Light-end products oxidation desulfurizing and deodorizing method

A light oil product, oxidative deodorization technology, applied in the direction of refining with oxygen-containing compounds, etc., can solve the problems of increasing the cost of the treatment process, failing to reduce the total sulfur of oil products, waste alkali discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

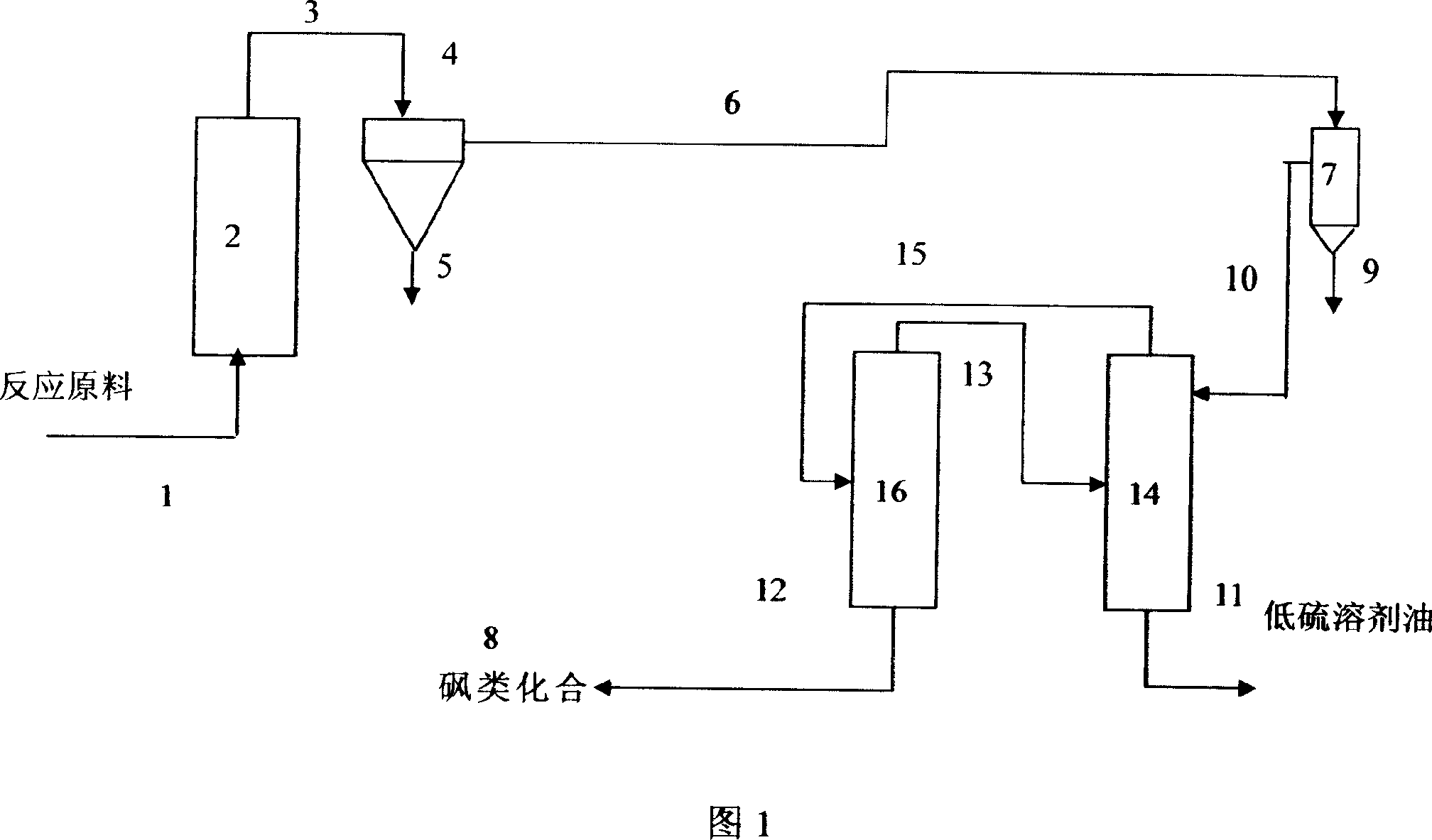

Method used

Image

Examples

Embodiment 1~3

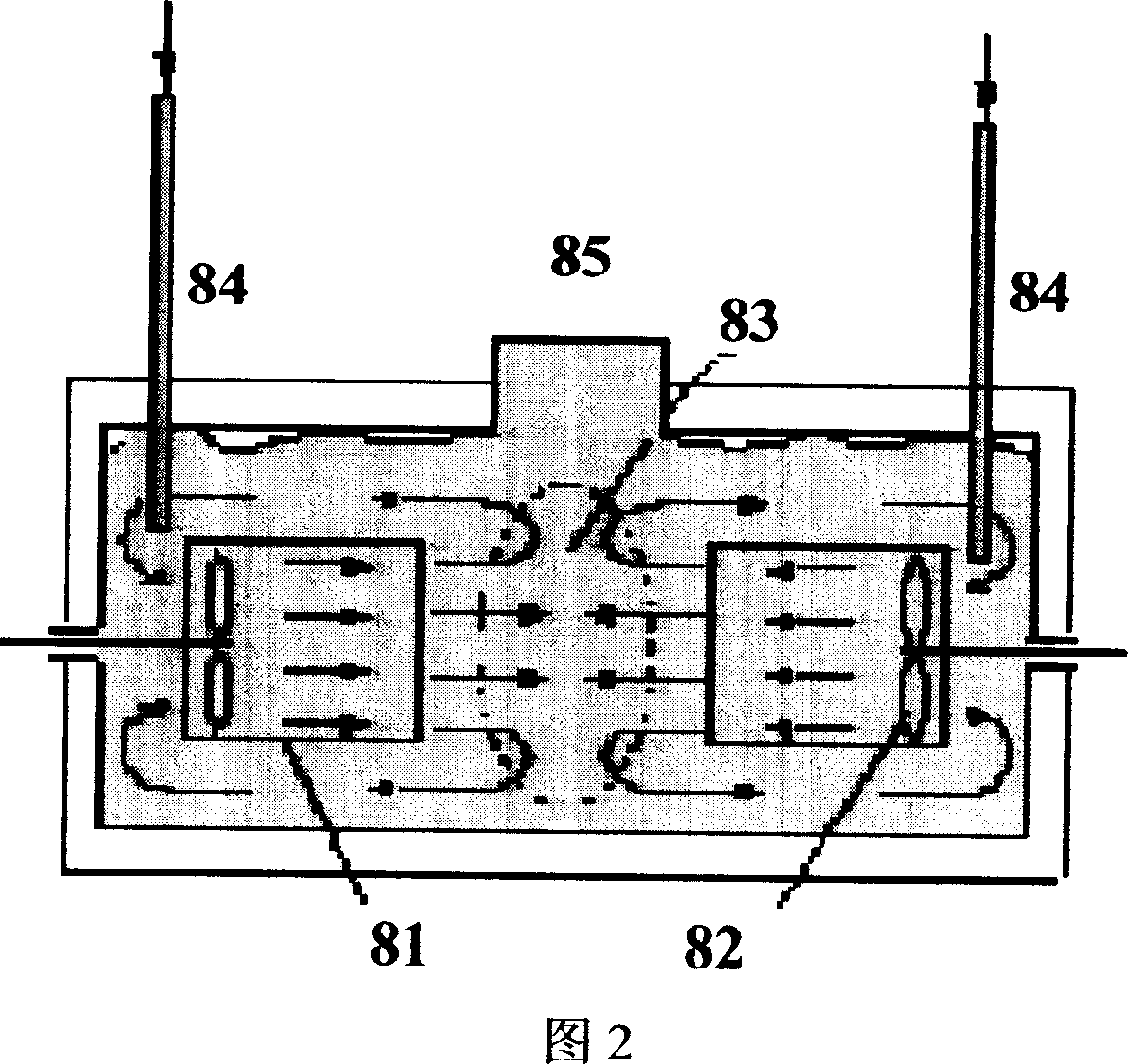

[0038] This example proves that the use of reaction equipment with high mass transfer efficiency can significantly improve the desulfurization efficiency. Experimental process and experimental raw material are the same as comparative examples 1~3, just react and carry out in the impingement flow reactor identical with Fig. 2 structure, adopt two propellers, propeller rotating speed is 900 rev / mins, intermittent operation, reaction temperature drops to 50°C. The reaction time was reduced to 30 minutes. The reaction raw material oils of Examples 1-3 correspond to Comparative Examples 1-3 respectively. The mercaptan sulfur content and total sulfur analysis data of the reaction products are also listed in Table 1.

[0039] example

[0040] Apparently, under the same raw materials and other reaction conditions, the use of an impingement flow reactor with higher mass transfer efficiency can significantly increase the desulfurization rate of the oxidation reaction, and th...

Embodiment 4

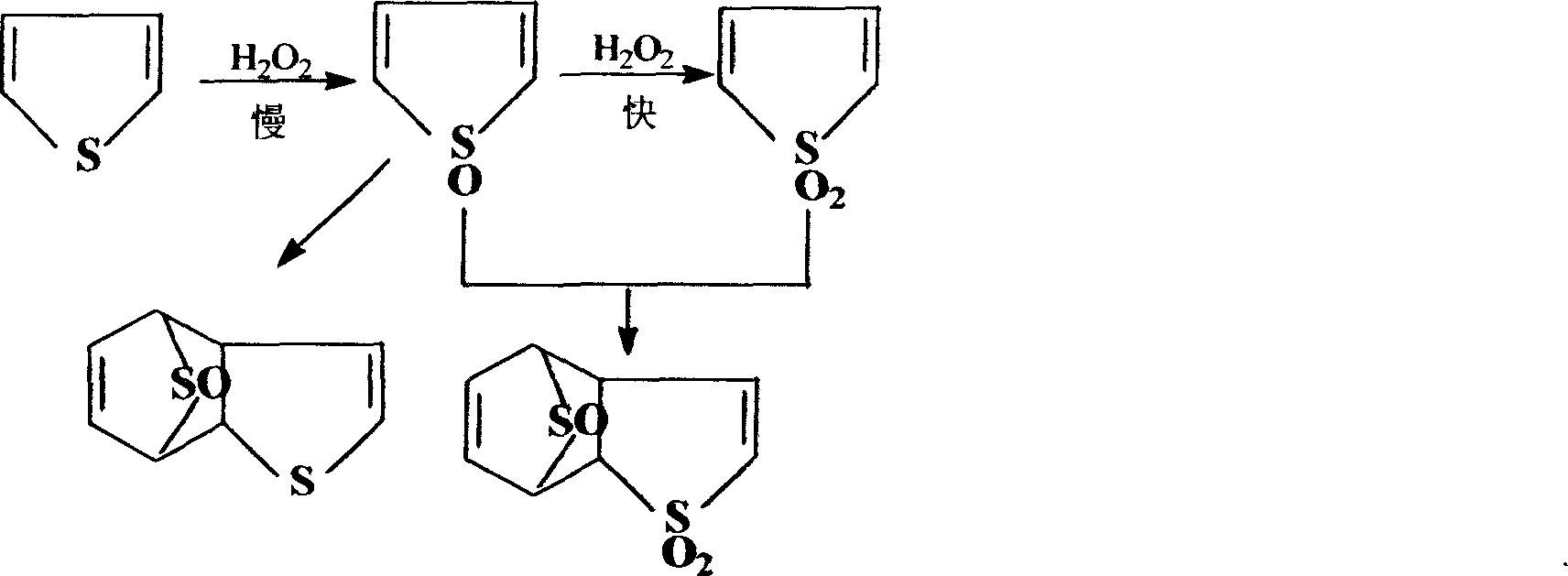

[0042] Example 4 According to the process of Example 2, the reaction temperature is 50° C., the reaction time is 30 minutes, the catalyst uses oil-soluble copper porphyrin, and the concentration of the catalyst in mineral spirits is 0.5 μg / g. The results are shown in Table 2.

Embodiment 5

[0044] Example 5 According to the process of Example 2, the reaction temperature is 40°C, the reaction time is 30 minutes, the catalyst is oil-soluble porline cobalt, the concentration of the catalyst in solvent oil is 0.05 μg / g, and the amount of hydrogen peroxide added is the theoretical requirement 2.5 times the amount, the results are shown in Table 2. Compared with Comparative Example 1, to achieve similar desulfurization rate, impinging flow reactor requires less oxidant amount and lower reaction temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com