High-pressure pulse discharge catalytic oxidation method for removal of undegradable organic substances in water

A technology of high-voltage pulse discharge and refractory organic matter, which is applied in the fields of oxidized water/sewage treatment, electrochemical water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

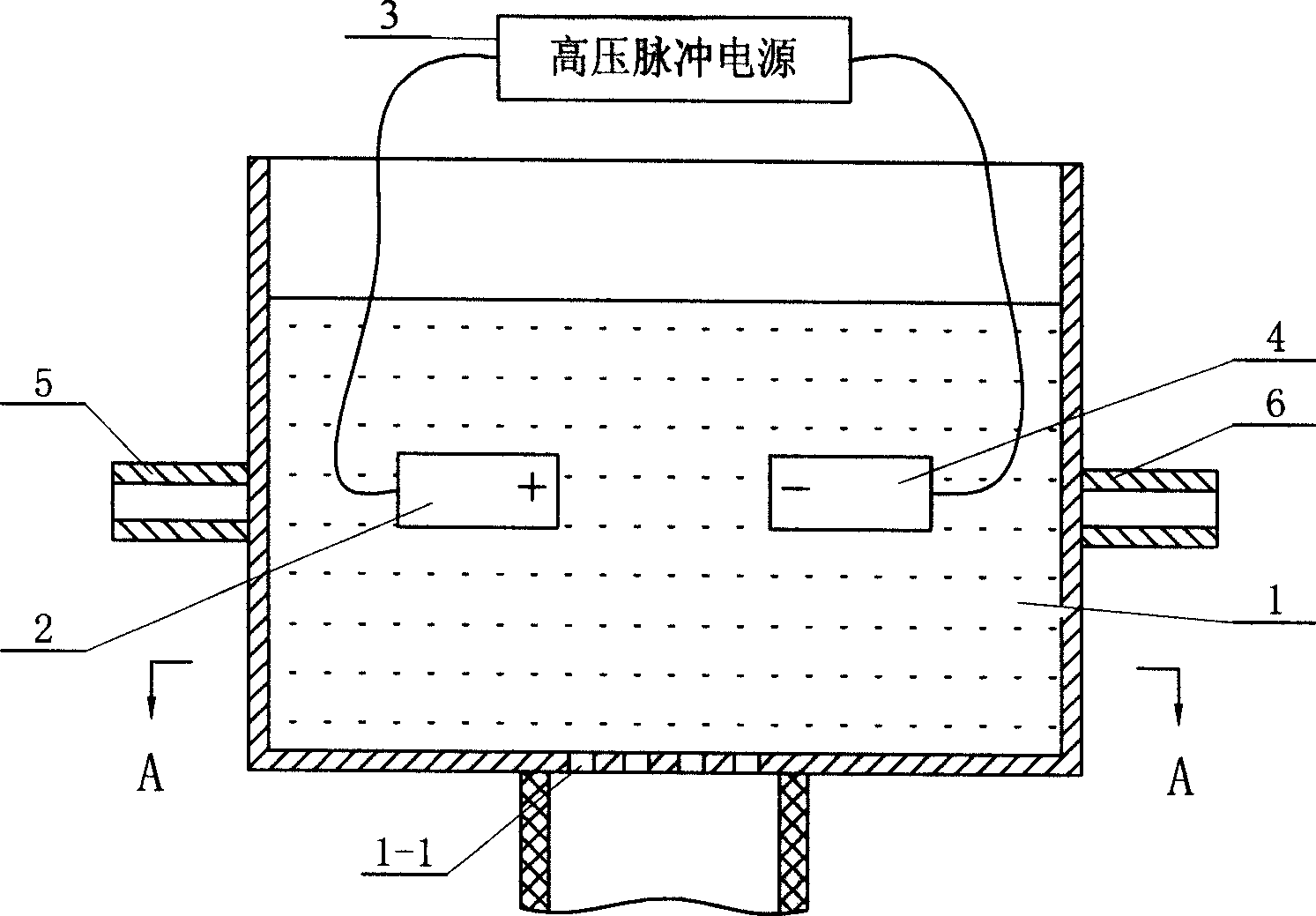

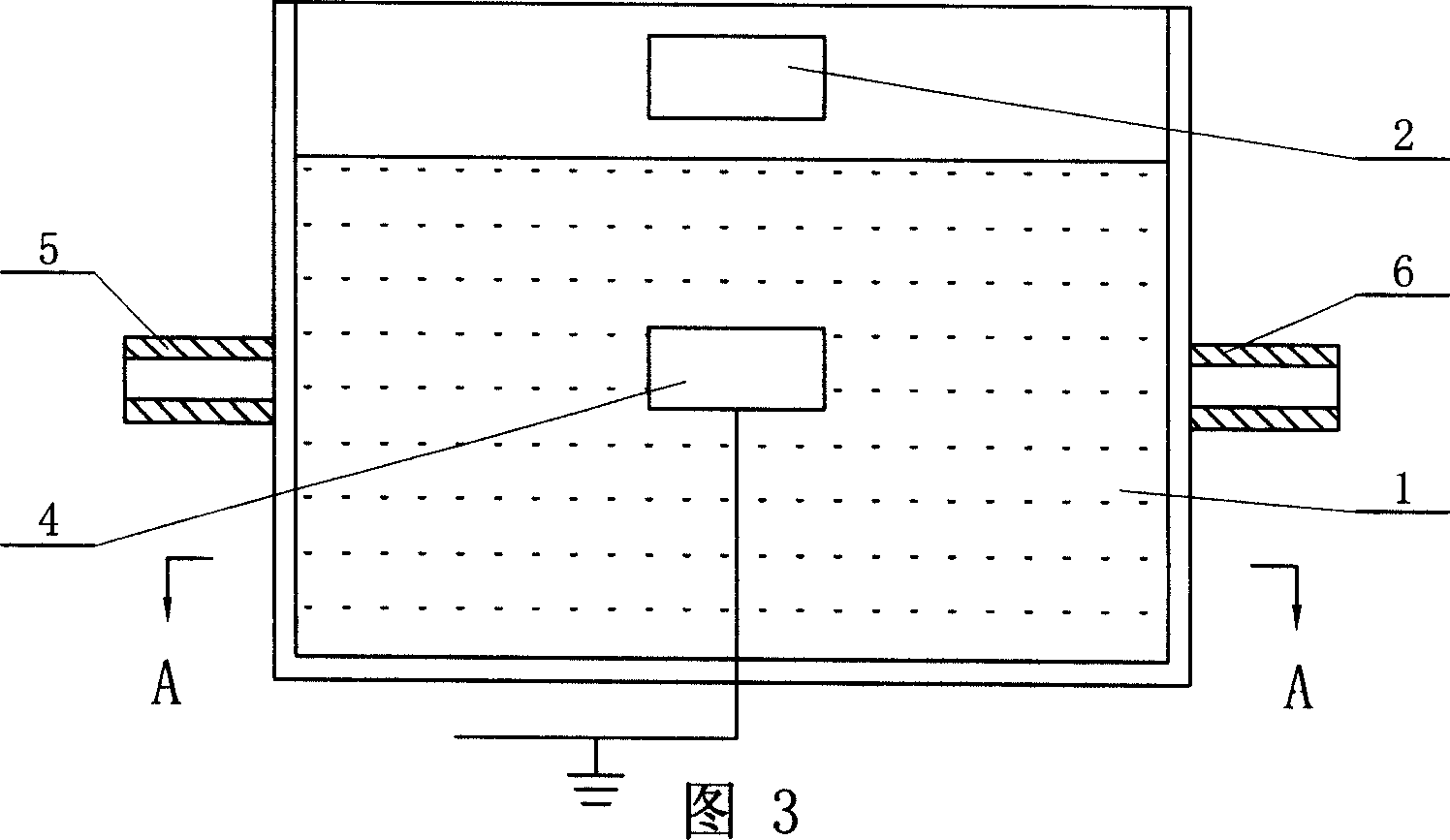

[0005] Specific implementation manner 1: The following specifically describes this implementation manner with reference to FIG. 1. The technical scheme of this embodiment is: it applies a high voltage pulse between the high voltage electrode 2 and the ground electrode 4 in the reaction vessel 1 containing the water to be treated through the high voltage pulse power supply 3, and applies the high voltage pulse to the high voltage electrode 2 and the ground at the same time. Oxygen, ozone, powdered activated carbon, transition metal oxides, hydrogen peroxide or transition metal ions are added to the solution to be treated between the electrodes 4. The transition metal oxides include iron oxide or manganese oxide and some ceramic oxides. The substances specifically include silicon oxide, aluminum oxide, magnesium oxide, and zirconium oxide. The transition metal ions include ferric ions, ferric ions, manganese ions, or cobalt ions. The two output terminals of the high-voltage pulse po...

specific Embodiment approach 2

[0006] Specific implementation manner 2: The following specifically describes this implementation manner with reference to FIG. 1. The difference between this embodiment and the first embodiment is that the high-voltage electrode 2 and the ground electrode 4 have opposite ends, one is pointed and the other is elongated, or both the high-voltage electrode 2 and the ground electrode 4 are rod-shaped and the ends are arranged opposite to each other. , Or the opposite ends of the high-voltage electrode 2 and the ground electrode 4 are elongated and the other is flat, or the opposite ends of the high-voltage electrode 2 and the ground electrode 4 are both flat, and the high-voltage electrode 2 and the ground electrode 4 are flat. The material is stainless steel, the high-voltage electrode 2 and the ground electrode 4 are placed horizontally and immersed in water, and the distance between the high-voltage electrode 2 and the ground electrode 4 is 0.5-10 cm. The other steps are the same ...

specific Embodiment approach 3

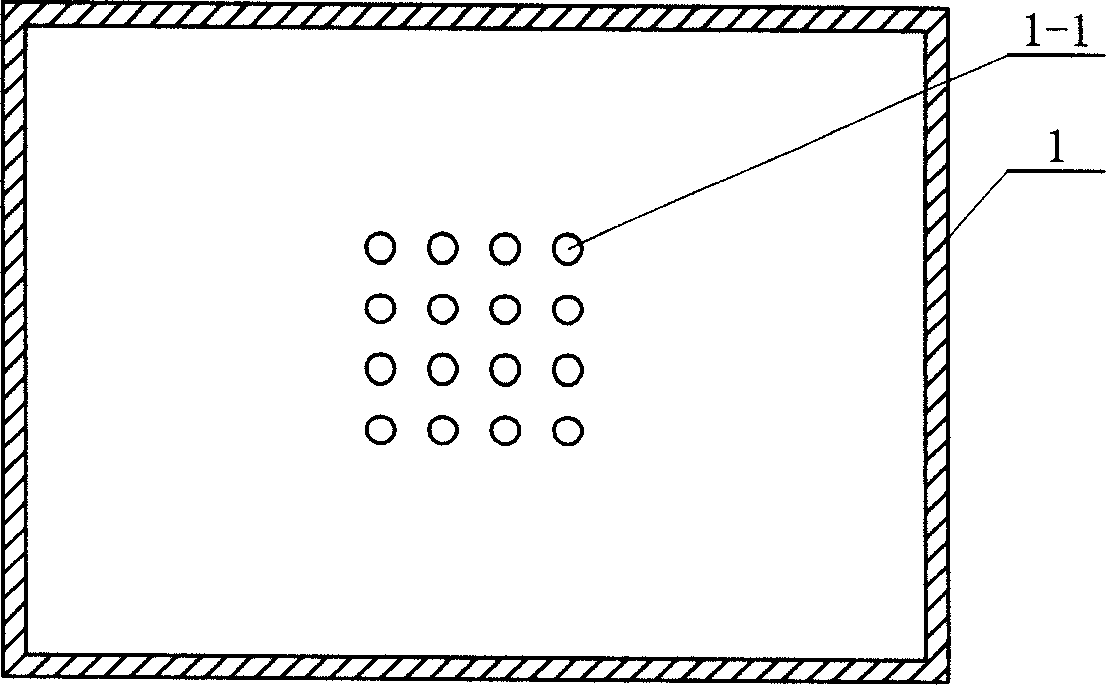

[0007] Specific implementation manner three: below in conjunction with Figure 1 and figure 2 This embodiment will be described in detail. The difference between this embodiment and the first embodiment is that oxygen and ozone are exposed from the bottom of the reaction vessel 1, and the bottom of the reaction vessel 1 is provided with a number of evenly arranged air holes 1-1, which enter the reaction vessel 1 from the air holes 1-1. The size of the bubbles formed by the oxygen and ozone is 10 microns to 1.0 mm, and the gas flow rate is 0.01 to 1 liter / sec. The other steps are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com