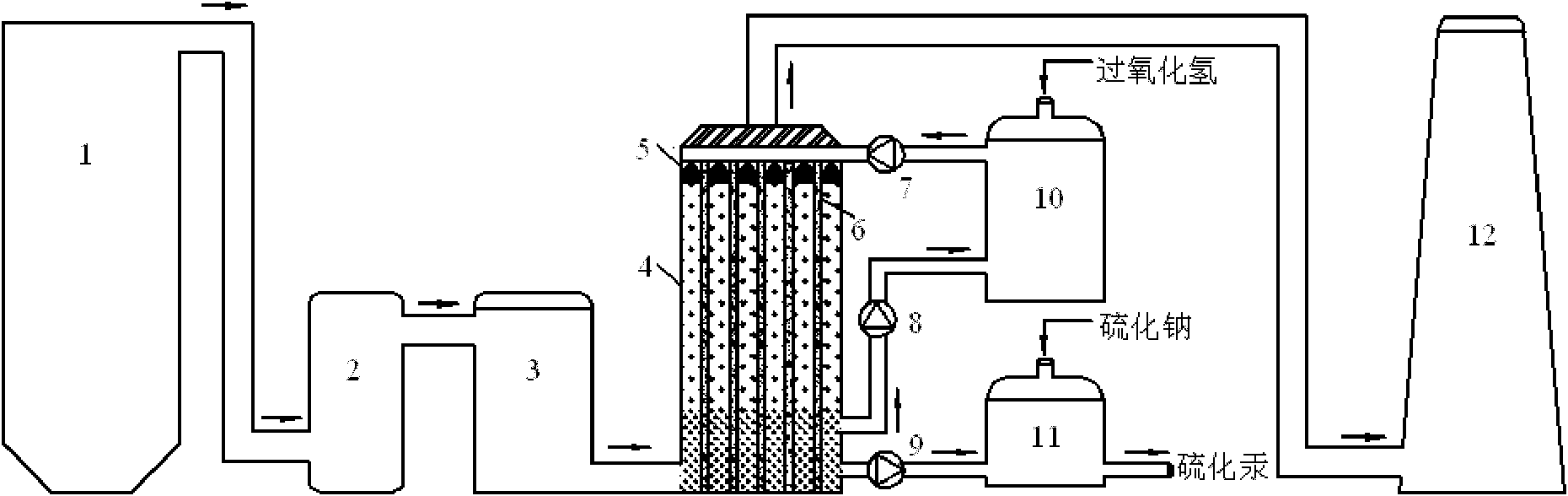

Flue gas mercury removal system based on photochemical advanced oxidation

An advanced oxidation and photochemical technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of increased resistance to liquid phase absorption, hindering industrial application, low removal efficiency, etc., to improve the absorption rate, Strong oxidizing ability, the effect of increasing the driving force of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

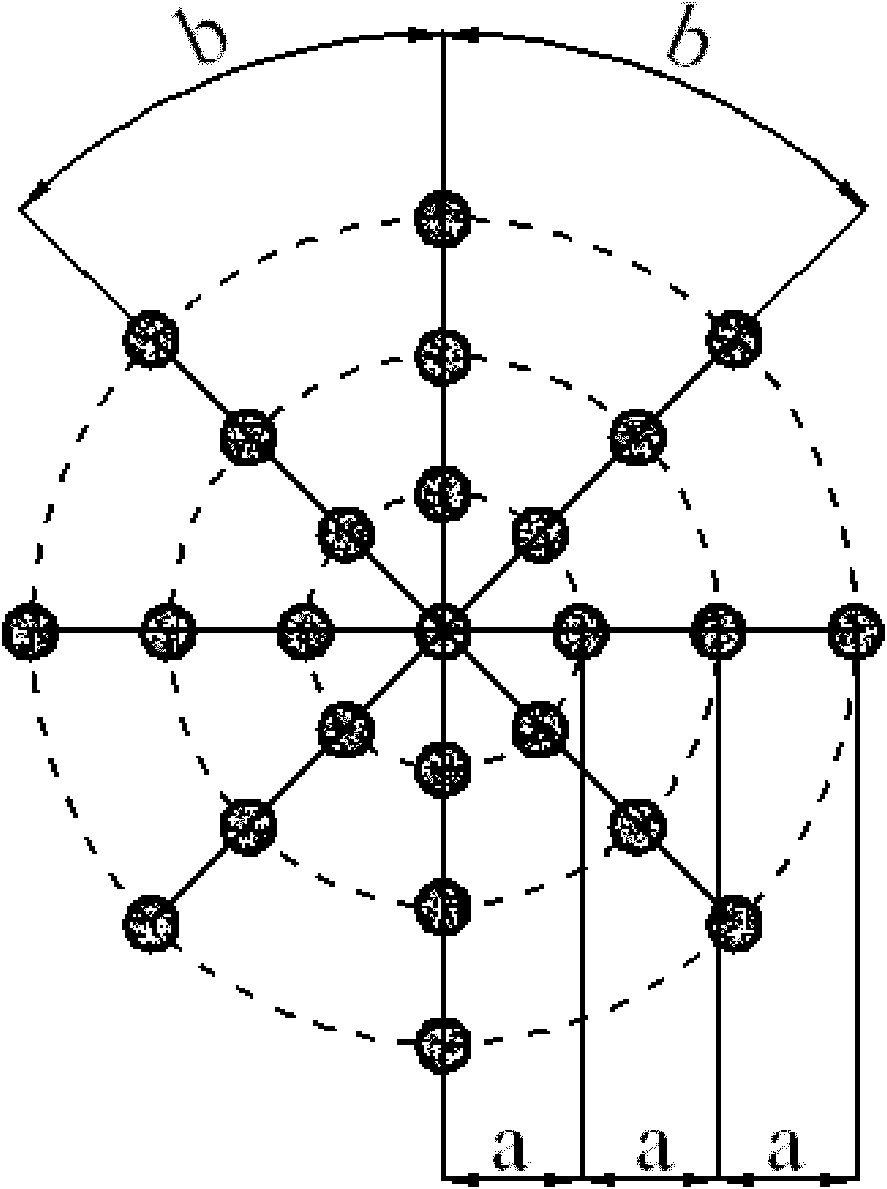

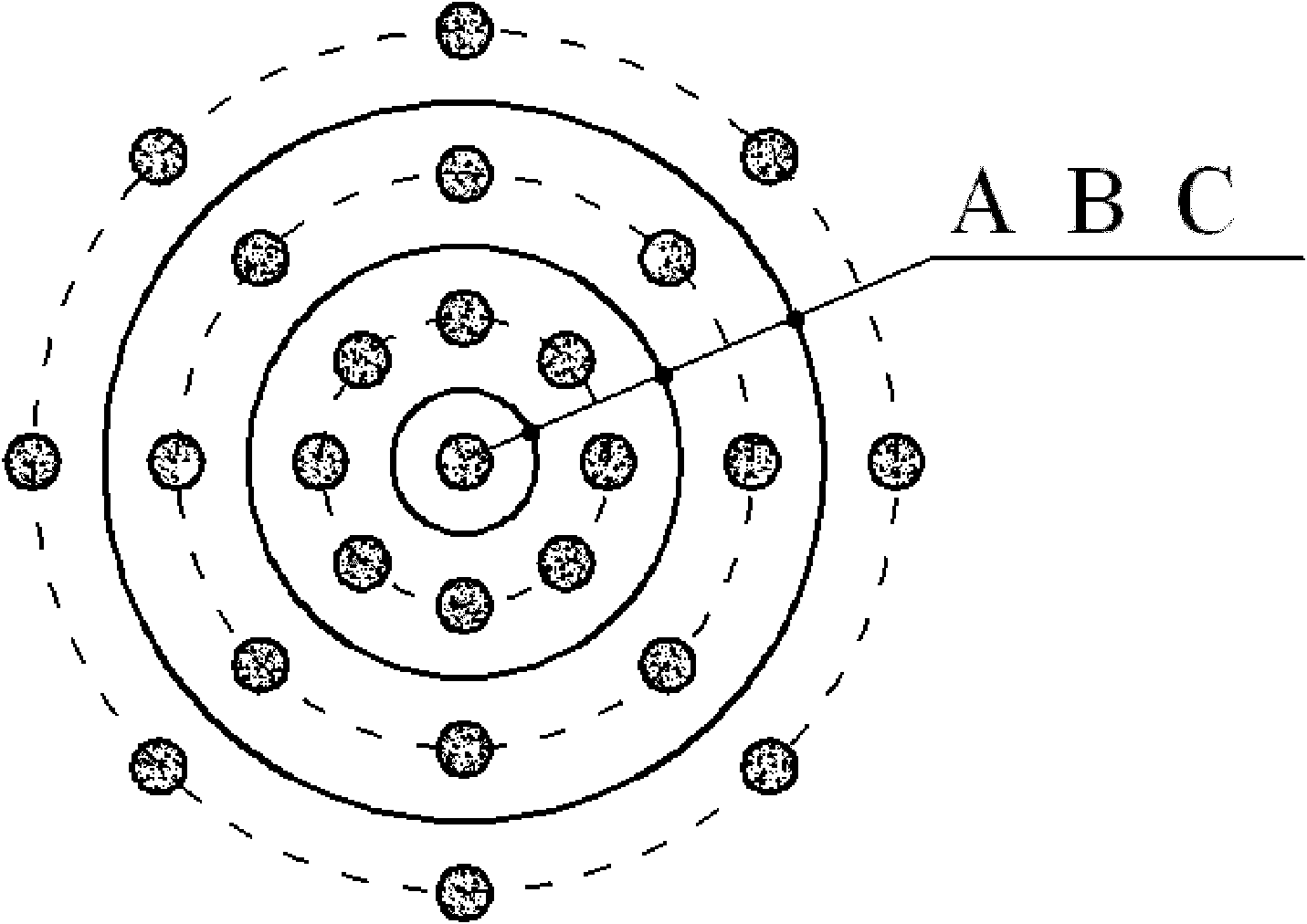

Method used

Image

Examples

Embodiment 1

[0043]

Embodiment 2

[0045]

Embodiment 3

[0047]

[0048] It can be seen from the implementation of 1, 2, and 3 that the upper part of the table is the operating parameters, and the lower part is the change of pollutant removal efficiency. The specific operation method is: only change the wavelength of ultraviolet light, and keep other parameters unchanged. It can be seen from the results that the ultraviolet light has the best removal efficiency at 253.7nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com