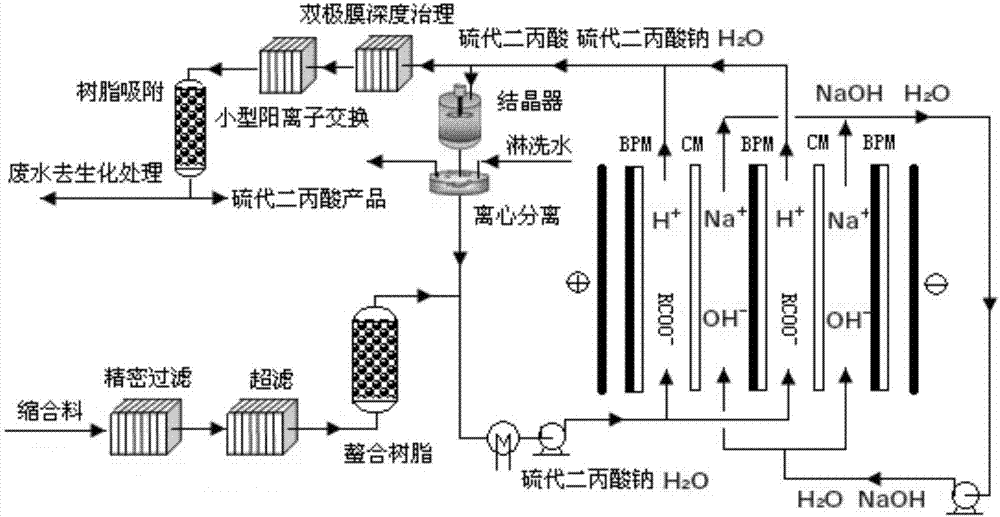

Method for producing thiodipropionic acid by bipolar membrane electrodialysis

A technology of bipolar membrane electrodialysis and thiodipropionic acid, applied in chemical instruments and methods, membrane technology, sulfide preparation, etc., can solve problems such as serious odor, hydrogen sulfide procurement, transportation, and use problems, and achieve The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add sodium sulfide aqueous solution into the reaction kettle, add acrylic acid dropwise according to the ratio of sodium sulfide:acrylic acid molar ratio of 1:2.1, the reaction temperature is 70-80°C, react for 2 hours, and the crude product yield of thiodipropionic acid is 90%. , to obtain the thiodipropionic acid condensation feed liquid, the condensation feed liquid is sent to the high-speed centrifugal sedimentation unit to remove the polymer and mechanical impurities through the delivery pump, and then the sodium polyacrylate is further removed through precision filtration and ultrafiltration, and the chelating resin processing unit Remove high-valent metal ions, pass the condensation feed solution after removing impurities into the salt chamber of the bipolar membrane electrodialysis device; ~0.5%) to ensure the passage of direct current and keep the temperature in the salt chamber and alkali chamber ≤35°C. Connect the anode and cathode respectively to the "+" and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com