Advanced oxidation method for treatment of dye waste water

A dye wastewater, advanced oxidation technology, applied in the direction of oxidation water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low pH value, secondary pollution, high sludge production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

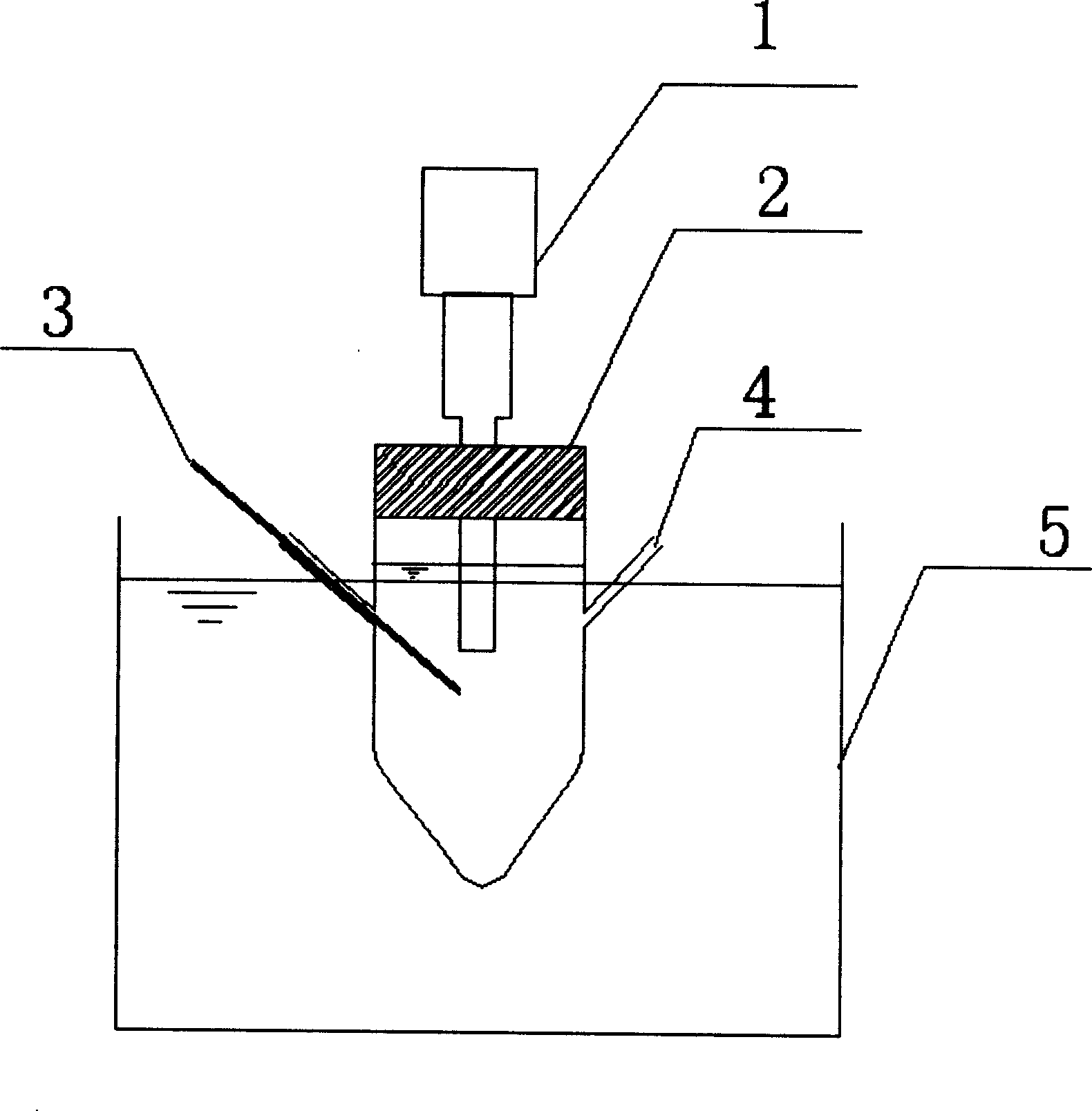

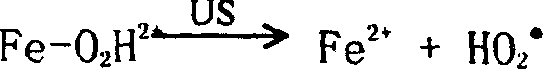

[0035] Example: In this example, other conditions are the same as those of the comparative example, after adding ultrasound, it is found that the COD removal rate of the two kinds of dye wastewater under the same time condition is about 20% higher than that without ultrasound. It can be seen that the present invention utilizes the strengthening effect of ultrasound to increase the mass transfer rate of reactants and chemical regeneration, thereby improving the COD removal rate of dye wastewater. The detailed operating conditions and processing results are as follows:

[0036] 1. Operating conditions:

[0037] Dye wastewater volume: 100mL

[0038] pH: 3

[0039] Ultrasonic conditions: 20kHz, 150W

[0040] Orange II dye wastewater: initial concentration of 100mg / L, Fe 2+ Ion concentration is 10mg / L, H 2 o 2 The concentration is 100mg / L

[0041] Reactive black K-BR dye wastewater: initial concentration is 400mg / L, Fe 2+ Ion concentration is 50mg / L, H 2 o 2 The concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com