Liquid-phase hydrogenation reaction device and liquid-phase hydrogenation reaction method

A liquid-phase hydrogenation and hydrogenation reaction technology, applied in the fields of hydrogenation treatment process, chemical instruments and methods, petroleum industry, etc., can solve the problem of low sulfur in the adsorbent, complex regeneration system, and no strict requirements on the height-to-diameter ratio of the reactor, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

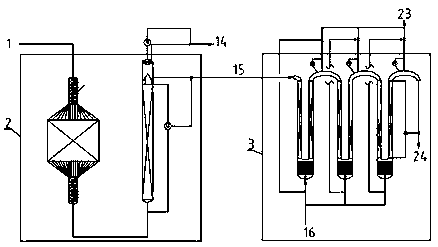

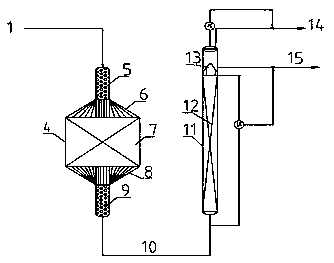

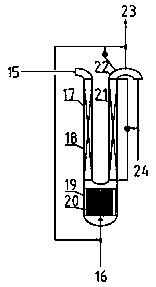

[0059] Attached figure 1 The method, wherein the high-efficiency hydrogenation reaction zone contains a fixed-bed reactor and a tubular reactor, wherein the feed section of the fixed-bed reactor has an aspect ratio of 10:1, and the feed section and the hydrogenation reaction section The diameter ratio of the reactor is 1:30, the height-to-diameter ratio of the hydrogenation reaction section is 1:5, and the height-to-diameter ratio of the tubular reactor is 20:1. The diameter ratio of the hydrogenation reaction section to the tubular reactor in the fixed bed reactor is 5:1; the feed section and the discharge section of the fixed bed reactor are filled with protective agent FBN-03B01, and the hydrogenation reaction section is filled Hydrogen catalyst FHUDS-5; the lower and upper parts of the tubular reactor are respectively filled with hydrogenation catalyst FHUDS-5 and protective agent FBN-03B01 according to the height of 1:1; the reaction conditions of the fixed bed hydrogenat...

Embodiment 2

[0064] Attached figure 1 The method, wherein the high-efficiency hydrogenation reaction zone contains a fixed-bed reactor and a tubular reactor, wherein the feed section of the fixed-bed reactor has an aspect ratio of 12.5:1, and the feed section and the hydrogenation reaction section The diameter ratio of the reactor is 1:40, the height-to-diameter ratio of the hydrogenation reaction section is 1:8, and the height-to-diameter ratio of the tubular reactor is 25:1. The diameter ratio of the hydrogenation reaction section to the tubular reactor in the fixed bed reactor is 8:1; Hydrogen catalyst FHUDS-5; the lower and upper parts of the tubular reactor are filled with hydrogenation catalyst FHUDS-5 and protective agent FBN-03B01 according to the height of 1:1; the reaction conditions of the fixed bed hydrogenation reactor are as follows: the reaction temperature is 330 ~368°C, reaction pressure 6.0MPaG, liquid hourly volume space velocity 4.5h -1 .

[0065] The ultra-deep hydr...

Embodiment 3

[0069] Attached figure 1 The method, wherein the high-efficiency hydrogenation reaction zone contains 1 fixed-bed reactor and 2 parallel tubular reactors, wherein the feed section of the fixed-bed reactor has an aspect ratio of 15:1, and the feed section and hydrogenation The diameter ratio of the reaction section is 1:50, the height-to-diameter ratio of the hydrogenation reaction section is 1:10, and the height-to-diameter ratio of the tubular reactor is 30:1. The diameter ratio of the hydrogenation reaction section to the tubular reactor in the fixed bed reactor is 10:1; the feed section and the discharge section of the fixed bed reactor are filled with protective agent FBN-03B01, and the hydrogenation reaction section is filled with Hydrogen catalyst FHUDS-5; the lower and upper parts of the tubular reactor are respectively filled with hydrogenation catalyst FHUDS-5 and protective agent FBN-03B01 according to the height of 1:1; the reaction conditions of the fixed bed hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com