention provides the method for preparation of hydrated nanometer ruthenium oxide loaded on carbon nanometer tube, comprising the following steps: putting the carbon nanometer tube into ruthenium chloride solution, vibrating with ultrasonic sound, at room temperature, adding hydrogen dioxide solution, carrying out heating-up reversed flow reaction, filtering, washing, drying and getting the product. The method is simple, and the hydrated ruthenium oxide has high dispersion degree on the carbon nanometer tube, small and homogeneous particles, good stability and high load capacity. The hydrated nanometer ruthenium oxide loaded on carbon nanometer tube has wide application in super capacitance and alcohol oxidative catalyst.

Owner:SOUTH CHINA UNIV OF TECH

Method of recovering noble metal from spent catalyst containing noble metal

InactiveCN1448522AEfficient use ofReduce manufacturing costProcess efficiency improvementPhysical chemistryPre treatment

The method of recovering noble metal from waste catalyst containing noble metal includes the first pre-treatment of waste catalyst containing noble metal to make noble metal exist in reductive state favorable to further treatment; the subsequent leaching of the waste catalyst with mixed solution containing hydrogen dioxide solution, hydrogen ion and chlorine ion to make the noble metal component exist in ion state in the mixed solution; and the final treatment of the mixed solution containing noble metal ion to recover noble metal component. Compared with available technology, the present invention has less investment, simple technological process, less pollution, short time consumption, high recovering rate and being easy use in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

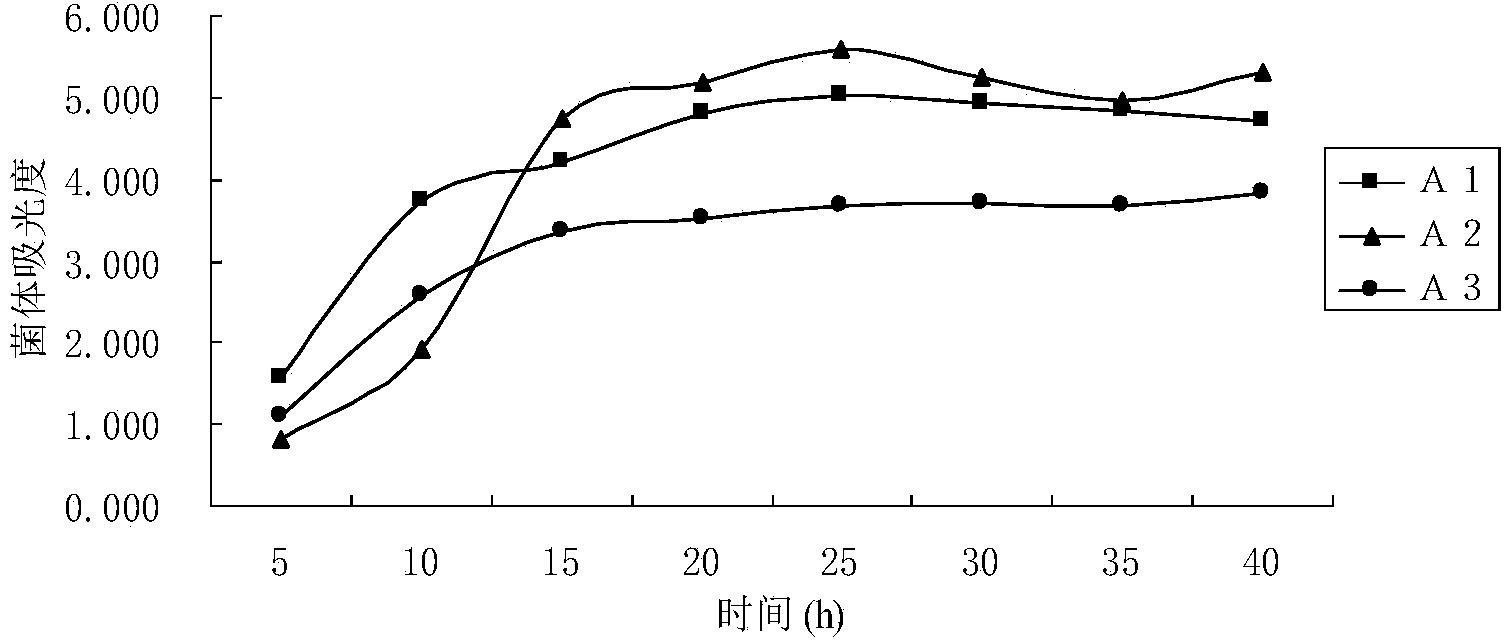

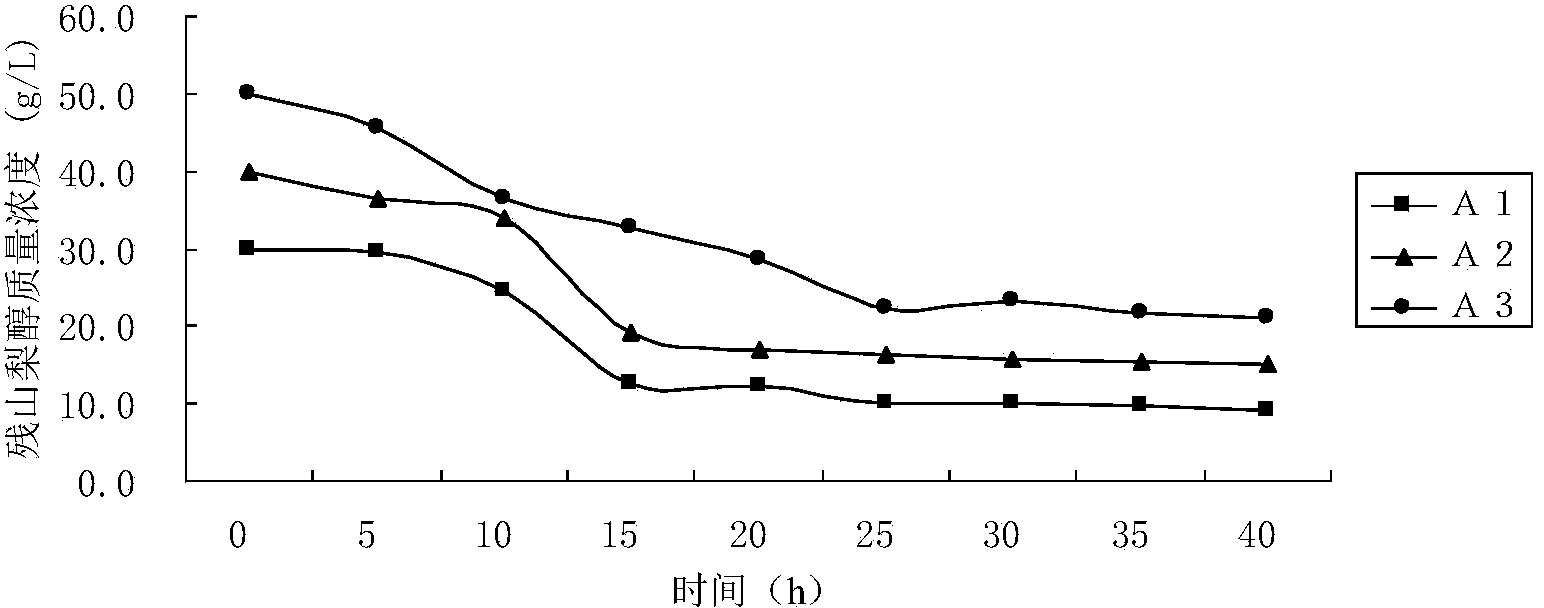

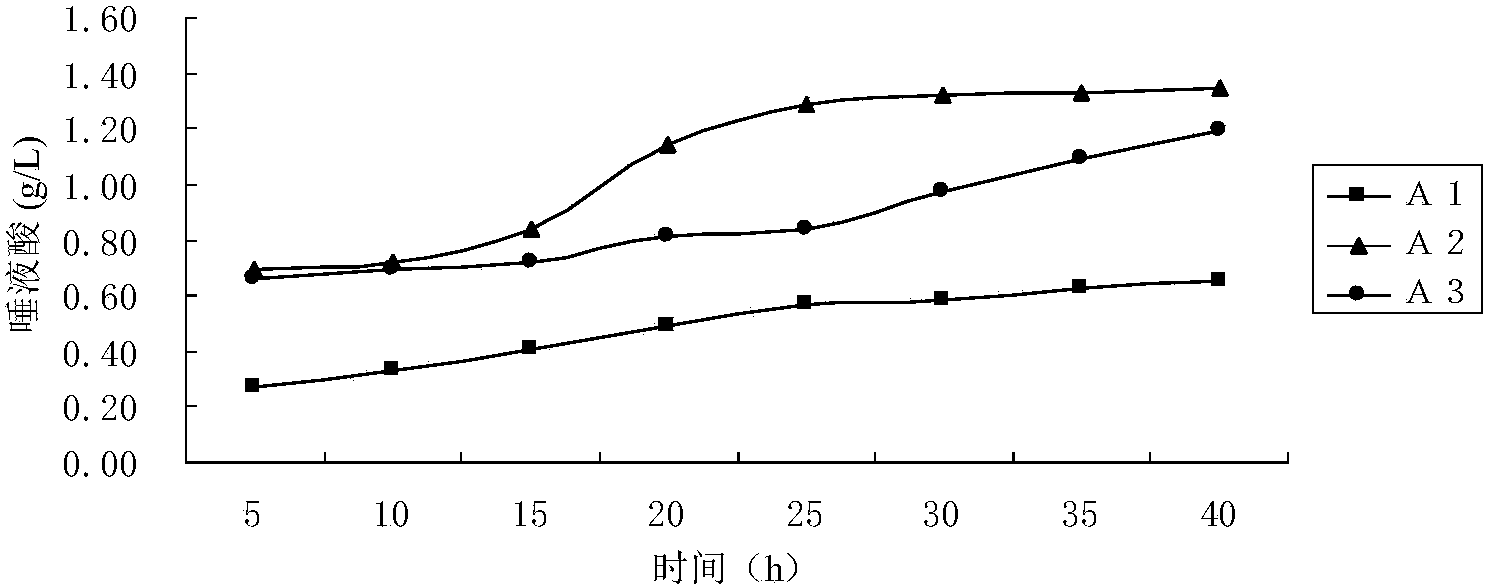

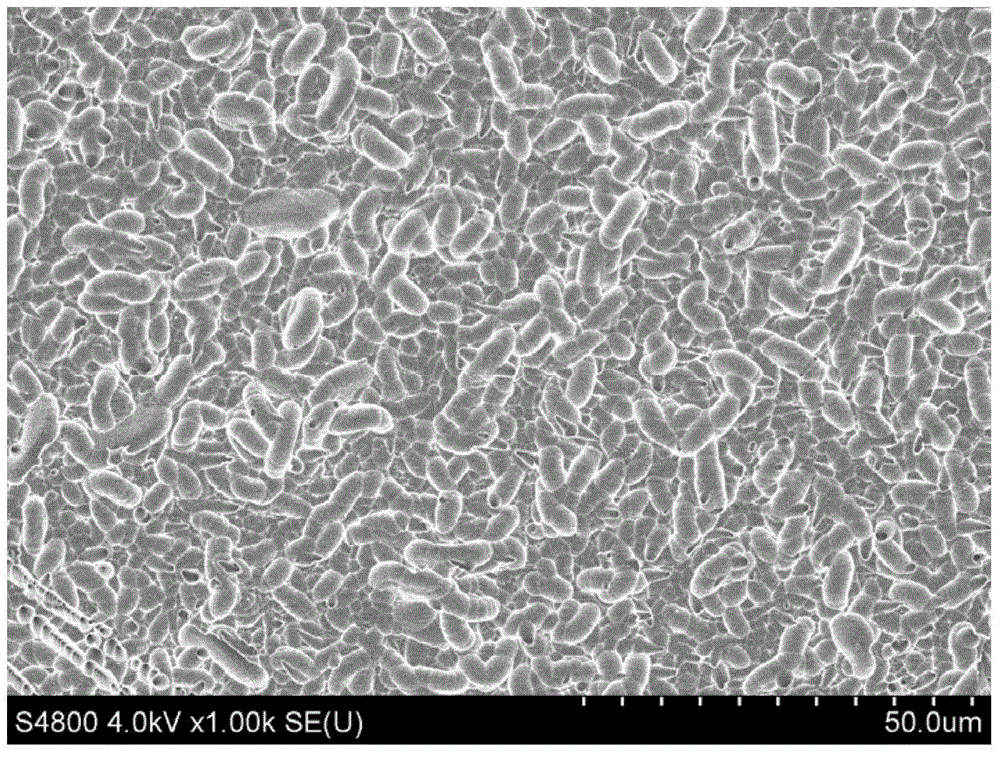

Fermentation production method of sialic acid

The invention discloses a fermentation production method of sialic acid and belongs to the technical field of bioengineering. The method comprises the following steps: adding a seed liquid into a fermentation tank containing a sterilizing fermentation culture medium; continuously fermenting to produce fermentation liquid containing polysialic acid in a way of replenishing feeding liquid and a hydrogen dioxide solution; then carrying out centrifugal separation, ethanol precipitation and filtration to obtain refined polysialic acid; then, carrying out acidolysis and crystallization on the polysialic acid; and finally, washing and freeze-drying to obtain sialic acid powder. The output of the polysialic acid produced by the method provided by the invention can reach 12.96g / L, the already reported maximum content of the polysialic acid is improved by 87.28%, the hydrolysis rate of polysialic acid is 95%, the content of purified sialic acid reaches 10.01g / L and the purity reaches 94.80%. The method is suitable for industrial promotion and application.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

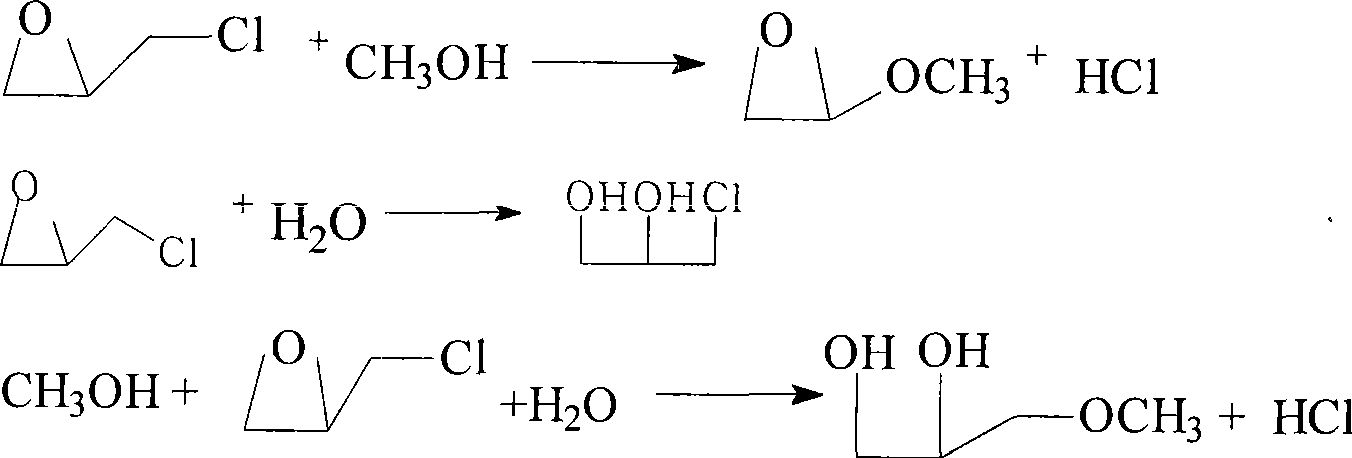

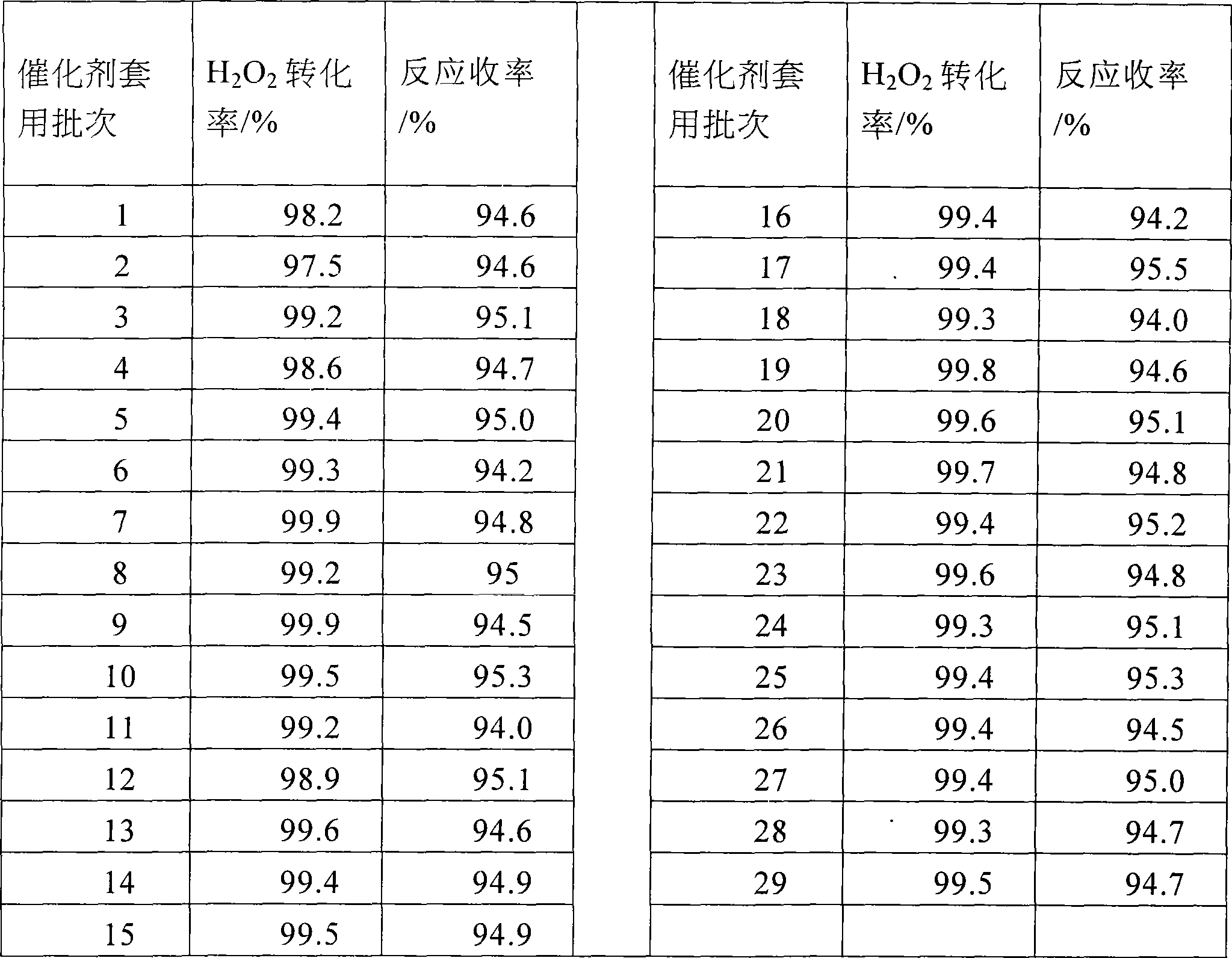

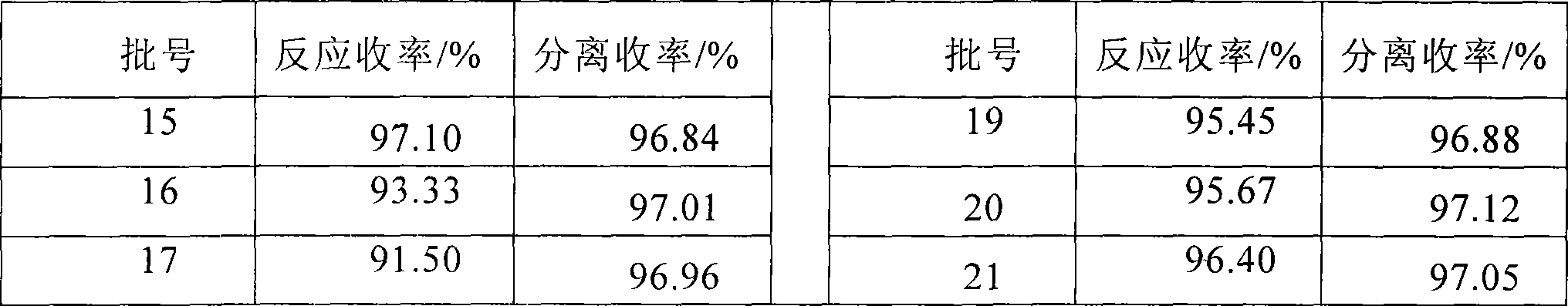

Production method of epoxy chloropropane by hydrogen peroxide method

The invention discloses a method for preparing epoxy chloropropane with the oxidation of chloropropene. The chloropropene, a solvent and fine particles of titanium silicate molecular sieve catalyst are put into a reaction pot and a hydrogen dioxide solution is added at 10 DEG C to 80 DEG C. The method is characterized in that a reaction is carried out under a subacidity condition and after the reaction, materials pass through an intermediate tank for oil-water dissociation to be divided into oil phase and water phase; the oil phase is sent into a rectifying tower for separating the chloropropene and ECH. After the water phase is filtered, a catalyst filter cake is washed by the solvent, regenerated or applied to an epoxidation reaction after being directly beat with the solvent. The ECH is extracted from an aqueous layer after filtration by the chloropropene. An extracted oil layer and an oil layer obtained from the separation of a reaction solution are combined and rectified, or the extracted oil layer is applied to the epoxidation reaction; water left from the extraction is rectified for recycling methanol and applied to the preparation of catalysts; and the method has simple procedures, small consumption amount of solvents, high separation yield of reaction products and easy realization of industrialization.

Owner:JIANGSU YANGNONG CHEM GROUP +2

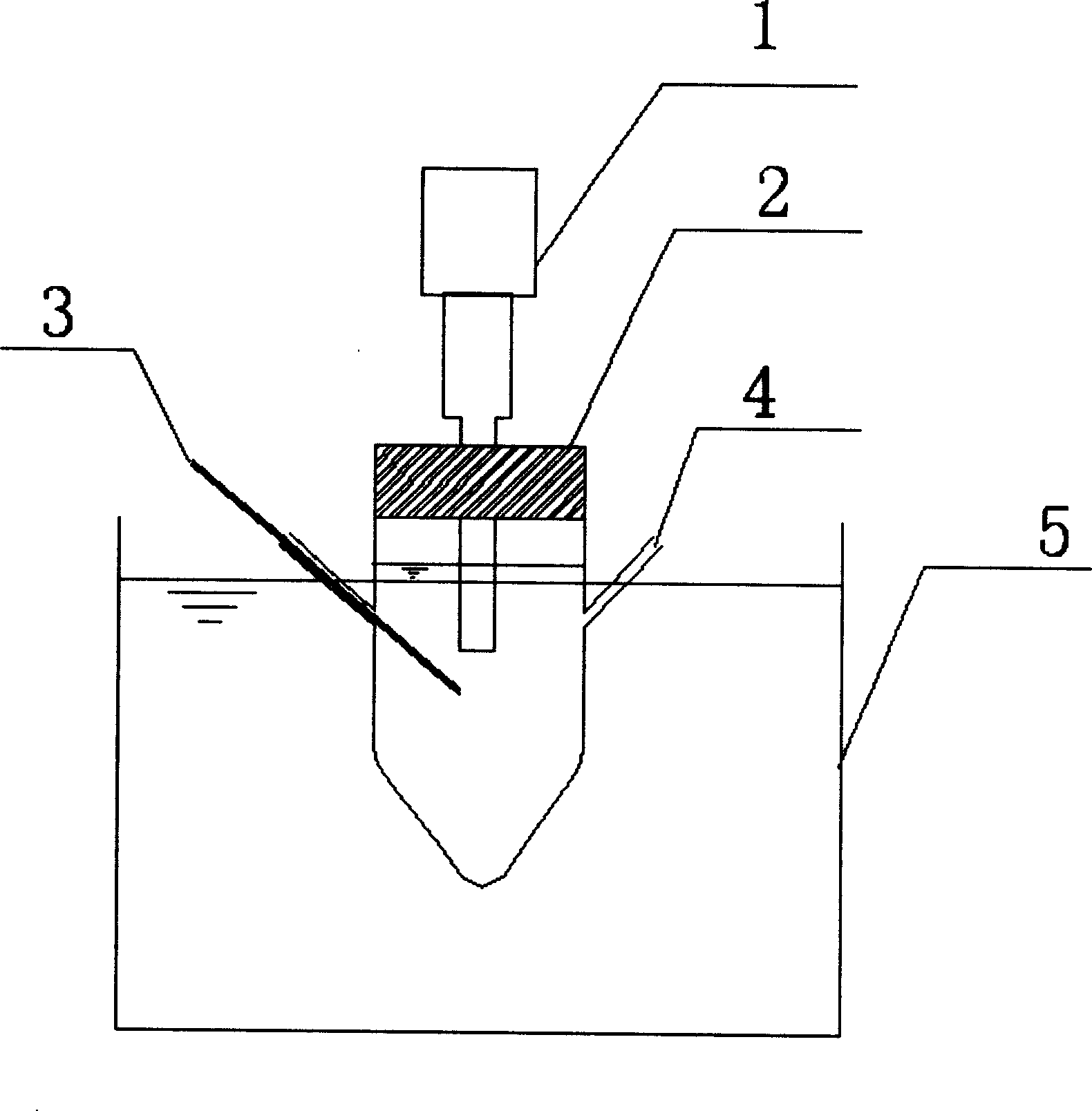

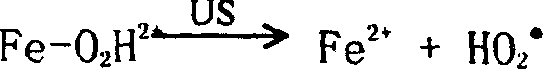

Advanced oxidation method for treatment of dye waste water

InactiveCN1546395AReduce consumptionReduce outputWater treatment compoundsWater contaminantsSludgeSupersonic waves

The invention discloses a high-level oxidization method for treating dyestuff waste water, which realizes dyestuff waste water decoloration through the Fenton method, characterized in that after throwing H2O2 and FeSO4 into dyestuff waste water, supersonic wave oscillation is carried out to the mixing liquid. The invention realizes high efficiency under the condition of equal COD removing ratio, in particular less hydrogen dioxide solution, ferrous iron ions and acid are consumed, thus minimizing sludge output and reducing the cost.

Owner:WUHAN UNIV

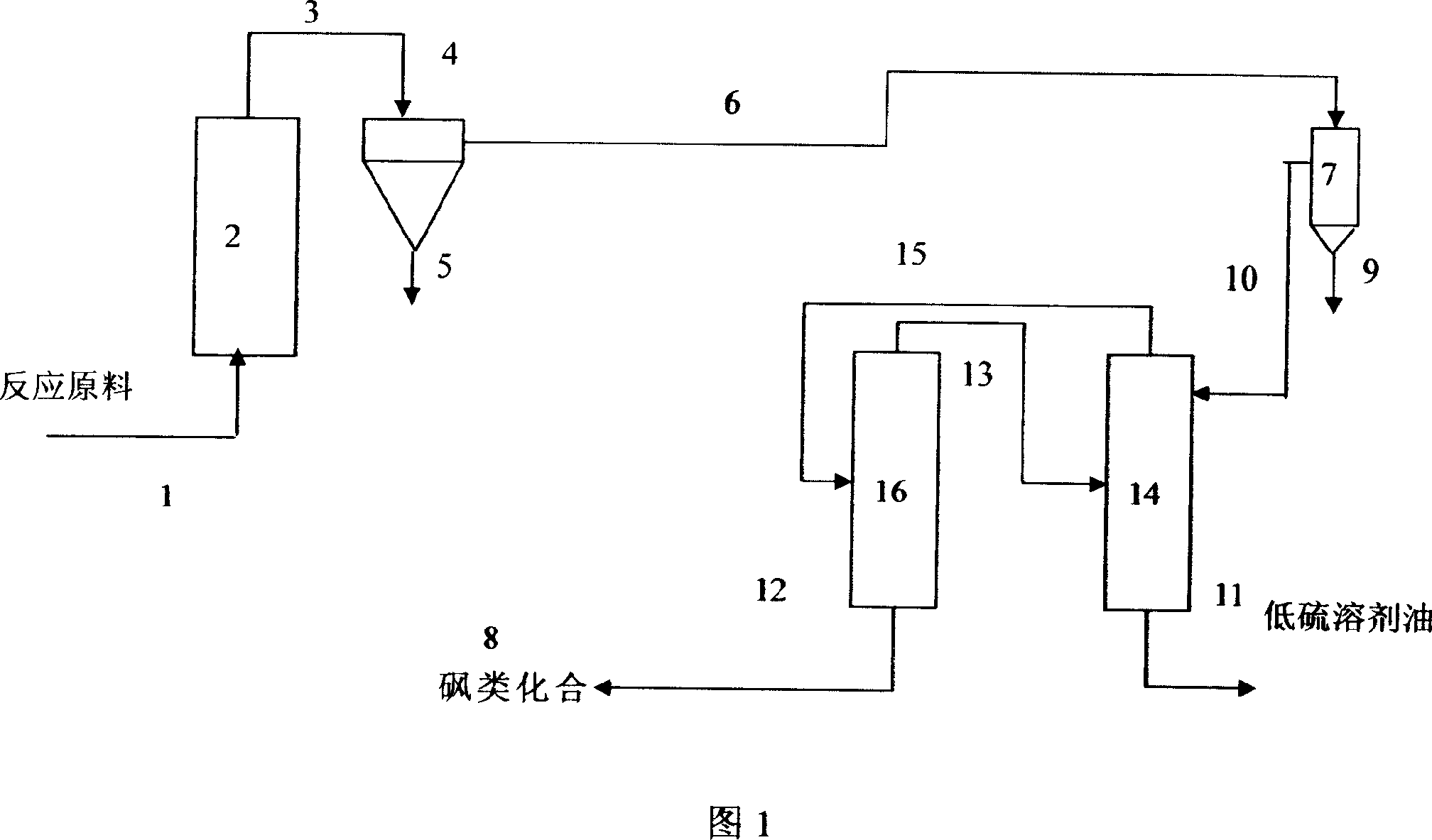

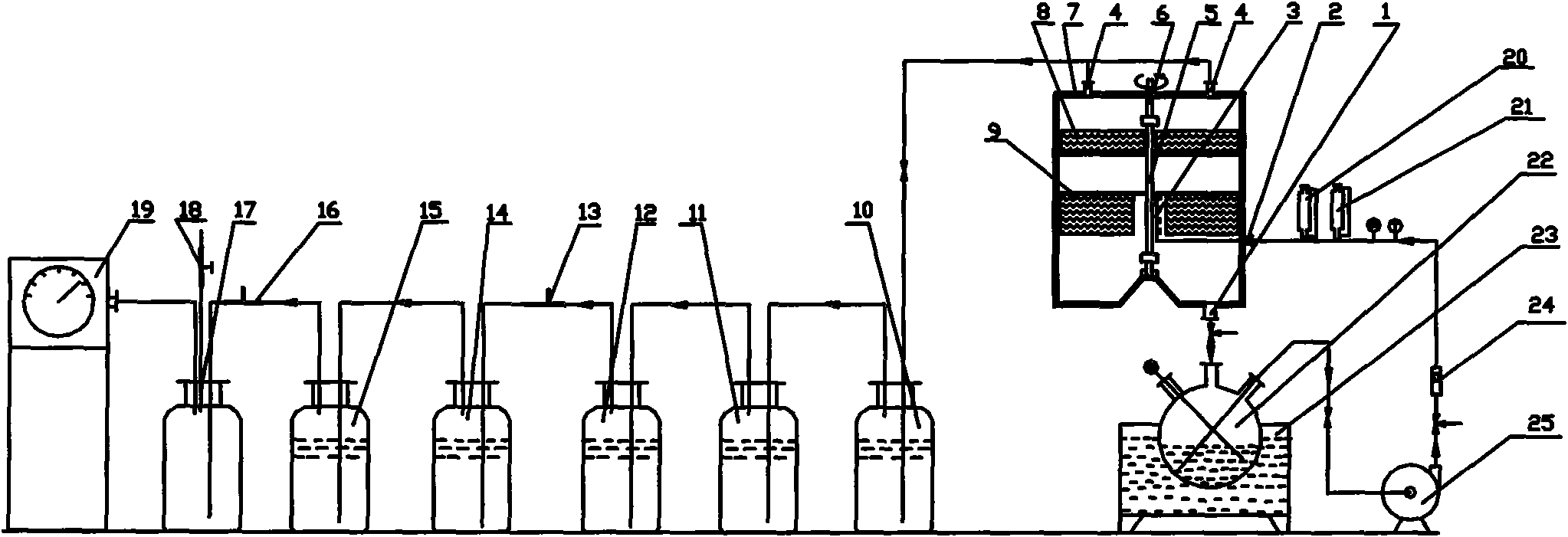

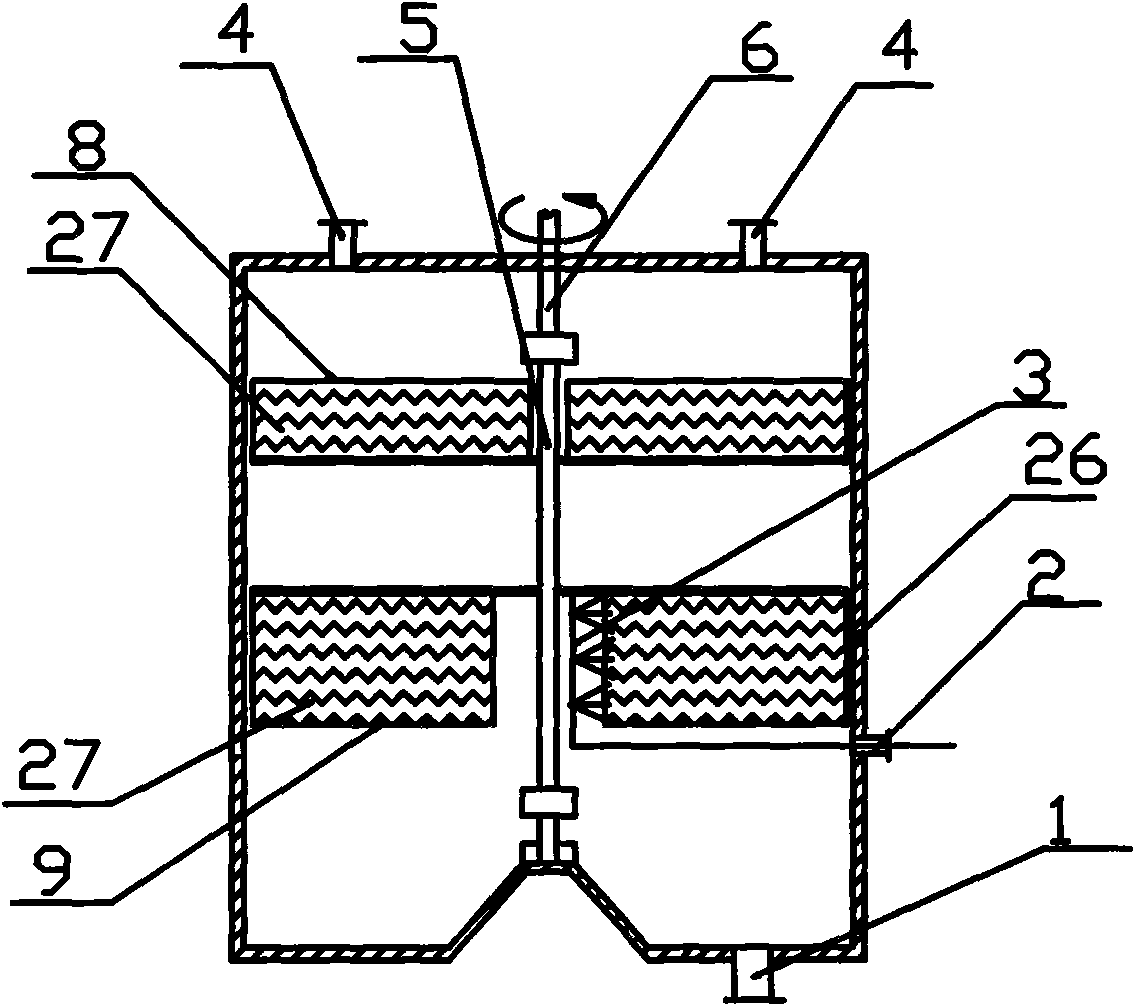

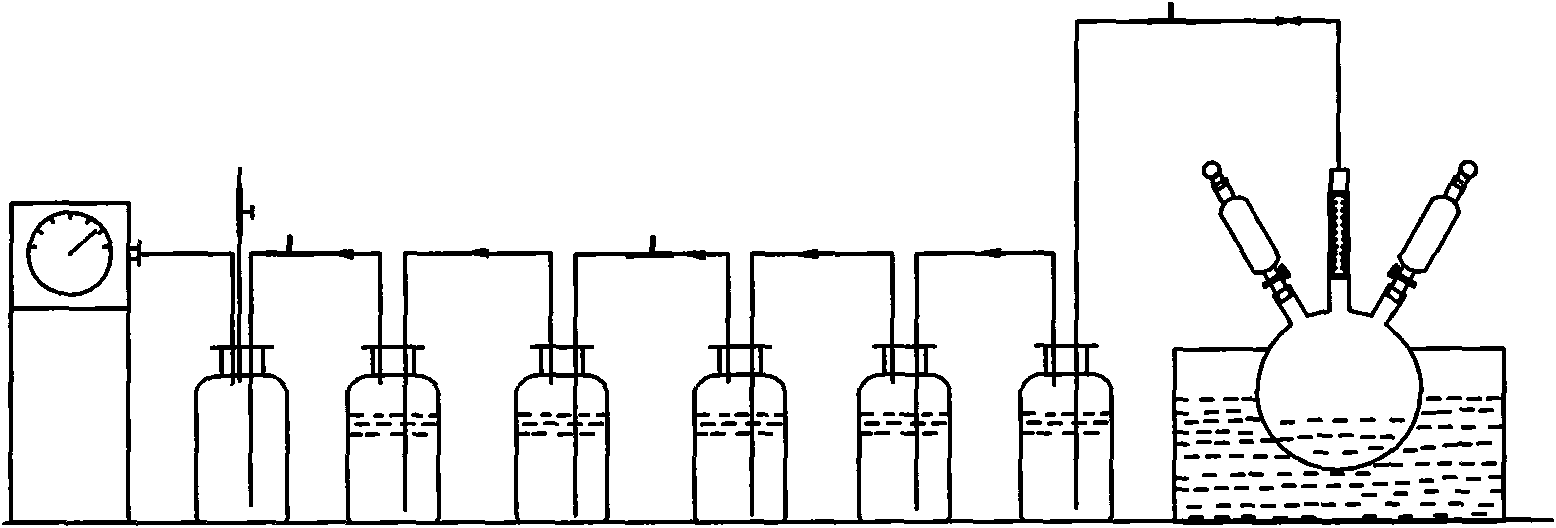

Light-end products oxidation desulfurizing and deodorizing method

ActiveCN101063042AReduce dosageLow mass transfer efficiencyRefining with oxygen compoundsSlagSolvent

The invention discloses an oxidation deodorizing and desulfurizing method of light-end products, which comprises the following steps: reacting light-end products and hydrogen dioxide solution in high effect mass transfer reactor such as knock current reactor with intensified turbulence inner component under existence of homogeneous catalyst; mixing evenly and completely in short time; proceeding effective bump quick-speed generating reaction; getting good reacting effect. This technique can eject sulfur-containing compound and bad odor substance of light-end products without discharging waste lye or waste slag, which can get high grade dissolvent oil raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Copper or copper alloy surface tiny-etching treatment fluid for smoothing

The invention relates to a metal surface processing liquid for printed circuit board, wherein the components of the process liquid include (by weight ratio): 35% hydrogen dioxide solution 3-12, 98% sulfuric acid 5-20, unsaturated alkane glycol compound 0.1-5, stabilizing agent 0.1-0.5, fluorine surface active agent 0.001-0.02, and balancing deionized water diluent.

Owner:广东省石油化工研究院

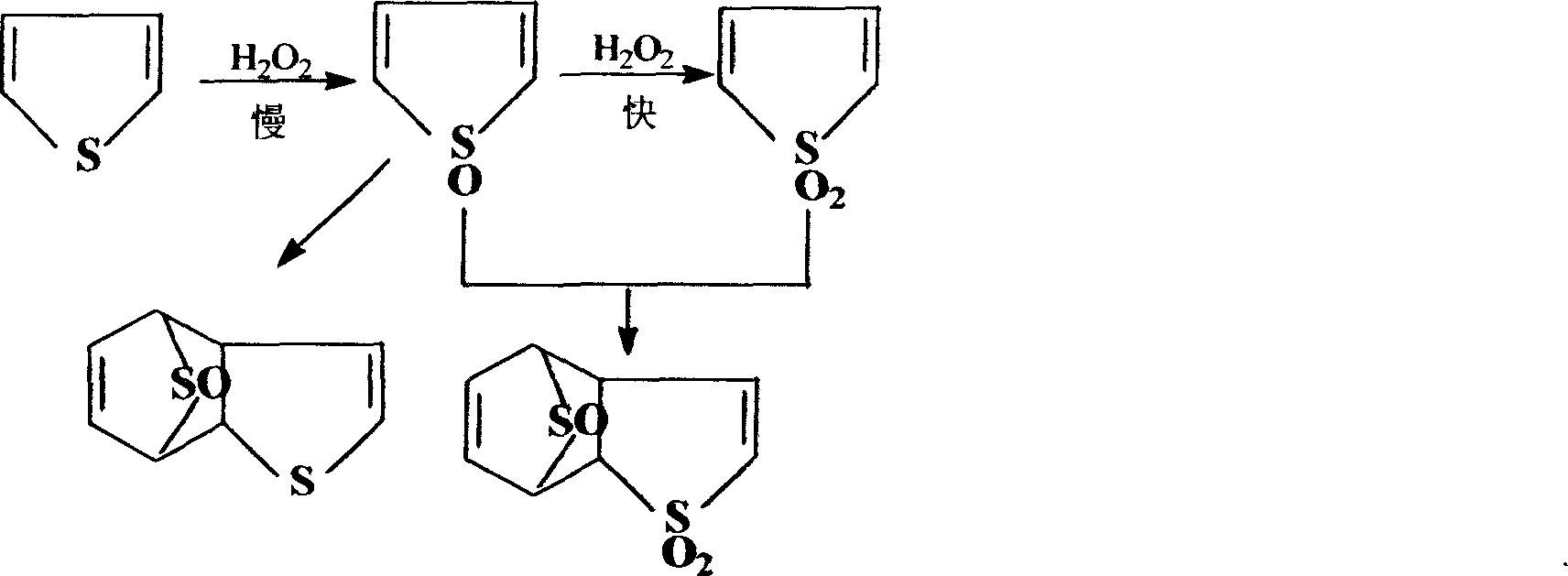

Oxidation sweetening process for diesel distillate

InactiveCN1504543APromote oxidationTo achieve the purpose of deep desulfurizationRefining with oxygen compoundsAcetic anhydrideDistillation

A process for diesel oil distillation oxidation sweetening comprises, adding in 0.1-20% diesel oil distillation volume of hydrogen dioxide and 0.1-20% acetic anhydride, reacting at the temperature of 30-90 deg. C, wherein the sulfide is oxygenized into sulfone or sulfoxide compounds, rinsing to remove acidic material, and removing sulfone or sulfoxide compounds from the diesel oil through adsorptive separation method. The catalyst has good regeneration effect and thus can be reutilized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for preparing high-purity ruthenium

InactiveCN101797649ASolve the sintered very hardSolve the problem of high chlorine and oxygen contentVacuum evaporation coatingSputtering coatingHydrofluoric acidHydrogen

The invention relates to a method and a device for preparing high-purity ruthenium. The method comprises the following steps that: hydrogen dioxide is added into ruthenium hydrochloride solution to be undertaken one section of oxidation distillation reaction, then oxidant is added into the liquid to be undertaken a second section of adequate oxidation distillation reaction, then the oxidation distillation is repeatedly performed to extract the ruthenium, ruthenium tetroxide gas which is discharged from the second section of oxidation reaction is adequately collected, the ruthenium tetroxide gas is transformed to ruthenium hydrochloride absorption liquid, ammonium chloride is added into the ruthenium hydrochloride absorption liquid to be crystallized and precipitated, and the prepared ammonium chloride ruthenium precipitant is calcined and reduced to sponge ruthenium under the atmosphere of hydrogen; and the prepared sponge ruthenium is dried under the atmosphere of the hydrogen after being boiled and washed by mixed acid of aqua regia and hydrofluoric acid to obtain the high-purity ruthenium.

Owner:LANZHOU UNIVERSITY

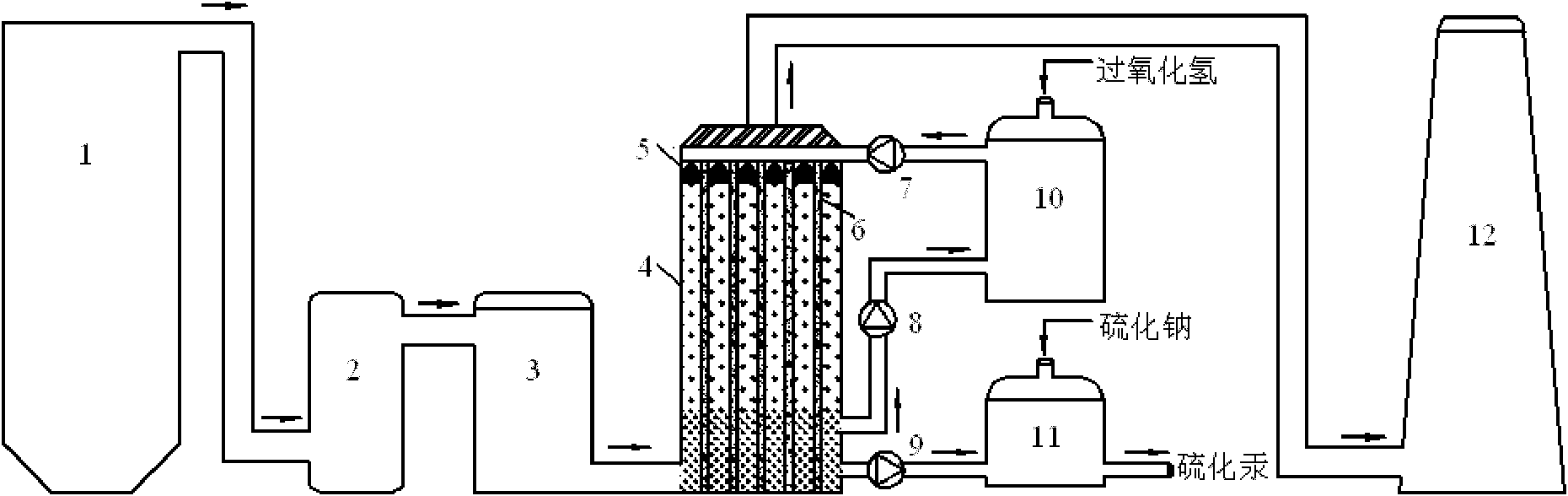

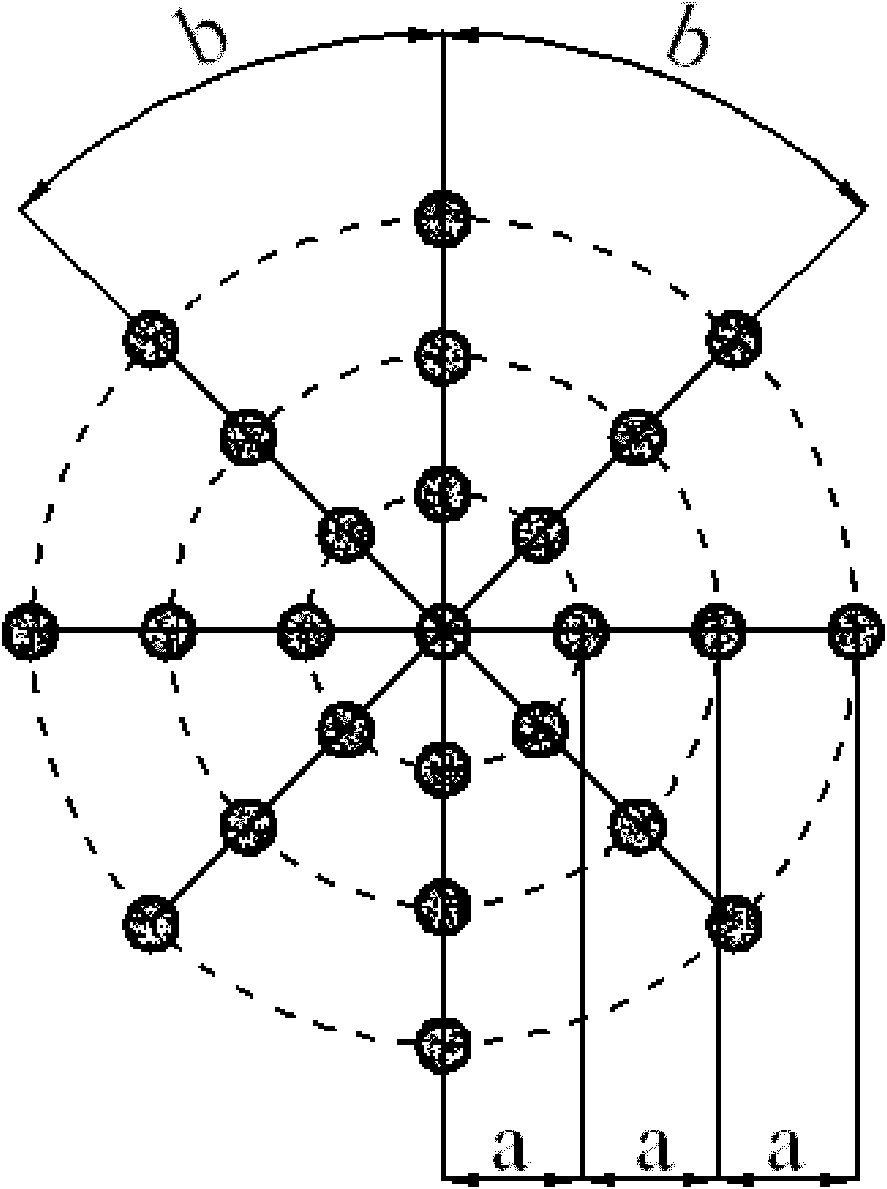

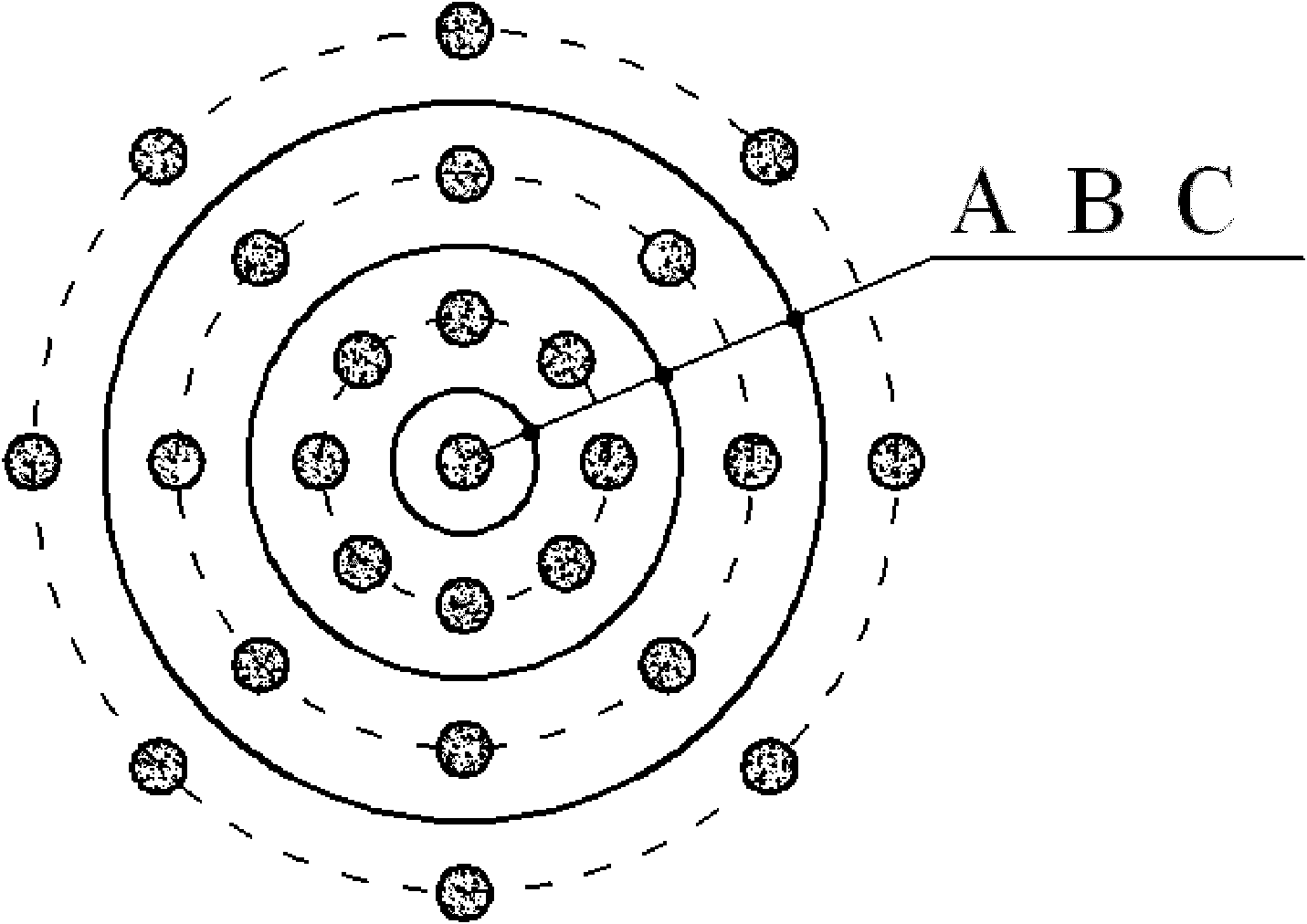

Flue gas mercury removal system based on photochemical advanced oxidation

InactiveCN101947409AIncrease mass transfer driving forceIncrease absorption rateDispersed particle separationParticulatesUltraviolet lights

The invention provides a flue gas mercury removal system based on photochemical advanced oxidation, which comprises a burning and discharging system composed of a burner, an electrostatic precipitator, a heat exchanger, a spray tower, a liquid-filling tower, a chimney and a knockout tower, wherein the flue gas generated by the burner is fed into the heat exchanger for carrying out refrigeration after removing particulate matters in the electrostatic precipitator, and then is fed into the spray tower; the spray tower is internally provided with ultraviolet tubes; hydrogen dioxide solution coming from the liquid-filling tower is extracted by a circulating pump, and then is sprayed into the spray tower by an atomizing nozzle; hydrogen peroxide is excitated and decomposed by ultraviolet lights in the spray tower to generate a hydroxyl radical (.OH) with strong oxidability which generates gas-liquid absorption reaction with the flue gas in the spray tower, thereby removing HgO in the flue gas by oxidation; the flue gas being subject to absorption and washing is fed into the chimney for discharging from the top of the spray tower; the HgO generated in the spray tower is oxidized to be soluble Hg<2+> which is fixed in the solution; the solution is sucked into the knockout tower by the circulating pump and then generates HgS to Hg<2+> with the added Na2S solution so as to perform capture recycle to realize the flue gas demercuration.

Owner:SOUTHEAST UNIV

Method for high frequency plant regenerating of tallow tree tissue culture adventitious bud

InactiveCN101057556ASlow differentiationSolve the survival ratePlant tissue cultureHorticulture methodsHypocotylBud

The invention relates to a method for high-frequency regenerating Chinese sapium bark through tissue culturing adventitious bud. The invention is characterized in that it comprises following steps: removing seed coat from Chinese sapium bark's seed, disinfecting surface with hydrogen dioxide solution and inoculating seed germinating culture medium, and getting intact Chinese sapium bark seed seedling; cutting the cotyledon of seed seedling, apical bud containing undeveloped true leaf and hypocotyl and root, and then inoculating them into adventitious bud inducing culture medium suitable for their growth, inducing adventitious bud directly or inducing with callus and getting light green adventitious bud cluster; replanting it into adventitious bud lengthening culture medium, getting lengthened adventitious bud seedling; replanting into seedling breeding culture medium for enlarged breeding, and replanting it into rooting culture medium, getting strong tube Chinese sapium bark with developed true leaf; finally replanting it out of room for natural growth and getting strong Chinese sapium bark seedling.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Method for synthesizing 1,2-epoxy butane

The invention discloses a method for synthesizing 1, 2- epoxybutane. It comprises following steps: mixing low- carbon alcohol, 1- butene and hydrogen dioxide solution, and the molar ratio of them is (1- 60): (0.5- 10): 1, feeding them into reactor filled with catalyst, the 1- butene and hydrogen dioxide solution reacts for epoxidation and getting 1, 2- epoxybutane, the temperature for reaction is 0- 100 Deg. C, pressure is 0.5- 8.5 Mpa, the liquid air speedis 0.1- 10 h-1.The invention is characterized by simple process, environment- friendly, high selectivity of 1, 2- epoxybutane is more than 99%, feasibility for continuous production and suitability for industrial production.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD +1

Method for recycling dimethyl sulfone and sodium nitrate from dimethyl sulfoxide waste slag

ActiveCN101195595AIncrease added valueEmission reductionOrganic chemistryOrganic compound preparationDimethyl SulphoneSlag

The invention relates to a method for recovering dimethyl sulfone and sodium nitrate from dimethyl sulfoxide waste slag, which comprises arranging waste slag waste slag in a decompression autoclave at 120-160DEG C to decompress and distill, distilling out the dimethyl sulfoxide and dimethyl sulfone from dimethyl sulfoxide waste slag to be arranged into an another autoclave to be cooled to obtain crystallized solid, arranging the distilled dimethyl sulfoxide and dimethyl sulfone into enough hydrogen dioxide solution to be oxidized and dried in vacuum to obtain dimethyl sulfone product, dissolving leavings in water to be discharged, adding concentrated nitric acid into the filtered mother liquid to adjust pH till 2-3 and convert sodium nitrite to sodium nitrate, neutralizing over nitric acid via soda, to neutralize the mother liquid, heating the solution to 120-125DEG C, evaporating at normal pressure, cooling to 50-70DEG C, crystallizing, separating and drying to obtain sodium nitrate product. The invention can reduce discharge of industrial waste slag and reduce environment pollution, with simple process and low energy consumption.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Process for degradation of organic waste water by fly ash

InactiveCN1837076AImprove utilization efficiencyReduce processing costsEnergy based wastewater treatmentWater/sewage treatment by sorptionFiltrationFenton reagent

A method is about using coal ash to degrade organic wastewater. The steps are: a. fully mixing coal ash and waste-water, the quality ratio is 0.8%-1.5%; b.adjusting the pH value of waste-water mixture as 1-4; c. adding hydrogen dioxide in the waste-water mixture to form allied Fenton reagent with soluble metallic ion in coal ash; d. letting waste-water getting acrossing the glass or earthenware duct have microwave field in 3-5min; e. finally, filtration, deposition, checking and collecting coal ash contains contaminant, discharging or circularly utilizing treated water. This invention ably utilizes the di-iron trioxide and so on transition metal oxide which contained in coal ash, forming the allied Fenton reagent with hydrogen dioxide; the multicellular structure of coal ash can absorb the microwave effectively, adsorbing-catalytic oxidation for organic matter by the stimulation of microwave, reaching the purpose of advanced oxidation treatment; improving the clearance for COD greatly; also saving the setting of biochemistry pool, reducing the dealing cost of waste-water.

Owner:CHONGQING UNIV

Blended yarn of flax and tencel and producing technology thereof

InactiveCN1920138ANo damage to physical and chemical propertiesHygroscopicYarnLiquid/gas/vapor textile treatmentYarnBoiling process

The invention relates to a blended yarn of flax and Tencel fiber, wherein the flax is 50-60%; the Tencel fiber is 40-60%; and its preparation comprises: (1) preparing the flax into blended yarn bar to be mixed with Tencel fiber into bar, and combining the bars into thick yarn; (2) boiling said thick yarn into thin yarn; (3) drying the thin yarn and winding to prepare the blended yarn; and the boiling process in the step (2) comprises: washing with hydric sulphate solution; bleaching with the mixture of sodium chlorite and sodium nitrate; first washing with water; oxygen bleaching with the mixture of sodium carbonate, caustic soda, sodium silicate and hydrogen dioxide solution; second washing with water. The inventive blended yarn has the advantages of two fibers, and the boiling process can increase the spinning number of flax; therefore, the product has crinkle resistance and better brightness, etc.

Owner:XINSHEN GROUP

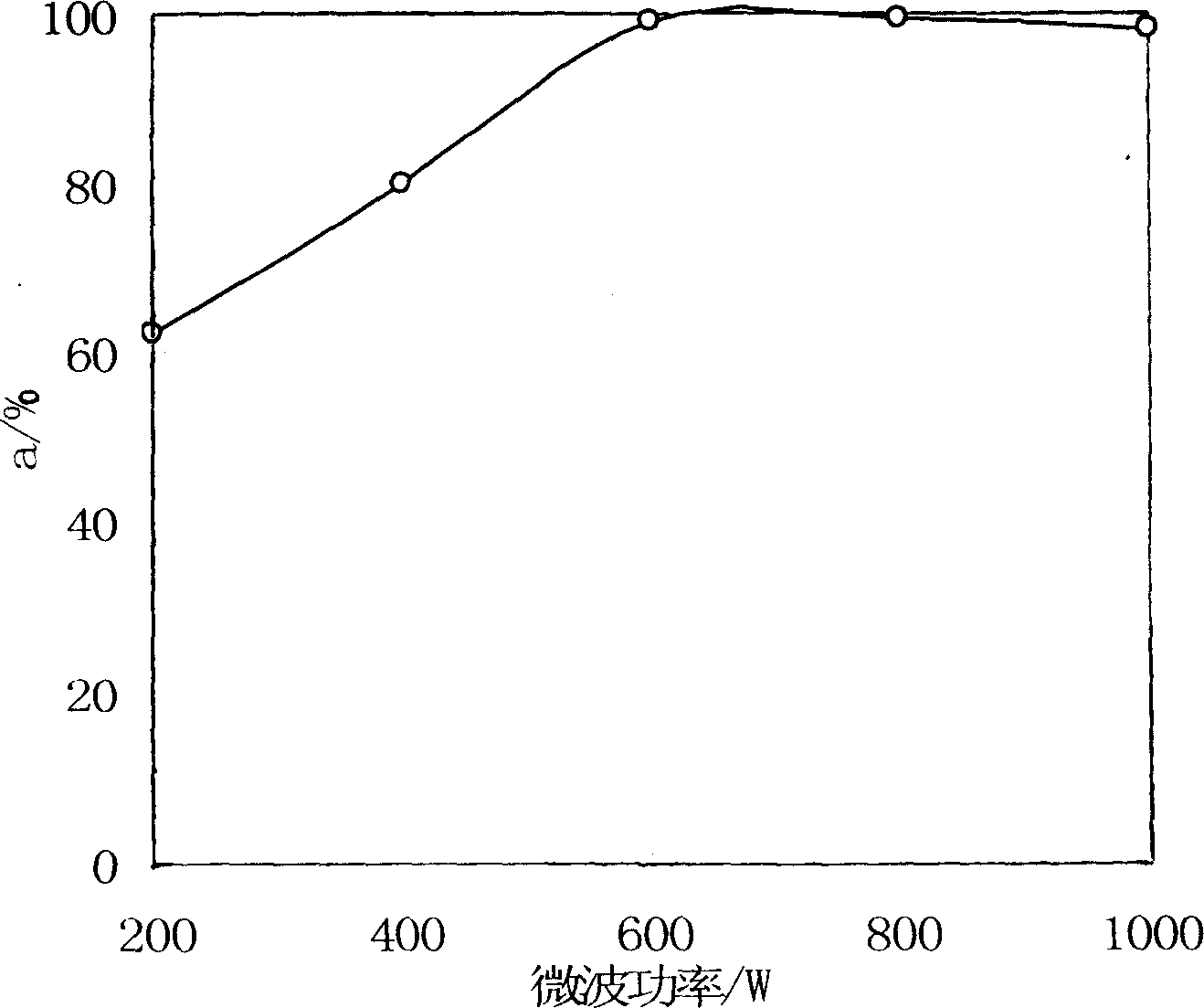

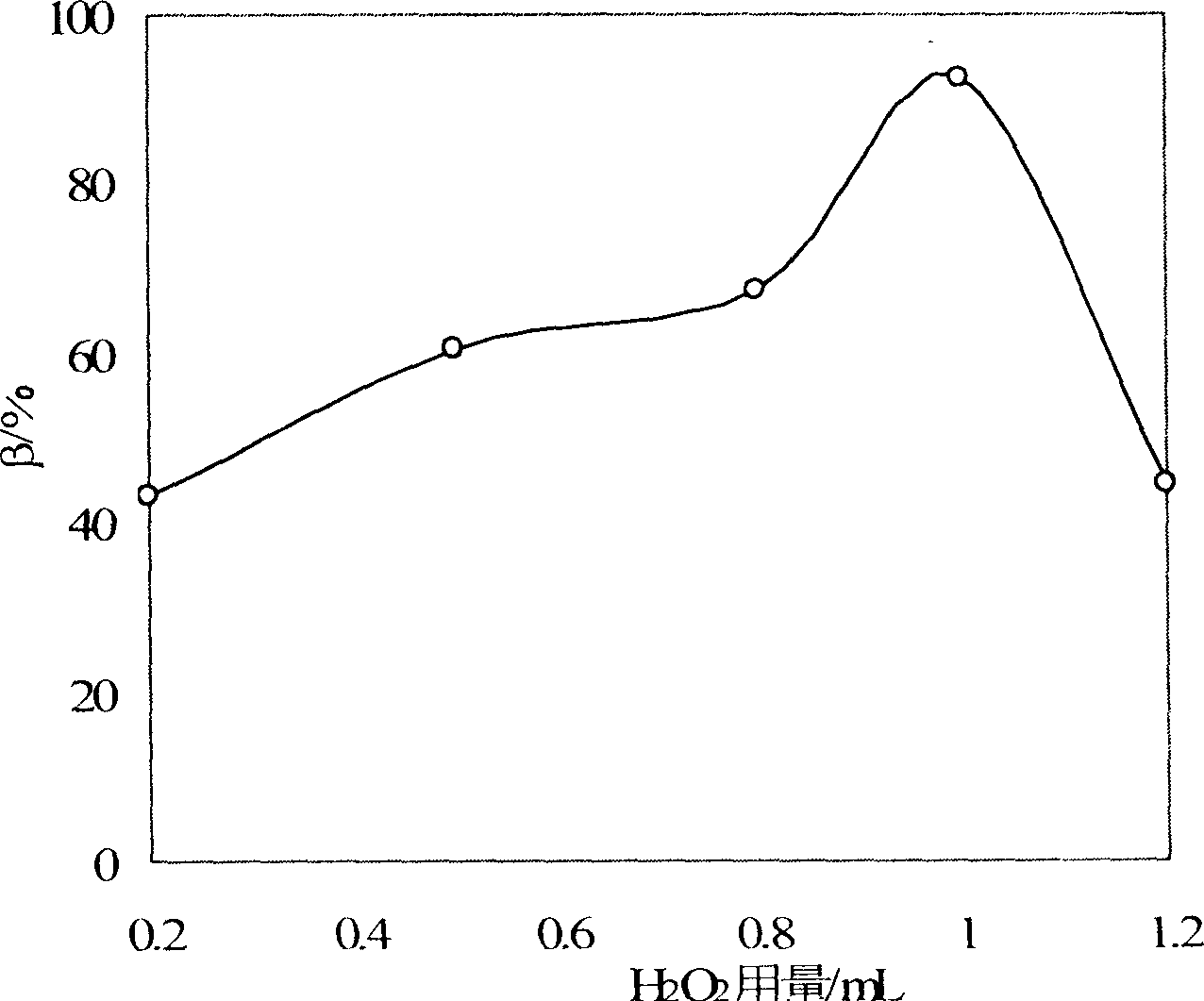

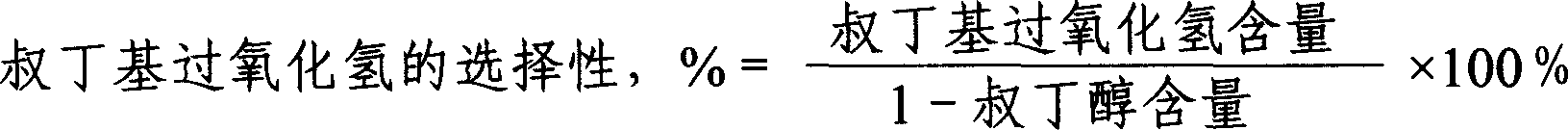

Process for preparing tert-butyl hydroperoxide

ActiveCN1699339AIncrease profitHigh activityOrganic compound preparationPeroxy compound preparationCatalytic oxidationTitanium

The invention provides a process for preparing tert-butyl hydroperoxide, which comprises contacting tert-butanol and hydrogen dioxide by the mol ratio of 0.5-10 for 0.5-10hours at 40-100 deg. C at the presence of titanium-silicon molecular screen, the content of titanium-silicon molecular screen is 0.005-0.1g molecular screen in each one ml of reaction liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

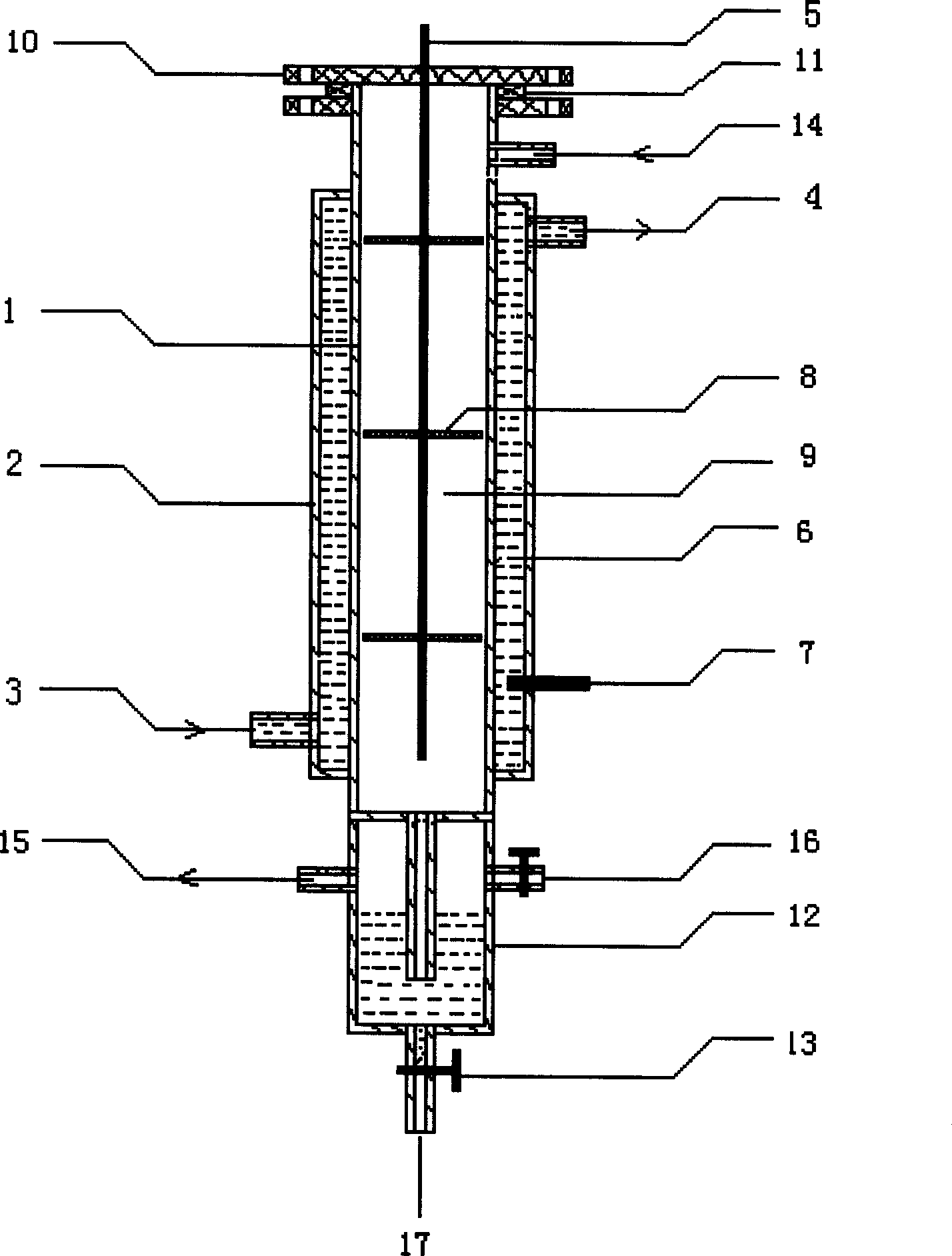

Method and device for directly synthesizing hydrogen peroxide at room temperature

InactiveCN1546367ASolve the cooling problemImprove discharge uniformityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPower flowGas phase

The invention relates to a self-cooled plasma generating apparatus by using dielectric barrier discharge, and a method for converting mixed gas of oxygen and hydrogen into hydrogen dioxide in gas phase at room temperature by using the apparatus, wherein the apparatus includes a coaxial sleeve configuration made of glass, the inner wall of the cartridge is a discharge medium, at the center of which a metallic discharged electrode is arranged, the mixed gas containing oxygen hydrogen flows downwards, wherein the annular space of the glass sleeve is filled with circulating water, which serves as an earth electrode.

Owner:DALIAN UNIV OF TECH

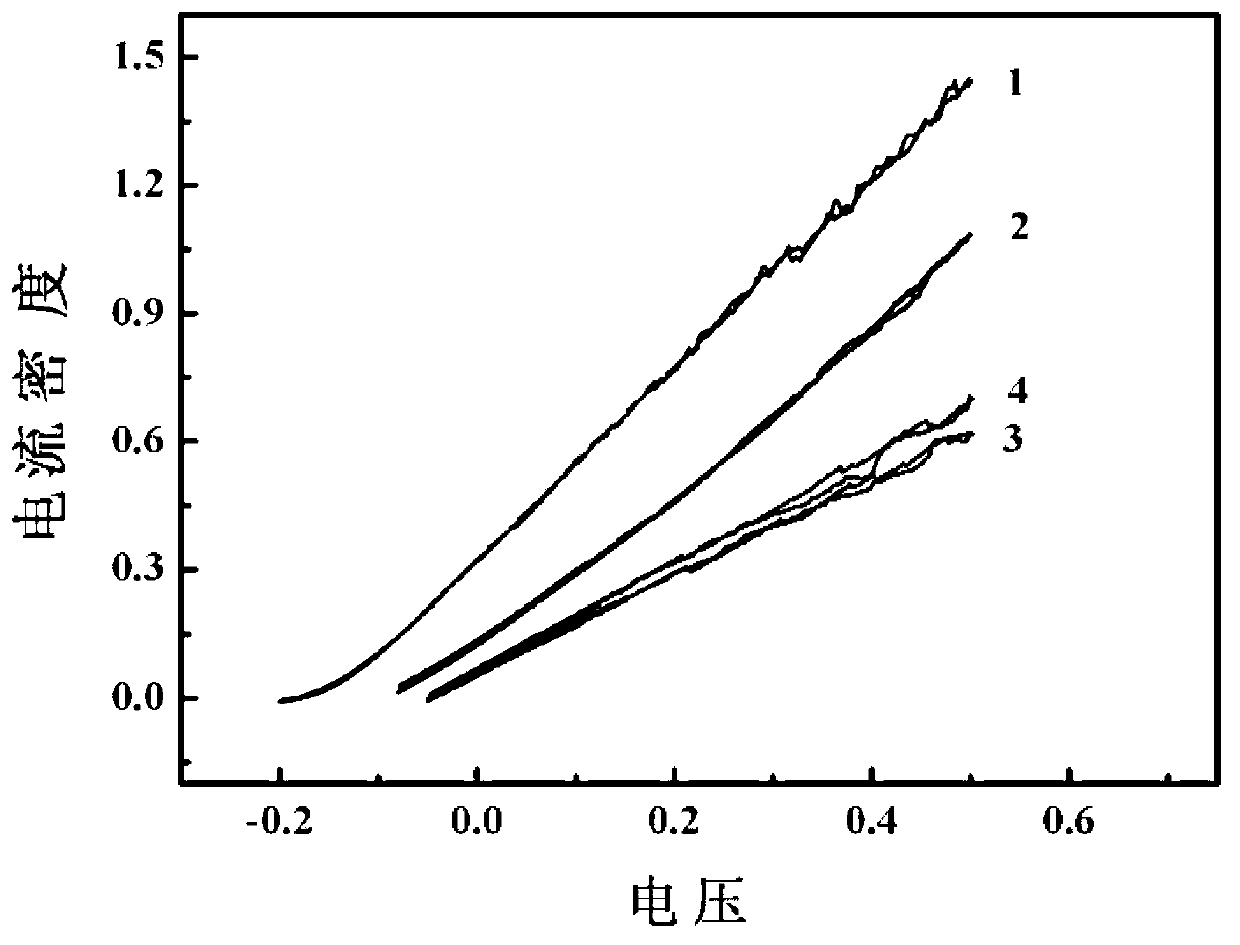

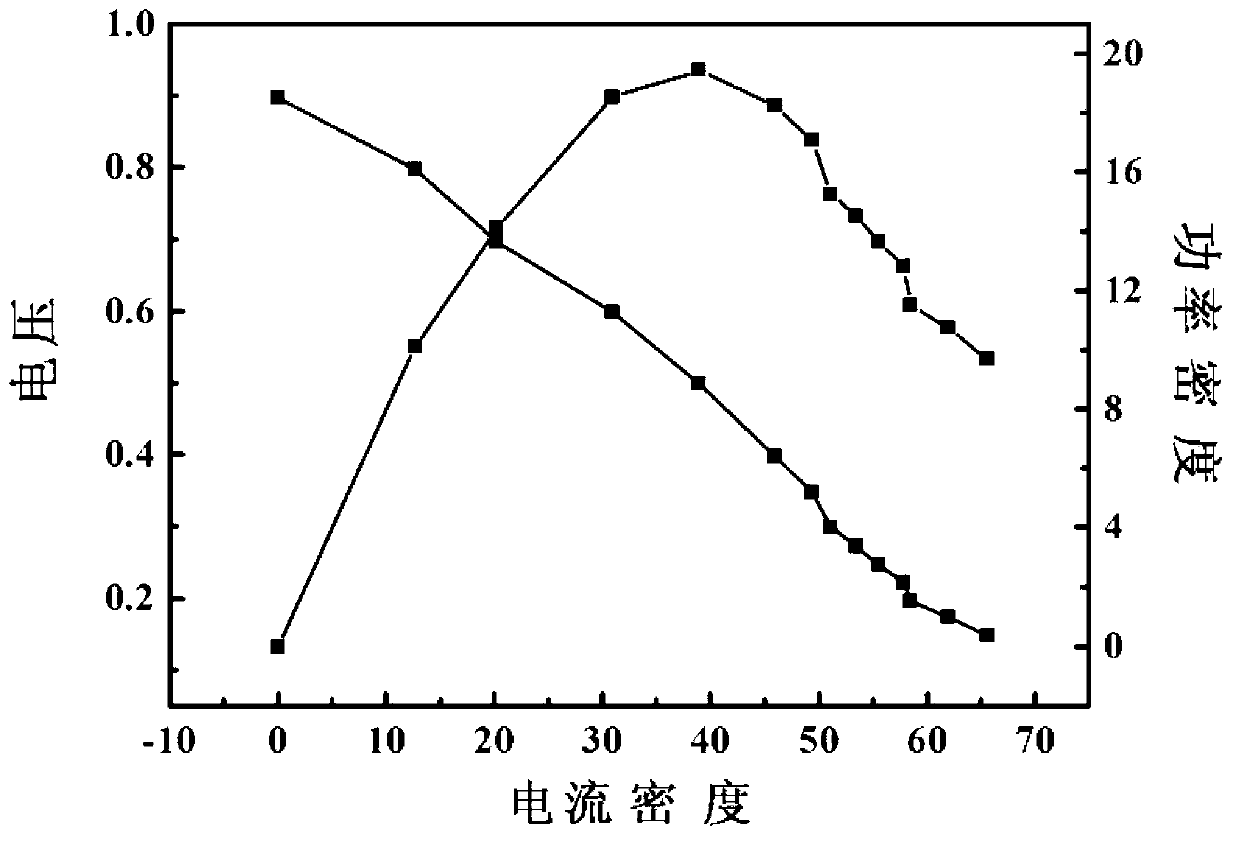

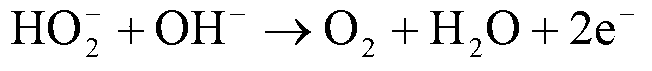

Preparation method of carbon-free binder-free all-metal three-dimensional porous H2O2 electrooxidation catalytic electrode

InactiveCN103346332AReduce adverse effectsImprove stabilityElectrode carriers/collectorsOperabilityMaterials science

The invention provides a preparation method of a carbon-free binder-free all-metal three-dimensional porous H2O2 electrooxidation catalytic electrode. The preparation method comprises: a metal salt of Ni, Co or Cu and a surfactant are fully dissolved in pure water, so that the concentration of Ni<2+>, Co<2+> or Cu<2+> in the solution is 0.05 mol / L to 0.5 mol / L, and the concentration of the surfactant in the solution is 0 mol / L to 2.0 mol / L; a three-electrode system is formed by Ni foam or a stainless steel wire as a working electrode, a platinum electrode as a counter electrode and a silver-silver chloride electrode as a reference electrode; and with an electrochemical method, an active component choosing from Ni, Co or Cu is deposited on an Ni foam substrate or a stainless steel wire substrate to form the carbon-free binder-free all-metal three-dimensional porous H2O2 electrooxidation catalytic electrode, and the electro-deposition time is 5 s to 200 s. The method of the invention is simple, has strong operability, has wide sources of the raw materials, and can be widely applied to the preparation of a DPPFC (direct hydrogen dioxide fuel cell) anode.

Owner:HARBIN ENG UNIV

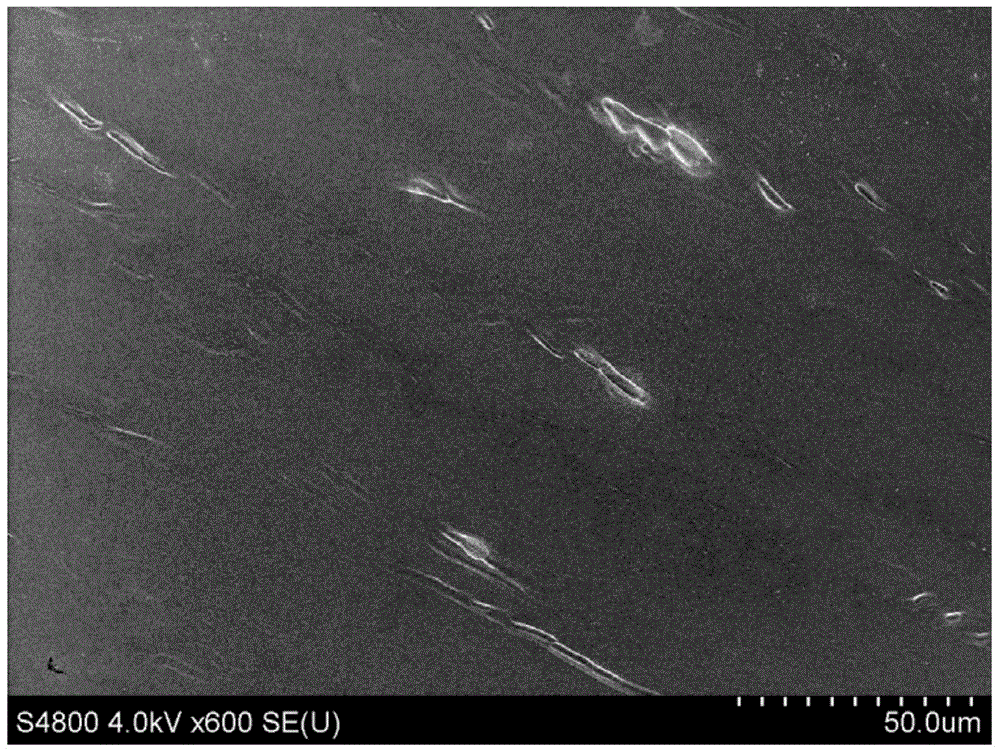

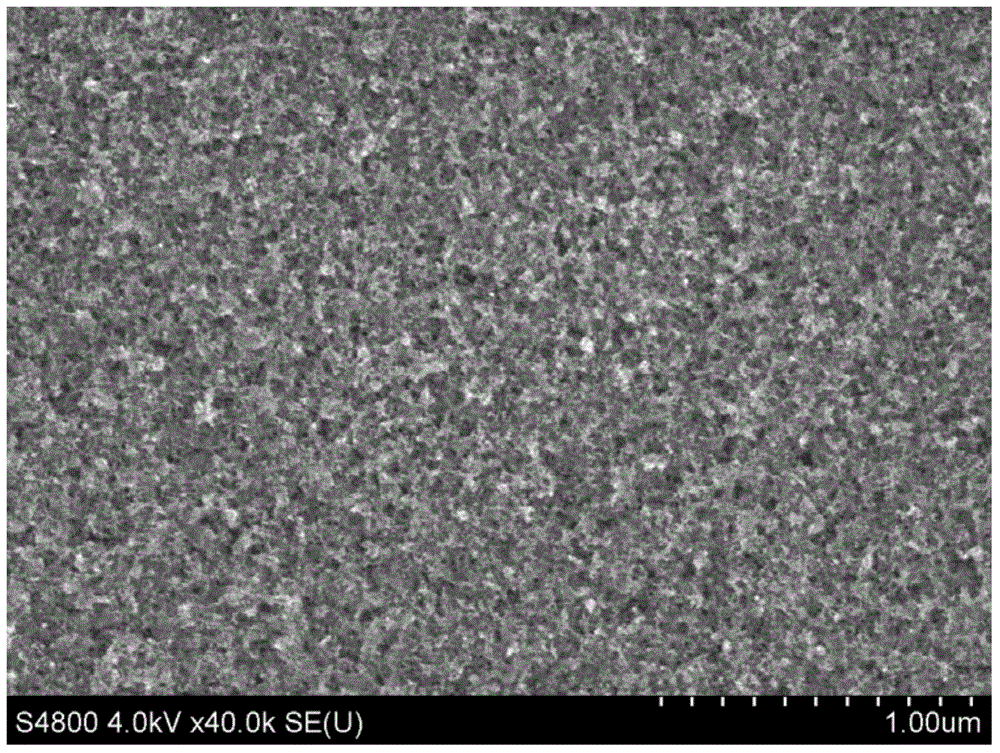

Diamond wire cutting-based silicon wafer texturing pretreatment method and silicon wafer texturing method

InactiveCN104962998AEffective cutting patternEffectively remove cut linesAfter-treatment detailsFinal product manufactureHydrofluoric acidNano structuring

The invention provides a diamond wire cutting-based silicon wafer texturing pretreatment method. The method comprises the following steps: a, mixing a hydrofluoric acid solution, a hydrogen dioxide solution, metal salt and water to obtain pretreatment liquid; b, putting a silicon wafer cut by a diamond wire into the pretreatment liquid and performing pretreatment A, until cutting lines on the silicon wafer are basically removed; c, cleaning the silicon wafer subjected to pretreatment A by an acid solution, so as to remove metal particles on the silicon wafer; d, putting the silicon wafer cleaned by the acid solution into the pretreatment liquid and performing pretreatment B, and forming a pretreatment texturing surface with a uniform micro / nano structure on the silicon wafer. The invention also provides a diamond wire cutting-based silicon wafer texturing method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for producing adipic acid and dibasic acid by using nitric acid to oxidizing cyclohexane bionic oxidation mixture

InactiveCN101186570ASolve the conversion rateSolve the large amount of cyclohexane circulationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexanoneDistillation

The invention relates to a method for directly preparing adipic acid and diacid from cyclohexane bionic oxidation mixture by nitric acid oxidation. The invention is characterized in that in the presence of 1-10mg / L metalloporphyrin catalyst, at 140-160DEG C and 0.8-1.2MPa, cyclohexane is oxidized by air, and the cyclohexane oxidation mixture is directly prepared into adipic acid and diacid by nitric acid oxidation. Compared with prior adipic acid preparation, the invention can simultaneously improve single-pass conversion of cyclohexane and total yield of diacid respectively more than 10% and 80%. At the same level of adipic acid yield, the circulation quantity of cyclohexane is reduced more than 50%, nitric acid consumption is reduced about 10%, to reduce the load on cyclohexane distillation system, reduce energy consumption, and reduce production cost. The invention can be directly used in prior industrial unit that prepares adipic acid from cyclohexane, to reduce production cost and improve yield. The invention can simplify prior production that prepares adipic acid by cyclohexane oxidation, to eliminate washing, cyclohexyl hydrogen dioxide decomposition, and cyclohexanone-and-cyclohexanol distillation systems, and avoid tert-butyl chromic acid catalyst.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com