Patents

Literature

35results about How to "Solve the conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Core-shell type catalyst for directional catalytic conversion of biomass synthesis gas, and preparation of core-shell type catalyst

PendingCN108906070AImprove conversion rateAvoid churnMolecular sieve catalystsHeterogenous catalyst chemical elementsCatalytic transformationFreeze-drying

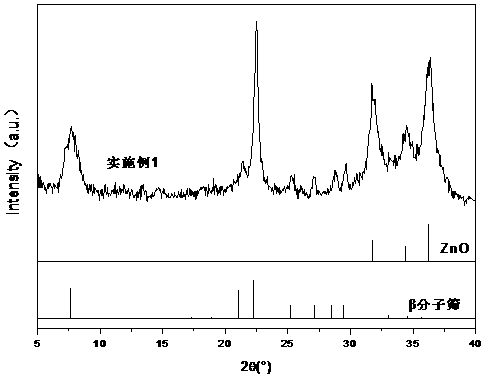

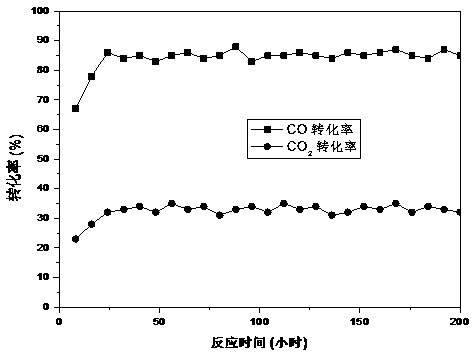

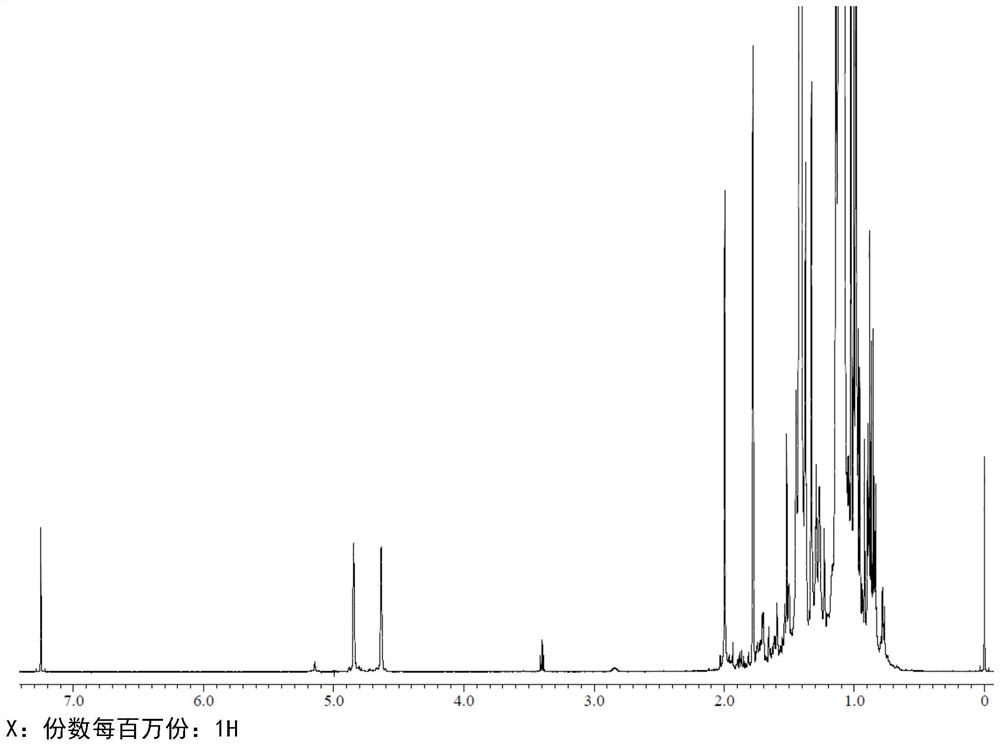

The invention provides a core-shell structure catalyst for directional catalytic conversion of biomass synthesis gas, and also provides a preparation method and application of the core-shell structurecatalyst. The core-shell structure catalyst comprises a core layer and a shell layer, wherein the core layer is prepared from small-grain composite metal oxide, and the shell layer is prepared from porous solid acid; the small-grain composite metal oxide is a solid solution or mixture of two or more oxides of ZnO, ZrO2, Co3O4, Fe2O3, In2O3, Ga2O3, CuO, Mn2O3, NiO, Cr2O3, La2O3 and CeO2. The core-shell catalyst adopts the solid solution or mixture of the small-grain composite metal oxide having a synergistic effect on hydrogenation of CO and CO2 as the core layer, and uses the solid acid having a microporous, mesoporous or multi-stage pore structure as the shell layer. The catalyst is prepared into a core-shell structure by means of a freeze-drying method, so that not only is the problem of lower hydrogenation conversion rate of CO2 in the biomass synthesis gas at present solved, but the conversion rate of CO hydrogenation is also further improved.

Owner:QINGDAO UNIV

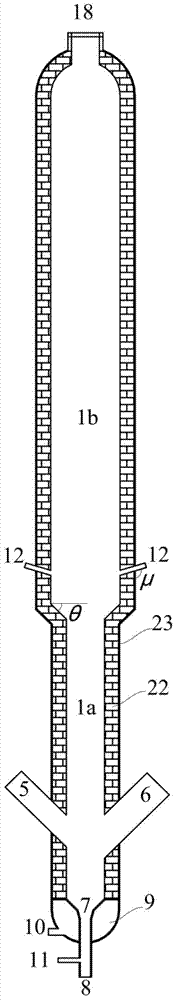

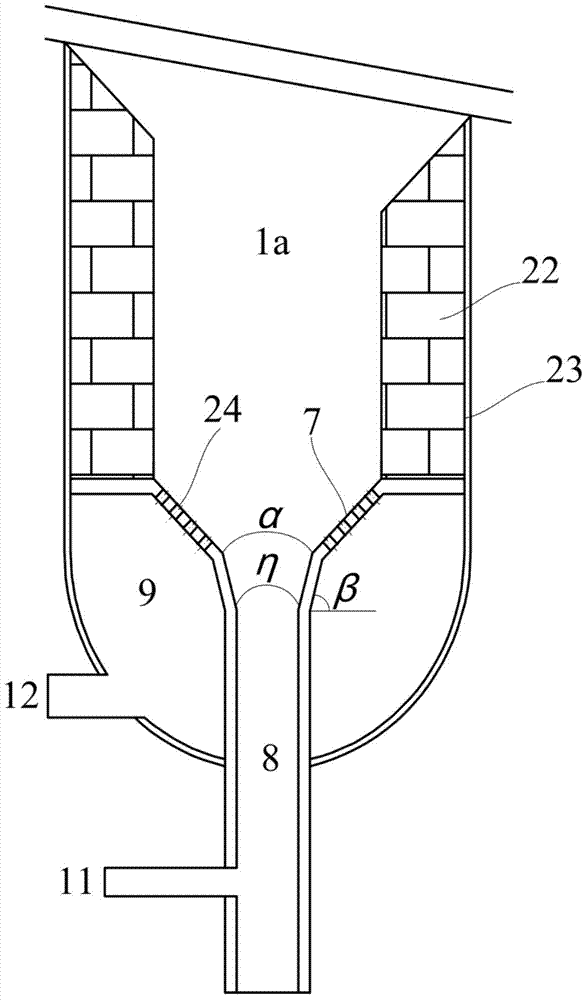

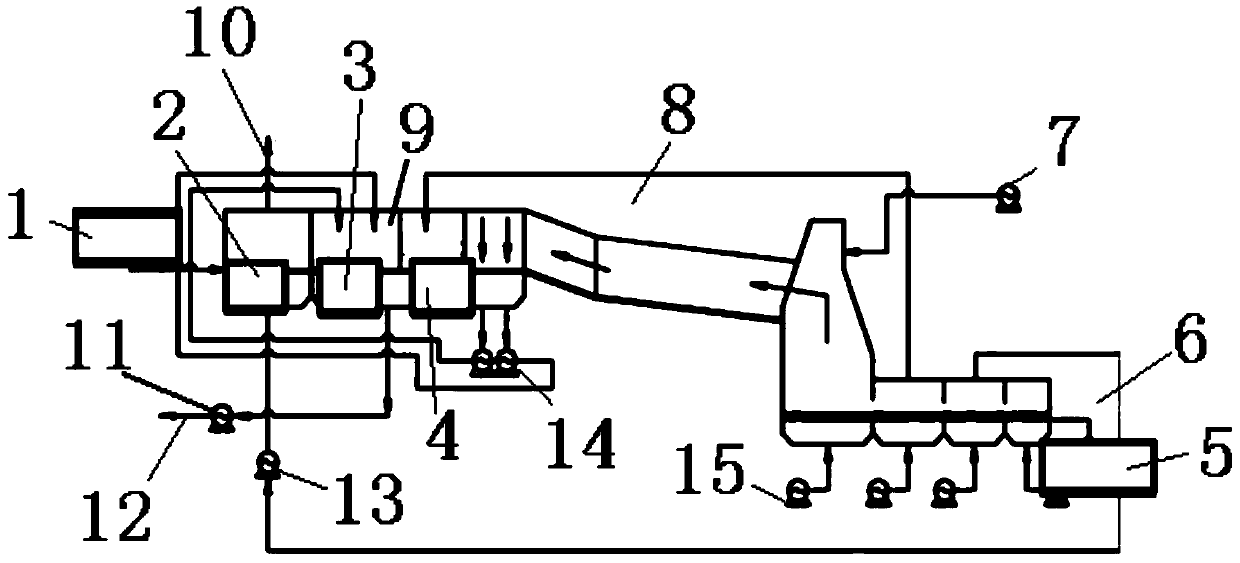

Dry-process deslagging fluidized bed gasification reaction device

ActiveCN104277881AGuaranteed uptimeEasy to scale upGasifier mechanical detailsGranular/pulverulent flues gasificationFluidized bedCyclonic separation

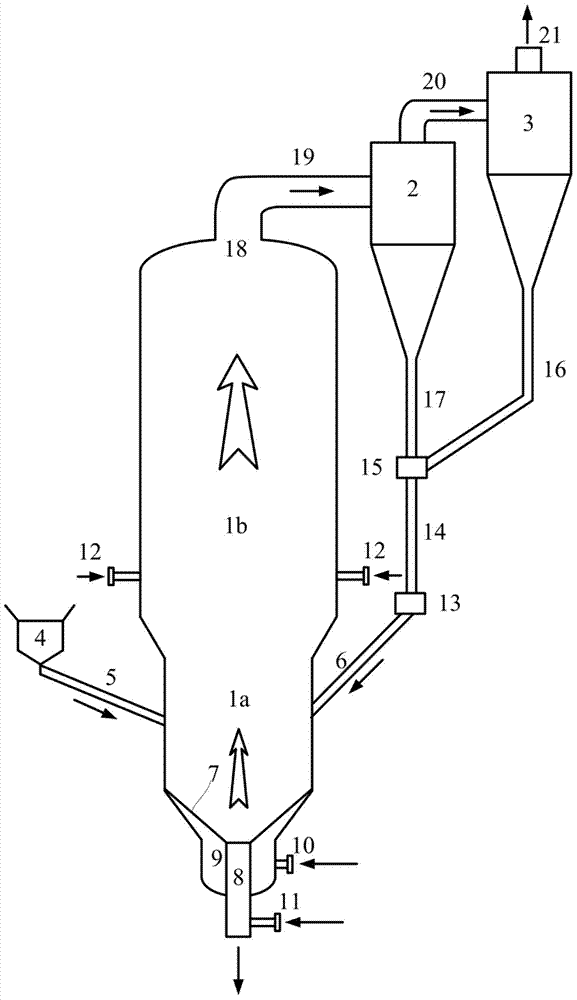

The invention discloses a dry-process deslagging fluidized bed gasification reaction device which comprises a reactor body, a multi-stage cyclone separating device, an air distribution device, a feed system and a return system. The dry-process deslagging fluidized bed gasification reaction device disclosed by the invention adopts a circulating fluidized bed reactor as a gasification reaction body, realizes the dry-process deslagging by adopting medium-high temperature gasification, achieves the purpose of improving carbon transformation rate and cooled coal gas efficiency by adopting two-stage type graded gasification, enhances the operation and running stability by combining a simplified deslagging device and an air distribution plate design, is suitable for the gasification transformation of various carbon-containing solid fuels and has large-scale popularization and application prospect.

Owner:SHANGHAI BOILER WORKS

Preparation method of forage bacillus subtilis powder

InactiveCN103271223ASolving activitySolve the conversion rateAnimal feeding stuffFermentation brothCulture mediums

The invention discloses a preparation method of a forage bacillus subtilis powder. The preparation method comprises the following steps: first, the bacillus subtilis strain is inoculated on a slant culture medium to carry on slant culture, then the slant is flushed with a sterile physiological-saline, and a seed bacteria suspension is obtained; second, the seed-bacteria suspension is inoculated in a seed tank with the inoculation amount of 3% to 5%,by volume, to carry on fermentation culture, and a seed bacteria liquid is obtained; third, the seed bacteria liquid is inoculated into a fermentation cylinder to carry on the fermentation culture using a pressure difference method, and a fermentation broth is obtained; and fourth, bacteria sludge is obtained through bacteria-liquid separation of the fermentation broth, and the forage bacillus subtilis powder is obtained through spray drying of the bacteria sludge. Through the exploring of culture medium formulas and fermentation conditions, the problems that the bacteria powder prepared by conventional methods has low viable bacteria count and low spore transformation rate are well solved, the production efficiency is increased, and the cost of enterprises is reduced. The forage bacillus subtilis powder prepared through the method of the present invention has high viable bacteria count and high spore transformation rate.

Owner:杨凌壹之农微生物工程技术研究院有限公司

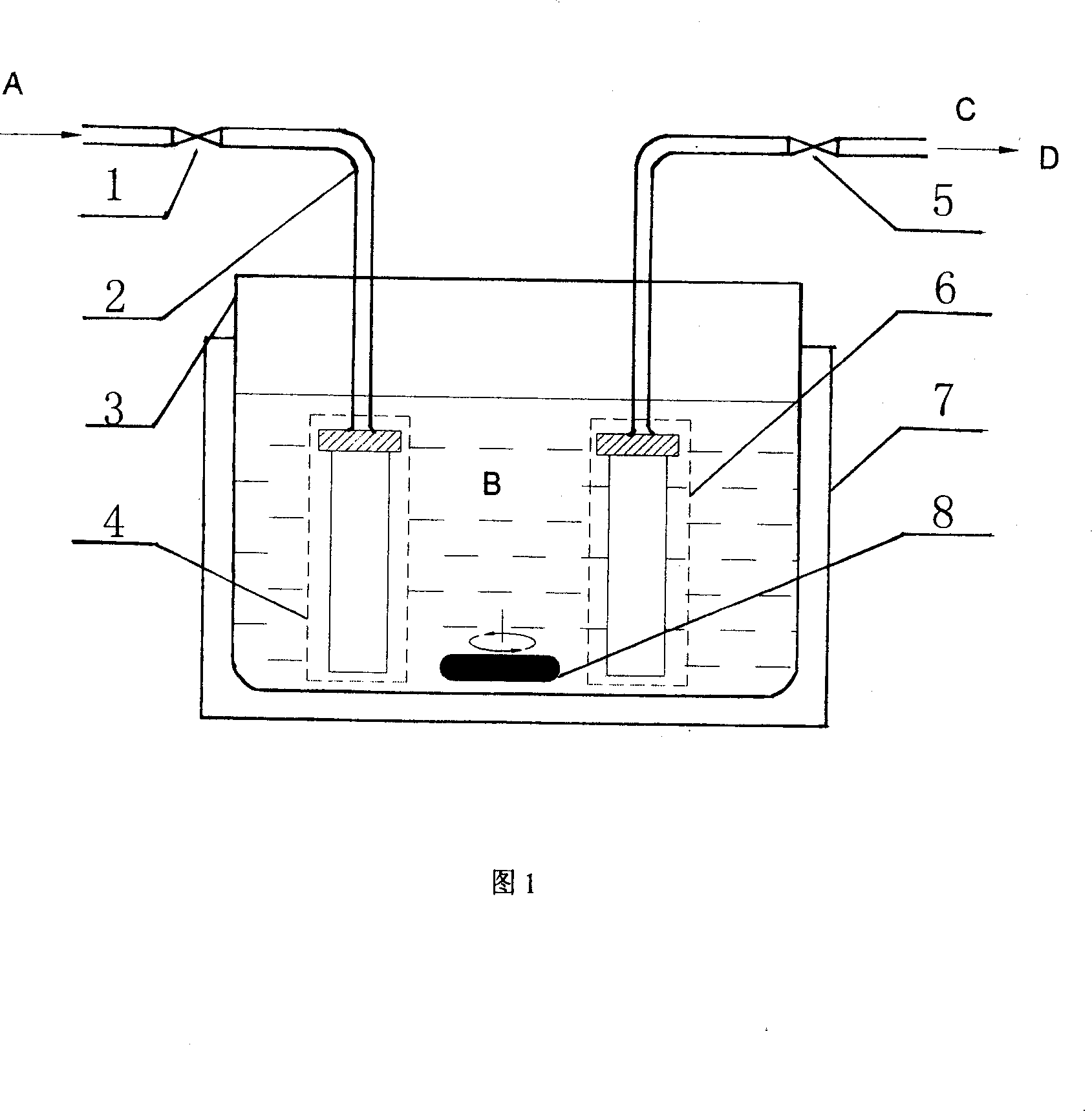

Preparation method of lactate

ActiveCN101045688AImprove mixing uniformitySolve the conversion rateOrganic compound preparationCarboxylic acid esters preparationAlcoholProcess integration

This invention relates to a kind esterification reaction technology of lactic acid, above all refer a coupling technology of adopting membrane course to integrate lactic acid esterification reaction. It takes lactic acid and alcohol as raw material. adding catalyzer and alcohol in reactor, adopting pressure actuated device to pressurize lactic acid, make lactic acid permeate porous membrane diverting device and enter liquid in reactor; heat reaction, at the same time adopt dehydration plant to deprive water from system; while reaction completed, adopt reduced pressure distillation method to separate mixed liquor of reaction which mostly contain lactic acid, alcohol, lactate as well as ounce water, to obtain high-purity lactate, and the rest materials for periodic duty. This invention solves a good many problems about low transformation efficiency, high dissipation of energy, equipment erosion and environmental pollution in existing esterification reaction craft.

Owner:NANJING UNIV OF TECH

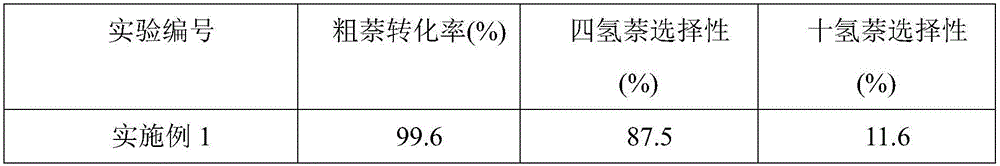

Catalyst used for reaction for preparing tetrahydronaphthalene through naphthalene hydrogenation and preparation method and application of catalyst

ActiveCN106563476AHigh activityImprove stabilityMolecular sieve catalystsHydrocarbon by hydrogenationActive componentCatalyst support

The invention discloses a catalyst used for a reaction for preparing tetrahydronaphthalene through naphthalene hydrogenation and a preparation method and application of the catalyst. The catalyst comprises a catalyst carrier, active components and auxiliaries, and the active components and the auxiliaries are loaded on the catalyst carrier. The catalyst is good in activity and stability, is not high in requirement for raw materials, and is applicable to the reaction for preparing the tetrahydronaphthalene through naphthalene hydrogenation, wherein the naphthalene content is larger than or equal to 94%, the naphthalene conversion rate can be higher than 95%, and the selectivity of the tetrahydronaphthalene is higher than 85%. A preparation process of the catalyst is simple, scientific and convenient to operate, equipment is simple, and the investment cost is low.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

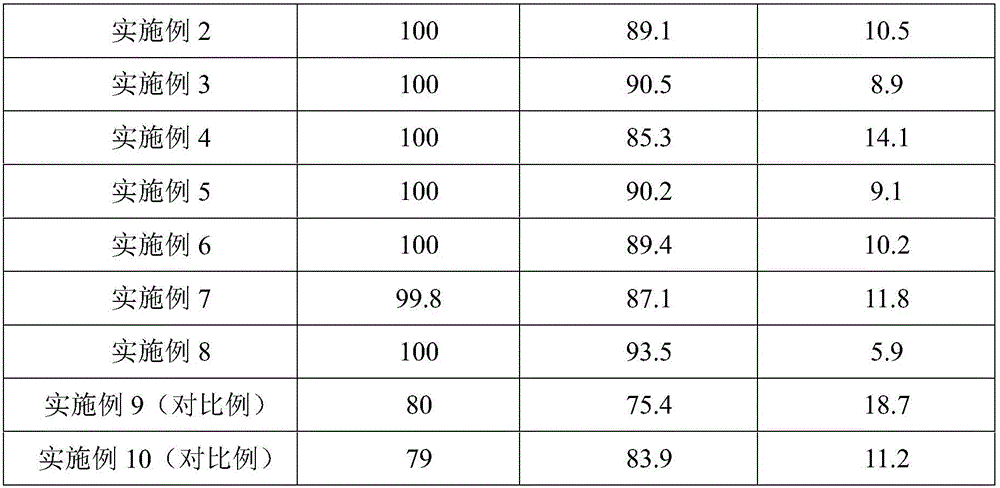

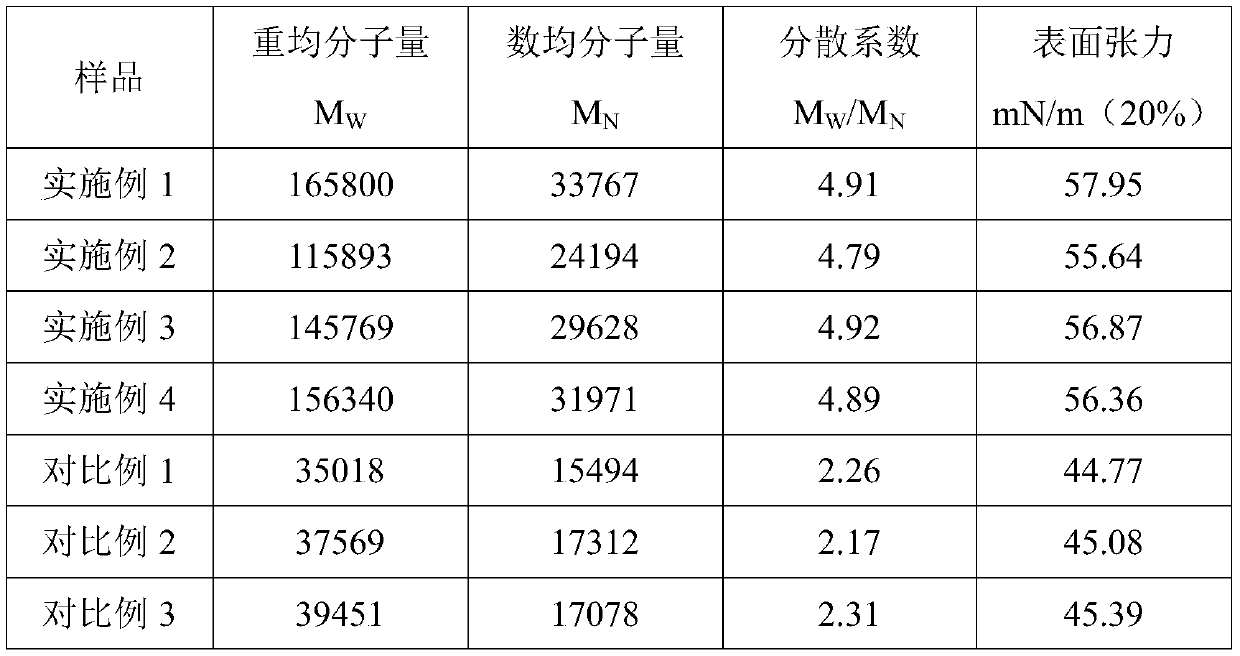

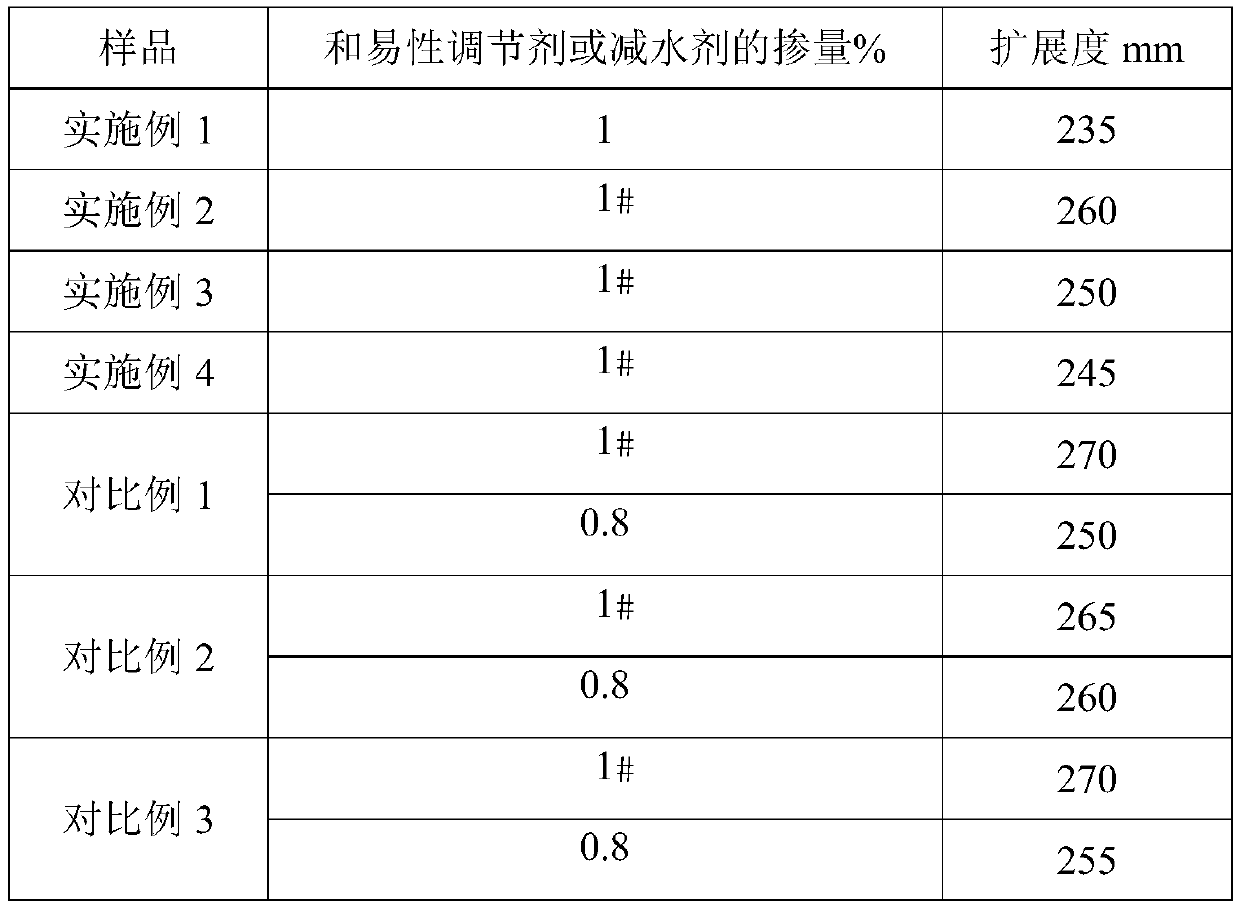

Concrete workability regulator and preparation method thereof

ActiveCN109880020AImprove workabilityWill not cause excessive air contentPotassium dichromateMacromonomer

The invention discloses a concrete workability regulator and a preparation method thereof. The concrete workability regulator comprises the following components: an unsaturated polyether macromonomer,an unsaturated ester monomer, a chain transfer agent, a strong oxidant and a hydrophilic modifier, wherein the molar ratio of the unsaturated polyether macromonomer to the unsaturated ester monomer to the hydrophilic modifier is (0.5-1.5):(0-0.2):(1.65-5.3); the addition amounts of the chain transfer agent and the strong oxidant respectively account for 0.17-0.67% and 0.25-1% of the mass of the unsaturated polyether macromonomer; and the chain transfer agent is a chain transfer agent with reducibility, and the strong oxidant is at least one of potassium permanganate and potassium dichromate.The concrete workability regulator is prepared by polymerizing the chain transfer agent with weak reducibility and the strong oxidant under the condition of no external heat source, the molecular weight of the concrete workability regulator is larger, the concrete workability regulator has thickening and water retention effects, the workability of concrete is improved, and the gas content of the concrete cannot exceed the standard.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

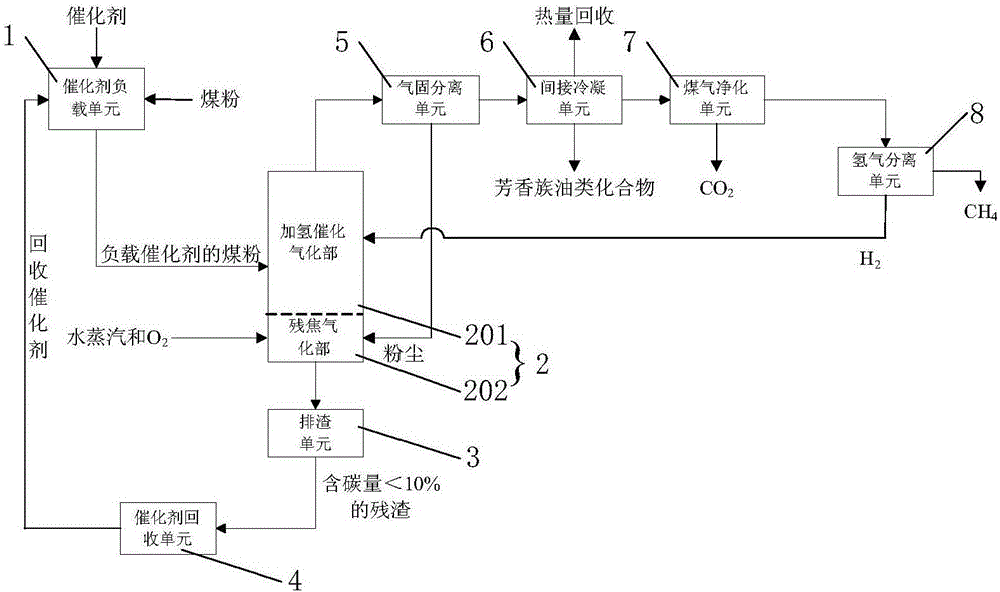

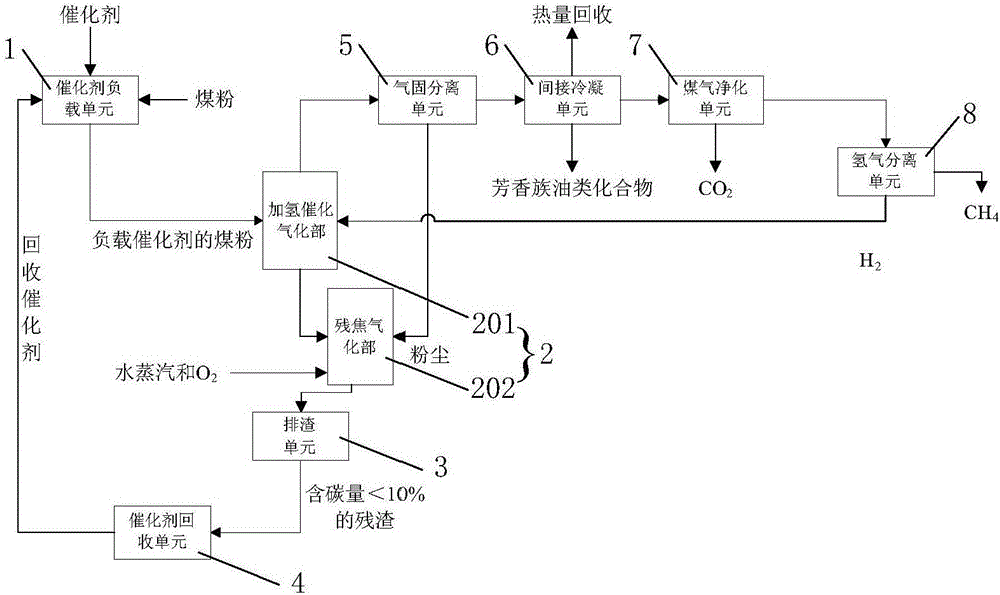

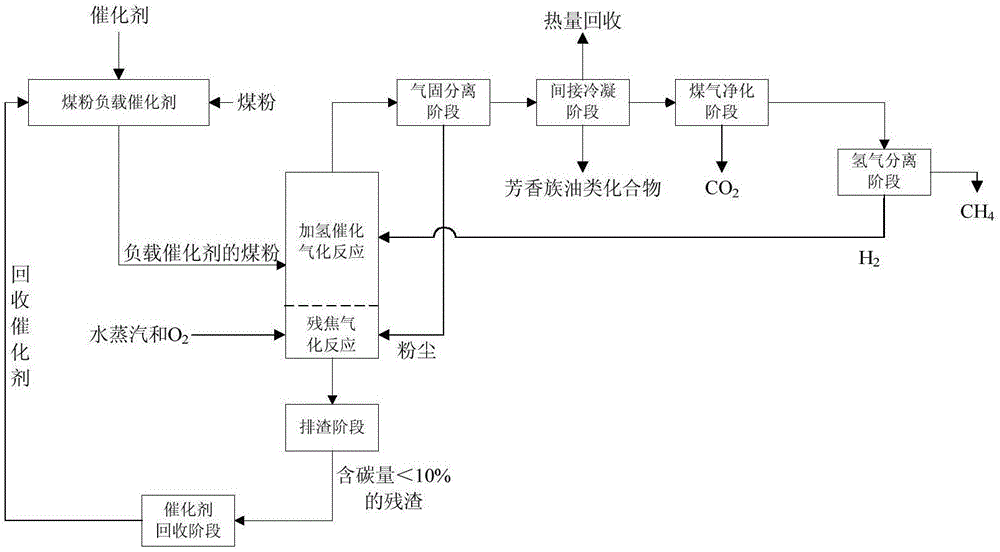

Coal hydrogenation catalytic gasification method and device

ActiveCN106590712AIncrease spawn rateImprove carbon conversionProductsReagentsMixed gasCoal gasification

The invention provides a coal hydrogenation catalytic gasification method and device and relates to the technical field of coal gasification, aiming at the problems in an existing coal catalytic gasification technology that the content of CH4 at a gas outlet of a gasification furnace is low and a process is complicated. The coal hydrogenation catalytic gasification method comprises the following steps: processing coal powder and a catalyst to generate coal powder loaded with the catalyst; under the action of the catalyst, carrying out a hydrogenation catalytic gasification reaction on the coal powder loaded with the catalyst and H2 to generate CH4 and remained coke containing the catalyst; taking CO2 and H2 to react, so as to generate CH4; under the action of the catalyst, taking the remained coke containing the catalyst and mixed gas of water steam and O2 to be subjected to a remained coke gasification reaction, so as to generate H2 and CO2; taking the coal powder loaded with the catalyst and generated H2 to be subjected to the hydrogenation catalytic gasification reaction to generate CH4 and the remained coke containing the catalyst; taking generated CO2 and H2 to react, so as to generate CH4; and repeatedly carrying out the hydrogenation catalytic gasification reaction and the remained coke gasification reaction until the remained coke containing the catalyst is converted into residues containing the catalyst, so as to obtain CH4. The coal hydrogenation catalytic gasification method provided by the invention is applied to the field of coal gasification.

Owner:ENN SCI & TECH DEV

Catalytic cracking process for producing vinyl chloride by using active carbon as accelerant

InactiveCN102766019ASolve the conversion rateSolve the problem of selectivityPreparation by hydrogen halide split-offHigh energyFixed bed

The invention discloses a catalytic cracking process for producing vinyl chloride by using active carbon as an accelerant. The method comprises the following steps: introducing dichloroethane into a fixed bed reactor with activated carbon catalyst, and separating the reaction products to obtain products of hydrogen chloride and liquid vinyl chloride. A preparation method of the active carbon catalyst comprises the following steps: pretreating coaly activated carbon, shell activated carbon or coconut shell activated carbon, and drying at a temperature of 80-100 DEG C for 20h-24h; and then activating in an atmosphere with nitrogen as a protective gas at a temperature of 200-250 DEG C for 10-24 h, so as to obtain the activated carbon catalyst. The invention solves problems of low conversion rate, poor selectivity and high energy consumption of dichloroethane high-temperature pyrolysis, and greatly reduces operating costs on the subsequent recovery and rectification separation of dichloroethane.

Owner:EAST CHINA UNIV OF SCI & TECH

Fermentation high-quality beef fattening feed and manufacture method thereof

InactiveCN104304669AThe formula is scientific and reasonableAddresses weakened immunityFood processingAnimal feeding stuffCampanula mediumSemen

The invention discloses a fermentation high-quality beef fattening feed and a manufacture method thereof. The fermentation high-quality beef fattening feed comprises the following raw materials in parts by weight: 400-500 parts of bean pulp, 300-400 parts of cottonseed meal, 100-200 parts of edible fungi residue, 100-200 parts of millet bran, 200-300 parts of sediment, 30-50 parts of bark, 40-50 parts of saw dust, 20-30 parts of bentonite, 10-20 parts of rock flour, 1.7-3.5 parts of a leavening agent, 300-400 parts of maize meal, 100-200 parts of glutinous rice flour, 50-80 parts of maize leaves, 50-60 parts of soybean straws, 30-50 parts of antigonon leptopus, 30-50 parts of imperata cylindrica, 2-3 parts of glossy privet fruits, 2-3 parts of canterburybells, 3-4 parts of orange peels, 3-5 parts of radix sileris, 2-3 parts of omei mountain bamboo juvenile leaves, 20-30 parts of semen sesami nigrum, 5-10 parts of arabian jasmine flowers, 30-40 parts of pig bone meal, 20-30 parts of skim milk powder, 10-20 parts of red dates, 30-50 parts of phagostimulant and the balance of water. The feed provided by the invention is scientific and reasonable in formulation and can increase economic benefits.

Owner:吴秀杰

Method for preparing composite micro-ecological enzyme for feeding the ruminant by using disused mushroom dregs

InactiveCN1653936ASolve UtilizationSolve the conversion rateAnimal feeding stuffAccessory food factorsBiotechnologyMicroorganism

Waste mushroom growing medium after picking up mushroom is compounded with crushed crop stalk, and the mixture is moistened with water, inoculated with 2-8 % enzyme producing composite microbial preparation and fermented at certain temperature for 3-15 days to convert all the material into semi-solid as composite micro ecological enzyme preparation for ruminant. After finishing the fermentation, the product is detected to possess total microbe amount not less than 3.0E10 CFU / g, cellulase FPA not less than 400 U / g, proteinase not less than 180 U / g, lipase not less than 240 U / g and amylase not less than 200 U / g.

Owner:迟乃玉

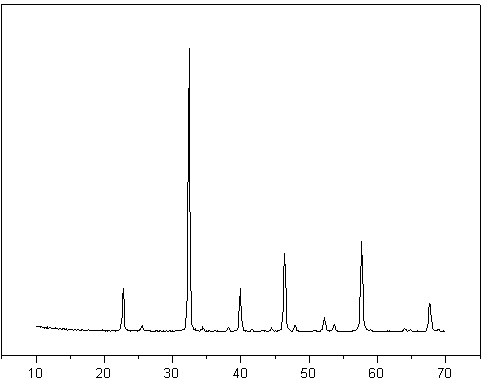

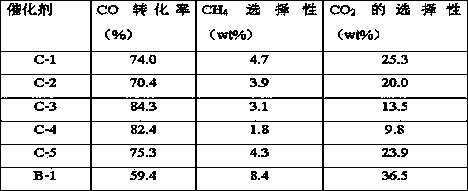

Catalyst for CO hydrogenation reaction, preparation method and application thereof

ActiveCN103611540ALow selectivitySolve the conversion rateLiquid hydrocarbon mixture productionEthylene productionSyngasOxygen vacancy

The invention discloses a catalyst for a CO hydrogenation reaction. The catalyst is composed of a composite metal oxide having a perovskite structure and a metal auxiliary agent, the composite metal oxide having a perovskite structure has a formula of ABO<3-Y>, wherein the A represents rare earth metals, the B represents transition metals comprising iron, the mole ratio of iron to other transition metals is not less than 3:1, and preferably not less than 4:1, and the y represents the mole number of oxygen vacancy existing in the composite metal oxide; by the weight of the catalyst, the simple substance auxiliary metal content is 1 to 15%, and preferably is 5% to 10%. The catalyst not only can improve the one-way conversion rate of the syngas, but also can effectively reduce the CO2 selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

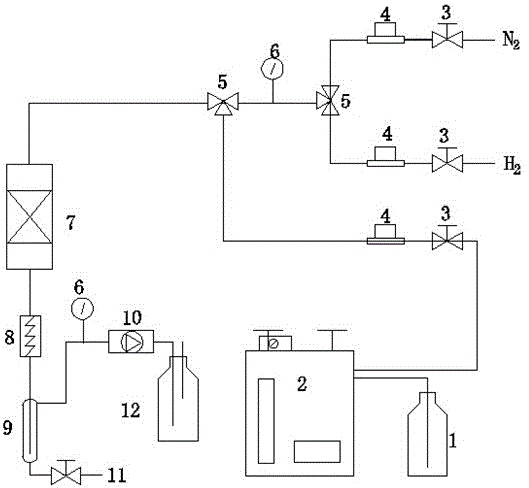

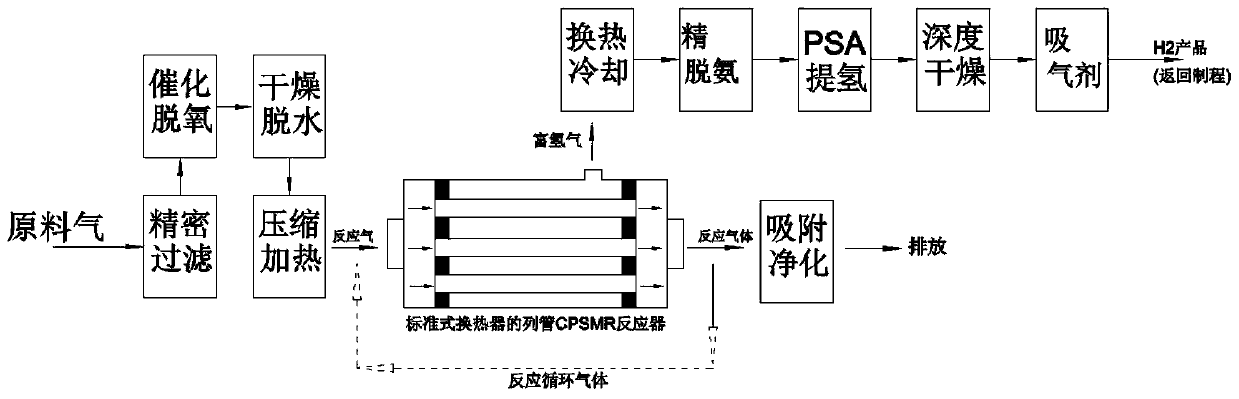

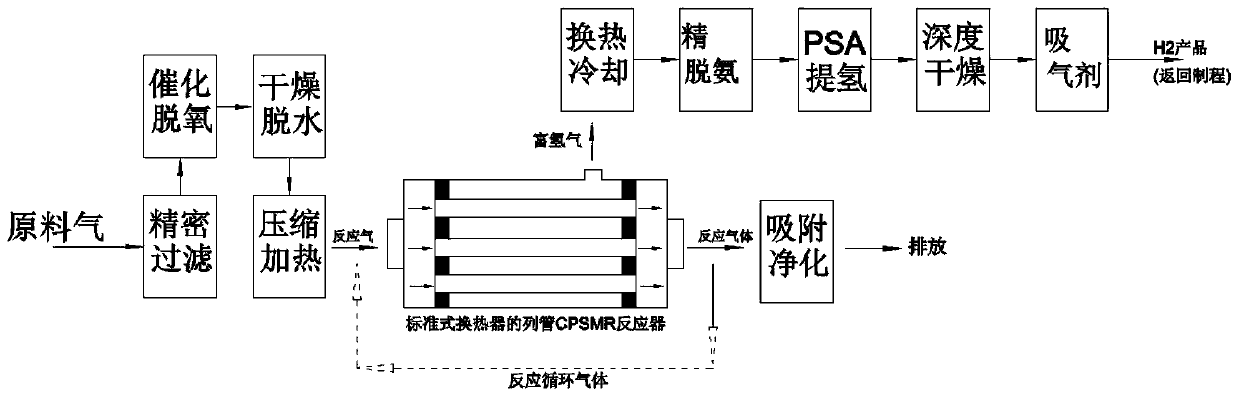

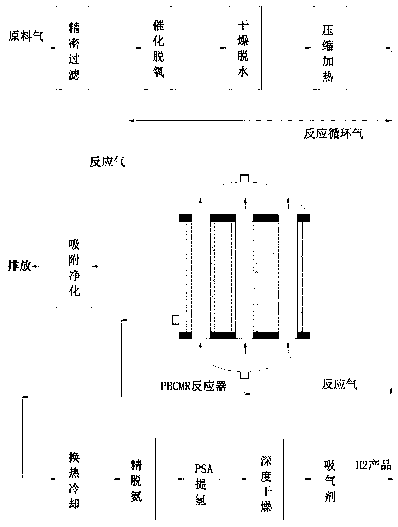

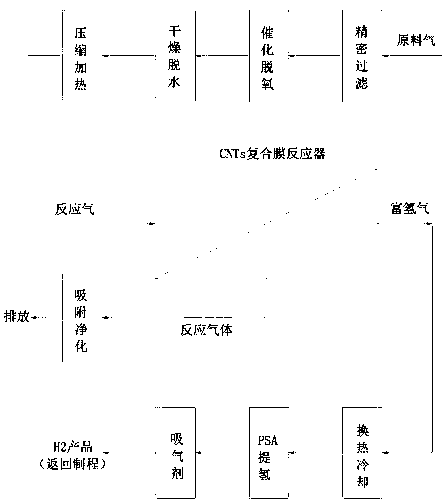

Catalytic permeable membrane reactor for producing hydrogen from ammonia-containing tail gas in MOCVDprocess as well as preparation method and application of the catalytic permeable membrane reactor

InactiveCN111137853ASolve the conversion rateSettlement yieldHydrogen separation using solid contactHydrogen productionOxide ceramicCarbon nanotube

The invention discloses a catalytic permeable membrane reactor for producing hydrogen from ammonia-containing tail gas in an MOCVD process. In the membrane reactor, a porous gamma-aluminum oxide ceramic circular tube containing 5-10% (w / w, similarly hereinafter) of metal palladium is dispersed is used as a support body; an inorganic carbon nano-membrane, which contains 10-30% of cobalt and 5-20% of molybdenum as active components, 1-10% of lanthanum serving as an auxiliary catalytic component and 1-5% of potassium serving as an accelerant, is embedded into pretreated carbon nanotubes (CNTs) and coats the inner wall of an alumina ceramic round tube, has thickness of 10 nm to 1 [mu]m and pore diameter of 0.20 to 10 nm; thus forming the catalytic permeable membrane reactor which simultaneously has catalytic activity and separation selectivity. Ammonia-containing tail gas in the MOCVD process is pretreated and then enters a membrane reactor; at the reaction temperature of 400-600 DEG C, an ammonia thermal cracking catalytic reaction is performed under the reaction pressure of 2.0-5.0 MPa; and hydrogen-rich gas generated by the reaction is subjected to adsorption refining deamination,pressure swing adsorption purification and metal getter purification to obtain a hydrogen product with the purity of more than 6-7 N, and the hydrogen product is returned to the MOCVD process to be recycled, thereby filling the blank for green and circular economy development of the LED industry.

Owner:SICHUAN TECHAIRS

Fluidization catalytic method for producing m-cresol and p-cresol through isomerization of o-cresol

InactiveCN103342629ASolve the problem of longevitySolve the conversion rateOrganic chemistryOrganic compound preparationCatalytic methodIsomerization

The invention relates to a fluidization catalytic method for producing m-cresol and p-cresol through isomerization of o-cresol. According to the method, o-cresol and a carrier gas are gasified in a preheater, and m-cresol and p-cresol are produced through isomerization by adopting the fluidization catalytic method, so that problems of short service life of a catalyst and low conversion rate in the isomerization process of cresol at present are better solved. The fluidization catalytic method can be applied to industrial production for large-scale production of the m-cresol and the p-cresol.

Owner:BEIJING RISUN TECH CO LTD

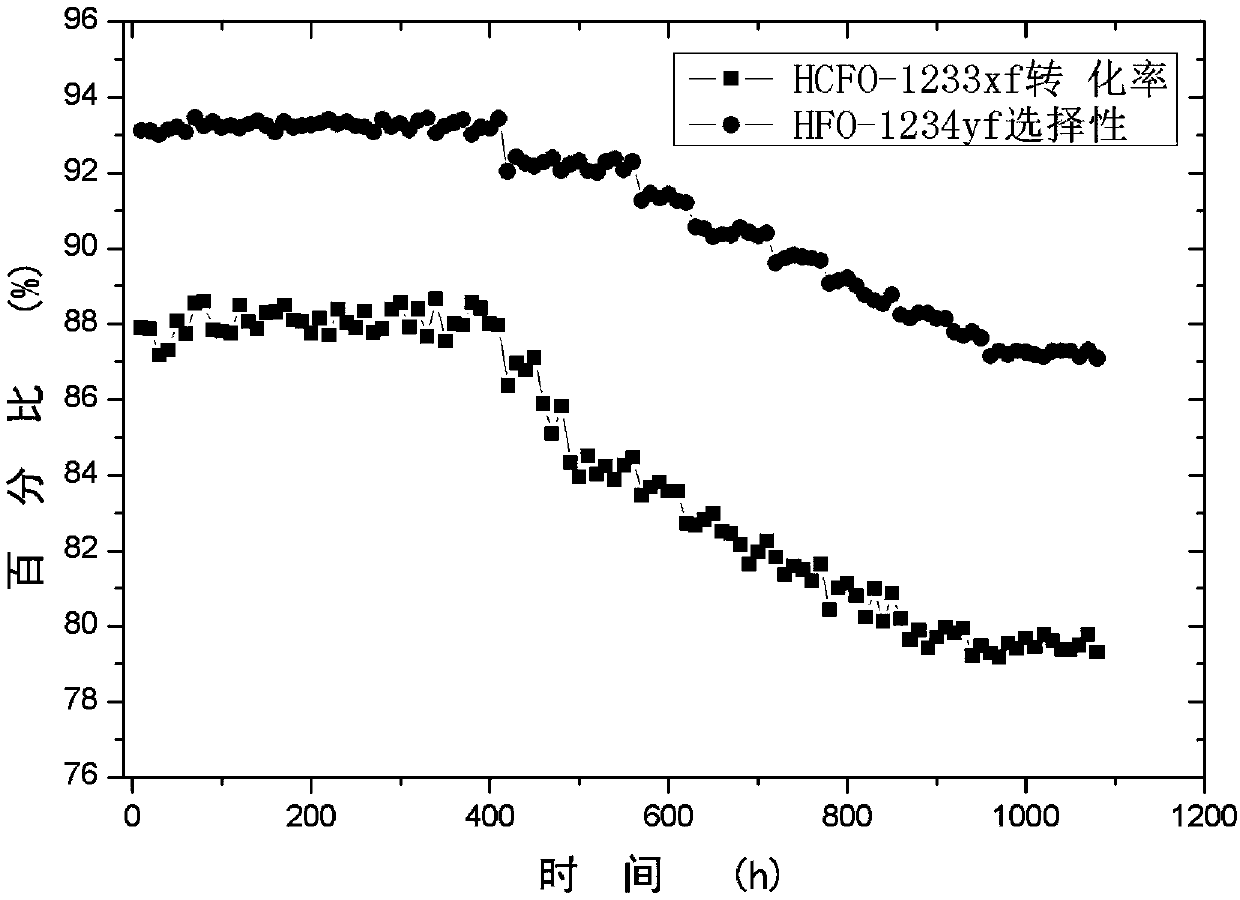

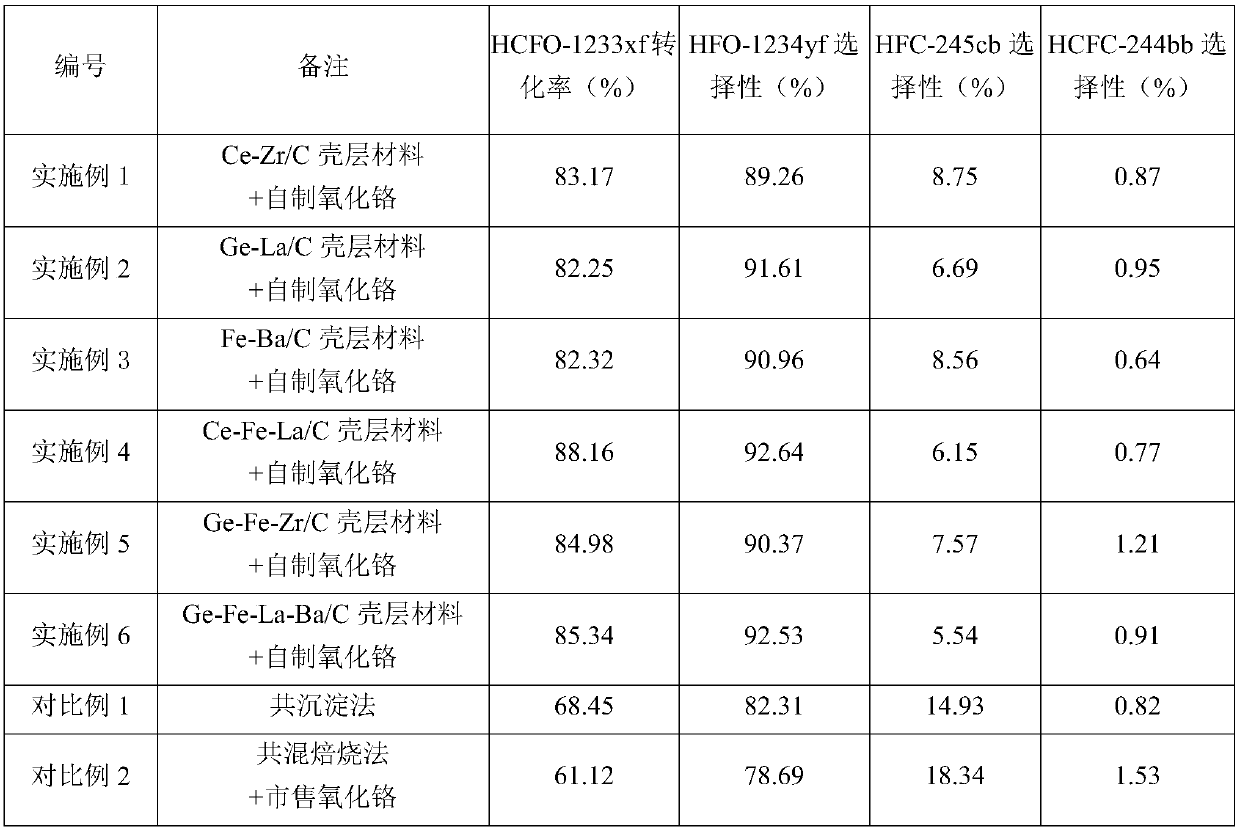

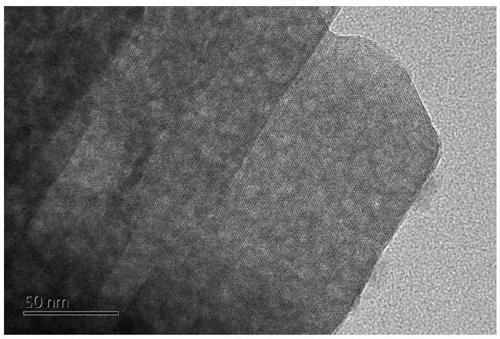

Fluorination catalyst and preparation method and application thereof

ActiveCN109569674ASolving activitySolve the conversion ratePhysical/chemical process catalystsPreparation by halogen replacementMicrowave methodHFO-1234yf

The invention provides a fluorination catalyst and a preparation method and application thereof. The preparation method comprises the steps of using a microwave combined blending method, preparing a metal aid / organic ligand compound by a microwave method at first, then roasting to prepare a metal aid / carbon shell layer material, and finally, blending the metal aid / carbon shell layer material with self-made chromium oxide, tabletting, roasting, and carrying out fluorination to prepare the fluorination catalyst. The fluorination catalyst is particularly suitable for being used for preparing and synthesizing HFO-1234yf from HCFO-1233xf.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

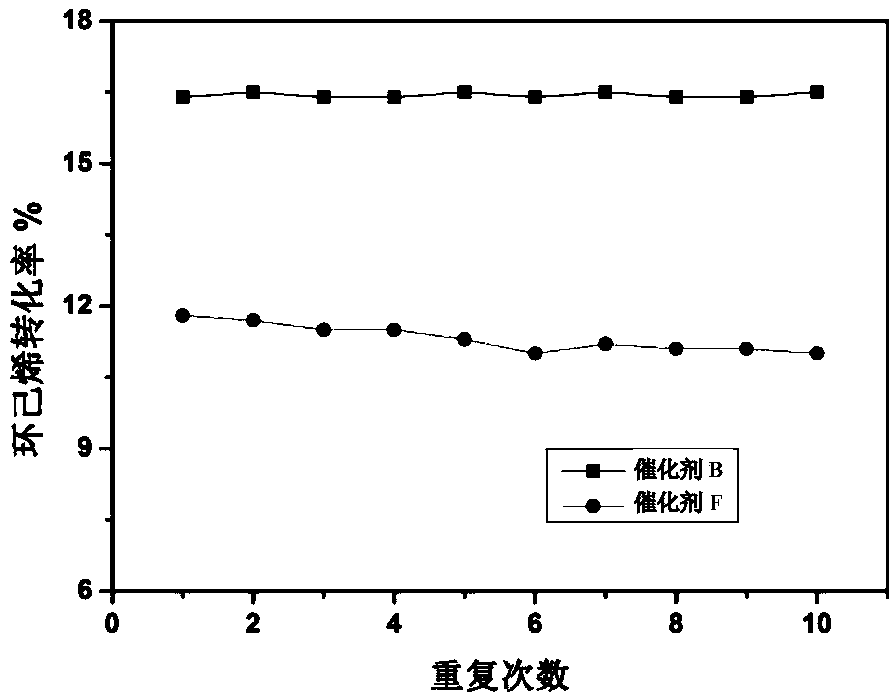

Method for preparing cyclohexanol by hydrating cyclohexene

ActiveCN111253217ASolve the speed problemSolve the conversion rateMolecular sieve catalystsPreparation by hydroxy group additionMolecular sieveEnvironmental chemistry

The invention discloses a method for preparing cyclohexanol by hydrating cyclohexene, and belongs to the field of catalyst materials. The method for preparing the cyclohexanol by hydrating the cyclohexene at least comprises the following steps: enabling a raw material containing cyclohexene and water to be in contact reaction with a catalyst to obtain cyclohexanol, wherein the catalyst comprises ahierarchical pore ZSM-5 molecular sieve. According to the method, the catalyst containing the hierarchical pore ZSM-5 molecular sieve is applied to a reaction for preparing cyclohexanol by hydratingcyclohexene, so that the conversion rate of the reaction and the stability of the catalyst can be remarkably improved; and the hierarchical pore ZSM-5 molecular sieve used in the method is readily available in raw materials and diverse in preparation method, and has strong feasibility and practicability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

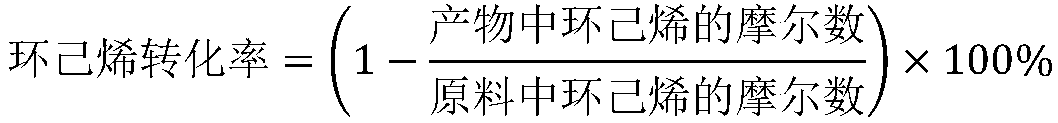

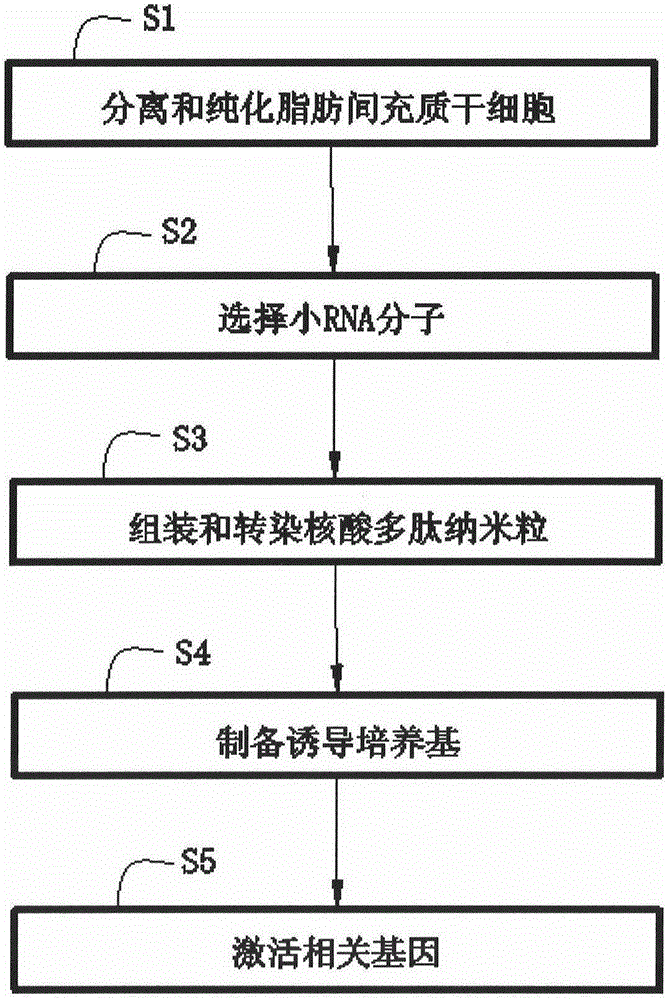

Method for inducing transdifferentiation of mesenchymal stem cells into skin stem cells

ActiveCN106318979ASolve the conversion rateResolution timeOther foreign material introduction processesForeign genetic material cellsTransdifferentiationHuman body

The invention discloses a method for inducing transdifferentiation of mesenchymal stem cells (AD-MSCs) into skin stem cells (AD-SSCs). The method specifically comprises: S1, rapidly separating and purifying homogeneous adipose mesenchymal stem cells; S2, selecting a variety of small RNA molecules stem capable of being used for stem cell epigenetic regulation; S3, assembling and transfecting nucleic acid polypeptide nanoparticles; S4, preparing a culture medium for inducing transdifferentiation of mesenchymal stem cells into skin stem cells; and S5, activating a variety of related genes for guiding the self-renewing and the transdifferentiation of the skin stem cells. According to the present invention, the human adipose mesenchymal stem cells with characteristics of easy obtaining, abundant source, no moral and ethical issue, safty and effectiveness are used as the induced object and are subjected to large-scale, rapid and high-purity transdifferentiation by transfecting the two small RNAs molecules under the effect of the special serum-free culture medium to obtain the AD-SSCs, wherein the induced skin stem cells are the same as the skin stem cells naturally produced in human body, and have the self-renewing ability and the potential for differentiation into the skin cells.

Owner:黄兵 +1

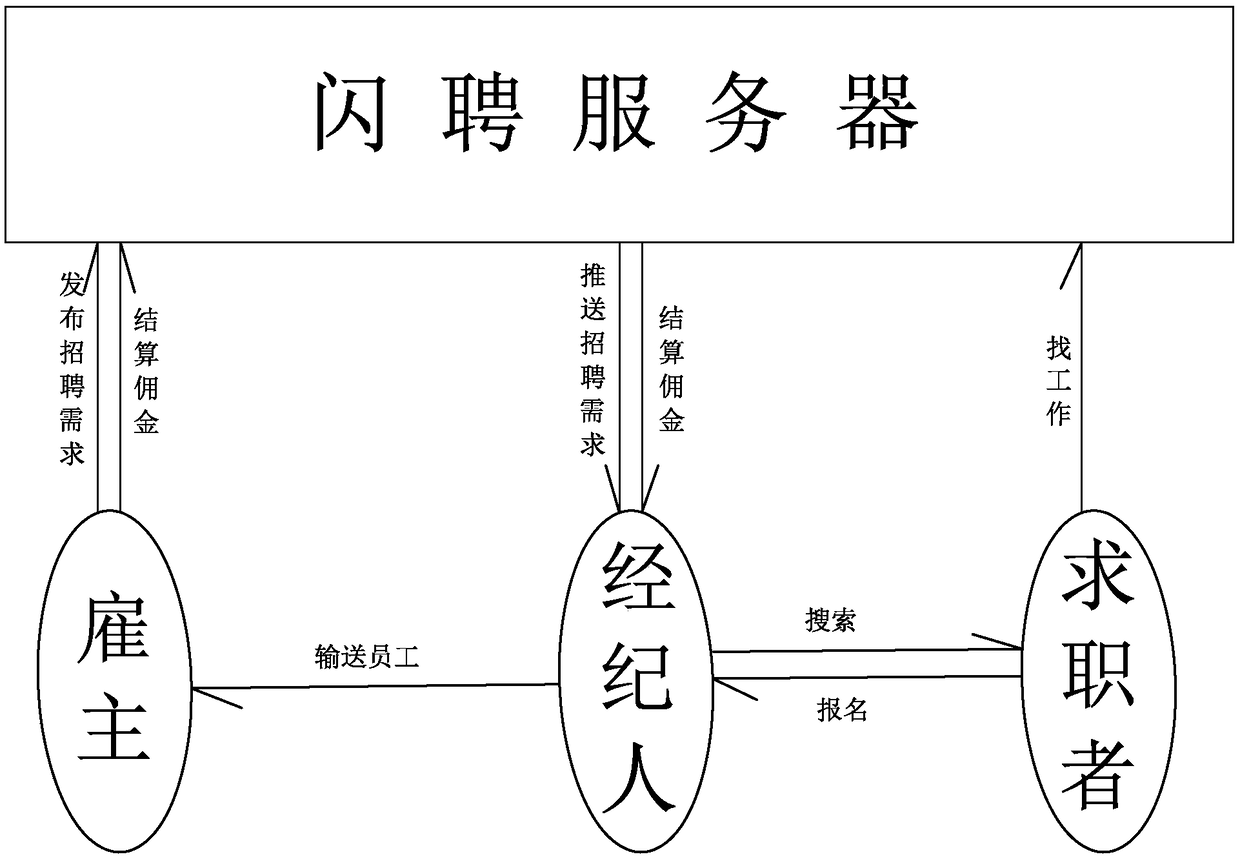

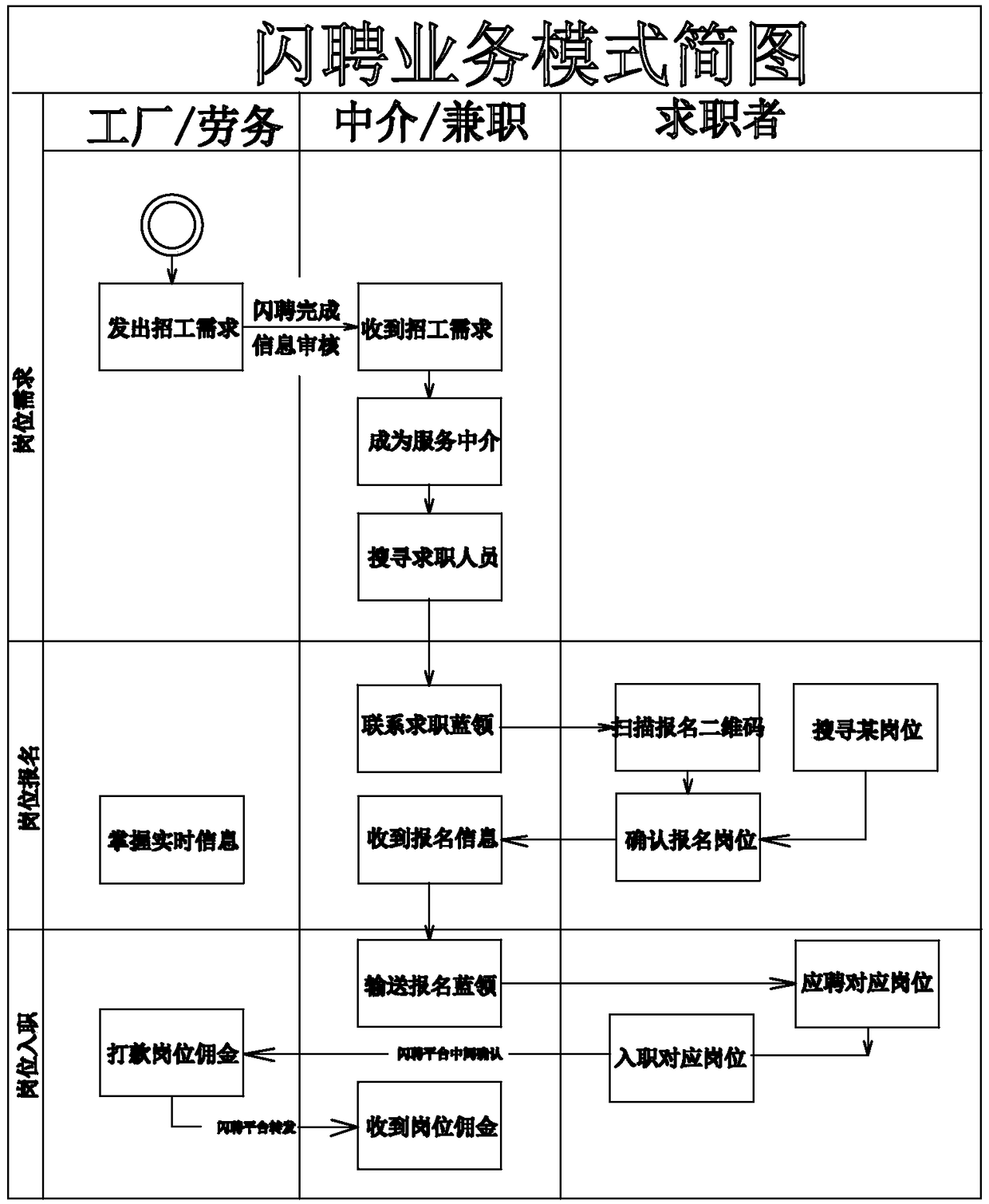

A B2b2C three-terminal online recruitment platform and a recruitment processing method

InactiveCN109003042AImprove recruitment efficiencyReduce recruitment costsPayment architectureOffice automationClient-sideBlue collar

The invention discloses a B2b2C three-terminal on-line recruitment platform and a recruitment processing method. The recruitment platform comprises an employer client end, which is used for publishingrecruitment requirements to a flash employment server, receiving information of job seekers meeting the recruitment requirements and settling commission; a job application client used for publishingjob application information to the flash employment server and sending job application information to the broker client; a broker client, configured to receive the recruitment request pushed by the flash employment server, search for qualified job applicants, and send the job applicants and the settlement commission to the employer client; the flash employment server is used for recording the recruitment requirement published by the employer client and the job application information published by the job seeker client, pushing the recruitment requirement to the broker client, and settling thecommission to the employer client and the broker client respectively. The invention has the advantages of low recruitment cost, higher recruitment efficiency and shorter recruitment time, and can realize rapid blue collar recruitment.

Owner:GUANGZHOU SHANPIN NETWORK TECH CO LTD

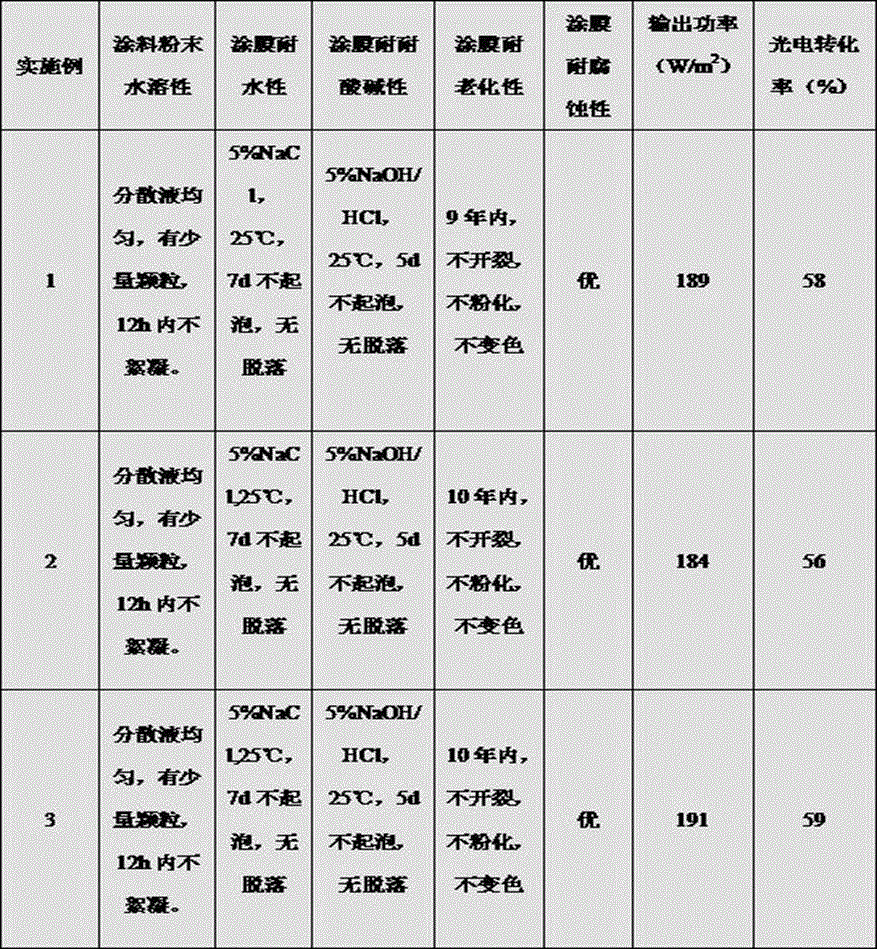

Novel solar photovoltaic conversion coating

InactiveCN106189735AImprove photoelectric conversion rateIncrease output powerAnti-corrosive paintsPolyester coatingsBuilding integrationAntioxidant

The invention discloses a novel solar photovoltaic conversion coating which is prepared from the following raw materials in parts by weight: 55-105 parts of matrix resin, 35-52 parts of graphite, 20-38 parts of pigment fillers, 30-58 parts of gallium arsenide, 5-10 parts of cerium oxide, 5-10 parts of lanthanum oxide, 4-8 parts of titanium oxide, 4-8 parts of aluminum oxide, 3-6 parts of zinc oxide, 60-100 parts of glycerol, 10-20 parts of addition agents, 6-10 parts of curing agents, 1-3 parts of degassing agents, 1-2 parts of dispersing agents, 0.5-1.2 parts of wetting agents, 0.4-1 part of emulgators, 0.2-0.5 part of corrosion removers and 0.2-0.4 part of antioxidant. The novel solar photovoltaic conversion coating provided by the invention has the advantages of excellent performance, high output power, high photoelectric conversion rate, low production cost, environmental protection, easiness in transportation and storage, easiness in industrial production and huge market application value, and especially can be applied to the field of solar building integration.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

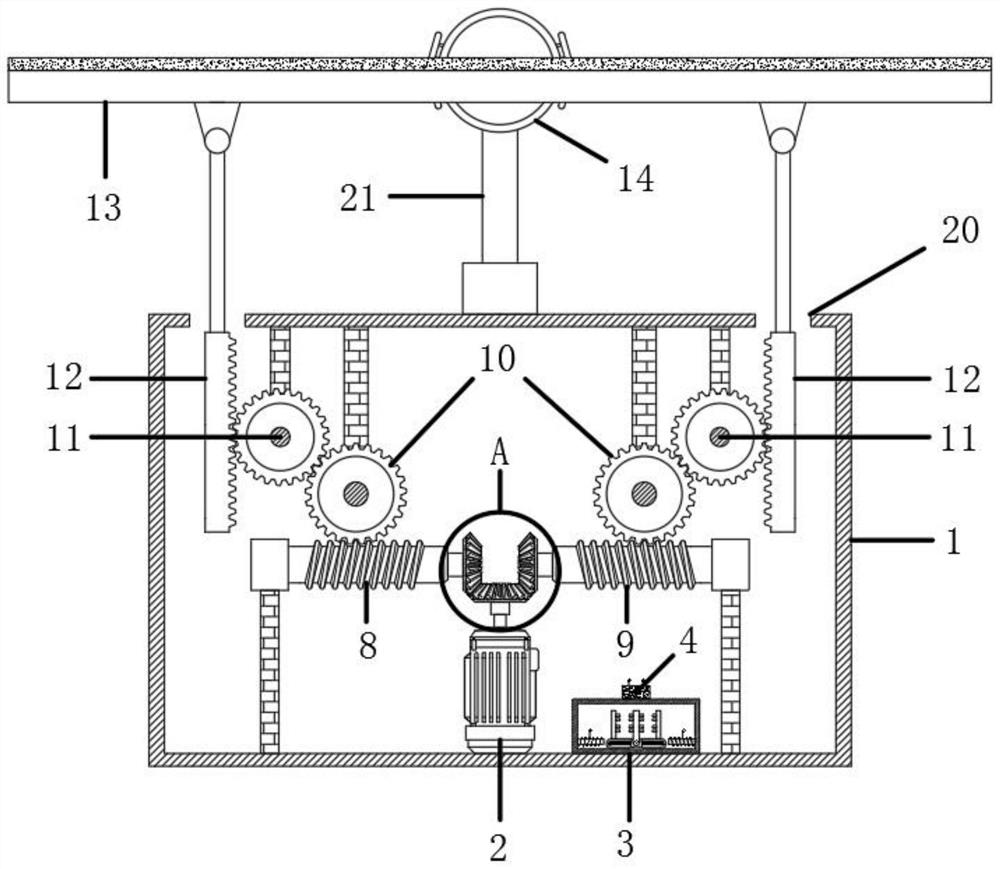

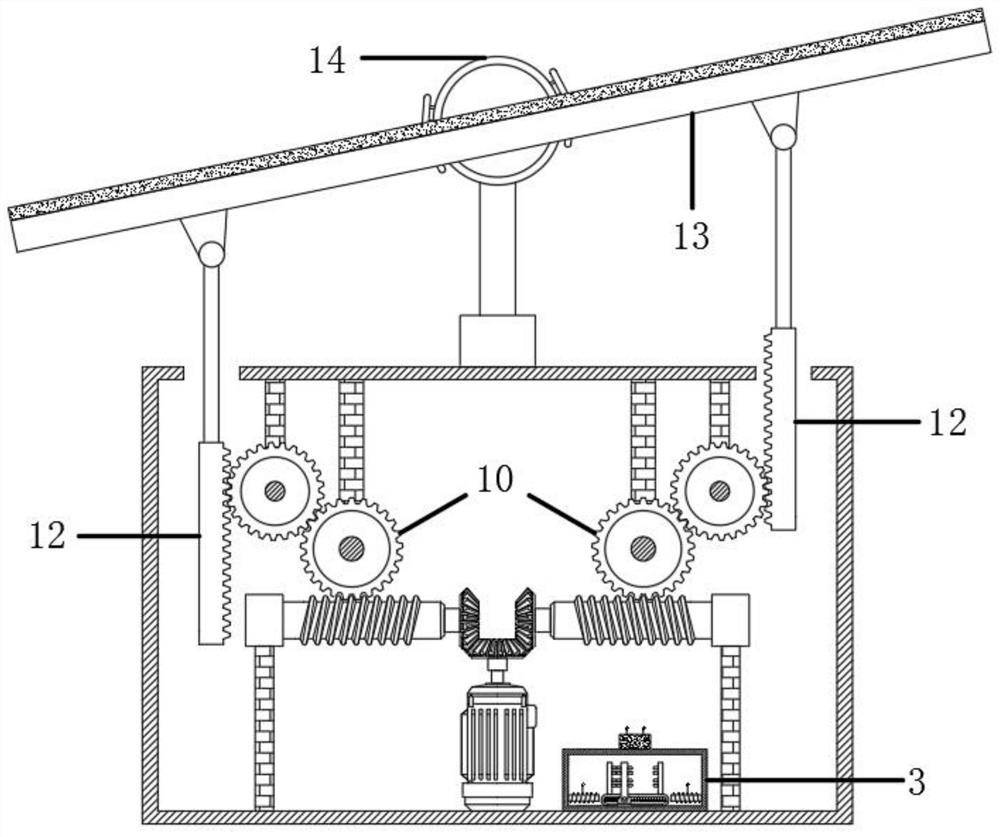

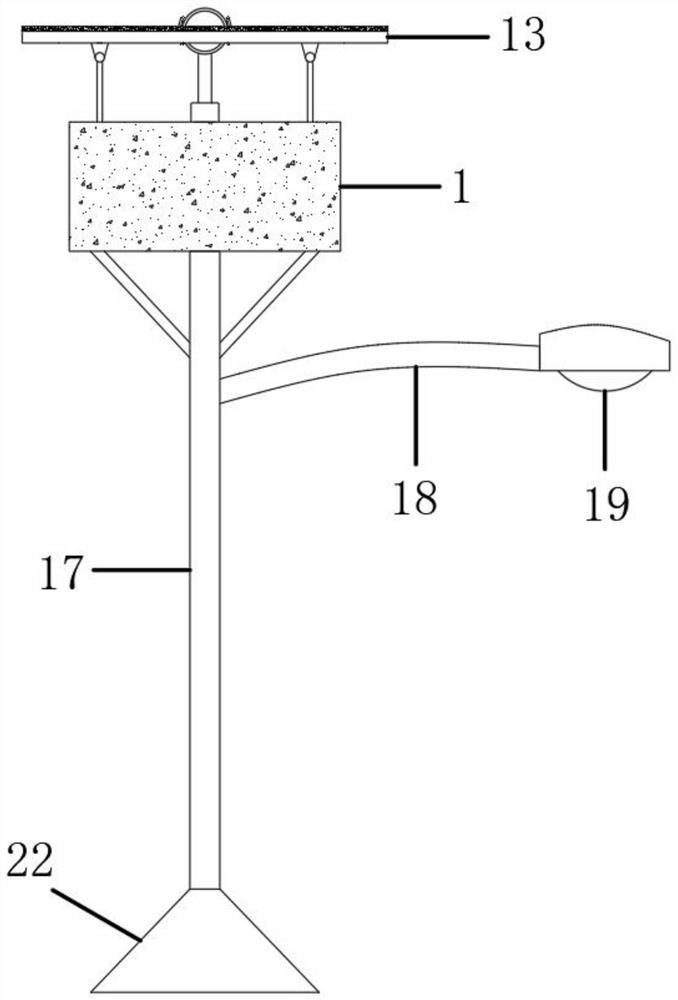

Solar street lamp capable of automatically adjusting angle of cell panel

InactiveCN111981418ASolve the adjustmentSolve the conversion ratePhotovoltaic supportsMechanical apparatusLight energyEngineering

The invention relates to the technical field of smart cities, and discloses a solar street lamp capable of automatically adjusting the angle of a cell panel. The solar street lamp comprises a mountingbox, a direct-current motor and a converter device are arranged in the mounting box, a storage battery is fixedly connected to the top of the converter device, a first bevel gear is movably connectedto the output end of the direct-current motor, and a second bevel gear and a third bevel gear are connected to the tooth edges of the left side and the right side of the first bevel gear in an engaged mode respectively. According to the solar street lamp capable of automatically adjusting the angle of the cell panel, when different photoresistors are irradiated by sunlight, two electromagnets respectively drive different contact blocks to abut against each other, and positive and negative electrodes of the storage battery are positively and negatively connected with positive and negative electrodes of the direct-current motor, so that the direct-current motor automatically changes the rotation direction. A first gear and a second gear are indirectly driven to rotate in cooperation with the direct-current motor, so that a toothed bar is driven to drive the solar cell panel to deflect, and the effects of automatically adjusting the angle of the solar cell panel and improving the light energy conversion and power storage efficiency are achieved.

Owner:张龙

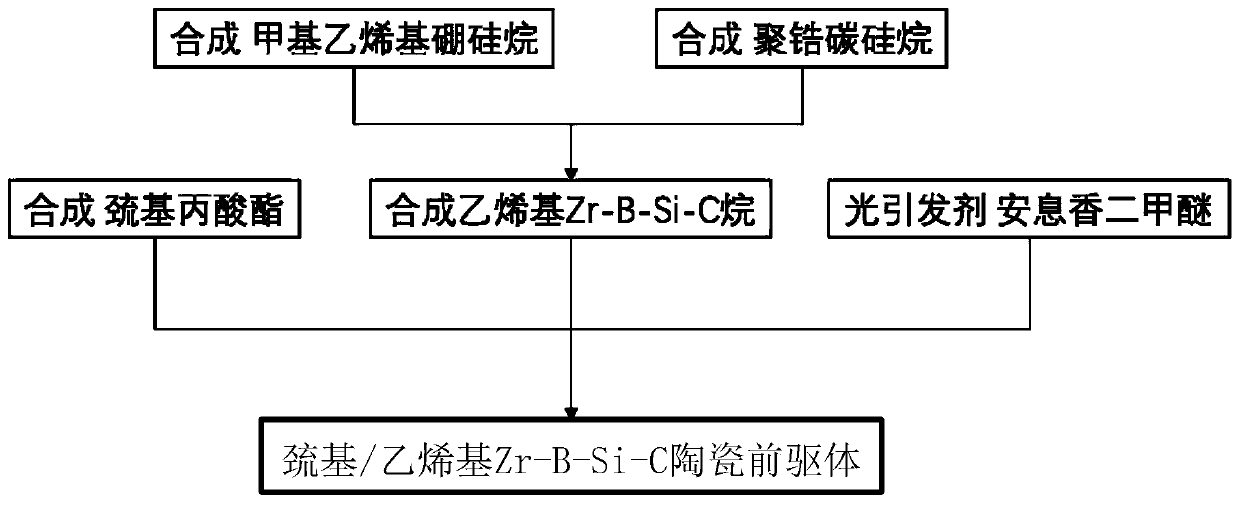

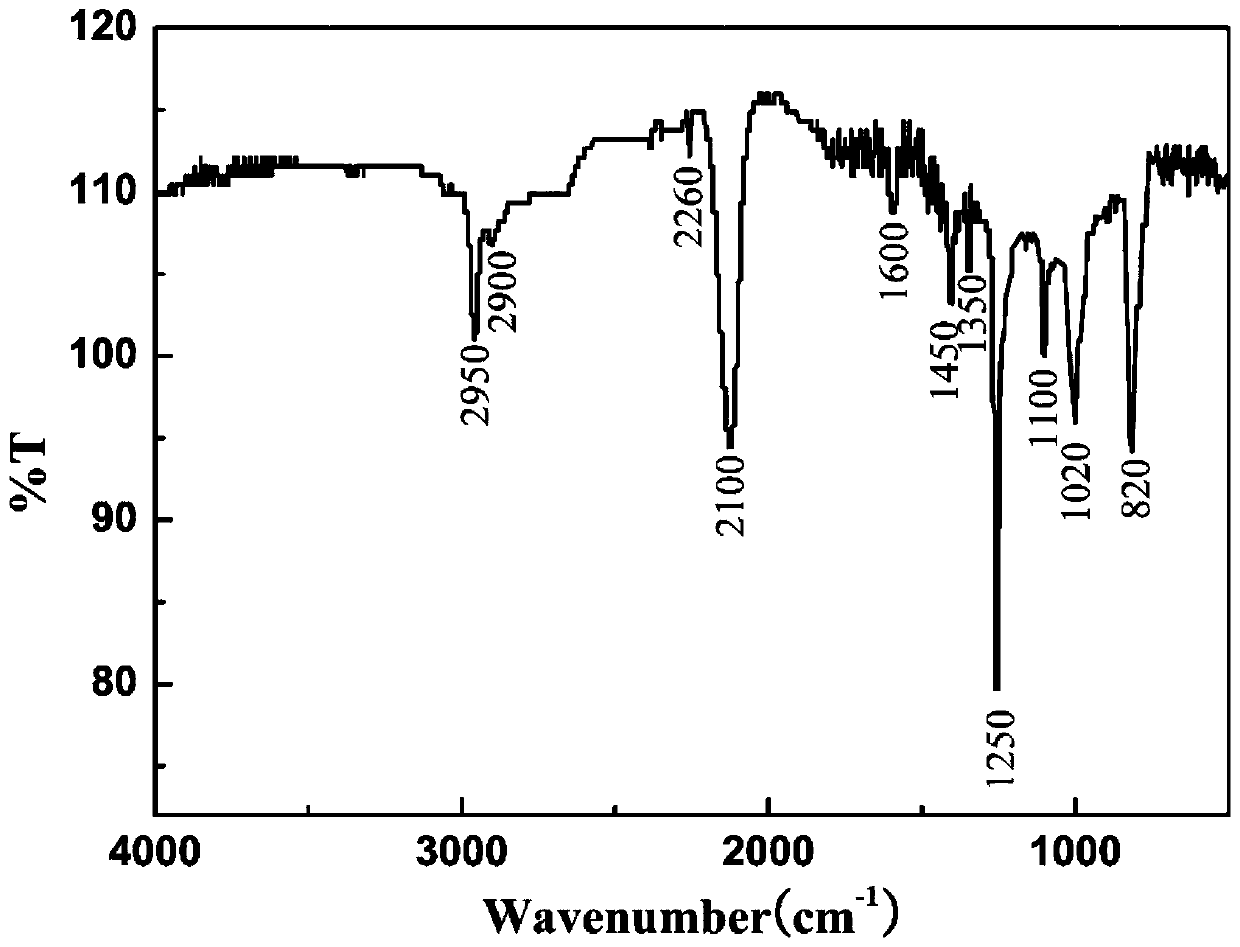

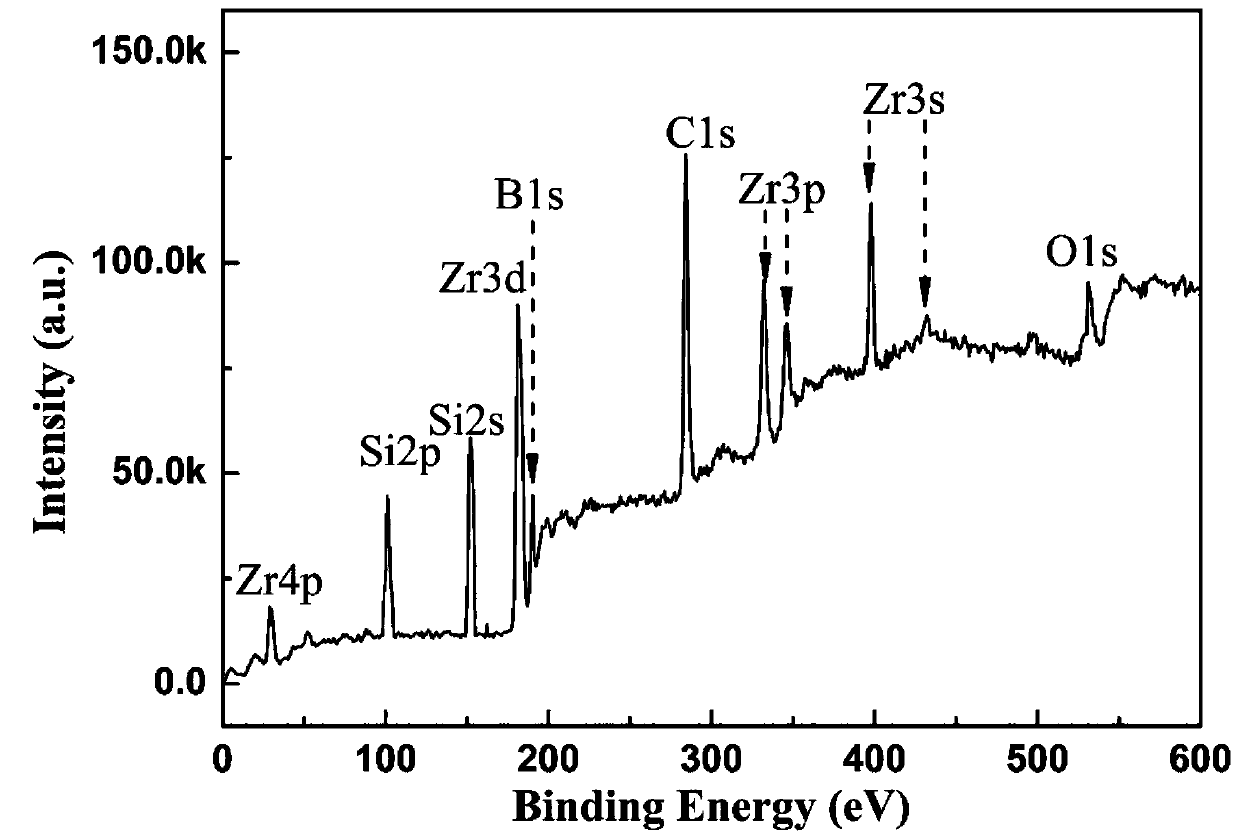

Light-sensitive Zr-B-Si-C ceramic precursor and in-situ preparation method thereof

The invention relates to a light-sensitive Zr-B-Si-C ceramic precursor and an in-situ preparation method thereof. The method comprises the following steps: uniformly mixing methylvinyldichlorosilane and a borane dimethyl sulfide complex, and then adding metal sodium for dechlorination to obtain methylvinyl borosilane; uniformly mixing chloromethyltrichlorosilane, methylchloromethyldichlorosilane and bis(cyclopentadienyl)zirconium dichloride, then adding metal magnesium to carry out a first heat preservation reaction, and then adding a reducing agent to carry out a second heat preservation reaction to obtain polyzirconocarbosilane; uniformly mixing methylvinyl borosilane and polyzirconocarbosilane to obtain vinyl Zr-B-Si-C alkane; and uniformly mixing the vinyl Zr-B-Si-C alkane with mercaptopropionate, and then adding a photoinitiator to initiate a polymerization reaction to prepare the ceramic precursor. The problems of high viscosity, high thermal stress, structural member mechanicalproperty attenuation and the like of a traditional photocuring system are solved, and a high-quality raw material is provided for photocuring 3D printing of an ultrahigh-temperature ceramic structuralmember.

Owner:XIAMEN UNIV OF TECH

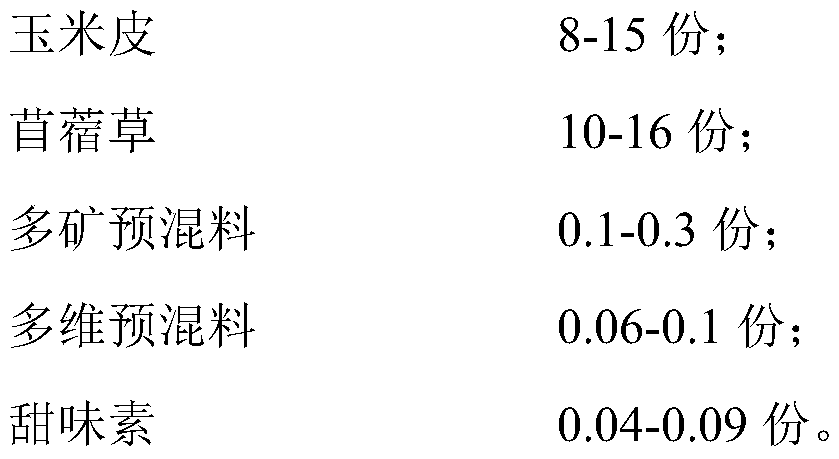

Total mixed ration feed for lambs and preparation method of feed

InactiveCN110692824AEvenly mixedSolve the conversion rateFodderAgricultural scienceFeed conversion ratio

The invention discloses total mixed ration feed for lambs and a preparation method of the feed. The feed is prepared from, by weight, 20-40 parts of corns, 6-13 parts of corn gluten feed, 5-9 parts ofpeanut shells, 2-5 parts of bean pulp, 0.4-0.9 part of salt, 1.2-1.6 parts of fine stone powder, 3-6 parts of vinasse, 17-26 parts of corn germ meal, 8-15 parts of corn husks, 10-16 parts of alfalfaherbs, 0.1-0.3 part of multi-mineral premix, 0.06-0.1 part of multi-dimensional premix and 0.04-0.09 part of sweeteners. The problems of stirring non-uniformity of premix, concentrated feed and foragegrasses for livestock farms, low feed conversion rate and the like are effectively solved, labor cost is reduced, the feed is suitable for major intensive culture bases, enzyme substance secretion volume is increased, ration utilization rate and growth speed are increased, and the shortcomings of pasturing caused by industrial adjustment and intensive culture are effectively overcome.

Owner:TIANJIN MODERN TIANJIAO AGRI TECH CO LTD

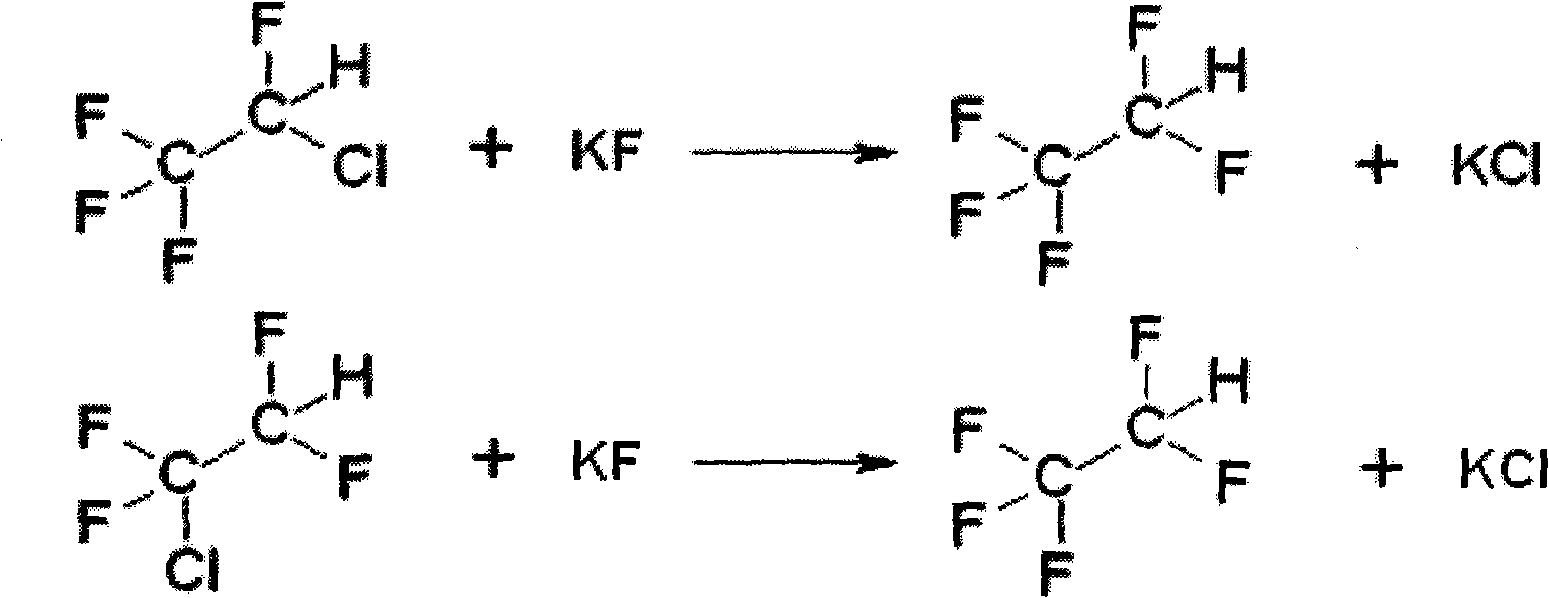

Method for preparing pentafluoroethane

ActiveCN102070395ASolve the problem of selectivitySolve the conversion ratePreparation by halogen replacementPotassium fluorideStructural isomer

The invention provides a method for preparing pentafluoroethane. The pentafluoroethane is prepared by reacting a raw material I and a raw material II, wherein the raw material I is 1, 1, 1, 2-tetrafluoro-2-chloroethane or a composition of the 1, 1, 1, 2-tetrafluoro-2-chloroethane and a structural isomer thereof, and the mass percentage of the raw material I is more than 99.8 percent; and the raw material II is 20 to 30 mass percent aqueous solution of potassium fluoride. The invention also discloses a specific preparation method. By the method, chlorinated pentafluoroethane serving as a by-product does not occur, and noxious substances are not discharged in the integral reaction process, and the used raw materials can be recycled. Simultaneously, the problem of converting the reaction rawmaterials into the pentafluoroethane with high selectivity and high conversion rate is solved, and the purity of the product is improved.

Owner:JIANGSU BLUESTAR GREEN TECH

Preparation method of potassium hexafluorophosphate

PendingCN114291805AImprove product qualitySolve the messSodium/potassium compoundsPhosphorus compoundsPotassium hexafluorophosphateMicroreactor

The invention provides a potassium hexafluorophosphate preparation method, which comprises: carrying out a first reaction on hydrofluoric acid and phosphorus pentoxide to obtain a reaction solution; and carrying out a second reaction on the reaction solution and a potassium salt solution to obtain potassium hexafluorophosphate. Compared with the prior art, the preparation method of the potassium hexafluorophosphate provided by the invention has the advantages that water generated by reaction is used as a solvent, the potassium hexafluorophosphate is prepared by liquid-liquid reaction, and the problems of product impurity wrapping and low reaction conversion rate in the traditional process are solved; meanwhile, the microreactor device is adopted, so that the automation degree is high, the reaction is more sufficient, the time is shorter, the control is more accurate, and continuous production can be realized. The preparation method of potassium hexafluorophosphate provided by the invention has the advantages of simple process, controllable reaction, good product quality, no emission of three wastes and the like, and is easy to industrially implement and popularize.

Owner:DO FLUORIDE CHEM CO LTD

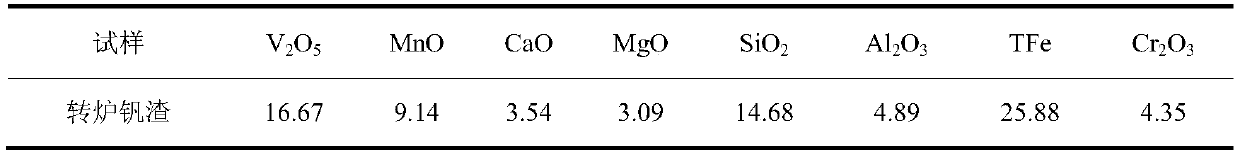

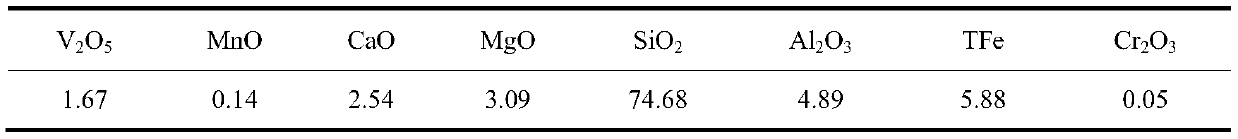

Method for roasting vanadium-containing material by using chain grate machine and rotary kiln

InactiveCN110878388ASolve cohesionSolve the conversion rateProcess efficiency improvementPregnant leach solutionProcess engineering

The invention relates to the field of chemical methods for extracting vanadium, and in particular relates to a method capable of greatly improving the conversion rate and leaching rate of vanadium forroasting a vanadium-containing material by using a chain grate machine and a rotary kiln. The method comprises the following steps: a, crushing the vanadium-containing material to a required particlesize, mixing the crushed particles and additives, and performing mechanical activation to obtain a mixture; b, uniformly arranging the formed material in the chain grate machine by using a roll screening machine, and performing drying, curing and strengthening in the chain grate machine; and c, allowing the formed material to enter the rotary kiln for concentrated high-temperature roasting, performing discharge to obtain a vanadium-containing formed clinker, crushing the vanadium-containing formed clinker to a required particle size, and performing water leaching or acid leaching to obtain avanadium-containing leaching solution, wherein the vanadium-containing leaching solution is used for subsequent vanadium precipitation. The method uses the chain grate machine and the rotary kiln to roast the vanadium-containing material, has the technical advantages of a simple and easy process, low requirements for equipment, convenient operation, a wide application range and low costs, and is particularly suitable for the vanadium-containing material roasting process.

Owner:四川大裂谷钒业有限公司

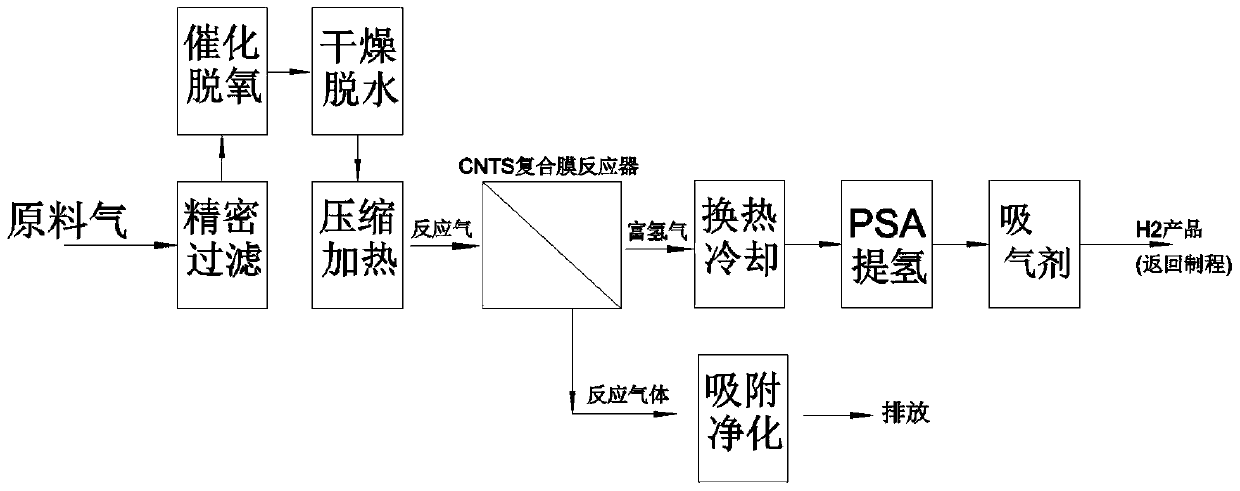

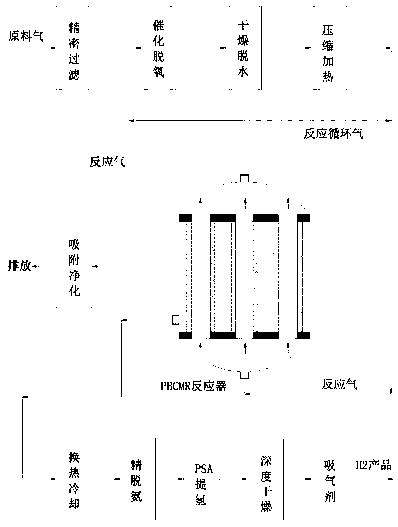

Non-catalytic permeable membrane reactor for producing hydrogen from ammonia-containing tail gas in MOCVD process and application

PendingCN111115572ARemoved in timeSolve the conversion rateHydrogen separation by selective and reversible uptakeHydrogen separation using solid contactPtru catalystCarbon nanotube

The invention discloses a non-catalytic permeable membrane reactor for producing hydrogen from ammonia-containing tail gas in an MOCVD process and application. The catalyst is catalyst granules whichcomprise10-30% (w / w) of an active component cobalt, 5-20% (w / w) of an active component molybdenum, 1-10% (w / w) of a co-catalytic component lanthanum, 1-5% (w / w) of an accelerant potassium, and 35-83%(w / w) of pretreated carbon nanotubes (CNTs), wherein the catalyst granules are loaded in a ceramic membrane tube employing aluminum oxide as a supporting body and being coated with a metal palladium membrane layer, thereby forming a packed bed catalytic membrane reactor (PBCMR) packed in a catalyst fixed bed layer in the membrane tube; ammonia-containing tail gas in the MOCVD process is pretreatedand then enters a membrane reactor; at the reaction temperature of 400 to 600 DEG C, ammonia thermal cracking catalytic reaction is carried out under the reaction pressure of 1.0-3.0 MPa, wherein thereaction gas is subjected to adsorption refining deamination, pressure swing adsorption purification and metal getter purification to obtain a hydrogen product with the purity larger than 6-7 N; thehydrogen product then is returned to the MOCVD process to be recycled. By means of the technology, the blank of LED industry green and circular economy development is filled.

Owner:ZHEJIANG TIANCAIYUNJI TECH CO LTD

Continuous preparation method of pyridine N-oxides

ActiveCN106928135AHigh reuse rateImprove catalytic performanceOrganic chemistryMolecular sieveSlurry reactor

The invention discloses a continuous preparation method of pyridine N-oxides. The method comprises the steps that a catalyst TS-1 molecular sieve and distilled water are added into a slurry reactor, the temperature is increased to 70-90 DEG C, the pressure is adjusted to be 0-1.5 MPa, then, a pyridine compound and hydrogen peroxide are added, and the air speed of the pyridine compound is adjusted to be 1-10 h<-1>, and the air speed of the hydrogen peroxide is adjusted to be 2-20 h<-1>; the molar ratio of the pyridine compound to the hydrogen peroxide is 1:1-1.1; the pyridine compound and the hydrogen peroxide are subjected to an oxidation reaction to generate a crude N-pyridine oxide, distillation separation and drying are performed to obtain the pyridine N-oxides, and the deactivated catalyst TS-1 molecular sieve is activated and continues to be adopted as a catalyst for use. According to the method, the titanium silicalite molecular sieve is adopted as the catalyst, the catalyst is high in repeated utilization ratio, the catalysis effect is good, the service life is long, the pyridine conversion rate and the pyridine N-oxide selectivity is high, and the effective utilization rate of the hydrogen peroxide is high; the slurry reactor is adopted as the reactor, operation is easy, postprocessing is simple, continuous production can be achieved, and the method is suitable for large-scale industrial production.

Owner:CHINA CATALYST HLDG CO LTD

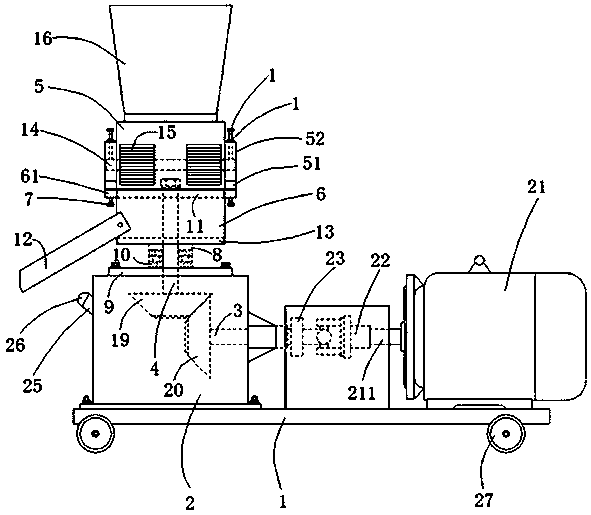

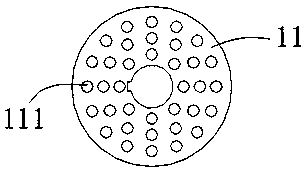

Feed granulator

InactiveCN110279131ASolve resource problemsSolve space problemsFeeding-stuffFodderMechanical engineering

The invention provides a feed granulator which comprises a support base, wherein a granulation device and a power device are arranged on the support base; the power device is connected with the granulation device through a gearbox; the gearbox comprises an input shaft and an output shaft which are in transmission connection with the power device; the granulation device comprises a granulation tank which is fixed above the gearbox; the granulation tank comprises an upper granulation tank and a lower granulation tank; the output shaft extends in an axial direction into the lower granulation tank; a mold disc is fixedly connected with the upper end of the output shaft; a mold hole is formed in the mold disc; a discharge hole is formed in the lower granulation tank; a throwing disc which is fixedly connected with the bottom, in the lower granulation tank, of the output shaft; a pressing roller shaft which extends in an axial direction in a left and right direction is arranged in the upper granulation tank; pressing rollers are rotationally connected with both ends of the pressing roller shaft; a feeding hopper and a height adjusting mechanism for adjusting heights of the pressing rollers are arranged on the upper granulation tank. Powdery fine materials can be processed into a granular feed, so that the defects that a powdery feed is liable to cause environment pollution, causes resource loss, is large in floor space, inconvenient to store or transport, low in conversion rate, and the like, can be overcome.

Owner:郑州金燕机械设备有限公司

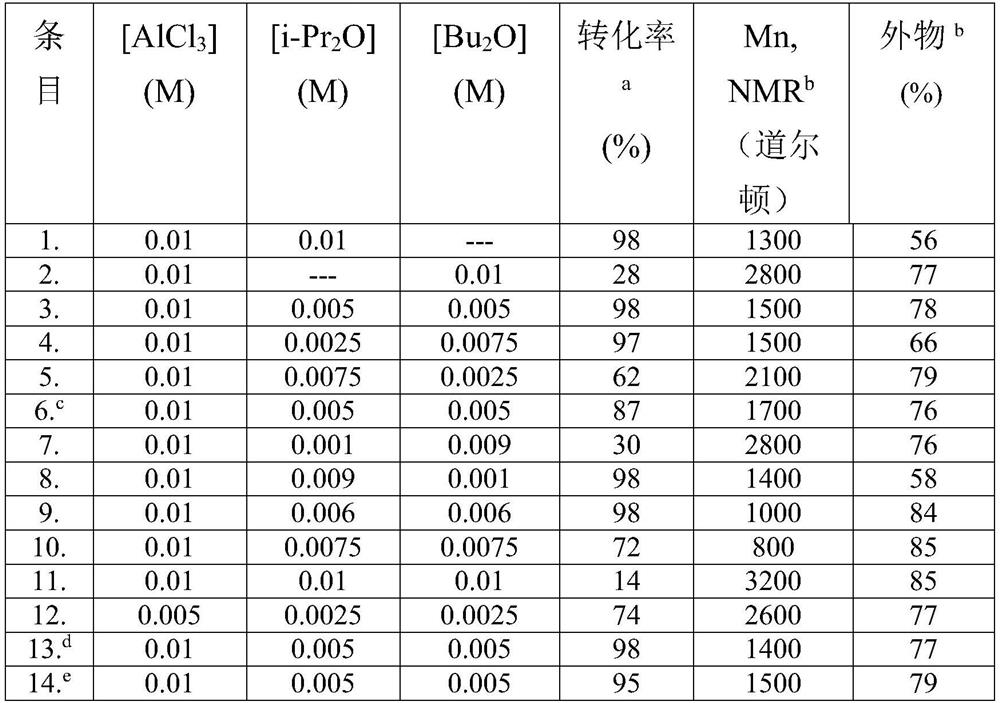

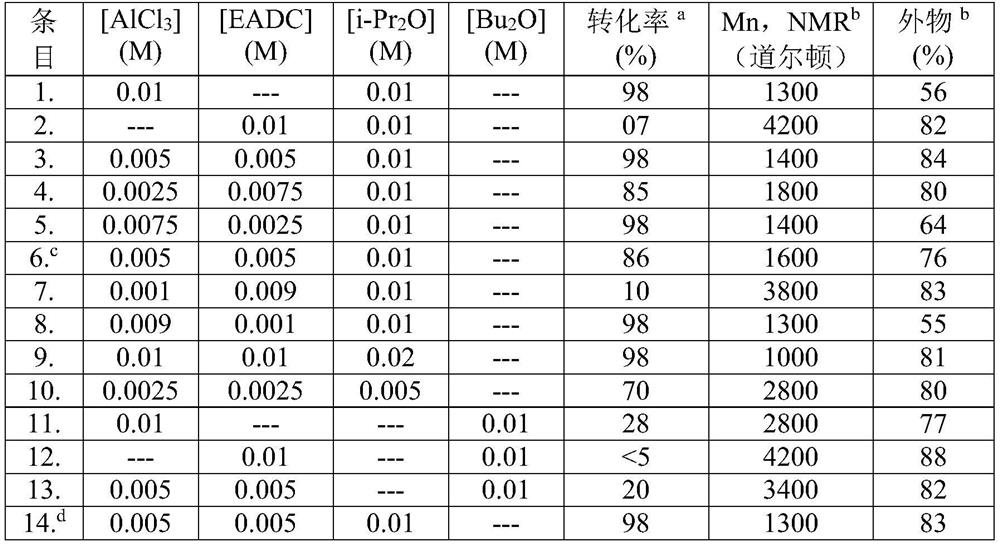

Polymerization catalyst system and method for preparing highly reactive polyisobutylene

Owner:INDIAN OIL CORPORATION

Equipment and technique for producing sulfur dioxide by using gypsum

ActiveCN103043621ASimple structureReduce manufacturing costSulfur compoundsEnergy inputEngineeringCopper

The invention discloses equipment and a technique for producing sulfur dioxide by using gypsum. The equipment comprises a preheating extruder, a blanking machine, a calcining extruder and a deoxidizing tank for accommodating fine copper powder, wherein a feeding port of a preheating cylinder of the preheating extruder is connected with an outlet of the blanking machine, and a discharging port is connected with a feeding port of a calcining cylinder of the calcining extruder through a precursor discharging device; a vacuum exhausting device is arranged at the back end of the preheating cylinder of the preheating extruder; an air extractor is arranged at the back end of the calcining cylinder of the calcining extruder, and is connected with the deoxidizing tank which accommodates fine copper powder through an air booster pump; and a discharging port of the calcining cylinder of the calcining extruder is provided with an unloading device. The invention further comprises the technique for producing the sulfur dioxide by using the gypsum. The equipment and the technique have the advantages of simple structure, low production cost and easiness in operation; and the purity of the produced sulfur dioxide is greater than and equal to 99%.

Owner:湖南湘湖新型建材有限公司

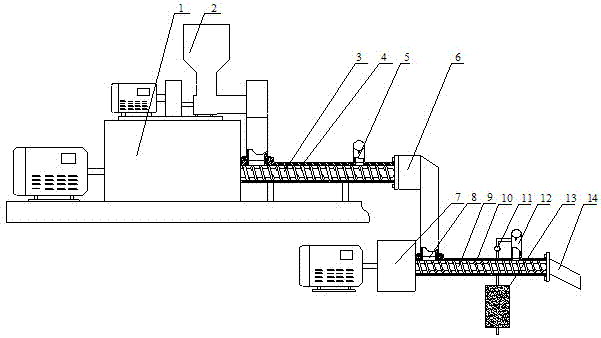

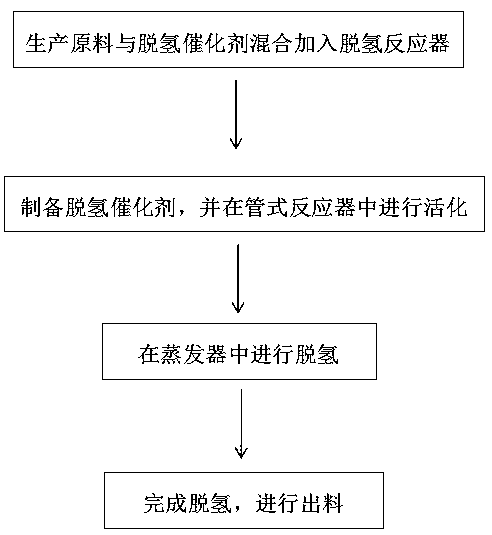

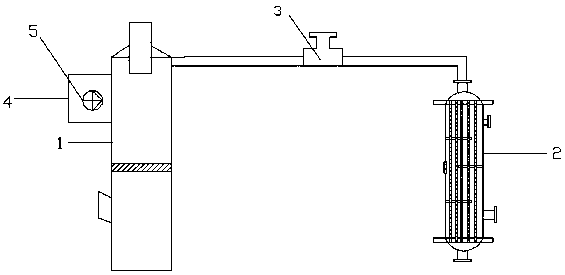

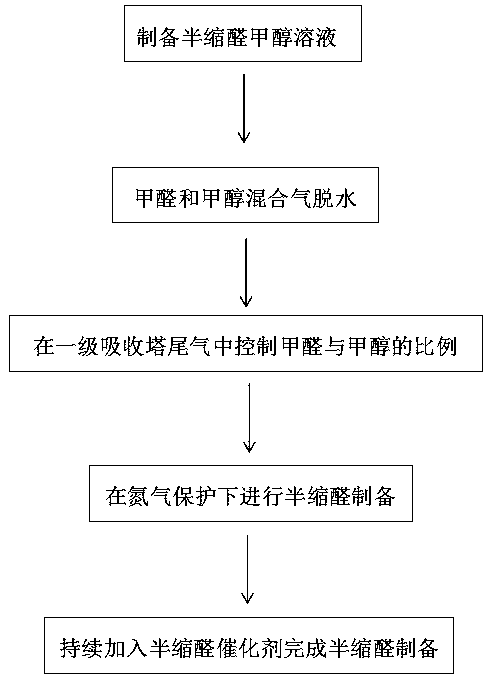

Method for preparing aldehyde or hemiacetal by alcohol dehydrogenation

InactiveCN107935832AImprove efficiencySolve the conversion rateOrganic compound preparationPreparation by dehydrogenationHemiacetalAlcohol

The invention discloses a method for preparing preparing aldehyde or hemiacetal by alcohol dehydrogenation, which improves the dehydrogenation production efficiency of the traditional process on the whole, solves the catalyst problem and process condition and operational problem, and improves the defects that low percent conversion and low selectivity commonly exist. Furthermore, the preparation method of the hemiacetal provided by the invention improves the effective utilization rate of raw materials, the process production cost is also controlled, and the pollution is reduced.

Owner:郑州智谷工业技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com