Regular packing of helical cylindrical net

A structured packing, cylinder technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increased pressure drop, increased operating costs, etc. The effect of reducing frictional resistance and overcoming shrinkage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

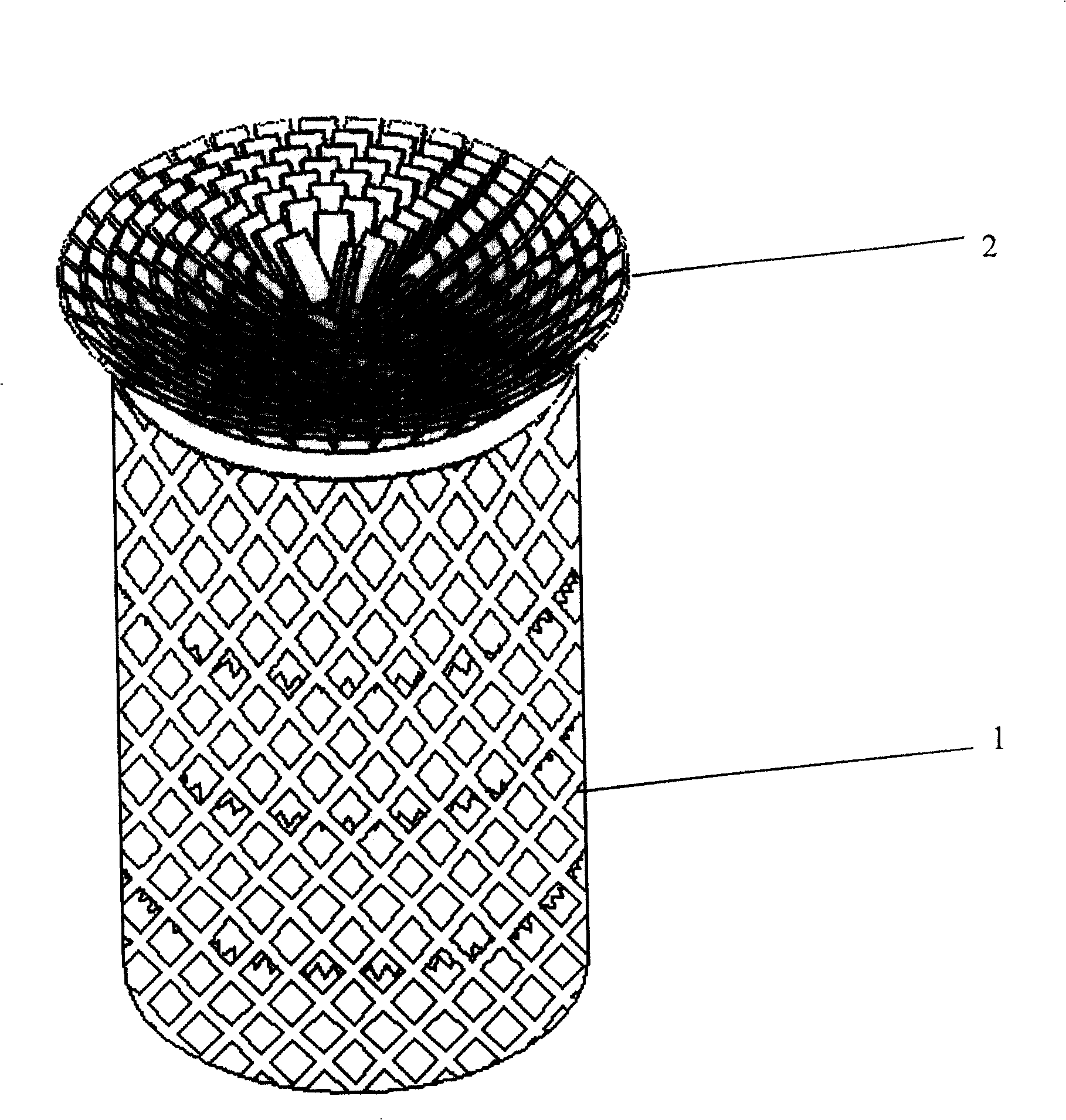

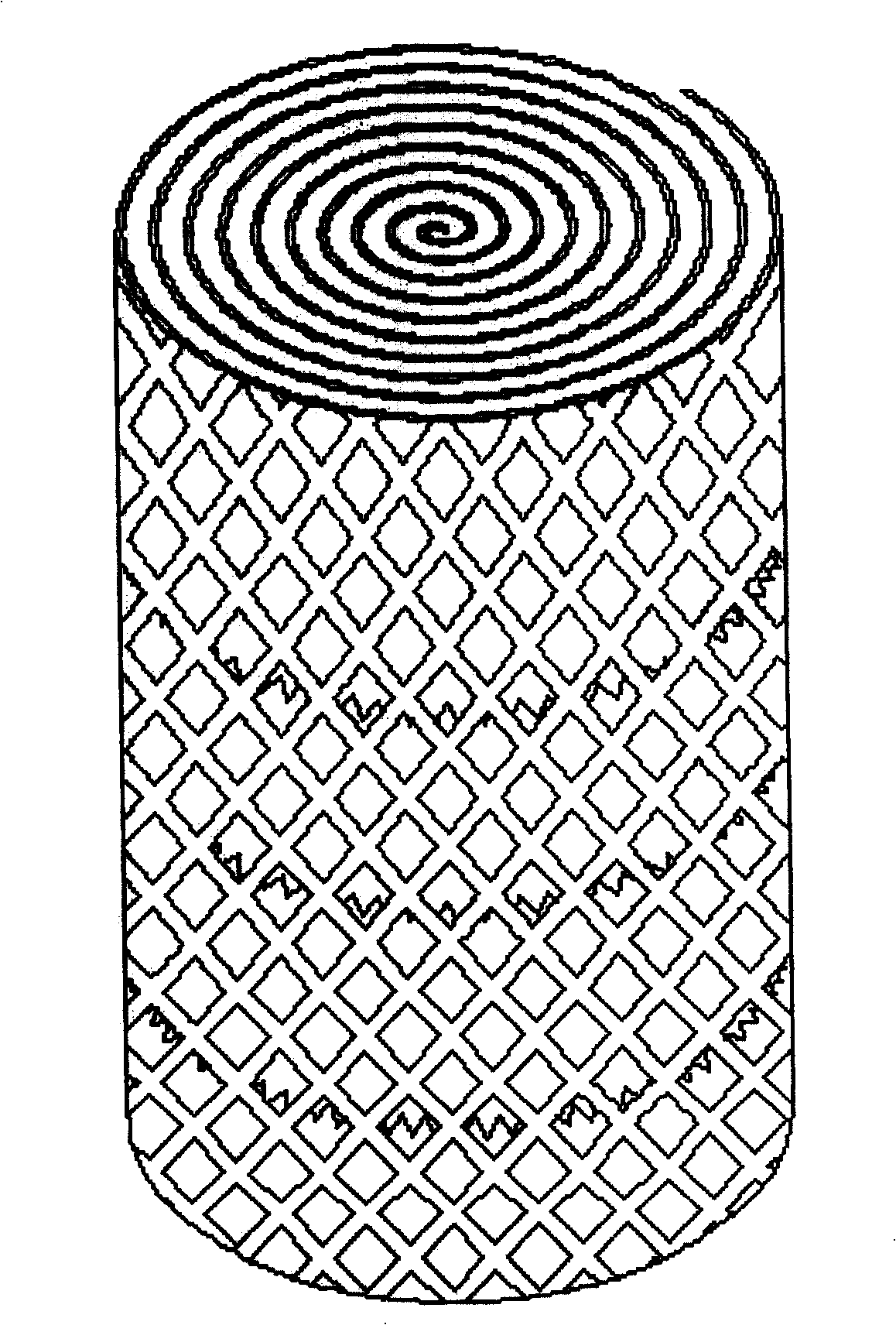

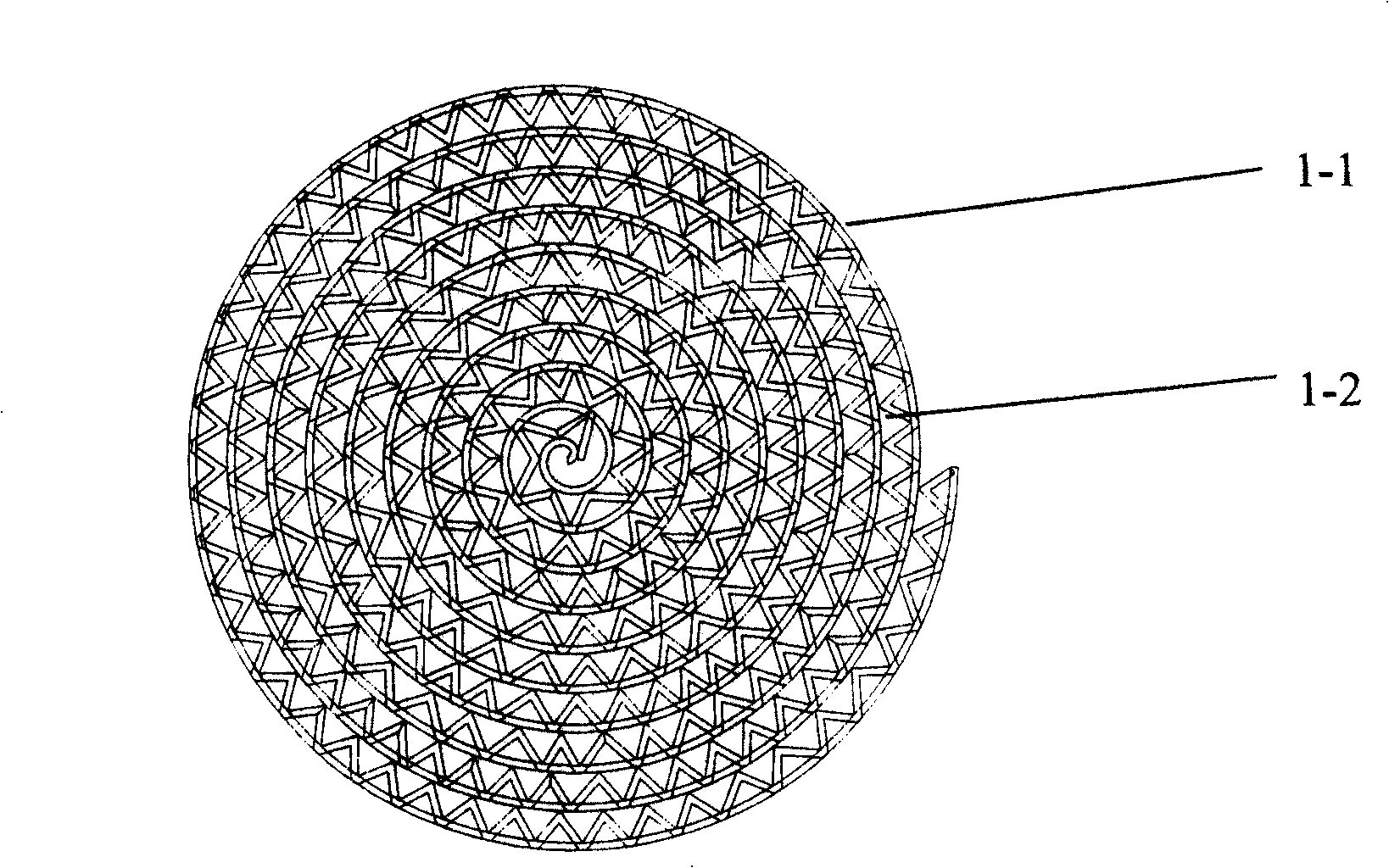

[0018] Choose spiral mesh cylinder structured packing, the raw material is 1mm thick stainless steel expanded mesh, the grid shape is parallelogram, the size is 3mm at the bottom and 6mm in height. A spring of 1 mm is welded to the flat net in a direction parallel to the long side of the flat net, and then rolled into a helical drum with the short side as the axis. The helical wire fixes the distance between each layer and maintains the shape. The cone cap disc on the top of the spiral mesh packing is made of a stainless steel plate with a height of 20mm and a thickness of 1mm in a spiral shape. At its upper end, every 10mm, a gap with a depth of 10mm is cut vertically downward to form a strip flap, and then the strip flap It is turned out so that it forms an angle of 45° with the vertical direction, which acts as a drain pan for the filler.

[0019] The working process of the present invention is that the liquid phase is sprayed from the liquid distributor from the top to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com