Patents

Literature

65results about How to "Removed in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

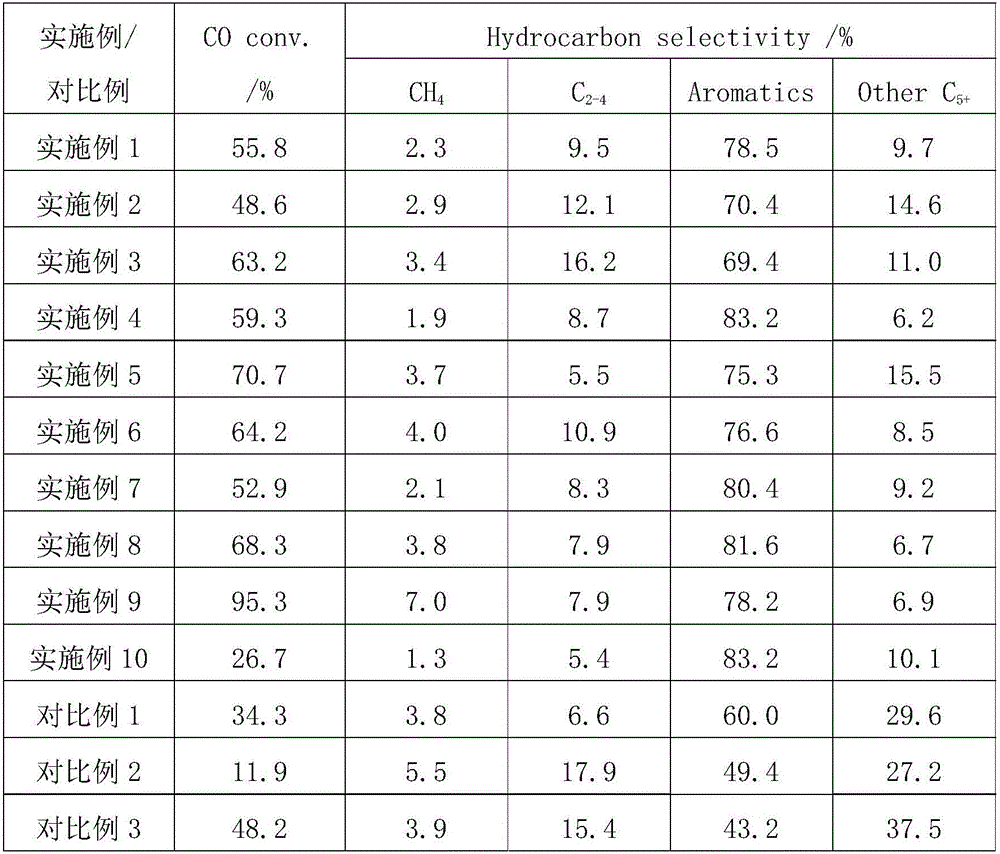

Catalyst for preparing arene from synthesis gas through one-step conversion and preparation method of catalyst

ActiveCN106215972AImprove catalytic performanceHigh selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsRare-earth elementMolecular sieve

The invention relates to catalysts, in particular to a catalyst for preparing arene from synthesis gas through one-step conversion and a preparation method of the catalyst. The catalyst is prepared from, by mass, 30%-70% of zirconium-containing perovskite, 30%-60% of multistage porous zeolite molecular sieve and 0.1%-10% of oxide additive. The preparation method comprises the steps that 1, a salt compound of at least one of IA, IIA, VB, VIB, VIIB, IIB and IVA family elements and rare earth elements is weighed according to the components of the catalyst and added into water or alcohol to be prepared into a solution A; the multistage porous zeolite molecular sieve is weighed and added into the solution A, suction filtration, washing and filter cake drying are carried out to obtain solid powder, then the solid power and the zirconium-containing perovskite are mixed, ground and calcined, hydrogen or mixed gas of hydrogen and inert gases is introduced, heating is carried out for reduction, the reduced solid sample is tablet molded, and the catalyst is prepared.

Owner:XIAMEN UNIV

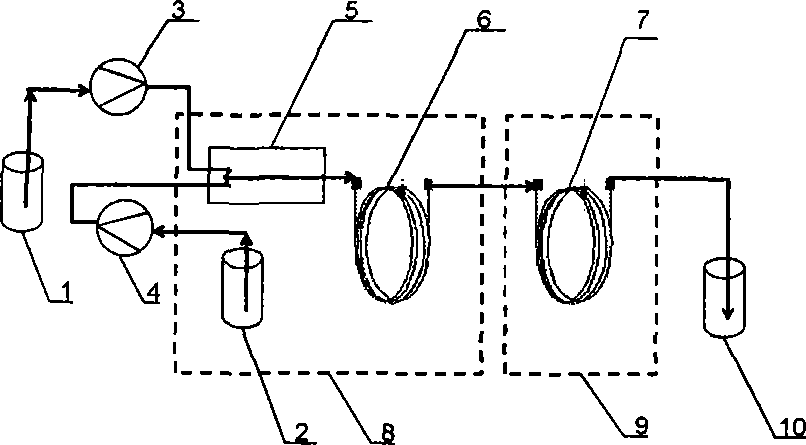

Method of preparing alpha-sulphonic acid fatty acid ester

InactiveCN101508660AImprove securityRelaxed reaction conditionsSulfonic acid preparationState of artReaction temperature

The invention relates to a method for preparing alpha-sulfonic fatty acid ester by sulfonating fatty acid ester, comprising the following steps: injecting the fatty acid ester and a sulfonating agent into a micro-structural reactor (5) and a reactor (6) inside diameter of which is a micro passage respectively, mixing and sulfonating the fatty acid ester and the sulfonating agent, controlling the reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 1ms to 1s in the micro-structural reactor (5) and stay for 0.5 to 30 minutes in the micro-passage reactor (6); and then injecting the reaction materials into a micro-passage reactor (7), aging the reaction materials at a reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 0.5 to 30 minutes in the micro-passage reactor to obtain the alpha-sulfonic fatty acid ester. In the method, the novel micro-structural reactor is adopted, the defect of difficult control due to strong reaction heat release in the prior art is overcome, the materials can be mixed evenly, the released reaction heat can be removed in time, the reaction time can be controlled accurately, and the method has the advantages of good sulfonating efficiency, simple and safe operation and good product quality.

Owner:NANJING UNIV OF TECH

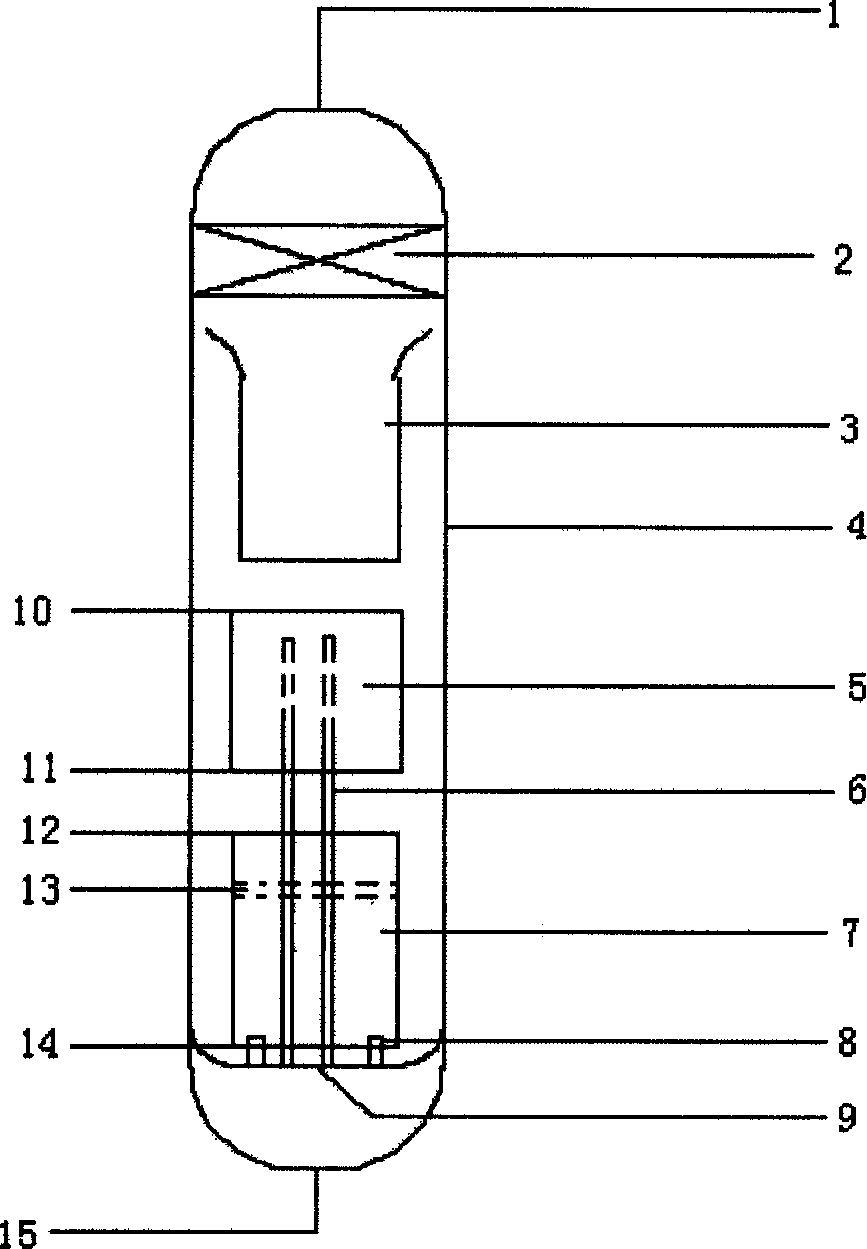

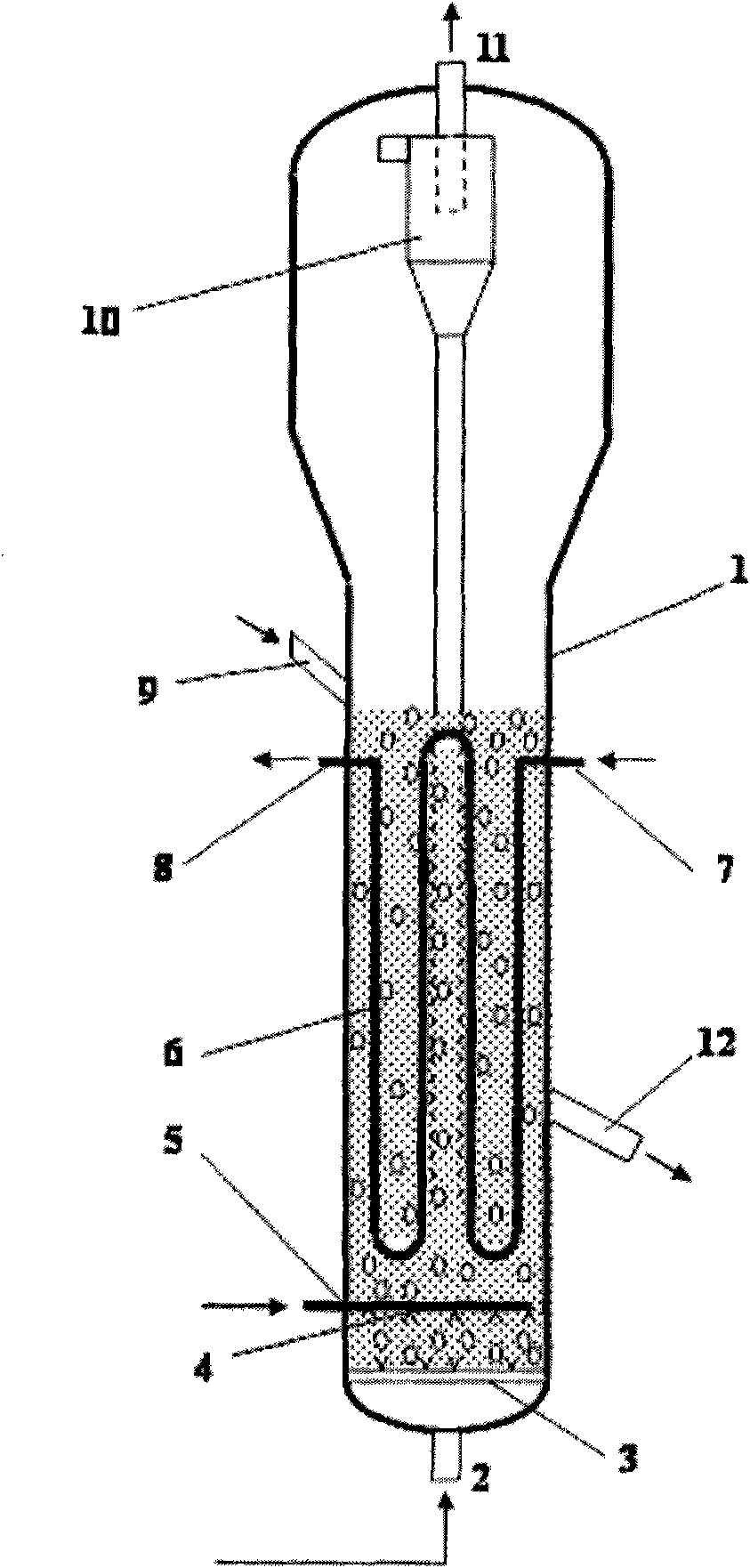

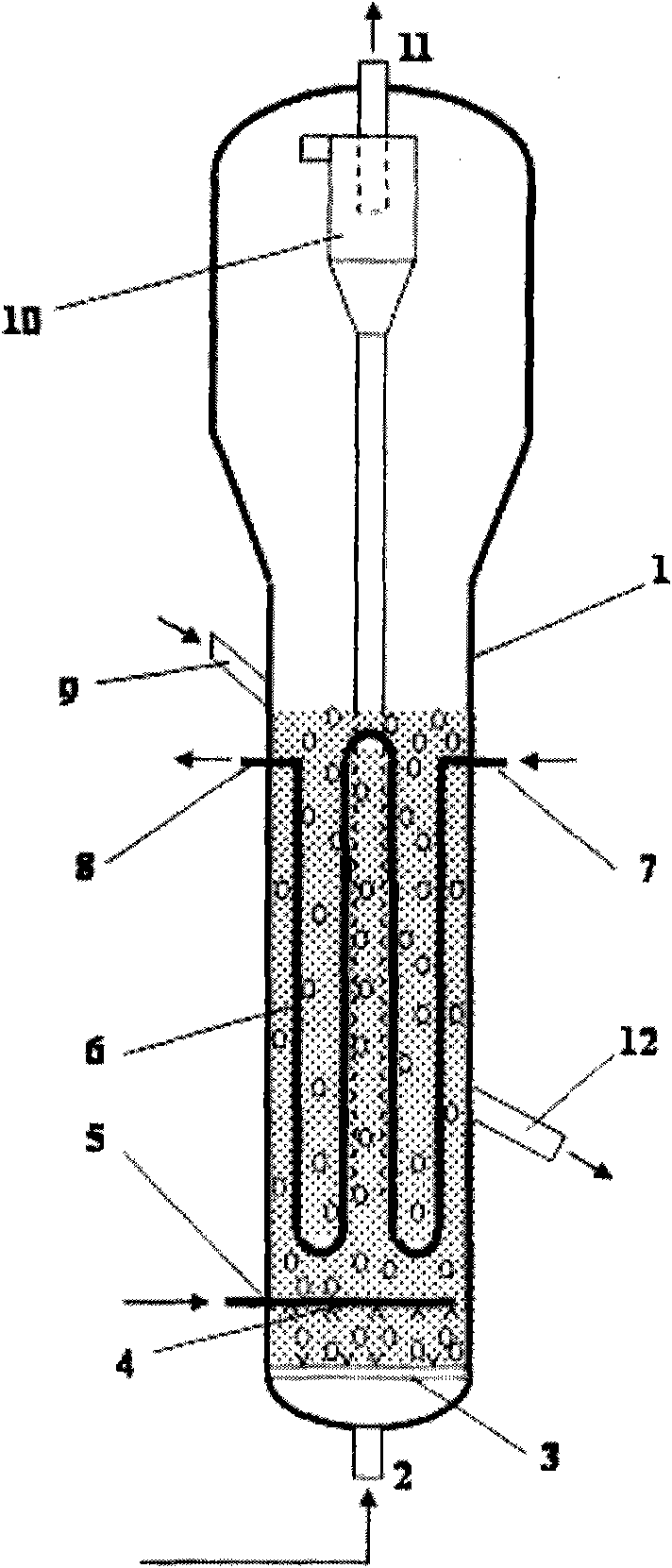

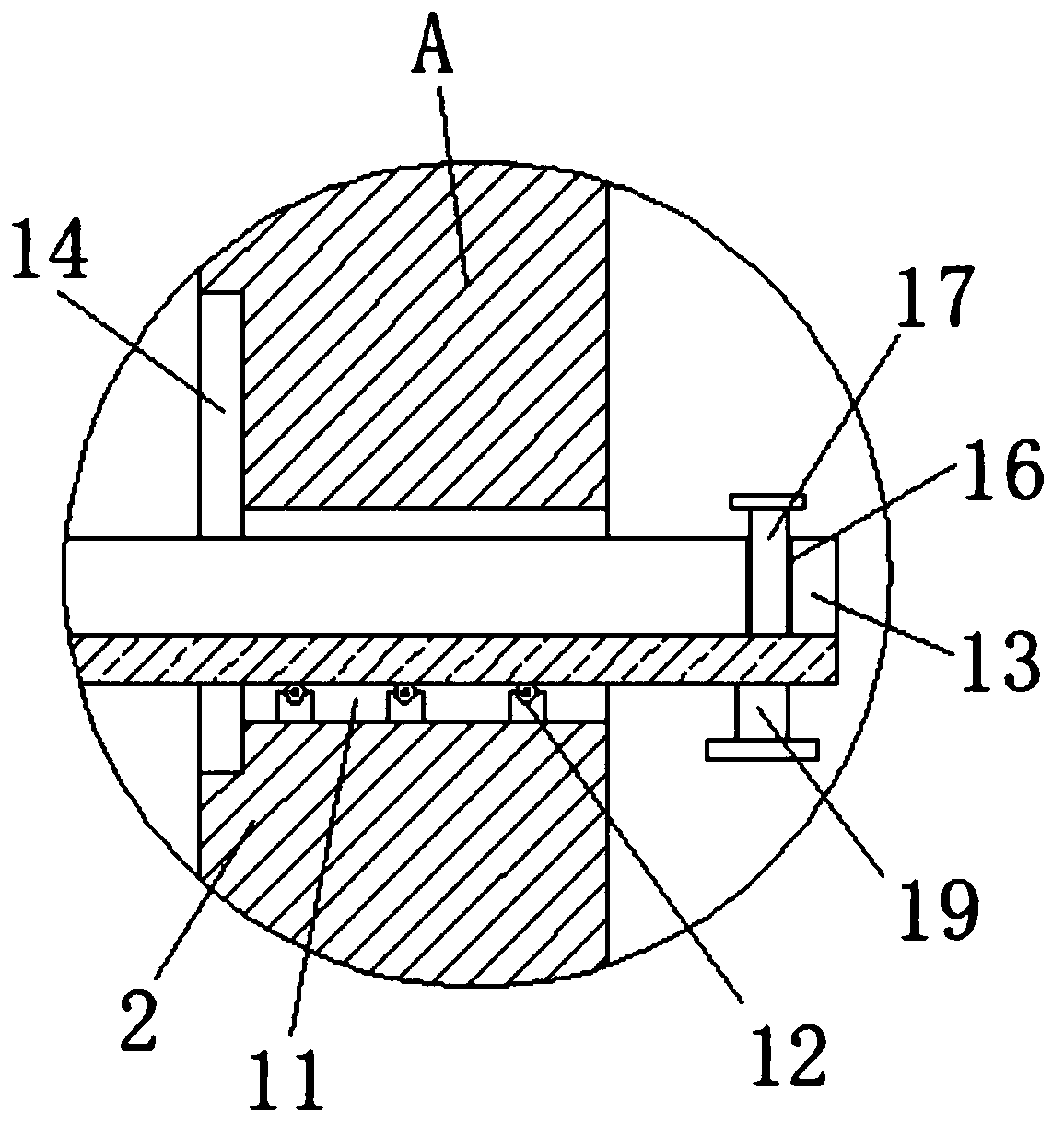

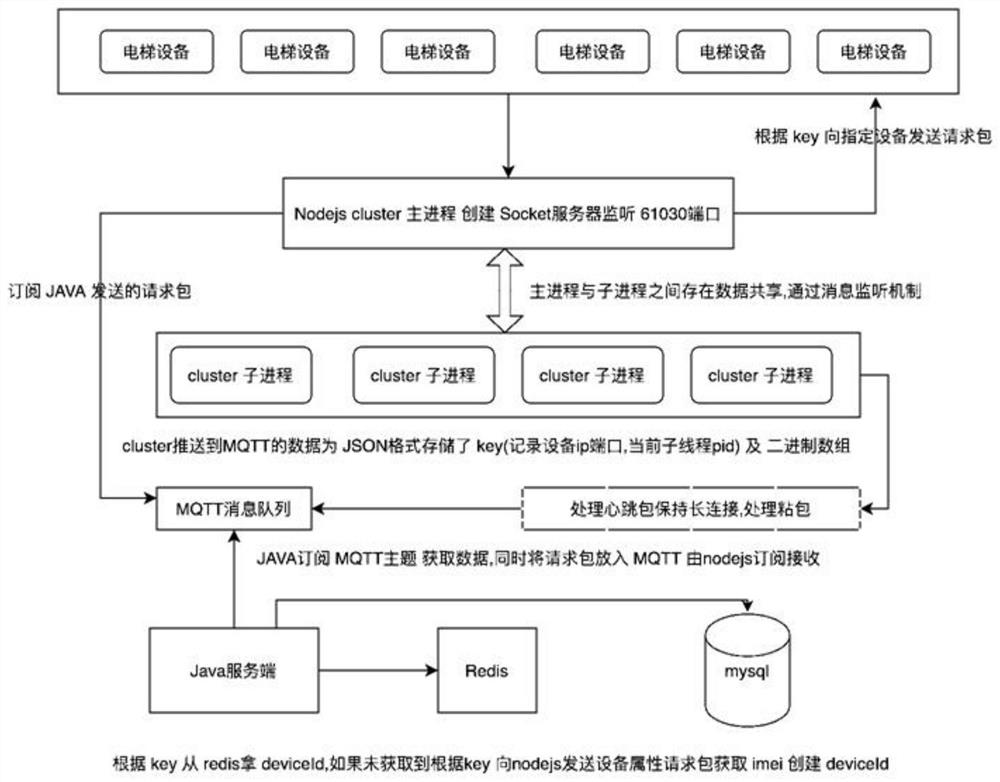

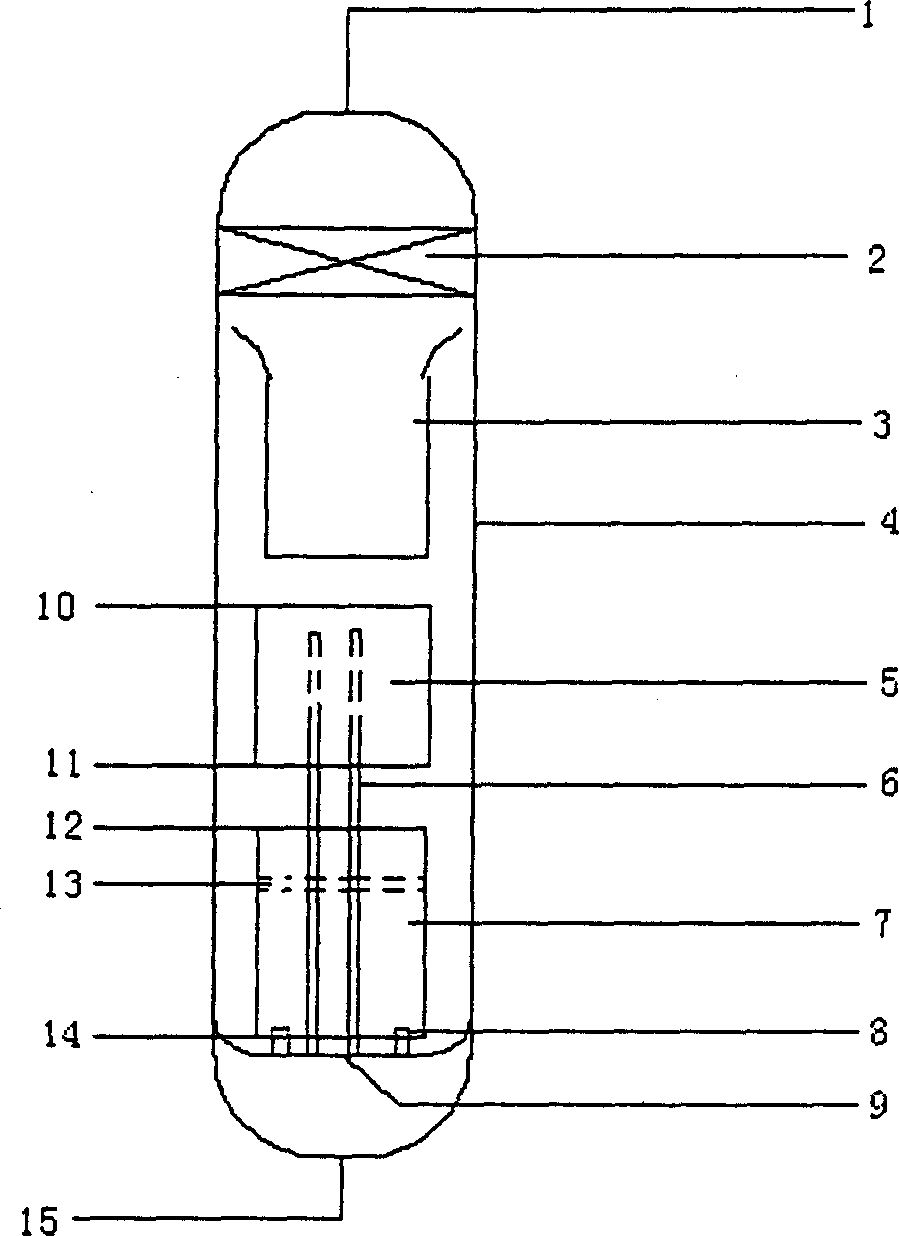

Highly effective slurry phase bed reactor

InactiveCN1593740AEasy to operateAvoid easy cloggingChemical/physical processesNuclear engineeringSpray nozzle

The invention relates to a kind of efficient reactor with paddle bed, which belongs to the chemical machinery field. It is composed mainly with the solid and liquid separator, the inner tube that the track is changeable, the reactor cover, the heat exchanger with an internal component, the riser with the spray nozzle, the inner-tube tank that has the heating and gas distribution function, the spray nozzle for protecting from choking, the mounting plate of the spray nozzle, the heat exchanger, the outlet of the heating coil, the quadratic distribution plate, the heating coil and so on. The beneficial effictiveness of the invention can be described as follows: the reactor and the distributor can't block up easily; the gas and the liquid can be mixed evenly; the reactive efficiency is high; the carrying amount of the catalyst and the solvent is so bit that it can not occur the bias current, channeling and dead bed; the size running quickly, and the viscosity of the size in the reactor is identical generally; the reactor can be shifted out in time, and especially in the stage of the catalytic, reducing and intensifying, it can realize to operate the reactor steadily; otherwise, the distribution of the virgin gas in the reactor along the axle is in agreement on the concentration of the catalyst, so that can make the catalyst have the most activity, and then it can be make the full use of the reactor space.

Owner:TAIYUAN UNIV OF TECH

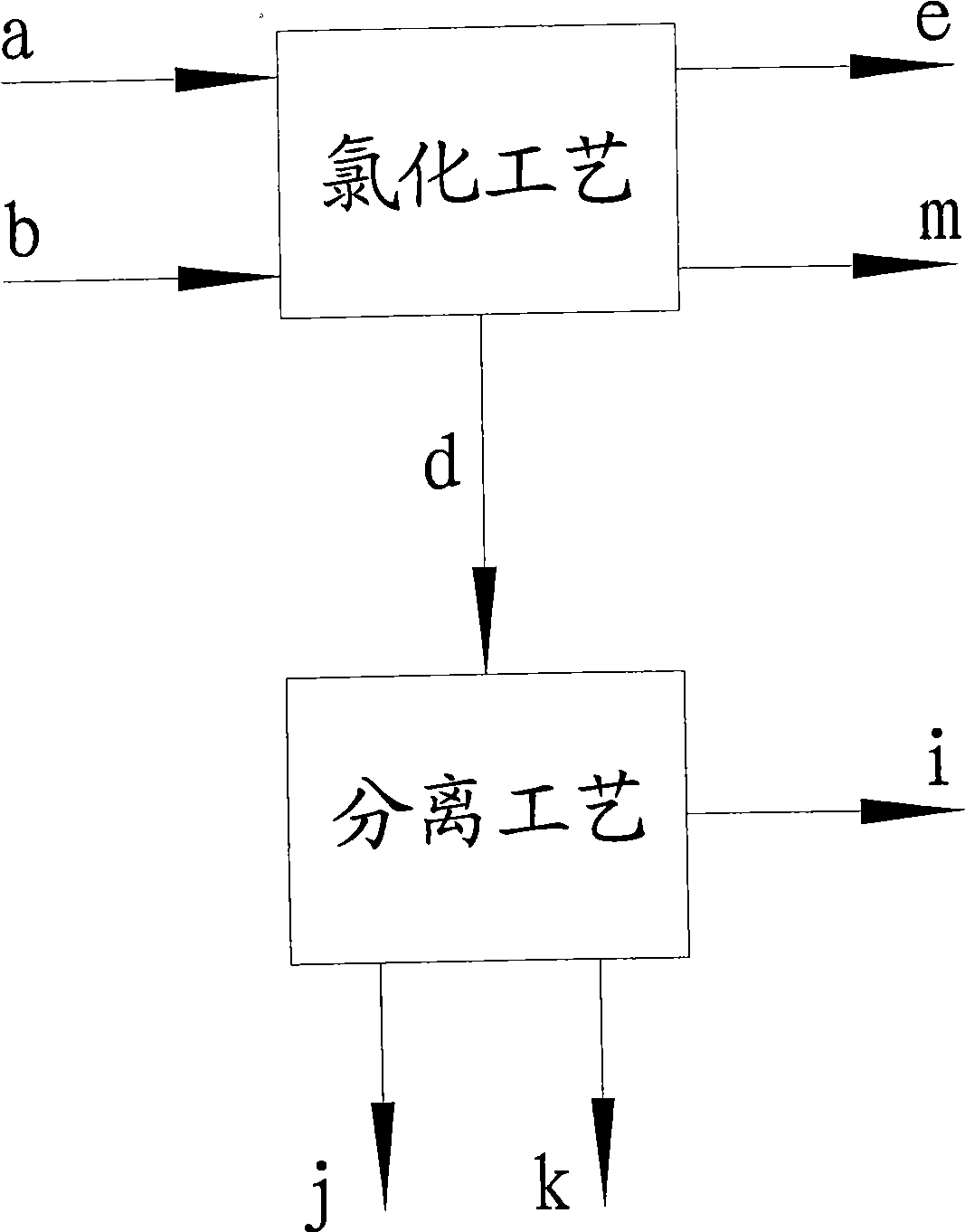

Method for preparing p-chlorotoluene and o-chlorotoluene by chlorination toluene

InactiveCN101497552AFull gas-liquid contactReaction heat can be removed in timeHalogenated hydrocarbon preparationSide productChemistry

Owner:江苏钟腾化工有限公司

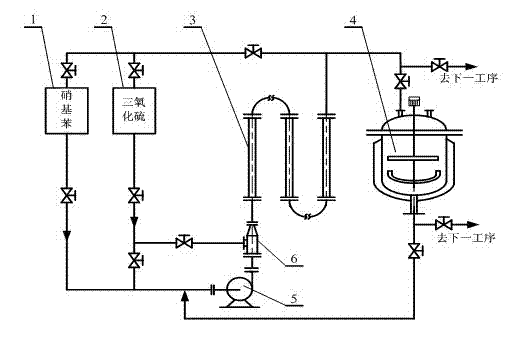

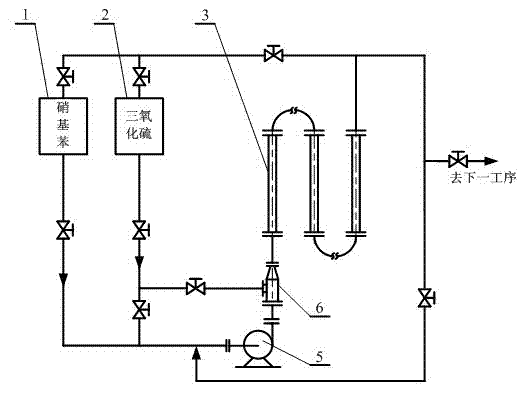

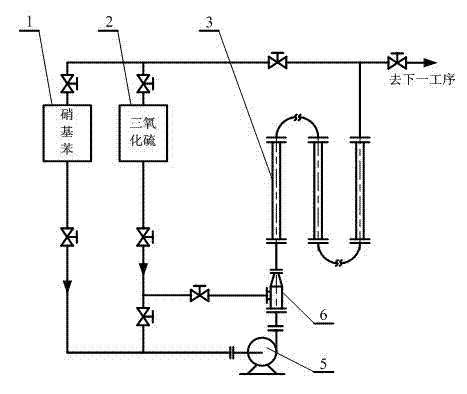

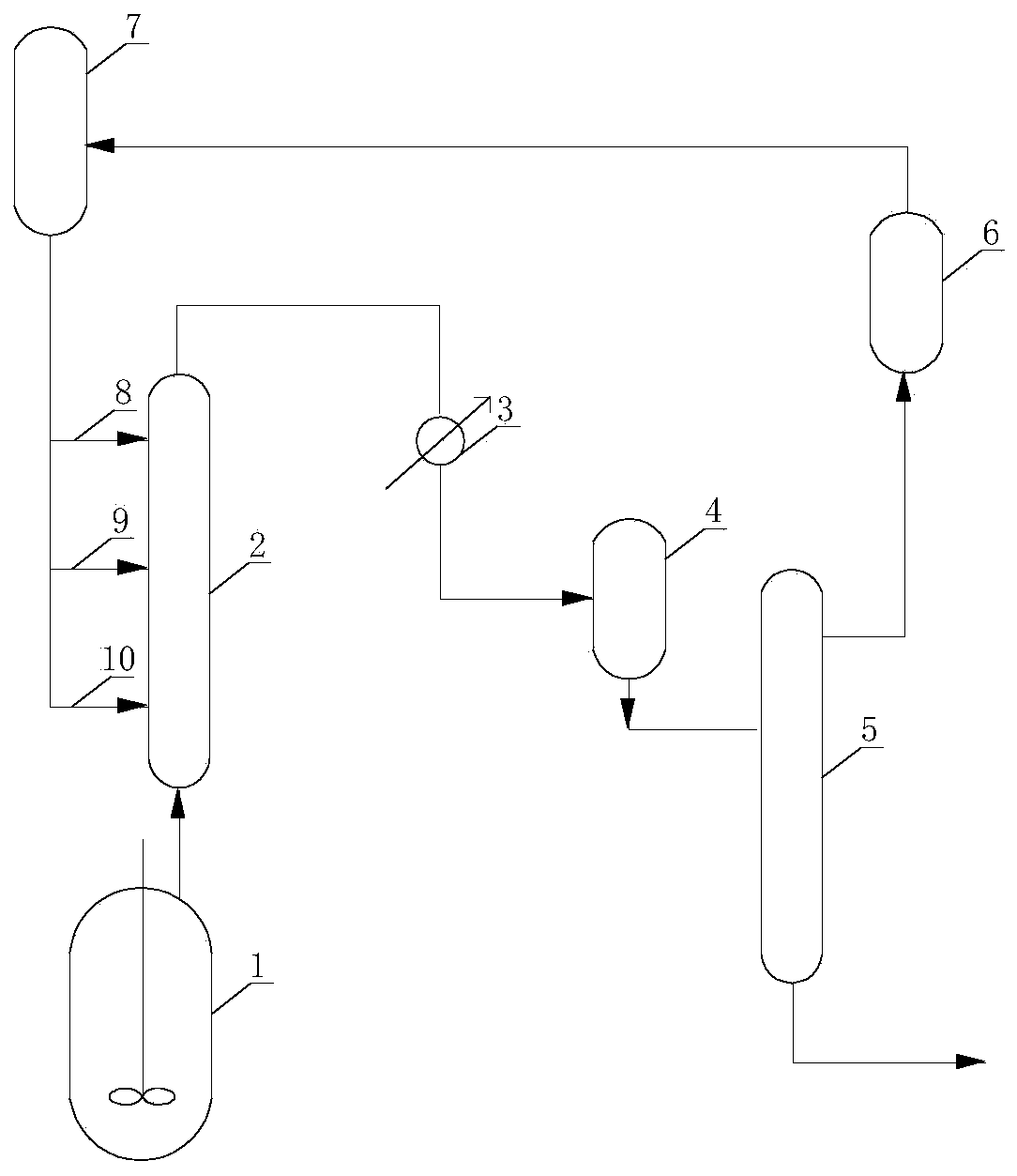

Production method for preparing m-nitrobenzenesulfonic acid by tubular sulfonation reactor

ActiveCN102188942AImprove heat transfer efficiencyRemoved in timeSulfonic acid preparationLiquid-liquid reaction processesNitrobenzeneSulfur trioxide

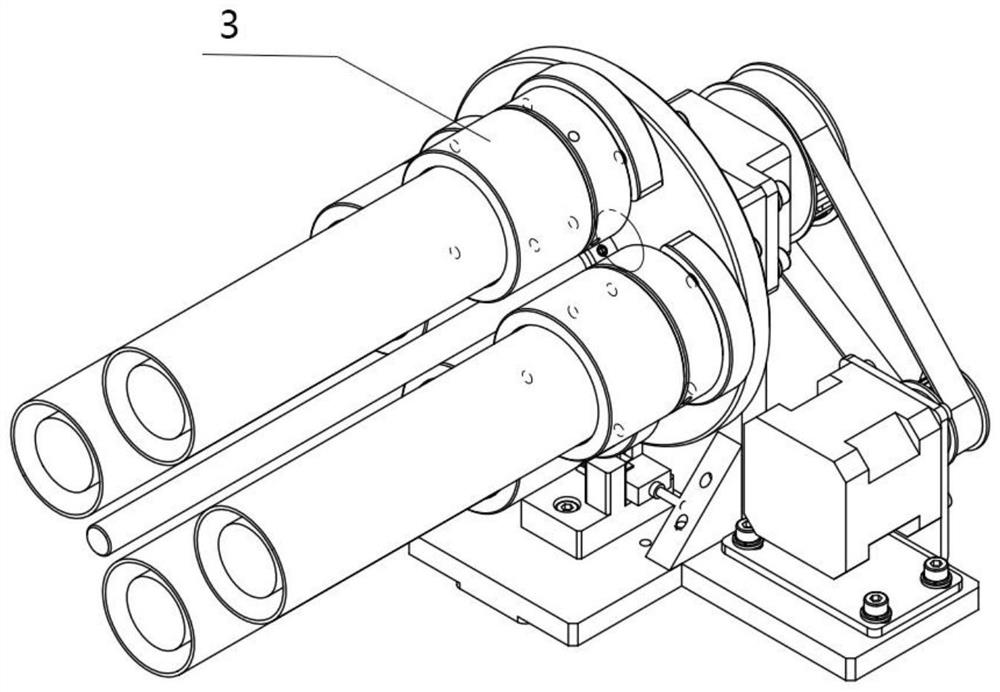

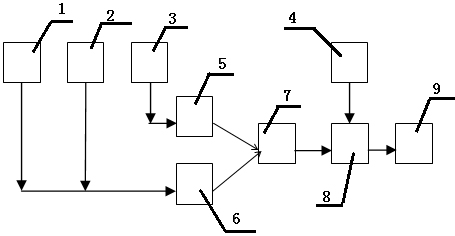

The invention discloses a production method for preparing an m-nitrobenzenesulfonic acid by a tubular sulfonation reactor and relates to the production method of a chemical product. A production device comprises a nitrobenzene storage tank (1), a sulphur trioxide storage tank (2), the tubular sulfonation reactor (3), a kettle sulfonation reactor (4), a material delivery pump (5), a spraying pump (6), a connecting pipeline and accessories (a valve, a flow meter, a thermometer, an anti-explosion film, sight glass and the like). Nitrobenzene and a sulphur trioxide sulfonating agent enter the tubular sulfonation reactor (3) in proportion, the tubular sulfonation reactor (3) and the kettle sulfonation reactor (4) are used in series, or the tubular sulfonation reactor (3) is used independently.The invention is applied to continuous or discontinuous sulfonation reaction, good in mixing and heat transfer effects, high in reaction speed, high in production efficiency and high in operational flexibility. The production device and the production method which are provided by the invention are applied to various sulfonation reaction production processes.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

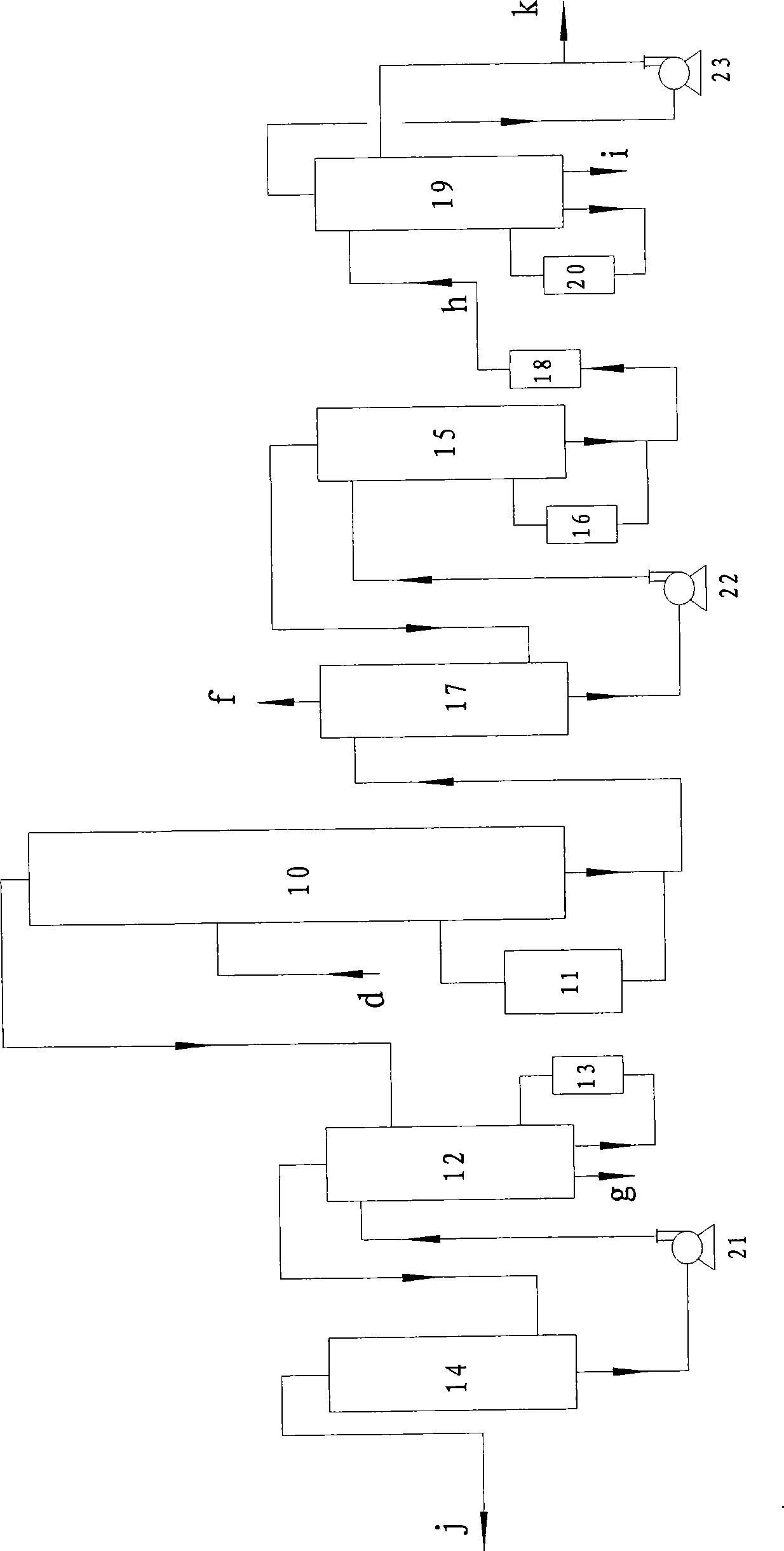

Method and device for recycling silicon tetrachloride

InactiveCN101940898ASimple processShort processChemical/physical processesHalogenated silanesChemistryHydrogen chloride

The invention relates to a method and a device for recycling silicon tetrachloride, which are characterized in that preheated silicon tetrachloride and water vapor are continuously and steadily loaded into a reactor to react according to a molar ratio of 2.0-5.0:1.0 so as to generate hydrogen chloride gas and silicon dioxide powder. The hydrogen chloride gas is recycled after being dried, and the silicon dioxide powder can be used as a product for sale after being treated in a subsequent handling. The device for recycling the silicon tetrachloride is a gas-solid fluidized bed reactor and comprises a fluidized bed cylinder, a water vapor gas inlet, a water vapor gas distributor, a silicon tetrachloride gas distributor, a tubular type heat exchange tube, a cyclone separator, a silicon dioxide powder discharge port and the like. The method and the device have the advantages of short process flow, low energy consumption, less equipment investment, easily controlled operation and the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

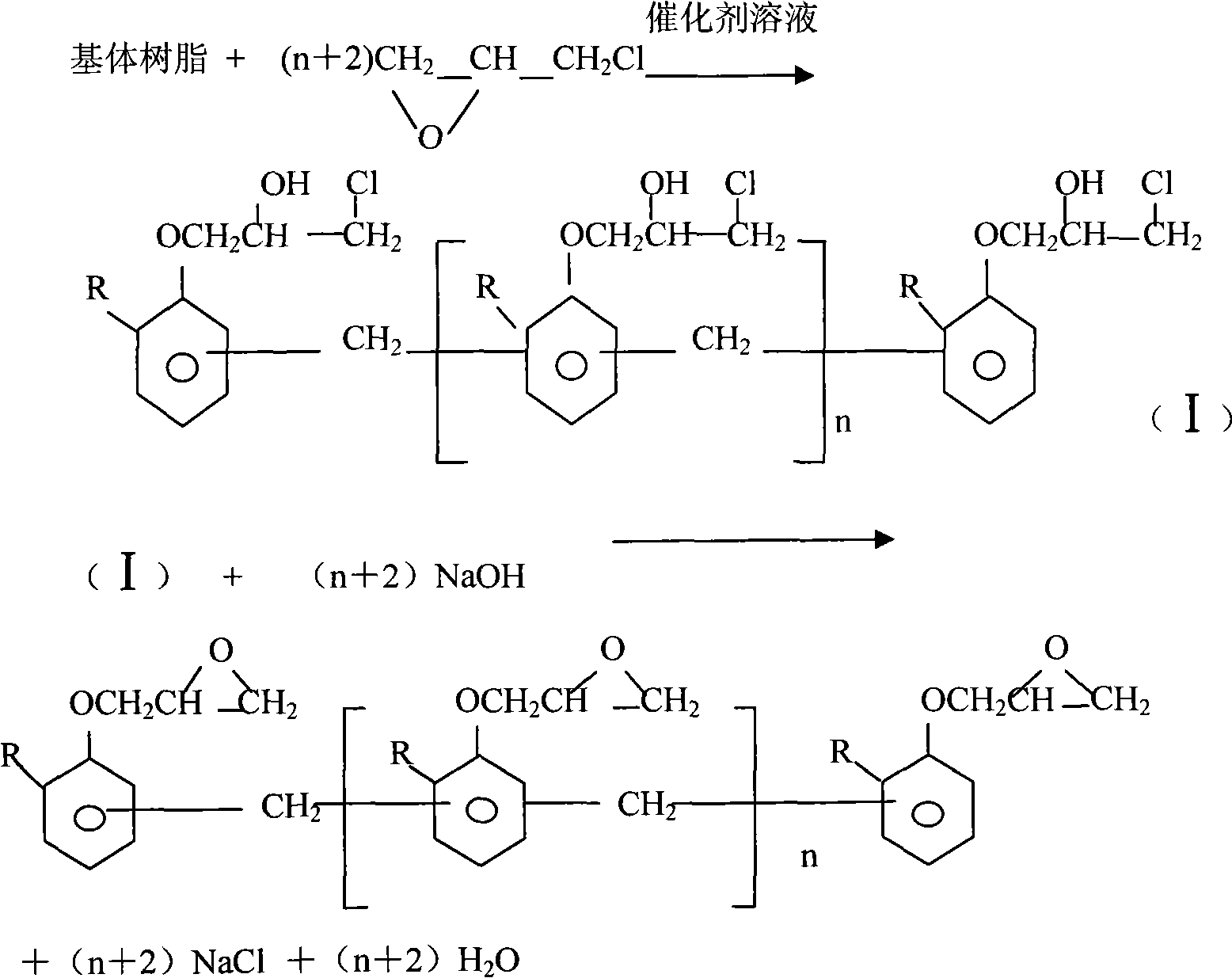

Method for preparing epoxy resins of phenol formaldehyde type

The invention discloses a method for synthesizing phenol formaldehyde epoxy resin with (alkyl)phenolic resin and epoxy chloropropane as raw materials. Base resin and epoxy chloropropane undergo epoxidation reaction under the existence of catalyzer and alkali, and then are refined and processed with post treatment; in this way, phenol formaldehyde epoxy resin can be prepared. The epoxidation technique applied by the invention can effectively reduce the occurrence of side reaction and reduce production of isomerized chlorine and is easy to produce the products with high softening point, high epoxy equivalent weight and low chlorine content and has remarkable effects in improving the stability and heat resistance of the product and in reducing the consumption of the raw materials.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

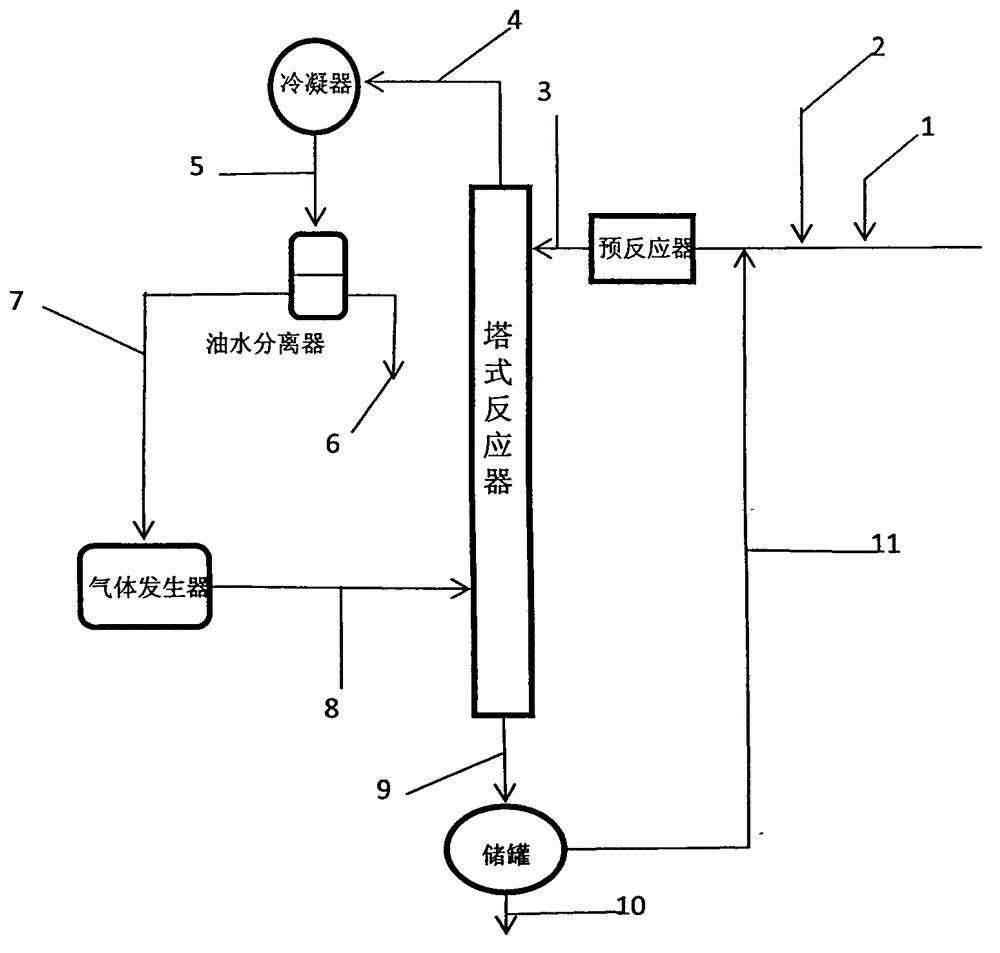

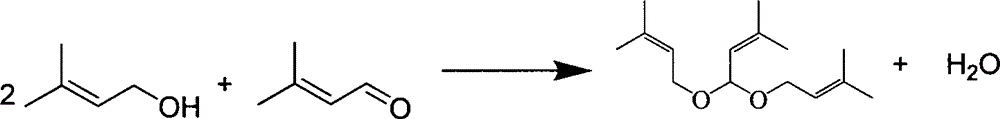

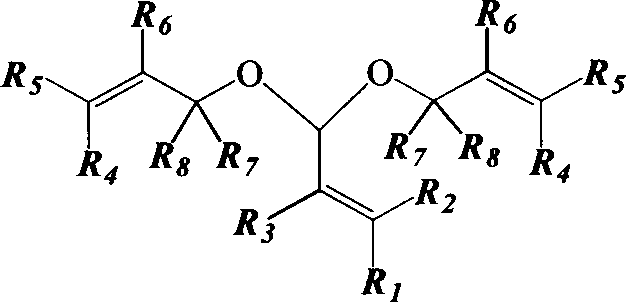

Unsaturated acetal preparation method

ActiveCN102942460AEvenly distributedSmooth responseOrganic chemistryOrganic compound preparationButene3-methyl-2-buten-1-ol

The present invention discloses an unsaturated acetal preparation method. According to the preparation method, an unsaturated alcohol and an unsaturated aldehyde are subjected to a reaction in a pre-reactor to achieve a thermodynamic equilibrium, and then enter a tower type reactor, a water carrying agent is subjected to gasification through a gas generator, and then is subjected to reverse contact with a reaction liquid, and the water generated from the reaction is removed, such that the unsaturated alcohol and the unsaturated aldehyde are subjected to a continuous condensation reaction to prepare the unsaturated acetal. The preparation method has the following characteristics that: the method can be performed under a normal pressure condition, the reaction temperature is constant, low cost synthesis of the unsaturated acetal can be achieved, particularly 3-methyl-2-buten-1-ol and 3-methyl-2-butenal can be adopted as raw materials to synthesize 3-methyl-2-butenal-1 diisopentenyl acetal, wherein the compound is an important intermediate of a synthetic perfume citral.

Owner:WANHUA CHEM GRP CO LTD +1

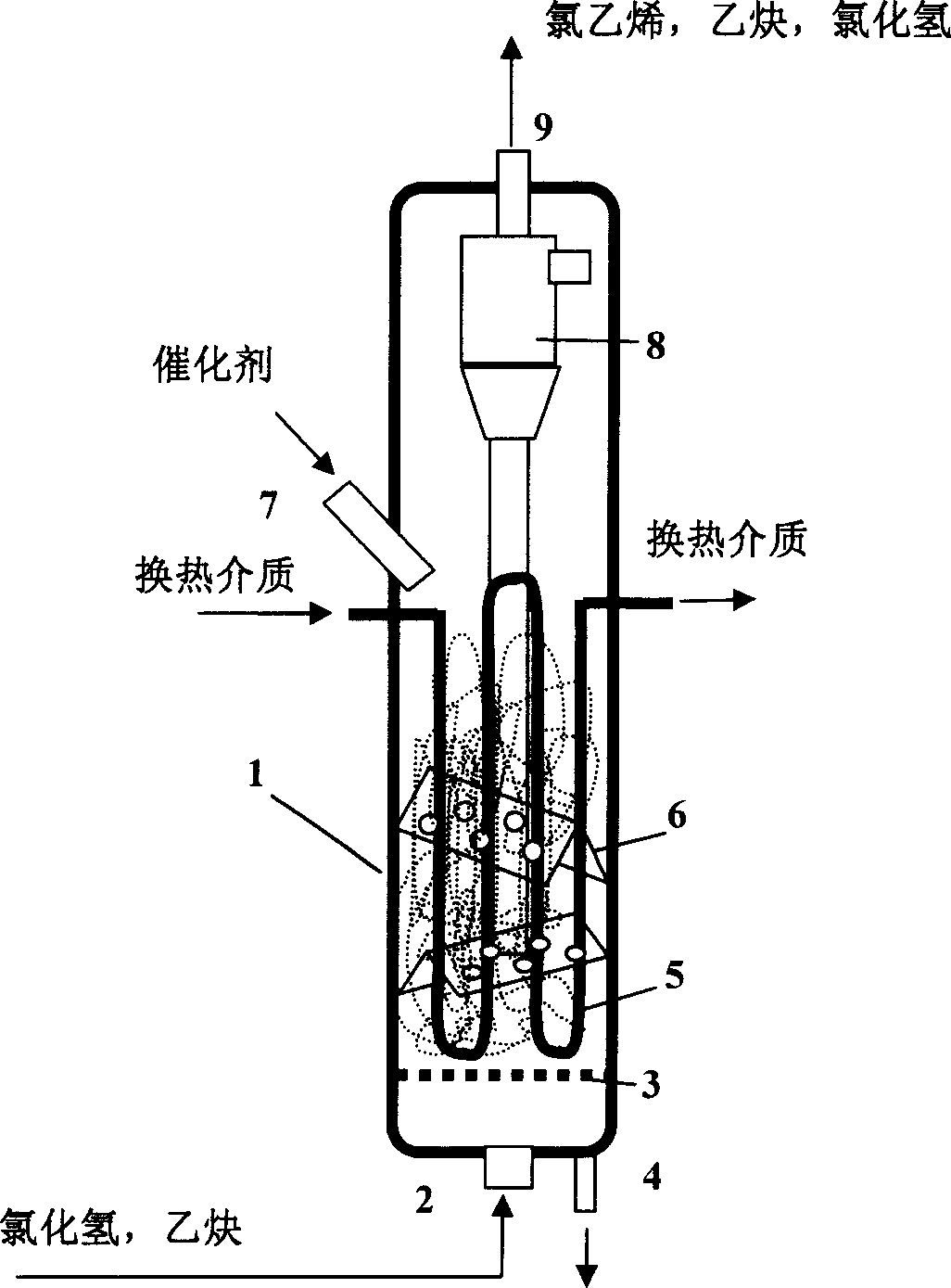

Fluidized bed reactor for preparing vinyl chloride by hydrogen chloride and acetylene reaction and method

InactiveCN1900036APromote conversionInhibit transformationPreparation by halogen halide additionChemical/physical processesPtru catalystFluidized bed

The fluidized bed reactor for preparing vinyl chloride through reaction between hydrogen chloride and acetylene and preparation process belongs to the field of chemical technology. The fluidized bed reactor includes fluidized bed, reactant material gas inlet, heat exchange pipes, member, cyclonic separator, reacted gas outlet, catalyst feeding port and catalyst removing port connected successively to the wall of the fluidized bed. After the catalyst in the molar ratio to the reactant material of 1.01-1.1 to 1 is fed, hydrogen chloride and acetylene are introduced are converted through reaction into vinyl chloride completely, and the reacted product is made to enter the post equipment through the gas outlet. The present invention has simple reaction member, high bubble crushing effect, low catalyst loss, greatly strengthened gas-solid contact, high vinyl chloride product purity and other advantages.

Owner:TSINGHUA UNIV

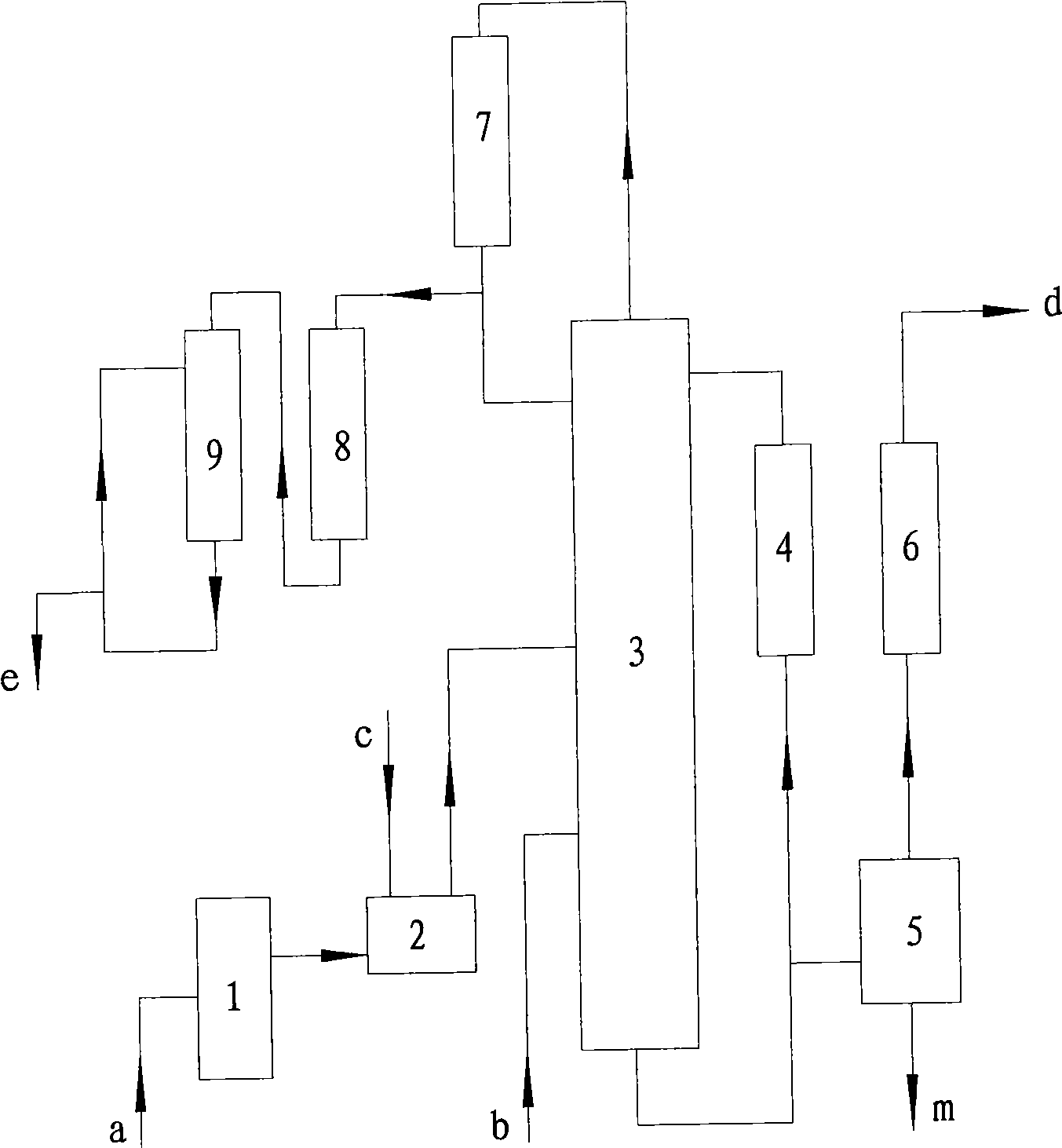

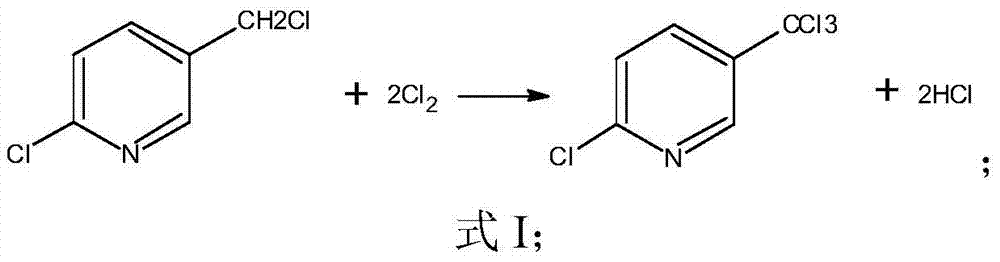

Industrial production method of 2-chloro-5-trichloromethyl pyridine

ActiveCN105439943AHigh yield of chlorination reactionLess impuritiesOrganic chemistrySolventPyridine

The invention discloses an industrial production method of 2-chloro-5-trichloromethyl pyridine, belonging to the technical field of pesticide chemical. The industrial production method of 2-chloro-5-trichloromethyl pyridine comprises the following steps: with 2-chloro-5-chloromethyl pyridine as a start raw material, introducing gaseous chlorine into the solvents such as trifluoromethyl monochlorobenzene, trifluoromethyl dichlorobenzene and trifluoromethyl trichlorobenzene at 80-205 DEG C; initiating a chlorination reaction through ultraviolet irradiation to obtain a crude product of 2-chloro-5-trichloromethyl pyridine directly by one-step chlorination, wherein the content of 2-chloro-5-trichloromethyl pyridine in the crude product is higher than or equal to 90%; and purifying the crude product by a rectifying process to obtain a product of 2-chloro-5-trichloromethyl pyridine, wherein the purity is higher than or equal to 99.0%. The method disclosed by the invention overcomes the shortcomings of the existing production method such as long reaction time, low reaction selectivity, high polymer generation and low yield; and without a catalyst, the reaction selectivity and yield are increased, the reaction is accelerated, and the industrial production is facilitated.

Owner:连云港埃森化学有限公司 +1

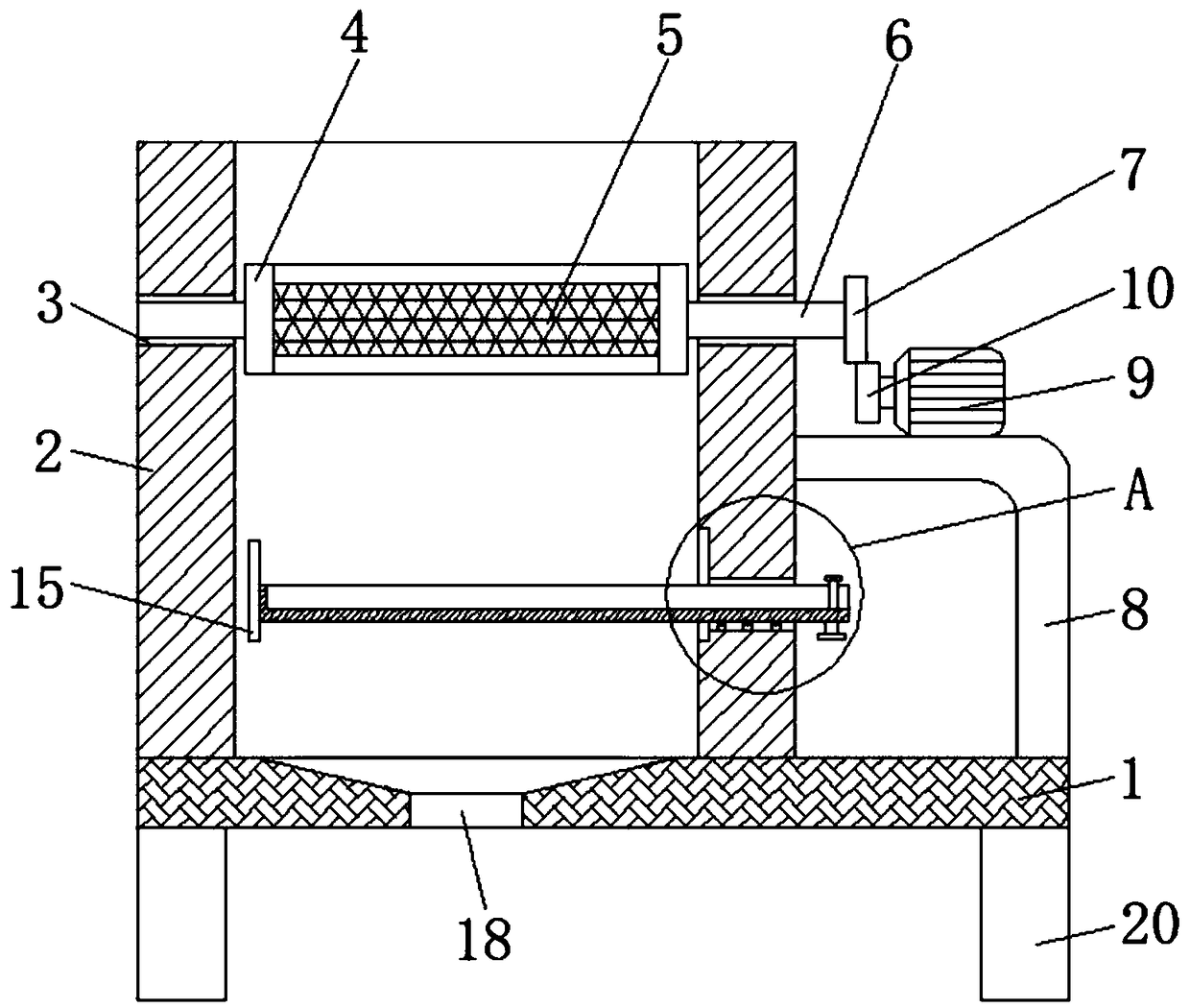

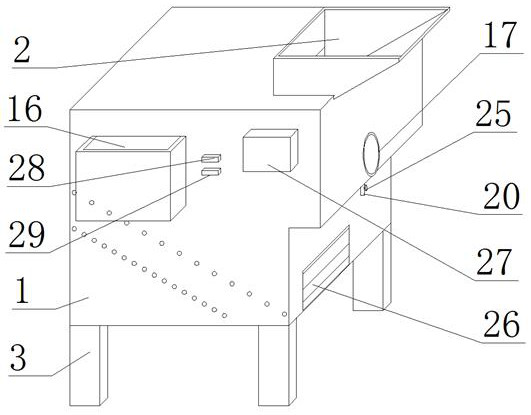

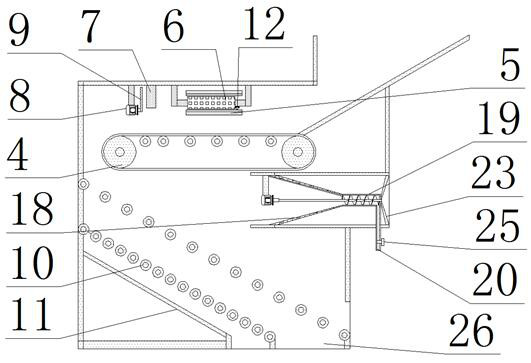

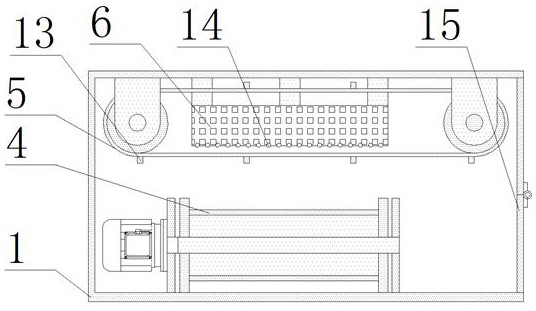

Filtering device facilitating clearing of filter residue for chemical industry

PendingCN109364556AEasy to cleanImprove filtering effectStationary filtering element filtersChemical industryEngineering

The invention discloses a filtering device facilitating clearing of filter residue for chemical industry. The filtering device comprises a bottom plate, a cylindrical cylinder is fixed to the top of the bottom plate, and a through hole is formed in the side face of the cylindrical cylinder; a frame and a filtering net are arranged inside the cylindrical cylinder, the filtering net and the inner wall of the frame are fixed, and a rotating rod is fixed to the outer side of the frame and penetrates through the through hole; a driven gear is fixed to the end, away from the frame, of the rotating rod, a supporting frame is fixed to the top of the bottom plate, and a motor is fixed to the top of the supporting frame; and a driving gear is fixed to an output shaft at the output end of the motor,an opening is formed in the side face of the cylindrical cylinder, and a fixed pulley is fixed to the inner bottom of the opening. According to the filtering device, by reversely rotating the filtering net, solid impurities fall from the filtering net through gravity, the filtering efficiency is acceleratedimproved, meanwhile, the solid impurities are quickly transferred through a movable groove plate, and thus the clearing efficiency is improved.

Owner:ANHUI HUAERTAI CHEM IND

Method for preparing o-nitro anisole by using micro-channel reaction apparatus

InactiveCN105503610APrecise control of reaction conditionsEasy to operateOrganic chemistryOrganic compound preparationO-NitroanisoleReaction rate

The present invention provides a new method for preparing o-nitro anisole by using a micro-channel reactor, particularly application of a micro-channel reactor with an enhanced mass transfer unit structure to carry out a continuous flow o-nitro chloro benzene etherification reaction. According to the present invention, the mass transfer and the heat transfer can be completed dependent on the kinetic energy of the fluid without the mechanical stirring process under the reactor operation condition higher than the normal temperature, the space time reaction rate of the micro-channel reactor can be substantially improved, the temperature fluctuation and the concentration fluctuation during the reaction process can be avoided, the phenomena such as temperature runaway and overheating do not exist, and the reaction process is safe.

Owner:CHINA PETROLEUM & CHEM CORP +1

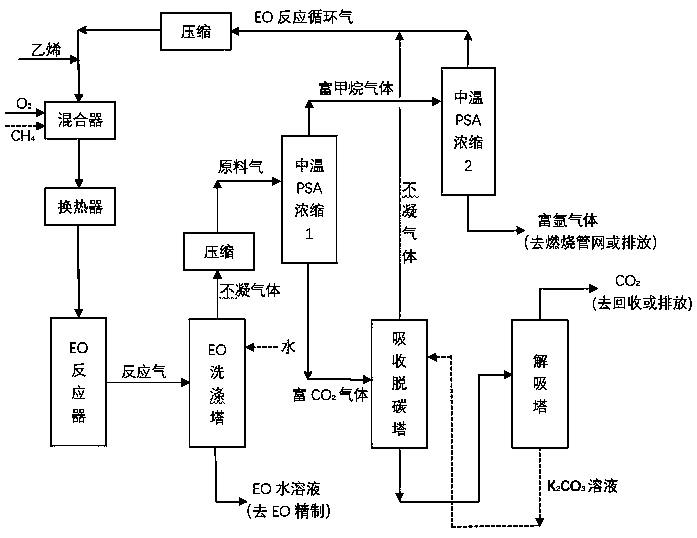

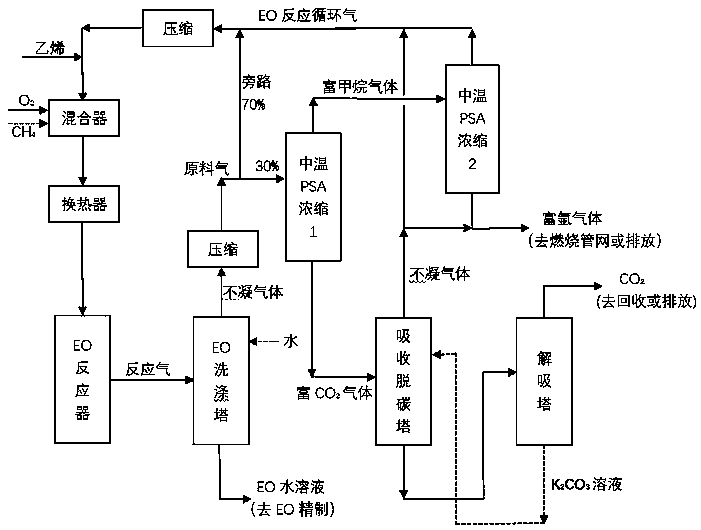

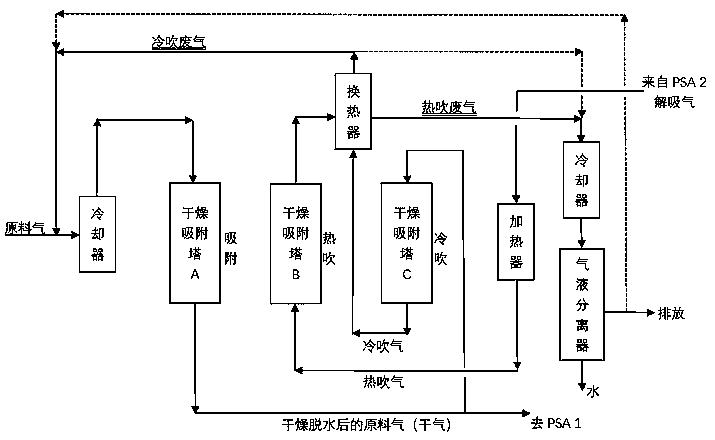

Full temperature range-pressure swing adsorption (FTrPSA) separation method for reaction cycle gas in direct oxidation of ethylene to ethylene oxide

ActiveCN110237650ARemoved in timeSolve wasteGas treatmentDispersed particle separationGas compressorDesorption

The invention discloses a full temperature range-pressure swing adsorption (FTrPSA) separation method for reaction cycle gas in direct oxidation of ethylene to ethylene oxide. The FTrPSA separation method comprises the following steps: (1) allowing raw material gas to undergo intermediate temperature pressure swing adsorption (PSA) concentration 1 (PSA1), allowing non-adsorbed phase gas to flow out and undergo intermediate temperature pressure swing adsorption (PSA) concentration 2 (PSA2), and allowing adsorbed phase gas to flow out and enter a decarbonization tower; (2) allowing the non-adsorbed phase gas flowing out from intermediate temperature pressure swing adsorption (PSA) concentration 2 (PSA2) to be directly discharged, and allowing the adsorbed phase gas rich in methane and ethylene to flow out as EO reaction cycle gas and pass through a recycle gas compressor to return to an EO reactor for a reaction; and (3) allowing non-condensable gas flowing out from the top of an absorption tower used for absorbing removed carbon to be used as EO reaction recycle gas to return to the EO reactor for recycling, allowing a carbon-dioxide-rich absorption solution flowing out from the bottom of the absorption tower to enter a desorption tower through a circulation pump, heating a potassium carbonate solution flowing out from the bottom of the desorption tower, then mixing the heated potassium carbonate solution with a part of a potassium carbonate solution newly supplemented at regular time, allowing an obtained mixed potassium carbonate solution to return to the absorption tower for recycling, and allowing carbon-dioxide-rich desorption gas flowing out from the top of the desorption tower to be directly discharged.

Owner:ZHEJIANG TIANCAIYUNJI TECH CO LTD

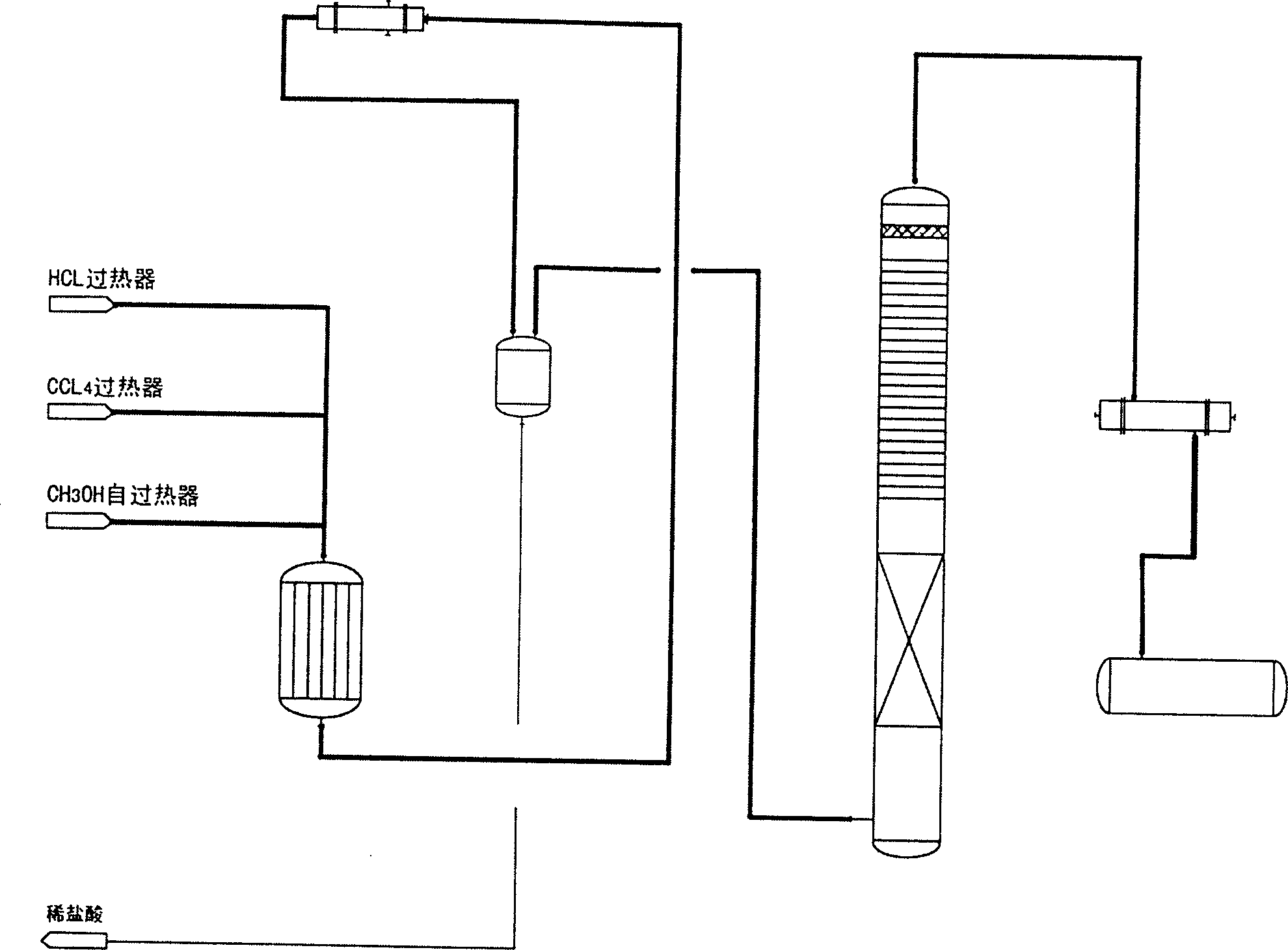

Industrial preparation method of carbon tetrachloride transferring to methyl chloride and its fixed bed reactor

InactiveCN1762934ARemoved in timeQuick responseHalogenated hydrocarbon preparationFixed bedCarbon Chloride

The present invention discloses industrial preparation process and fixed bed reactor for converting carbon tetrachloride into methane monochloride. After methanol and carbon tetrachloride are evaporated separately in evaporators and methanol, carbon tetrachloride and hydrogen chloride are overheated in overheaters at 150-240 deg.c, they are catalytically reacted as required inside a fixed bed reactor at reaction temperature 160-300 deg.c and reaction pressure 0.05-0.45 MPaG. In the initial stage, the volume ratio of materials is methanol / hydrogen chloride of 1 to 1-1.4, or methanol / carbon tetrachloride / water is 1 to 0.25-0.35 to 0.5-1; and during the normal reaction, the volume ratio of materials is methanol / carbon tetrachloride / hydrogen chloride of 1 to 0.25-0.35 to 0-0.4, or methanol / carbon tetrachloride of 1 to 0.25-0.35. The fixed bed reactor is a shell-and-tube one with bed layer diameter 1500-3200 mm, effective tube array length 1500-4500 mm and tube array diameter 32-80 mm.

Owner:江苏梅兰化工有限公司

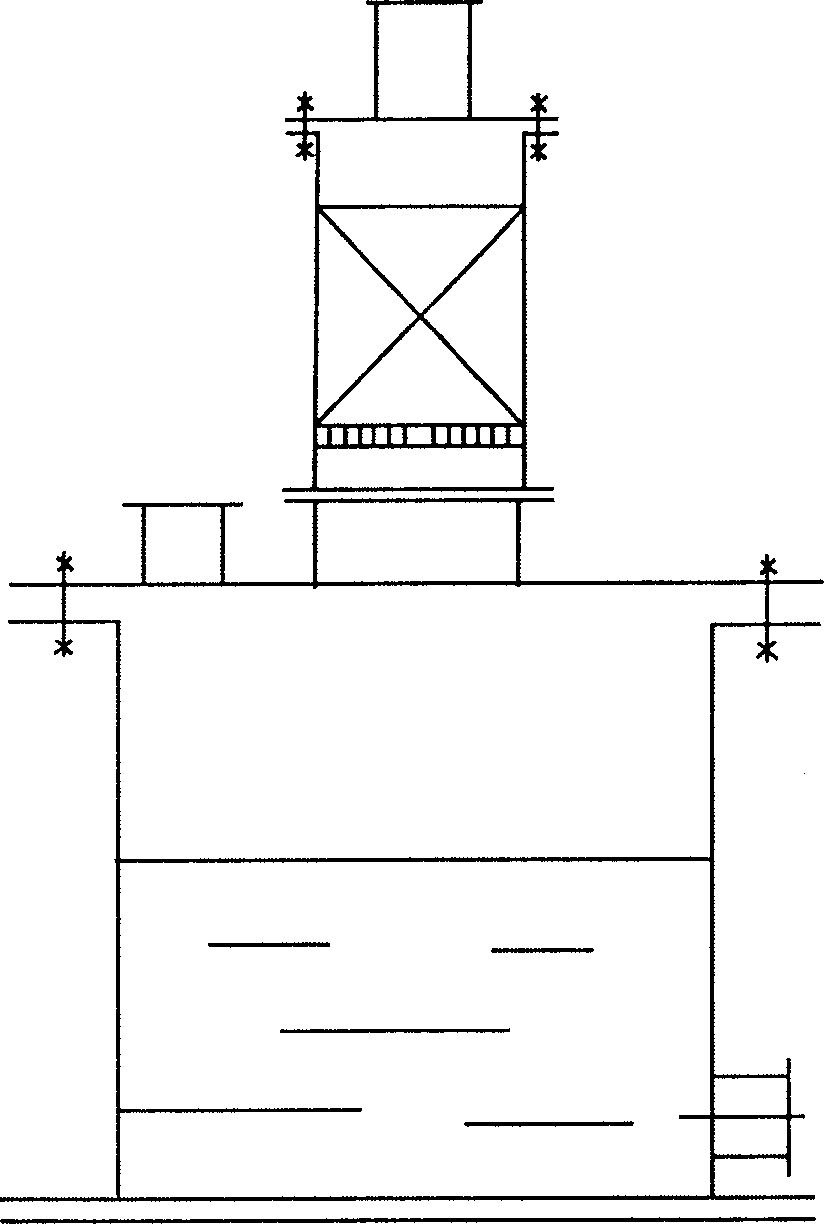

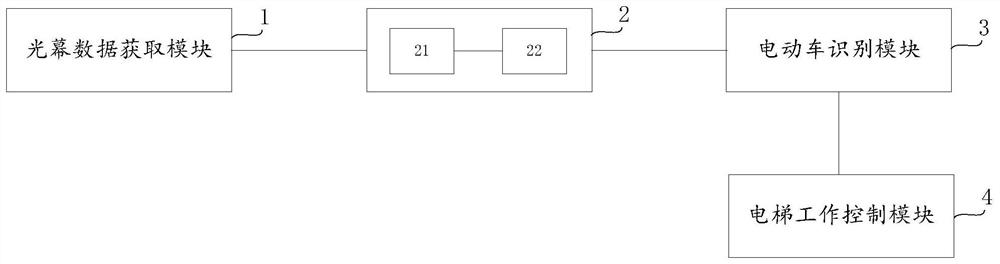

Elevator control system and elevator equipment

The invention discloses an elevator control system and elevator equipment. The elevator control system comprises a light curtain data acquisition module, a light curtain imaging drawing module, an electric vehicle identification module and an elevator work control module; the light curtain data acquisition module is used for acquiring signals received by each receiver of a light curtain; the lightcurtain imaging drawing module is used for drawing an image according to the signals acquired by the light curtain data acquisition module; the electric vehicle identification module is used for comparing the image drawn by the light curtain imaging drawing module with a set image in a database to identify whether the vehicle is an electric vehicle; and the elevator work control module is used for controlling the running state of the elevator equipment according to the identification result of the electric vehicle identification module. According to the elevator control system and the elevator equipment, the situation of a battery car entering the elevator can be monitored in real time, and it is ensured that the imaging situation of the electric car entering the elevator can be accurately displayed when the electric car enters the elevator; and elevator passengers can be prompted to forbid the electric vehicle from going upstairs, so that fire safety of residents is guaranteed.

Owner:MOCHITEC SHANGHAI CO LTD

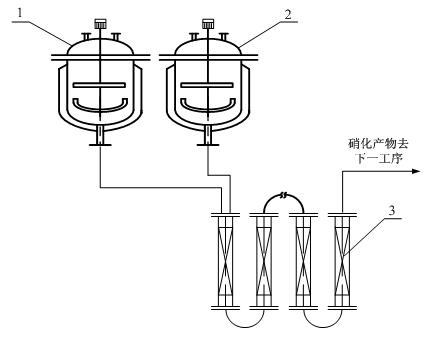

Method for performing tubular continuous nitrification on naphthalene-2,7-disulfonic acid during production of H acid

InactiveCN102320995AUniform residence time distributionImprove product qualitySulfonic acid preparationNitrationReaction temperature

The invention provides a method for performing tubular continuous nitrification on naphthalene-2,7-disulfonic acid during production of H acid, and relates to a production method of a compound, in particular to a method for producing 1,8-dinitronaphthalene-3,6-disulfonic acid by performing continuous nitrification on naphthalene-2,7-disulfonic acid in the preparation process of the H acid and mixed acid of nitric acid and sulfuric acid in a tubular reactor. By the method, the tubular continuous production of the nitrification of the naphthalene-2,7-disulfonic acid is realized, wherein the reaction temperature is between 35 and 120 DEG C and the reaction time is less than 120 minutes. The production process is high in safety, the consumption of raw materials is low, products have good quality and productive capacity is large.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

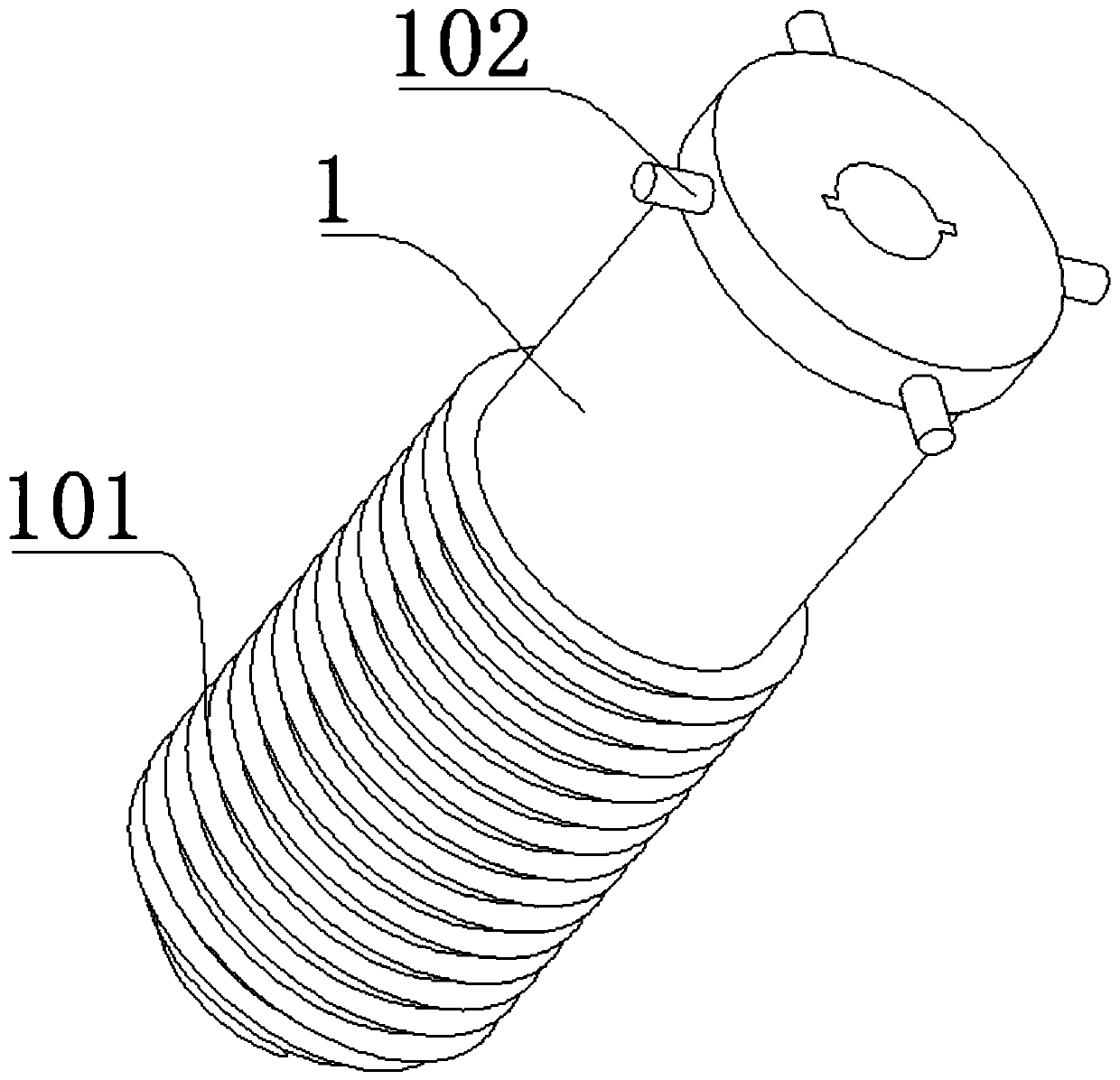

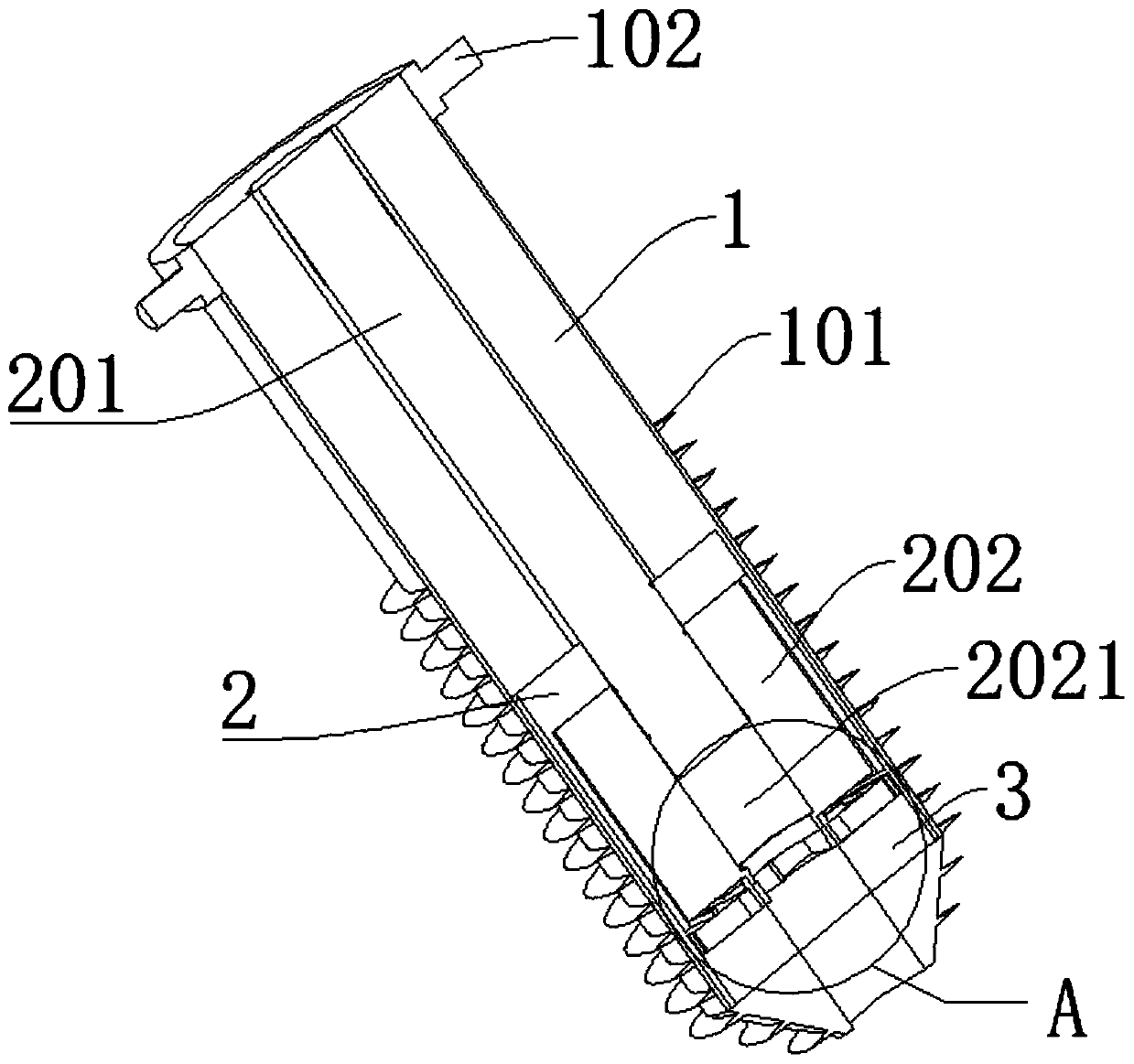

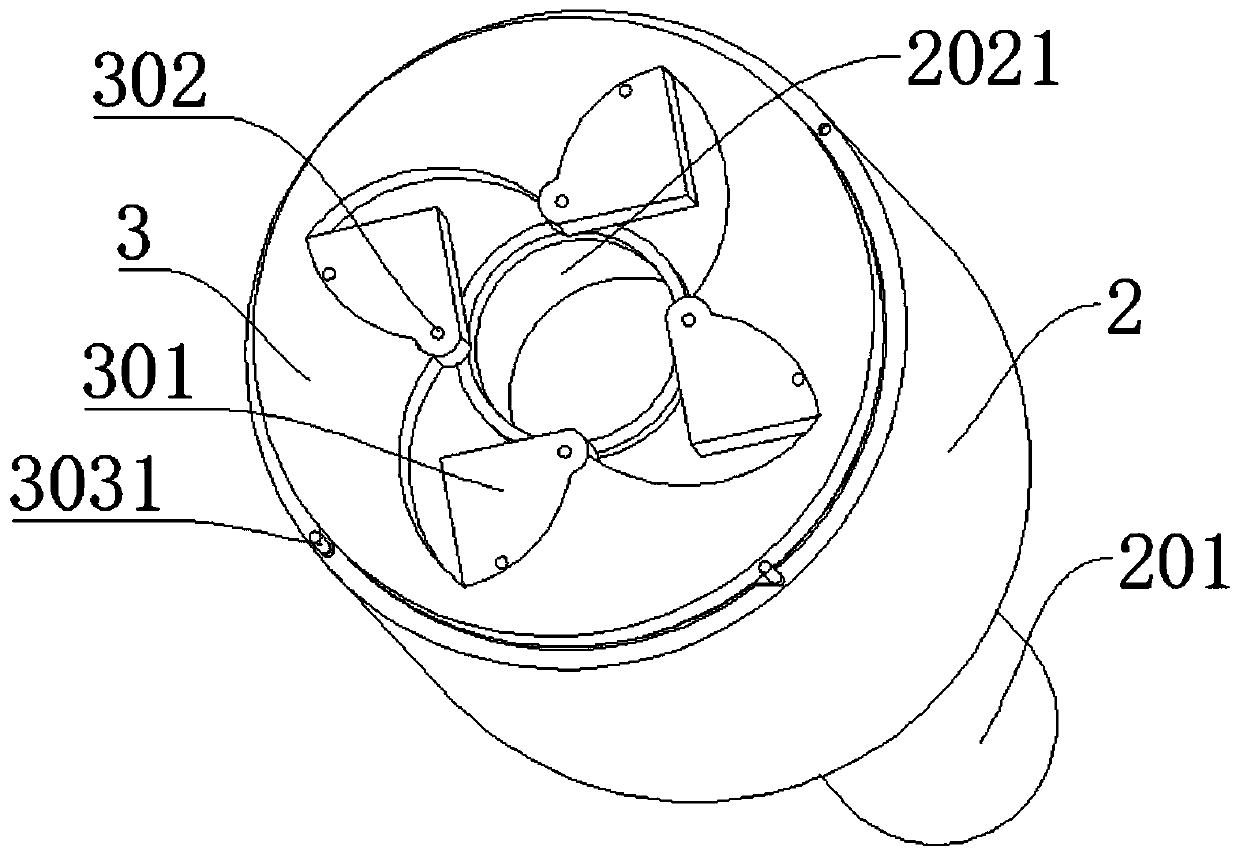

Soil layer drilling device

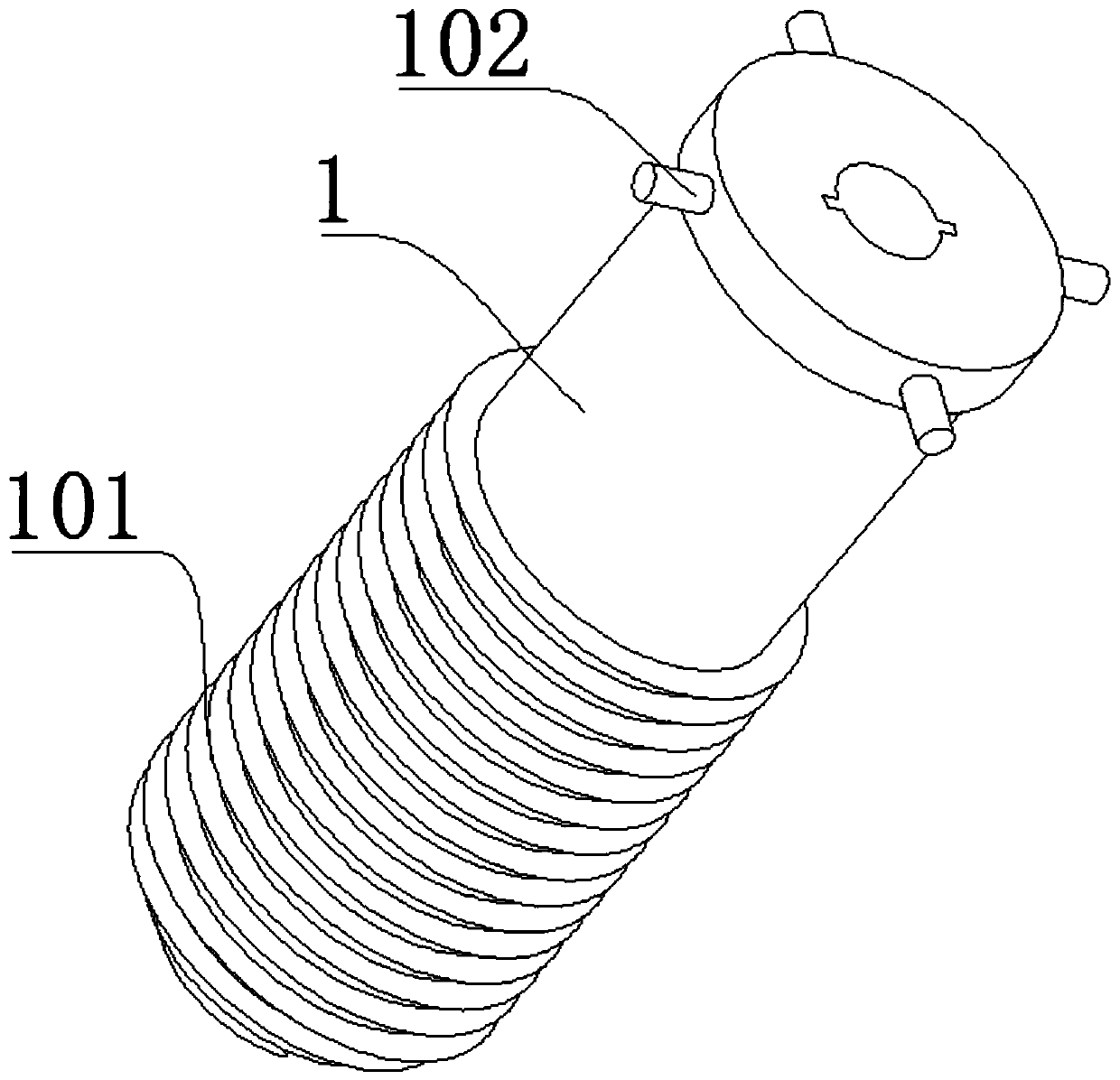

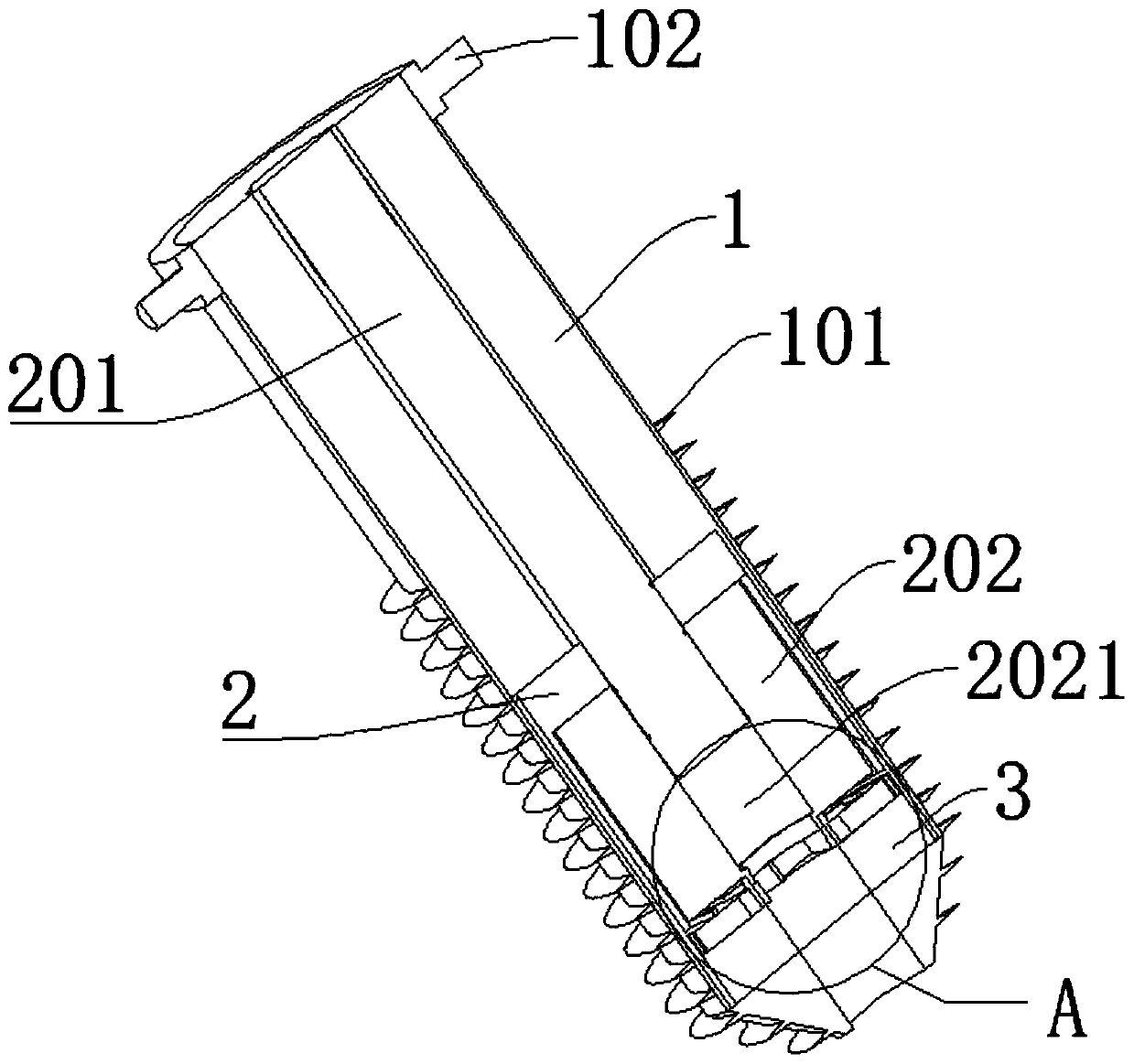

ActiveCN110411782AShorten the timeGood collection effectWithdrawing sample devicesSoil horizonEngineering

The invention discloses a soil layer drilling device, and belongs to the technical field of soil sampling. The soil layer drilling device comprises a box body, and a spiral blade is sleeved with the side wall of the box body. The device further comprises a rotating block and a lifting column, the rotating block is rotationally connected to the interior of the box body, the inner wall of the rotating block is connected with a collecting ring column, a collecting chamber is formed in the inner wall of the collecting ring column, the lifting column is connected to the interior of the box body, the lifting column and the rotating block are connected through a threaded strip, one end of the lifting column is arranged in the collecting chamber, and a closer is connected to the bottom of the rotating block. When soil is collected by the device, the soil cannot be scattered, the collecting effect is good, the soil can be conveniently taken out from a sampler, and the device is convenient to carry.

Owner:HUNAN ZHUANGYUAN GEOLOGICAL EQUIP

Ester-exchange reaction device

InactiveCN103772084ARemoved in timeHigh reaction conversion rateCarboxylic acid ester formation/introductionAlcoholBiochemical engineering

The invention discloses an ester-exchange reaction device. The ester-exchange reaction device comprises a reaction kettle, a rectifying tower, a condenser, an azeotrope storage tank and an entrainer, wherein the reaction kettle is communicated with the rectifying tower by a pipeline; the condenser is communicated with the top part of the rectifying tower by a pipeline; the azeotrope storage tank is respectively communicated with the top part, the middle part and the bottom part of the rectifying tower by a feeding pipe at the top part of the rectifying tower, a feeding pipe at the middle part of the rectifying tower and a feeding pipe at the bottom of the rectifying tower. Due to adoption of the technical scheme, the ester-exchange reaction device disclosed by the invention can overcome the defects that the by-product (alcohol) is not removed in time, the removing speed of the by-product (alcohol) is slow, the reaction conversion rate is not high and the reaction time is longer in the existing production process of ester-exchange reaction, the simple and effective ways are provided for increasing the reaction conversion rate, shortening the reaction time, reducing the energy consumption and lowering the material consumption.

Owner:JIANGSU FEYMER TECH

Production method of polyvinyl chloride with small pot suspension method

The invention relates to a polyvinyl chloride, in particular to a production method of the polyvinyl chloride with a small pot suspension method, belonging to the technical field of chemical industry, characterized in that: EHP (peroxydicarbonate-diethylhexyl ester) which has high activity, uniform heat generation, and light sticking is used, based on using the EHP, a composite initiator is used, heat exchange capability of the kettle is fully utilized to allow the reaction speed to be uniform, prevent the acceleration of the post reaction speed to guarantee the timely removal of polymerization heat, and reduce the polymerization time; a composite system of binary PVA (polyvinyl alcohol) with different alcoholysis degrees and a polybasic composite system of HPMC (hydroxypropyl methyl cellulose) and PVA are used; and a secondary water injection technology is used, so that viscosity of the materials is reduced, the heat removing capability of the polymerizing pot is improved, and the quality of the PVC products is increased. According to the invention, the polymerization time is reduced, the viscosity of the materials is reduced, the cleaning time of the polymerizing pot, and a low water-oil ratio can be used for filling, so that the production capacity is improved.

Owner:邱飞

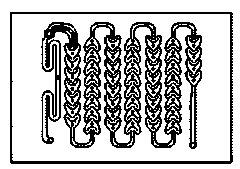

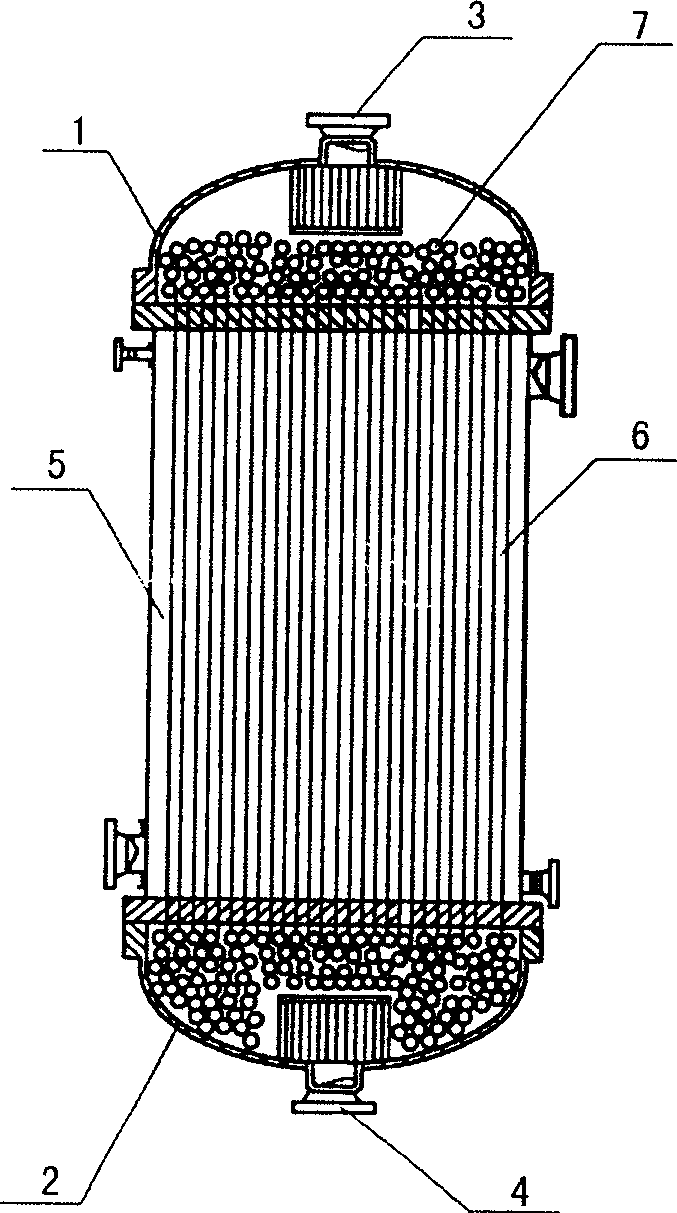

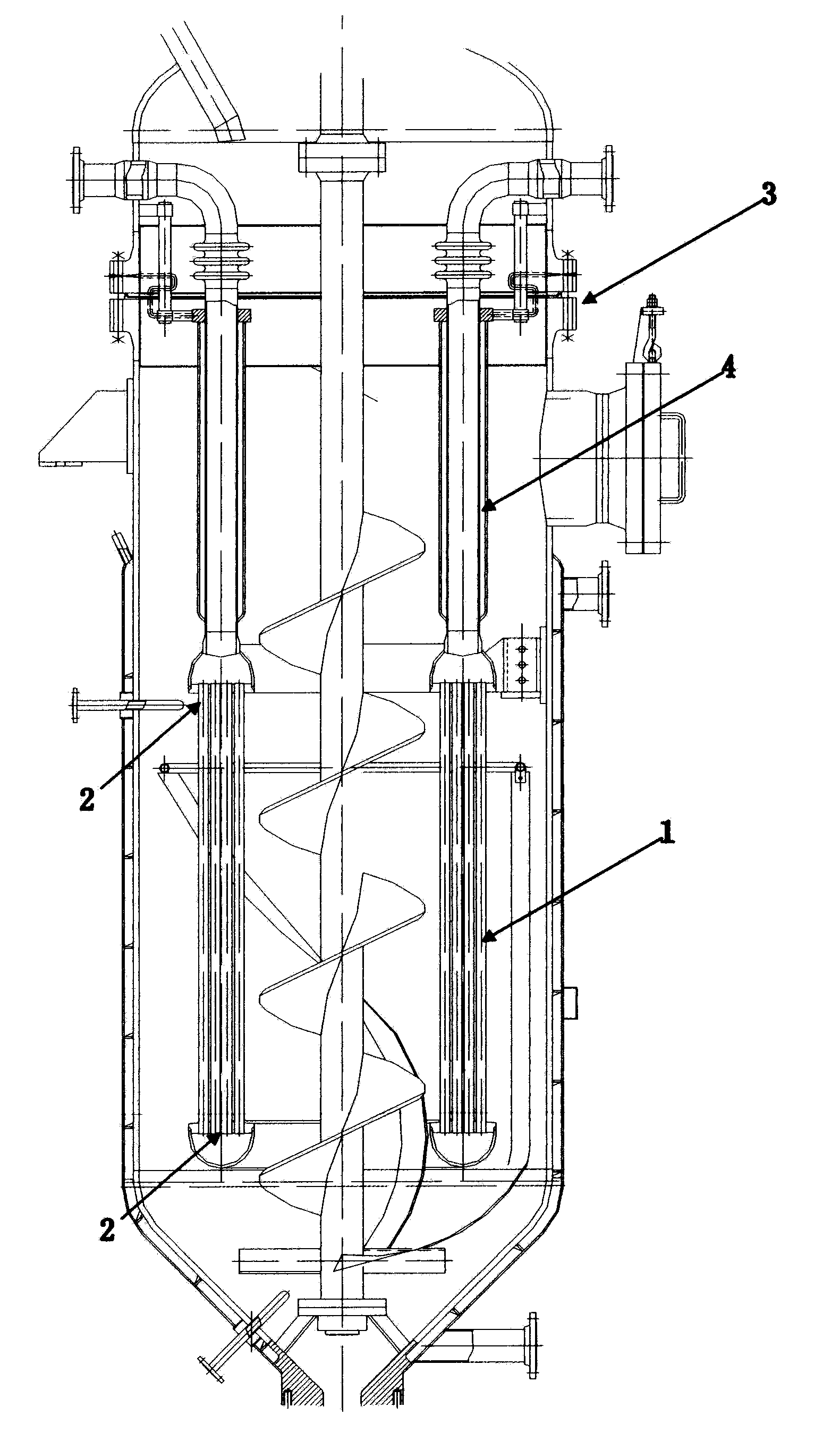

Built-in high-efficiency tube nest reaction heat exchange device

InactiveCN103657578ARemoved in timeIncrease the heat exchange areaChemical industryChemical/physical/physico-chemical stationary reactorsHeat conductingCompound (substance)

The invention discloses a built-in high-efficiency tube nest reaction heat exchange device which is suitable for the fields of reaction equipment needing forced heat exchange, such as chemical engineering, petroleum, foods and power. The built-in high-efficiency tube nest reaction heat exchange device has the main structure that heat exchange tube nests are firstly arranged and connected to a tube plate in a U shape or straight pipe shape, and the tube plate and the heat exchange tube nests are arranged in a reaction kettle; for increasing the heat exchange efficiency, the tube plate and the heat exchange tube nests can be connected to a heat conducting medium pipe, and the heat conducting medium pipe is used for inputting a heat conducting medium pipe into a reaction kettle through a kettle casing and is connected with all heat exchange tube nests through the tube plate.

Owner:王仲明

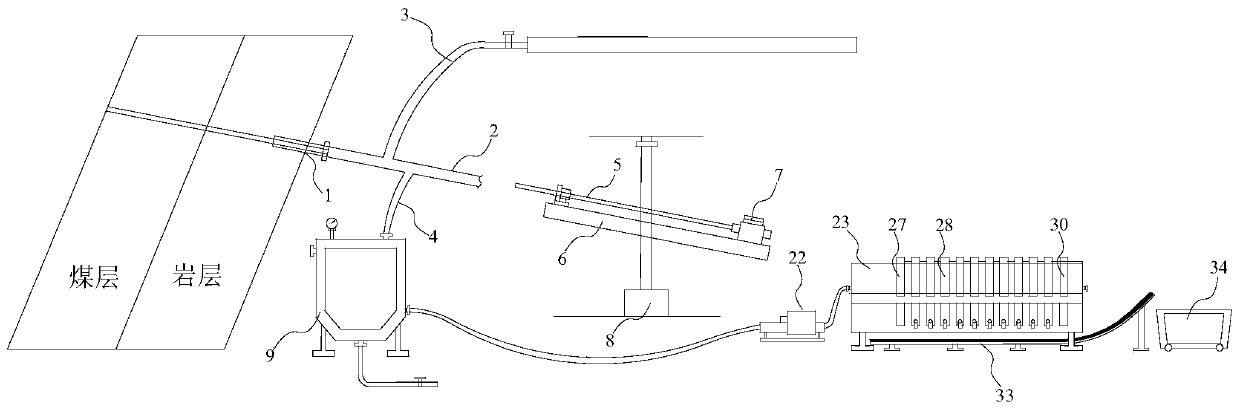

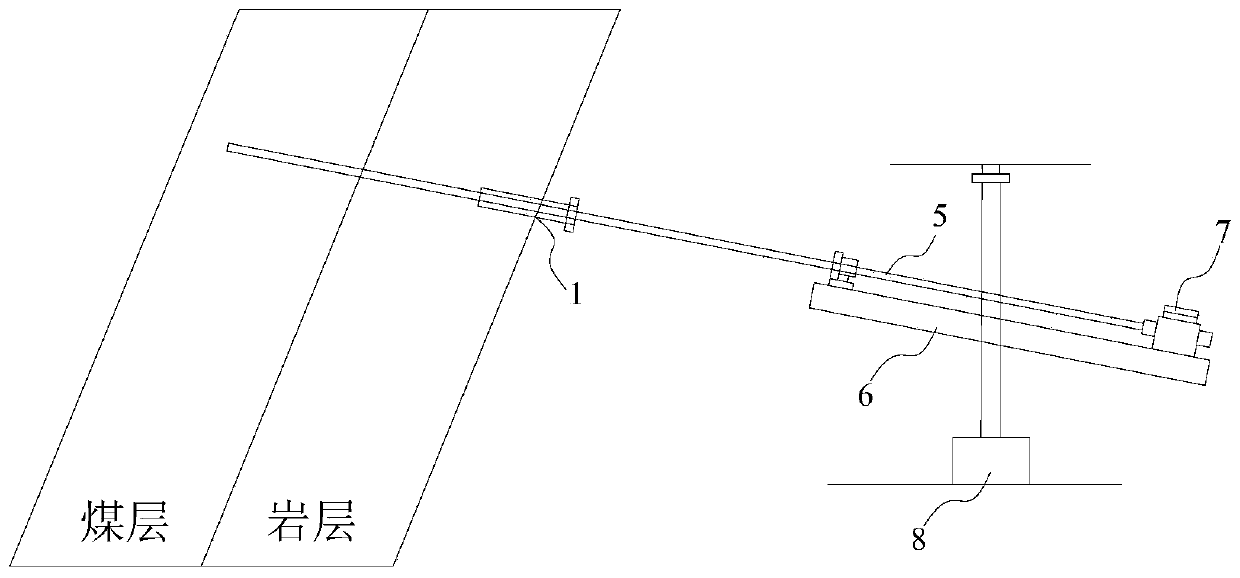

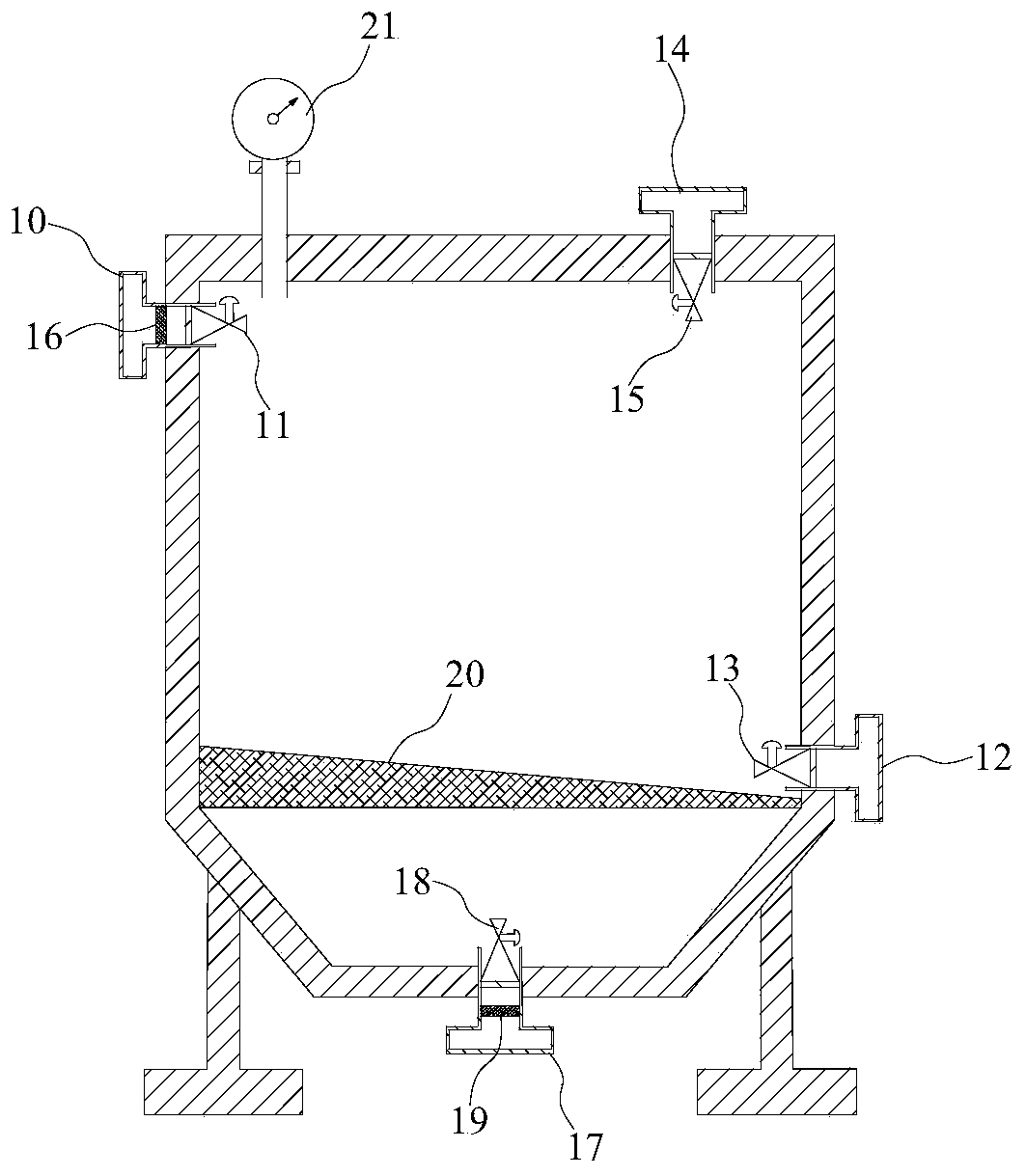

Bottom plate rock roadway layer penetrating drilling hydraulic slag discharging efficient cleaning system and method

PendingCN110953012AAvoid stackingImprove working environmentFluid removalGas removalCoal waterCoal briquette

The invention discloses a bottom plate rock roadway layer penetrating drilling hydraulic slag discharging efficient cleaning system and method, and relates to the technical field of coal and gas outburst prevention and treatment. An extraction device, a coal water separation device, a filter pressing device and a transportation device are included. The extraction device comprises a drilling machine and an extraction pipeline. A coal water extracting and releasing pipe of the extraction pipeline is connected with the coal water separation device. A coal water separation bin of the coal water separation device is connected with a filter pressing pump of the filter pressing device through a coal unloading pipe. After the filter pressing device extrudes coal slime, the transportation device isused for conveying coal cakes. When the system works, the drilling machine is used for drilling, then, the extraction pipeline is installed, coal-water-gas mixture is extracted and released, gas is collected through a gas extracting and releasing pipe, and the coal water mixture enters the coal water separation device. The coal water separation device separates coal and water, and residual gas iscollected. After the coal slime enters the filter pressing device, the coal slime is extruded into the coal cakes and then conveyed out through the transportation device. According to the system andthe method, the coal-water-gas mixture can be efficiently separated, and the gas extraction operating efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

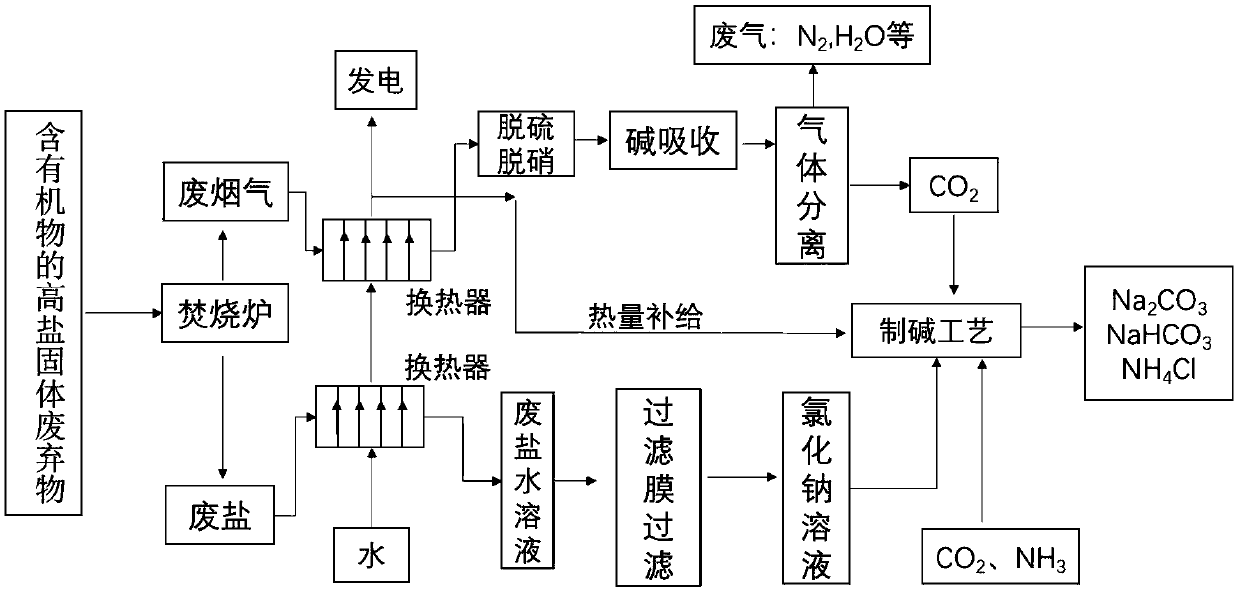

Treatment method of high-salt solid waste containing organic matters

InactiveCN109681880ATake advantage ofEffective treatmentSemi-permeable membranesGas treatmentCompound (substance)Organic matter

The invention discloses a treatment method of high-salt solid waste containing organic matters; the treatment method comprises the following steps of: conveying high-salt solid waste containing organic matters to an incinerator for incineration, wherein the incineration temperature is 1000-1300 DEG C; generating waste smoke and salt after incineration; through an exhaust gas treatment process, theseparated CO2 gas of the waste smoke enters an alkali making process for recycling; the waste salt can obtain saturate sodium chloride solution by a waste salt treatment process to enter alkali making reaction for recycling; the heat in the waste smoke and waste salt is supplied to power generation through a part of the smoke heat exchanger and the waste salt heat exchanger, and the other part isused for alkali production reaction. The treatment method provided by the invention can treat the high-salt solid waste containing organic matters by an incineration method; the high-salt solid wastecontaining organic matters can be subsequently converted into a series of chemical productsAt the same time, the heat generated by the incinerator is used for supplying each application section during the whole process, and the whole process is energy-saving and efficient.

Owner:CHANGZHOU INST OF TECH

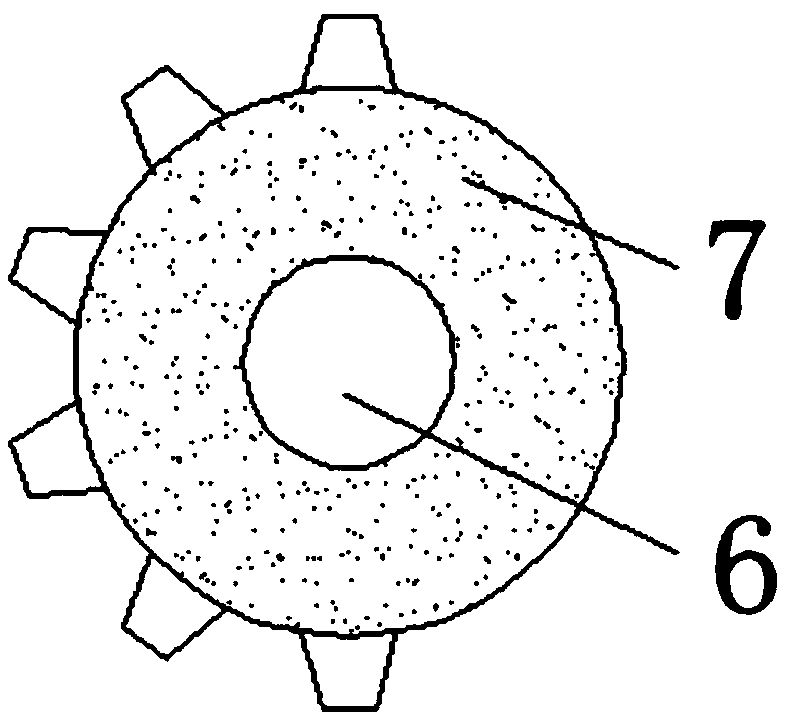

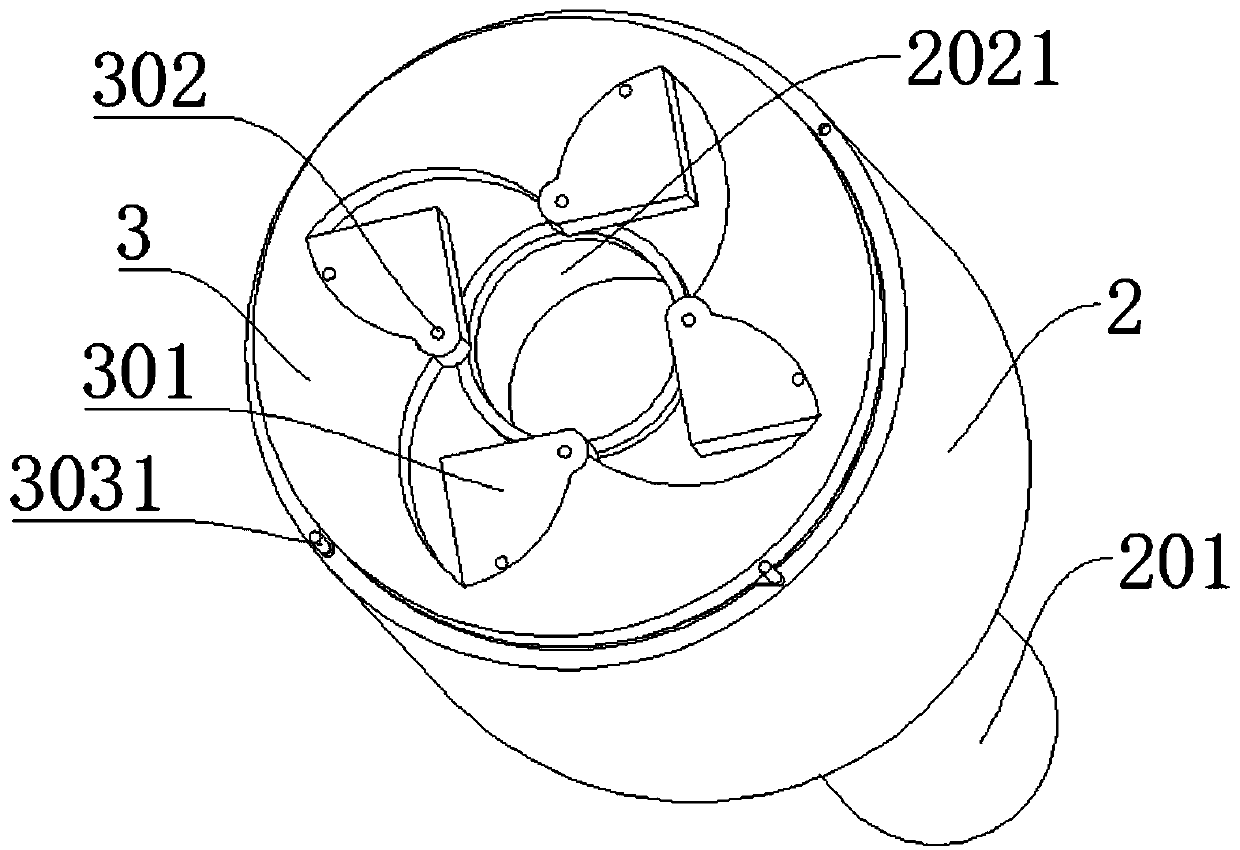

Multi-station automatic switching type opticalpath device and spectrograph

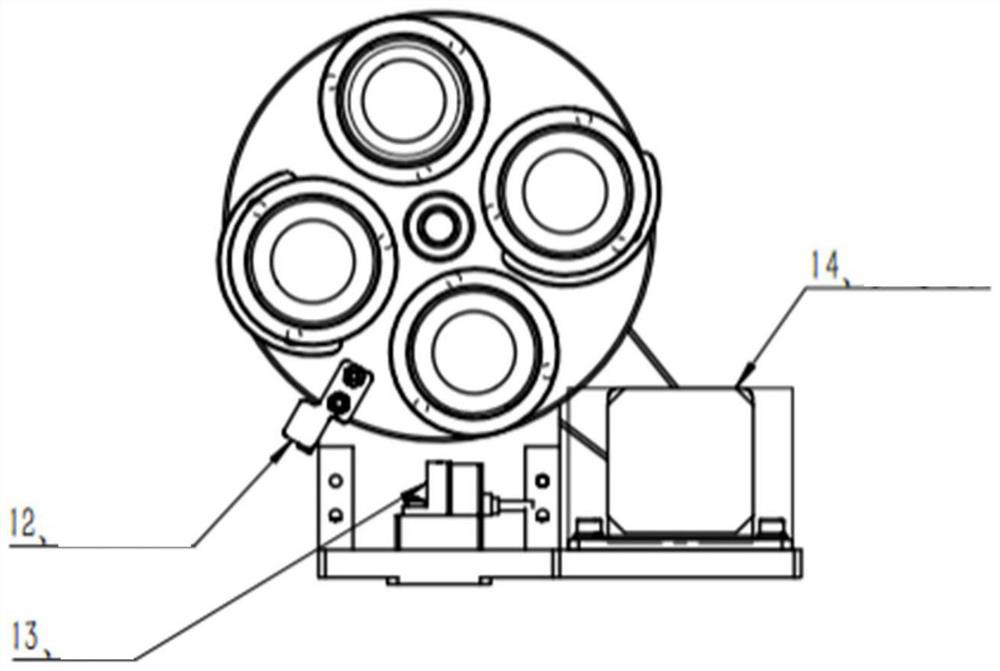

ActiveCN111707628AEasy to manufactureSimple structureColor/spectral properties measurementsCircular discOptical spectrometer

The invention provides an optical path device supporting multi-station automatic switching and fine tuning of lamp sources. The device comprises a mounting fine tuning device and a power output device; a multi-station flange in the mounting fine tuning device is a disc with a central hole; a plurality of light source mounting seats are symmetrically arranged; and a rotary support shaft penetratesthrough the central hole of the flange. The power output device can drive the multi-station flange to rotate by rotating the supporting shaft and drive the light source to rotate to reach a designatedposition. The invention also provides a gas-phase molecular absorption spectrograph comprising the optical path device. According to the invention, the light source can be automatically selected to reach the designated to-be-detected position, and the fault light source can be moved out of the designated to-be-detected position at any time; meanwhile, a stepping motor is matched with an infraredoptical coupling induction technology, and the position of the lamp source installed on the multi-station flange plate is accurately and finely adjusted.

Owner:SHANGHAI ANJIE ENVIRONMENTAL PROTECTION TECH

A soil drilling device

The invention discloses a soil layer drilling device, and belongs to the technical field of soil sampling. The soil layer drilling device comprises a box body, and a spiral blade is sleeved with the side wall of the box body. The device further comprises a rotating block and a lifting column, the rotating block is rotationally connected to the interior of the box body, the inner wall of the rotating block is connected with a collecting ring column, a collecting chamber is formed in the inner wall of the collecting ring column, the lifting column is connected to the interior of the box body, the lifting column and the rotating block are connected through a threaded strip, one end of the lifting column is arranged in the collecting chamber, and a closer is connected to the bottom of the rotating block. When soil is collected by the device, the soil cannot be scattered, the collecting effect is good, the soil can be conveniently taken out from a sampler, and the device is convenient to carry.

Owner:HUNAN ZHUANGYUAN GEOLOGICAL EQUIP

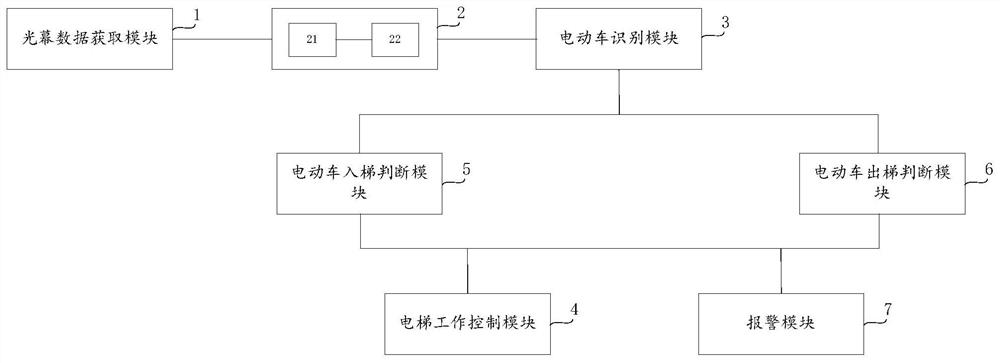

Scanning imaging monitoring system and method and electric vehicle entering-ladder scanning imaging monitoring system

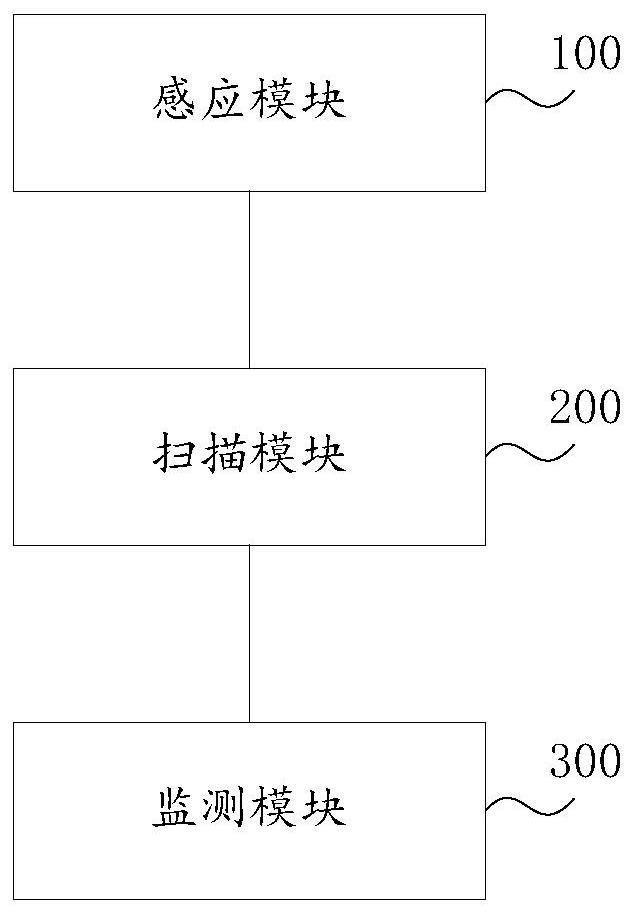

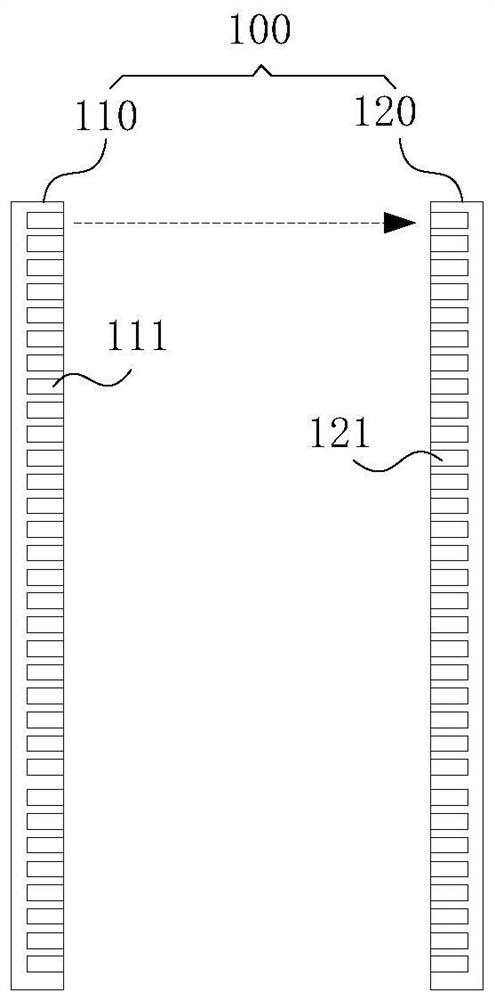

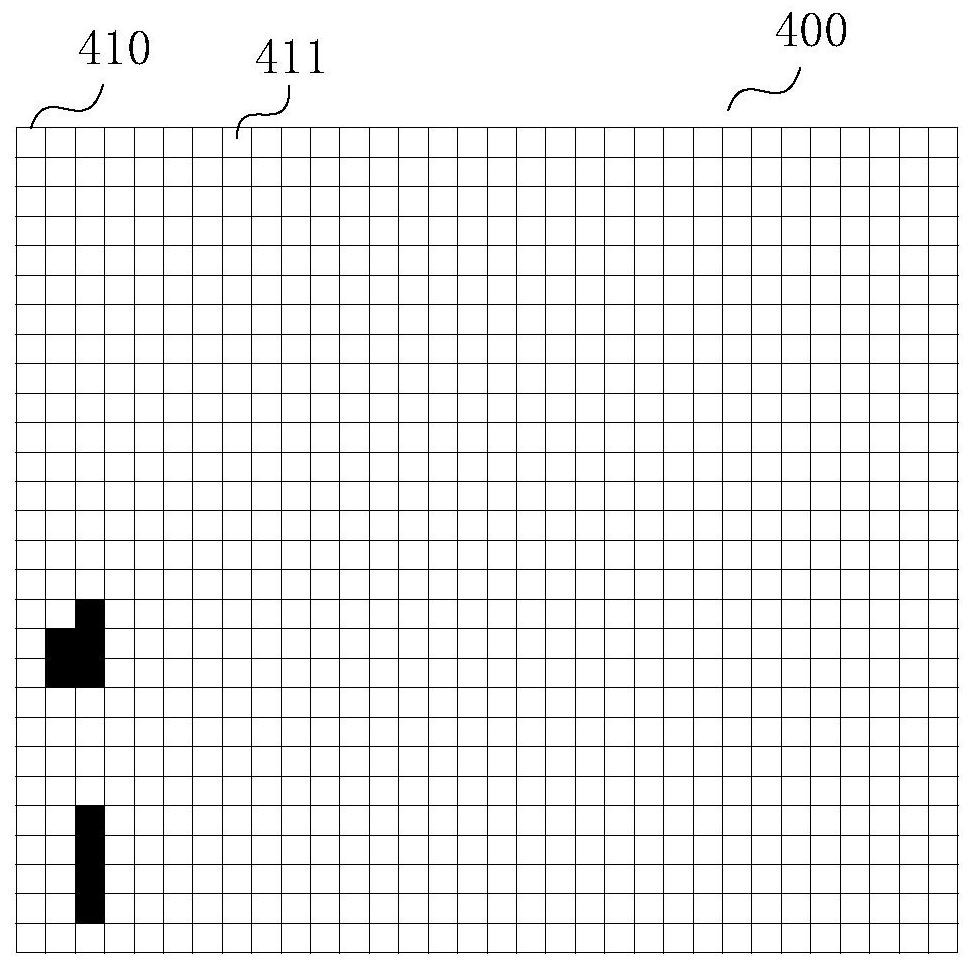

InactiveCN112433261AImprove intelligenceAccurately display the imaging situation of entering the elevatorOptical detectionAlarmsMonitoring systemEngineering

The invention discloses a scanning imaging monitoring system and method and an electric vehicle entering-ladder scanning imaging monitoring system. The scanning imaging monitoring system comprises a scanning module and a monitoring module, and the scanning module can be connected with an induction module; the scanning module is used for generating an image of an object or / and a person passing through a set area according to the data received by a receiving unit in each time interval point sensing module; the set area serves as an imaging area, the imaging area comprises a plurality of imagingsub-areas, and imaging of each imaging sub-area is determined according to a situation that each receiving mechanism receives data at a key time point; each imaging sub-area comprises a plurality of imaging unit areas, and each imaging unit area determines a color value according to the condition that the corresponding receiving mechanism receives data at at least one corresponding key time point;and the monitoring module is used for judging whether the set object or / and the person passes through the set area or not according to the scanning result of the scanning module. The object or / and the person entering and exiting the set area can be recognized, and the intelligence of the system is improved.

Owner:MOCHITEC SHANGHAI CO LTD

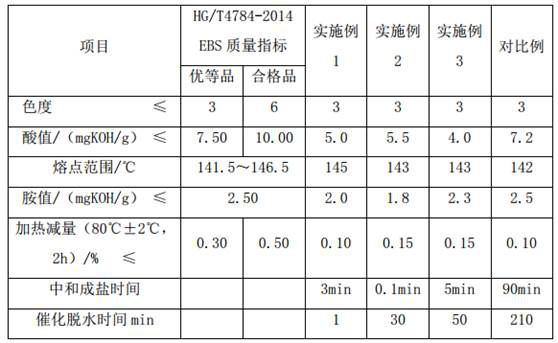

System for continuously preparing N, N'-ethylene bis stearamide through micro-channel and method thereof

ActiveCN111704556AHigh mass and heat transfer efficiencyImprove securityOrganic compound preparationCarboxylic acid amides preparationPtru catalystPhysical chemistry

The invention relates to a system for continuously preparing N, N'-ethylene bis stearamide. The system comprises a stearic acid melting tank, ethylenediamine storage tank, the stearic acid conveying and metering device and the ethylenediamine conveying and metering device are respectively connected with the stearic acid melting tank and the ethylenediamine storage tank; the neutralization and salification micro-reaction device is connected with the stearic acid conveying and metering device and the ethylenediamine conveying and metering device, and is sequentially connected with a catalytic dehydration device and a spray granulation device; and a catalytic dehydration device is connected with a catalyst antioxidant storage tank. The invention further provides a method for preparing N, N'-ethylene bis stearamide, continuous production of N, N'-ethylene bis stearamide is achieved through the micro-channel continuous reaction system with efficient mass and heat transfer performance, the automatic control level is high, the safety is high, the production cost is low, the product purity is high, and the quality is stable.

Owner:石家庄华复化工科技有限公司

Highly effective slurry phase bed reactor

InactiveCN1283349CEasy to operateAvoid easy cloggingChemical/physical processesGas solidSlurry reactor

Owner:TAIYUAN UNIV OF TECH

Multistage screening and sorting device for construction waste

ActiveCN111905925ARemoved in timeImprove screening efficiencySievingConstruction waste recoveryElectric machineMechanical engineering

The invention provides a construction waste multi-stage screening and sorting device, and the device comprises a box body, a hopper and supporting legs; a first conveyor is installed on the inner sideof the box body, a second conveyor is arranged at the top of the first conveyor, an electromagnet is installed on the inner side of the second conveyor, and a metal detector is installed on the innerside of the box body through bolts; a first motor is installed on one side of the metal detector, a guide rod is installed on the first motor, and a roller is installed at the bottom of the first conveyor. According to the invention, iron can be moved out in time, the screening efficiency is improved, balls can be effectively used for reducing friction force, and the safety of the second conveyorand an electromagnet is protected; a filter cartridge can be effectively and automatically cleaned, the filter cartridge can be effectively prevented from being blocked, dust can be effectively pressurized into blocks and cannot be blown up again by wind, air is prevented from being polluted again by the dust in the conveying and cleaning process, and the device is suitable for multi-stage screening and sorting of construction waste.

Owner:兰陵县冠东环保科技有限公司

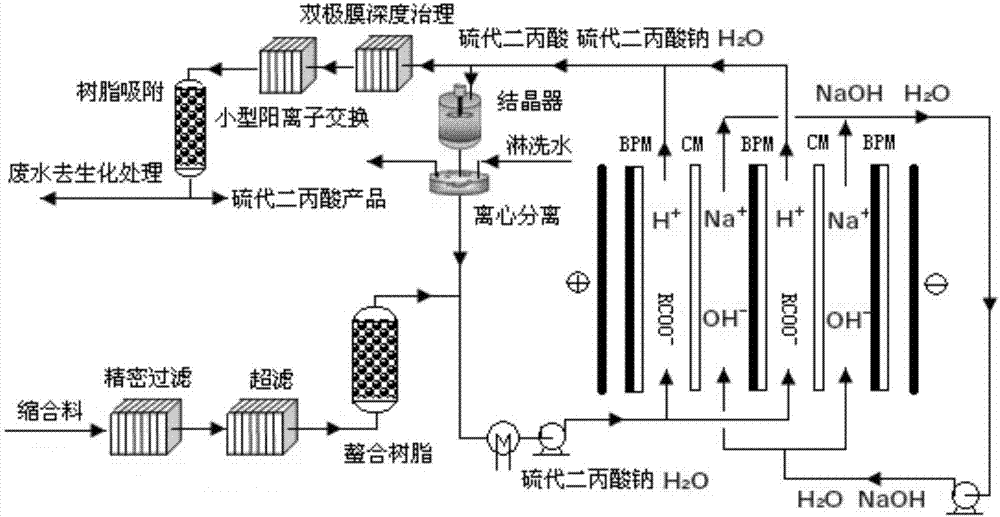

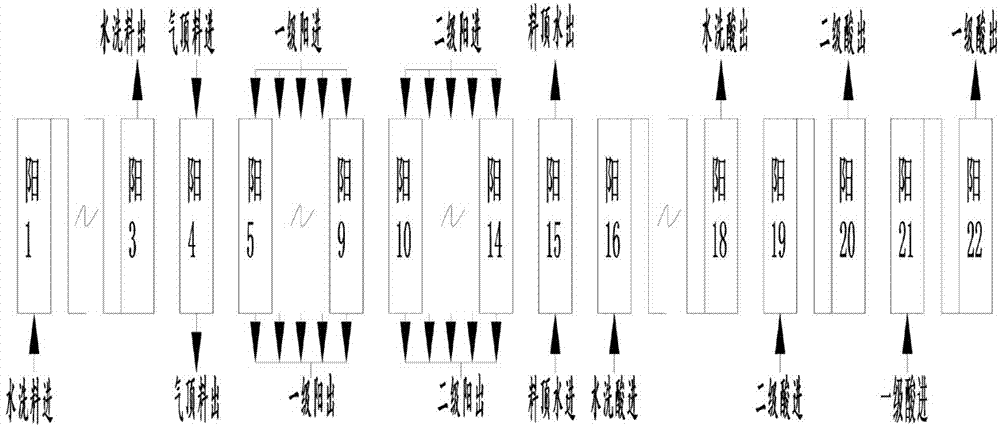

Method for producing thiodipropionic acid by bipolar membrane electrodialysis

InactiveCN107376650ANo generationImprove working environmentSemi-permeable membranesSulfide preparationSolid particleImpurity

A method for producing thiodipropionic acid by bipolar membrane electrodialysis is characterized in that sodium sulfide and acrylic acid are used as raw materials and undergo a condensation reaction, and sodium polyacrylate and solid particles are removed from a feed liquid (a main component is sodium thiodipropionate) obtained after completion of the condensation reaction by a high-speed centrifugal sedimentation technology; a condensed feed liquid obtained after visible impurities are removed passes through a filter unit and then passes through a salt chamber of a bipolar membrane electrodialysis device composed of a bipolar membrane and a cationic membrane; a low-concentration sodium hydroxide solution is introduced into an alkali chamber of the bipolar membrane electrodialysis device to guarantee passing of direct current, temperature in the salt chamber and the alkali chamber is maintained to be less than or equal to 35 DEG C, and the positive pole and the negative pole are respectively accessed to ''+'' and ''-'' direct current for electrodialysis; and with electrodialysis, pH value of the condensed feed liquid is gradually transitioned to 2-3, thiodipropionic acid is moved out of the salt chamber, thiodipropionic acid is refined and dried to obtain a product, and about 6% caustic soda aqueous solution is obtained in the alkali chamber.

Owner:天津力生化工有限公司

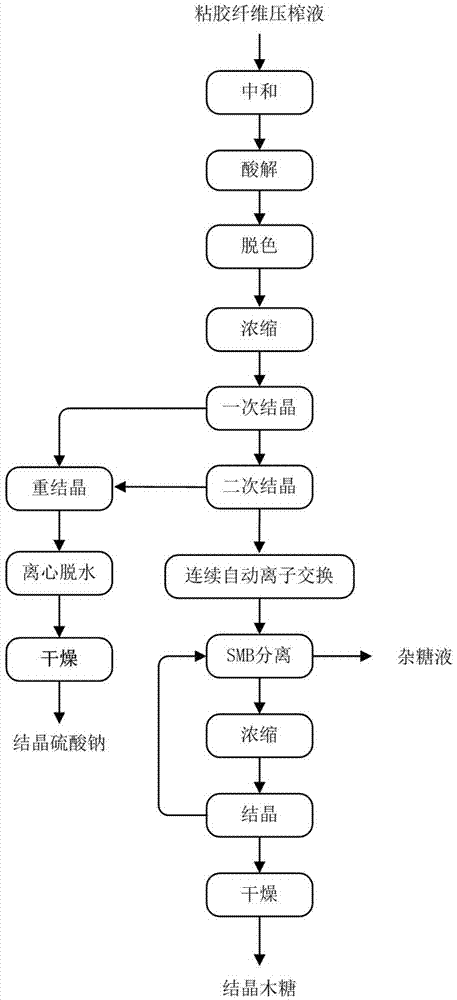

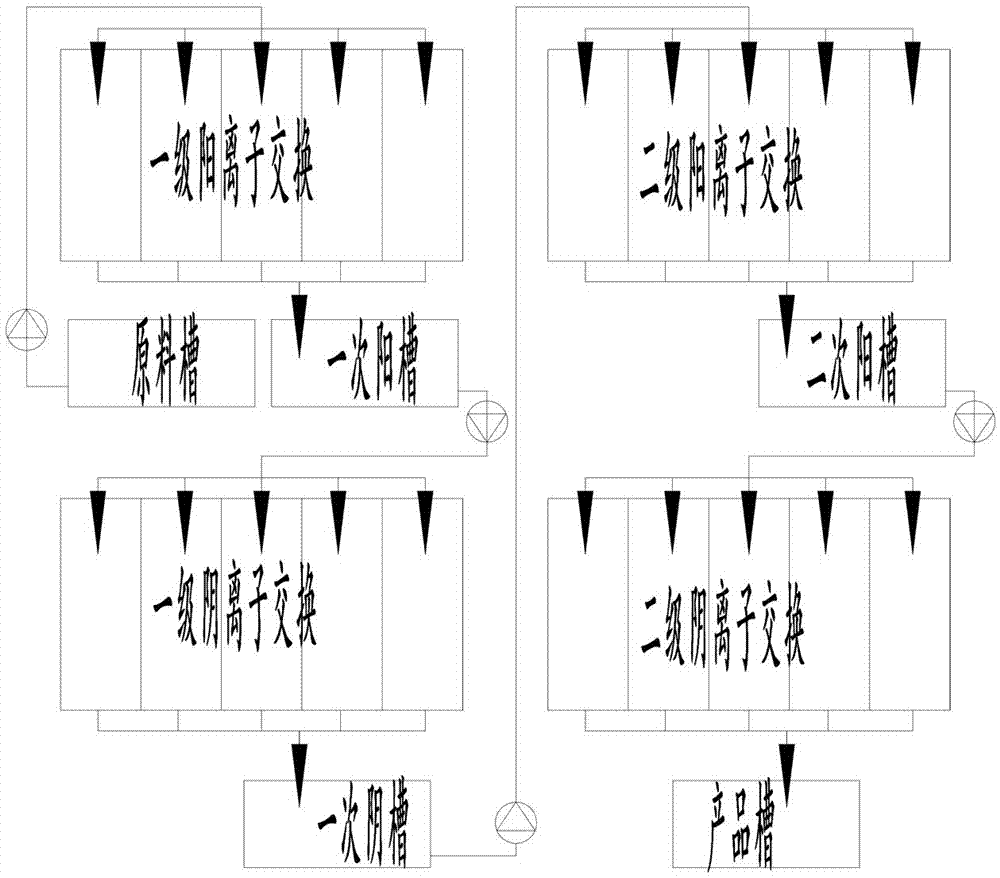

Method for preparation of xylose and co-production of sodium sulfate by employing viscose fiber squeeze liquid as raw material

InactiveCN106884059AGuaranteed uptimeRemoved in timeSodium sulfate recoveryAlkali metal sulfite/sulfate purificationChromatographic separationSimulated moving bed

The invention provides a method for preparation of xylose and co-production of sodium sulfate by employing a viscose fiber squeeze liquid as raw material. The method comprises the following processing processes: neutralizing the viscose fiber squeeze liquid by using sulfuric acid, carrying out acidolysis, decoloration and concentration, and removing ions through a crystallization process; carrying out primary crystallization to obtain sodium sulfate coarse crystal and a primary crystallization mother liquor; carrying out recrystallization on the primary crystallization mother liquor to obtain sodium sulfate coarse crystal and a secondary crystallization mother liquor; dissolving the sodium sulfate coarse crystal obtained through two times of crystallization, then carrying out recrystallization, centrifugal separation and drying to obtain a sodium sulfate crystal product; concentrating the secondary crystallization mother liquor, removing the ions through a continuous automatic ion exchange method and then separating and purifying xylose by using a simulated moving bed chromatographic separation device to obtain a xylose solution and a hybrid syrup solution; and carrying out concentrating, crystallization, centrifugal separation and drying on the xylose solution to obtain a xylose crystal product.

Owner:南京凯通粮食生化研究设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com