Patents

Literature

37 results about "3-methyl-2-buten-1-ol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3-methyl-2-buten-1-ol; 3-methylbut-2-en-1-ol; prenol; from MeSH. Depositor-Supplied Synonyms. Chemical names and identifiers provided by individual data contributors and associated to PubChem Substance records. Synonyms of Substances corresponding to a PubChem Compound record are combined.

Production method of C5 enol

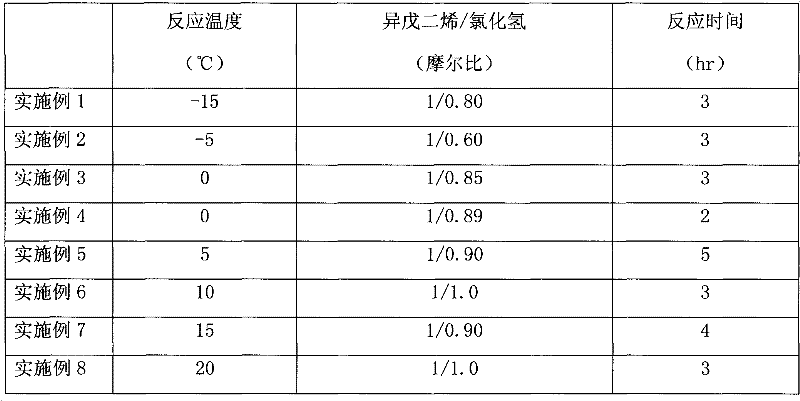

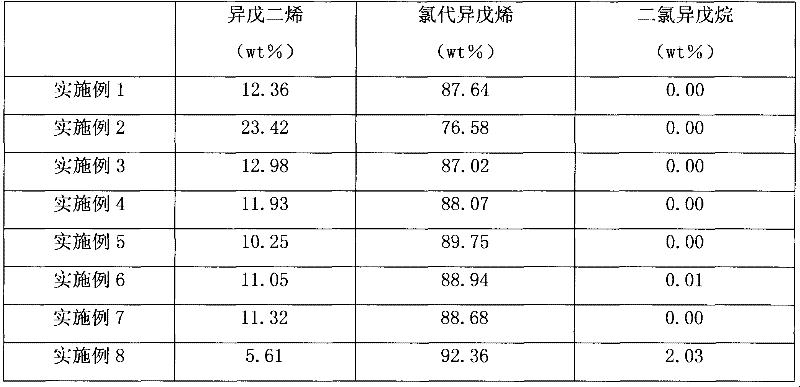

InactiveCN102381940AInhibit side effectsSimple processPreparation by hydrolysis2-methylbutaneOil phase

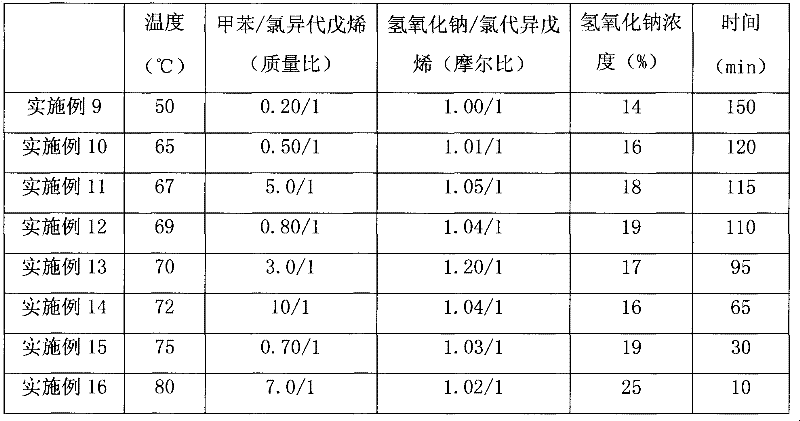

The invention relates to a production method of a C5 enol. The production method uses isoprene and hydrogen chloride as raw materials and comprises the following steps: 1) performing addition reaction on isoprene and hydrogen chloride to generate a mixture of 1-chloro-isopentene and 3-chloro-isopentene; and 2) performing a hydrolysis reaction on the product of the addition reaction, adding one or more of toluene, ethylbenzene, n-hexane, cyclohexane, 2-methylpentane, 3-methylpentane, 2,2-dimethylbutane, 2,3-dimethylbutane and heptane as the solvent in the hydrolysis process, separating out the oil phase product after the hydrolysis, and rectifying to obtain products, namely methylbutenol and 3-methyl-2-buten-1-ol. Compared with the C5 enol production process of the prior art, the side reaction, in which dichloro-isopentane is generated, in the addition reaction process is effectively inhibited; after the solvent is added in the hydrolysis reaction, the yield of the hydrolysis reaction can be increased and the purification of the product can be facilitated; the yields of the addition reaction and the hydrolysis reaction are both more than 98% and are obviously increased as compared with the prior art; and the production cost is greatly reduced.

Owner:赵明江

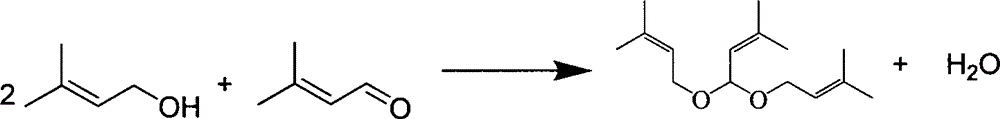

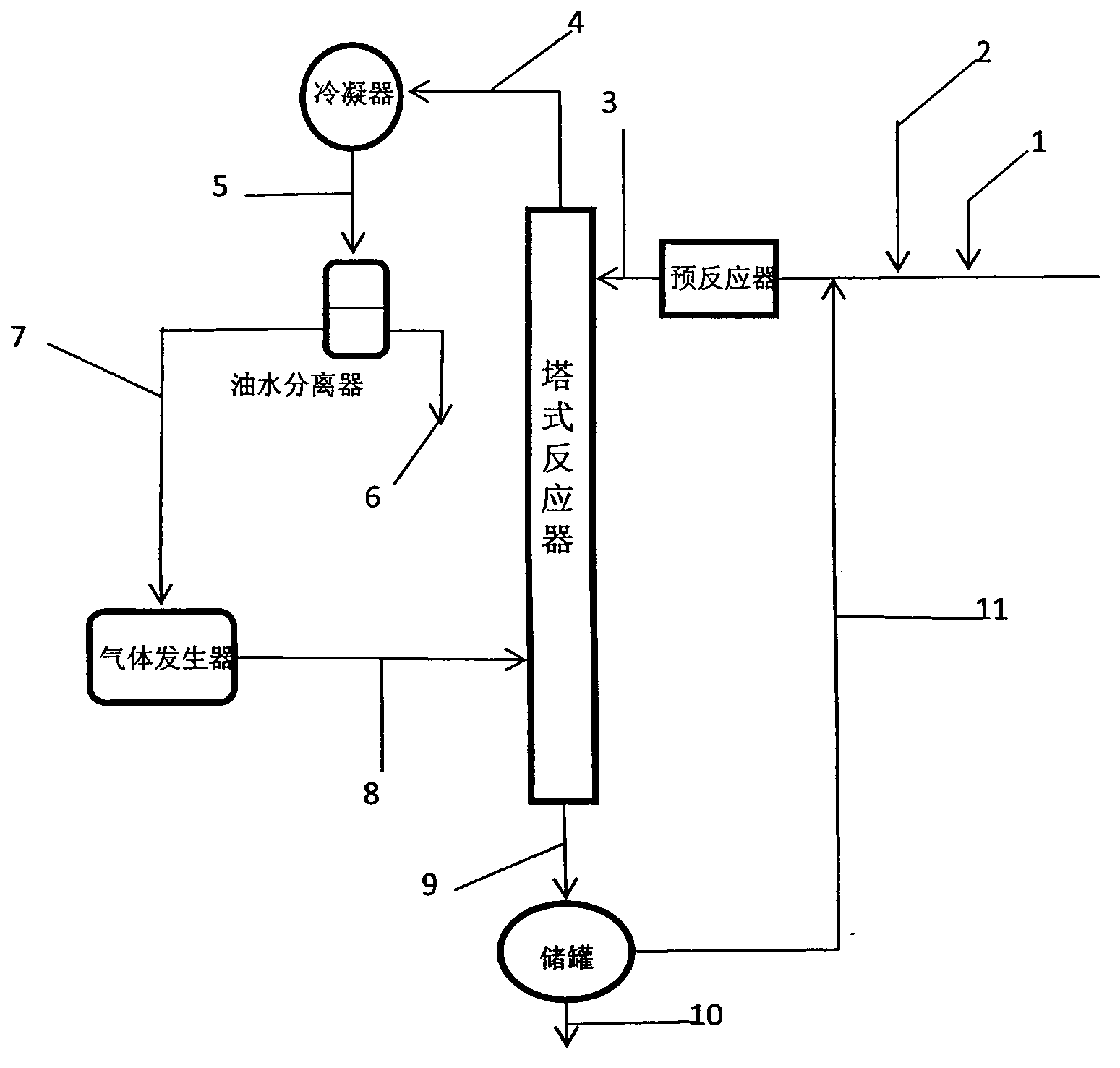

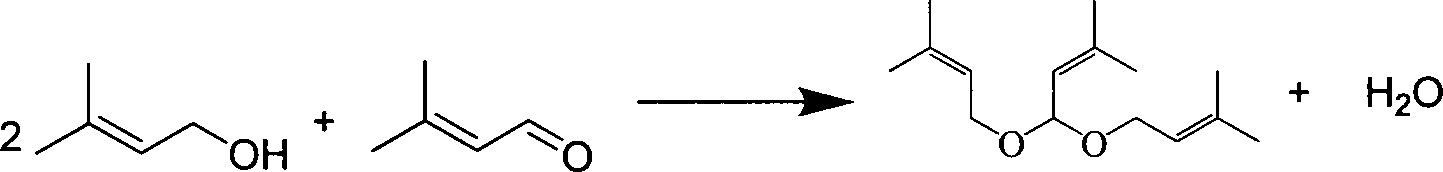

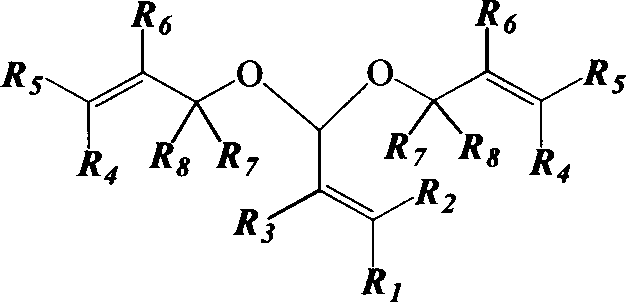

Unsaturated acetal preparation method

ActiveCN102942460AEvenly distributedSmooth responseOrganic chemistryOrganic compound preparationButene3-methyl-2-buten-1-ol

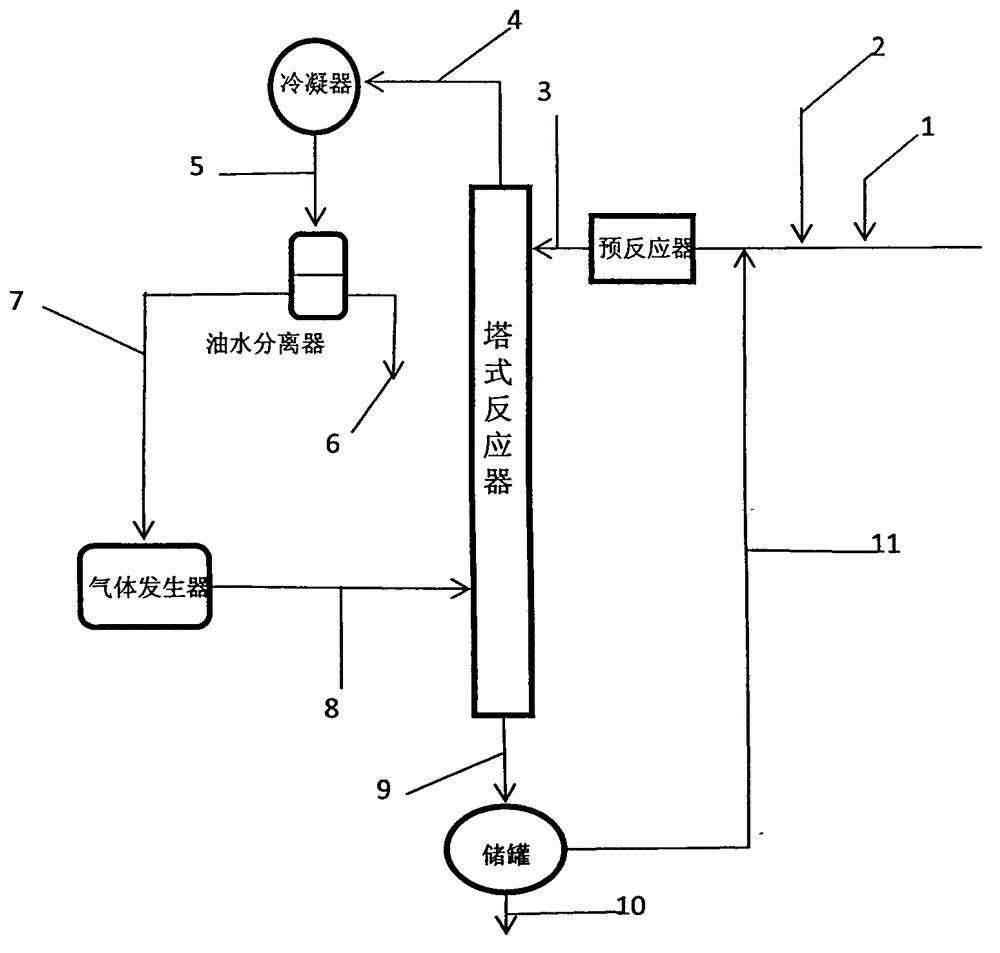

The present invention discloses an unsaturated acetal preparation method. According to the preparation method, an unsaturated alcohol and an unsaturated aldehyde are subjected to a reaction in a pre-reactor to achieve a thermodynamic equilibrium, and then enter a tower type reactor, a water carrying agent is subjected to gasification through a gas generator, and then is subjected to reverse contact with a reaction liquid, and the water generated from the reaction is removed, such that the unsaturated alcohol and the unsaturated aldehyde are subjected to a continuous condensation reaction to prepare the unsaturated acetal. The preparation method has the following characteristics that: the method can be performed under a normal pressure condition, the reaction temperature is constant, low cost synthesis of the unsaturated acetal can be achieved, particularly 3-methyl-2-buten-1-ol and 3-methyl-2-butenal can be adopted as raw materials to synthesize 3-methyl-2-butenal-1 diisopentenyl acetal, wherein the compound is an important intermediate of a synthetic perfume citral.

Owner:WANHUA CHEM GRP CO LTD +1

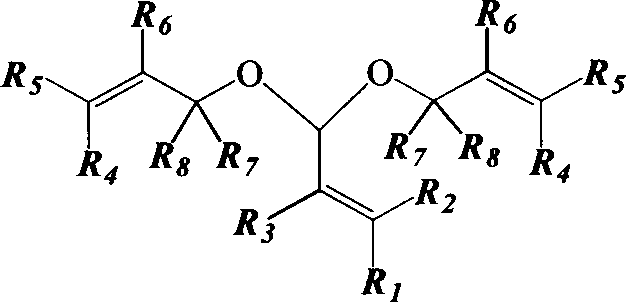

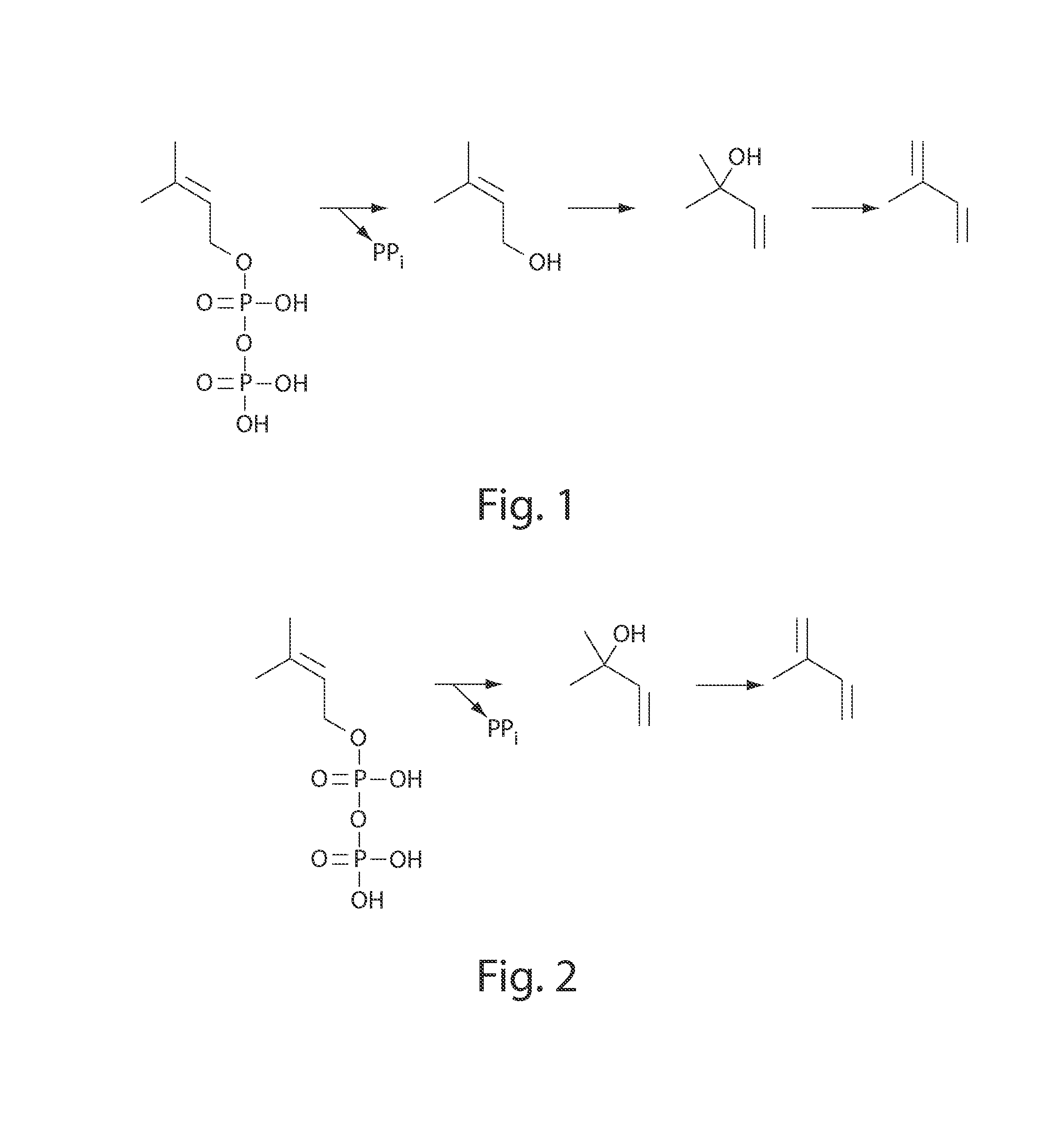

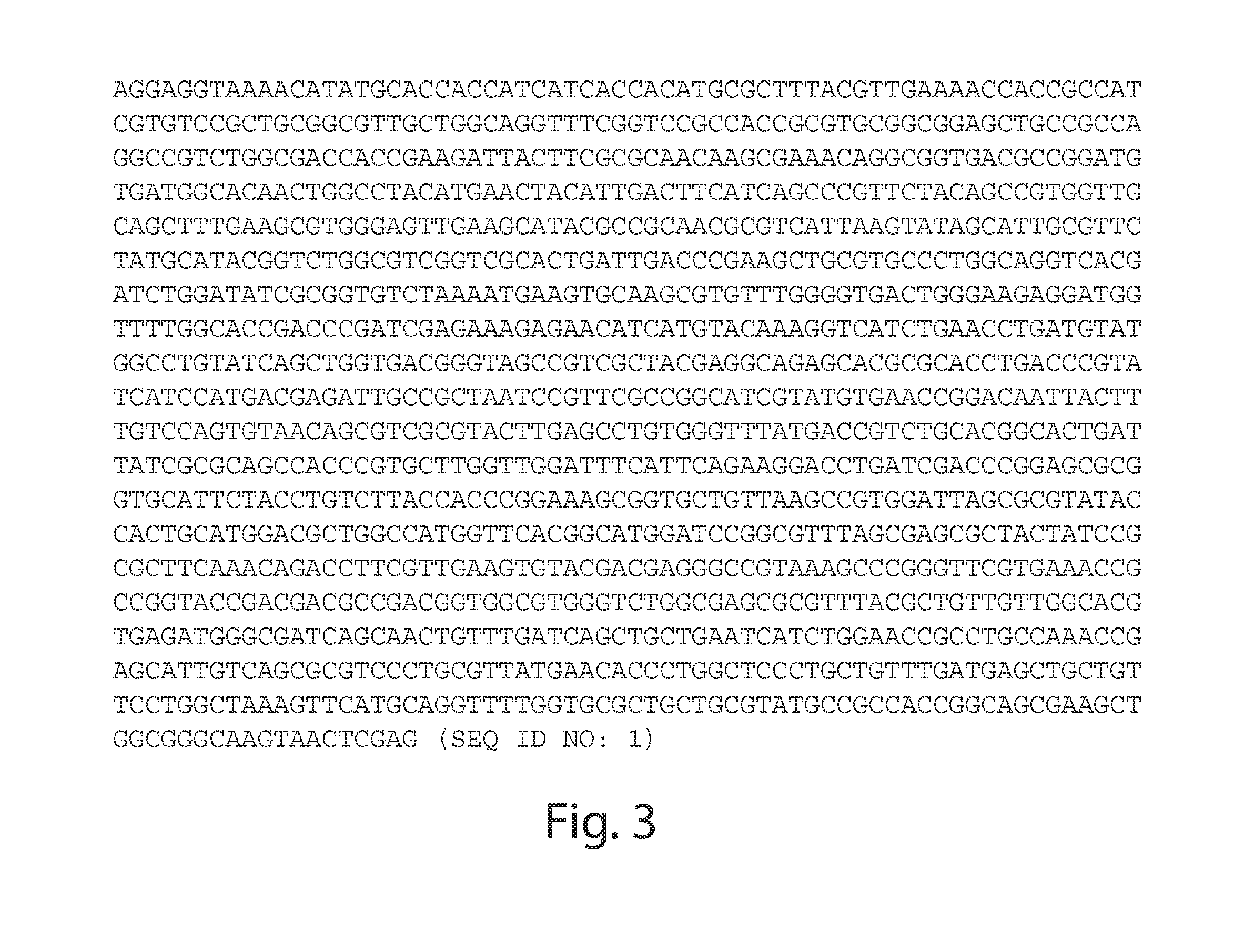

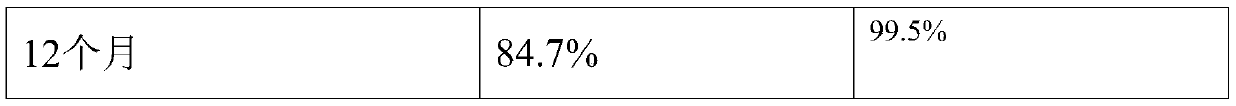

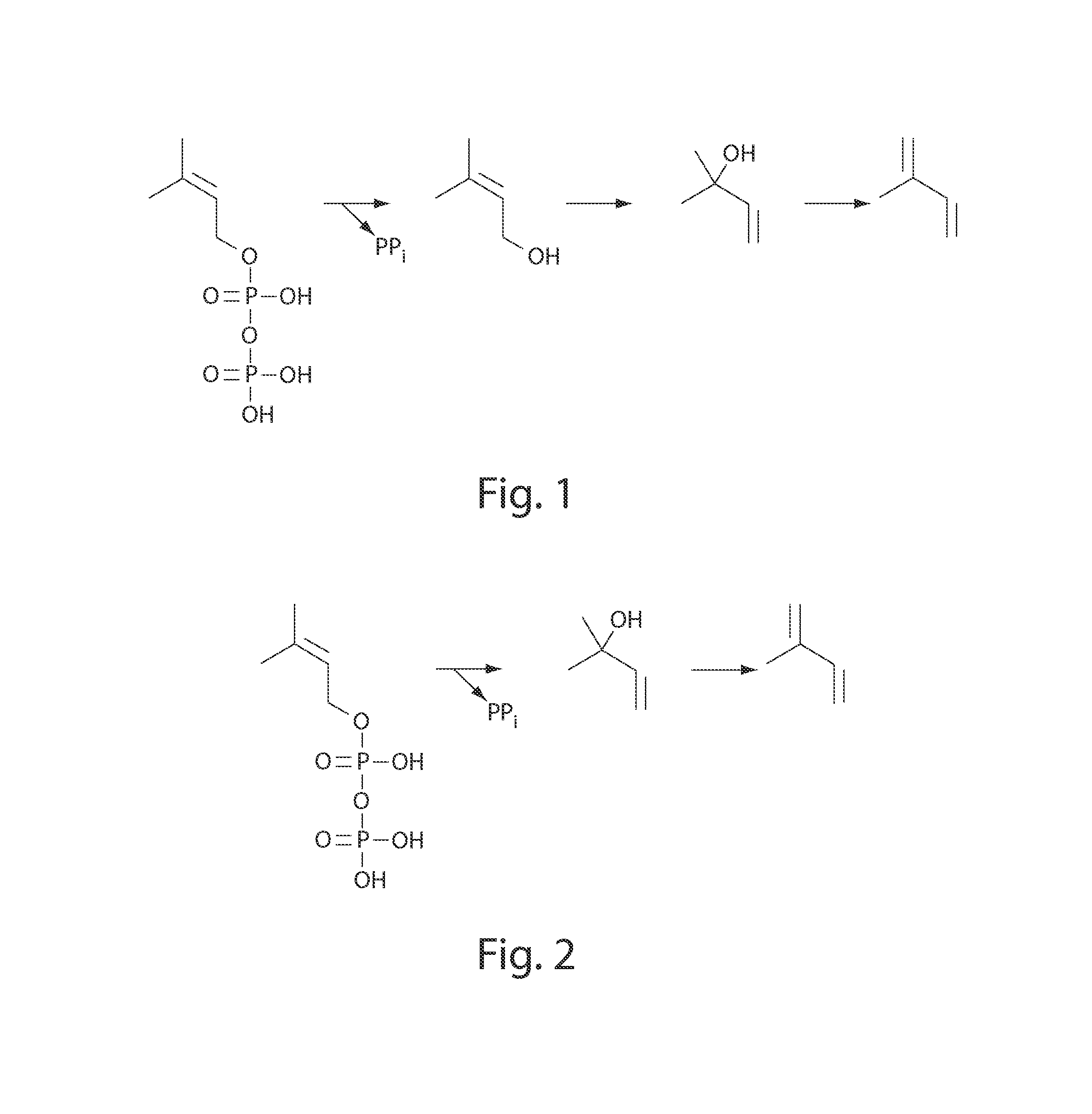

Microorganisms and processes for the production of isoprene

The present invention provides a novel biosynthetic pathway for the production of isoprene from 3-methyl-2-buten-1-ol or 2-methyl-3-buten-2-ol. Further embodiments provide non-naturally occurring microorganism that have been modified to produce isoprene from 3-methyl-2-buten-1-ol or 2-methyl-3-buten-2-ol and methods of producing isoprene using said microorganism.

Owner:GLYCOS BIOTECH

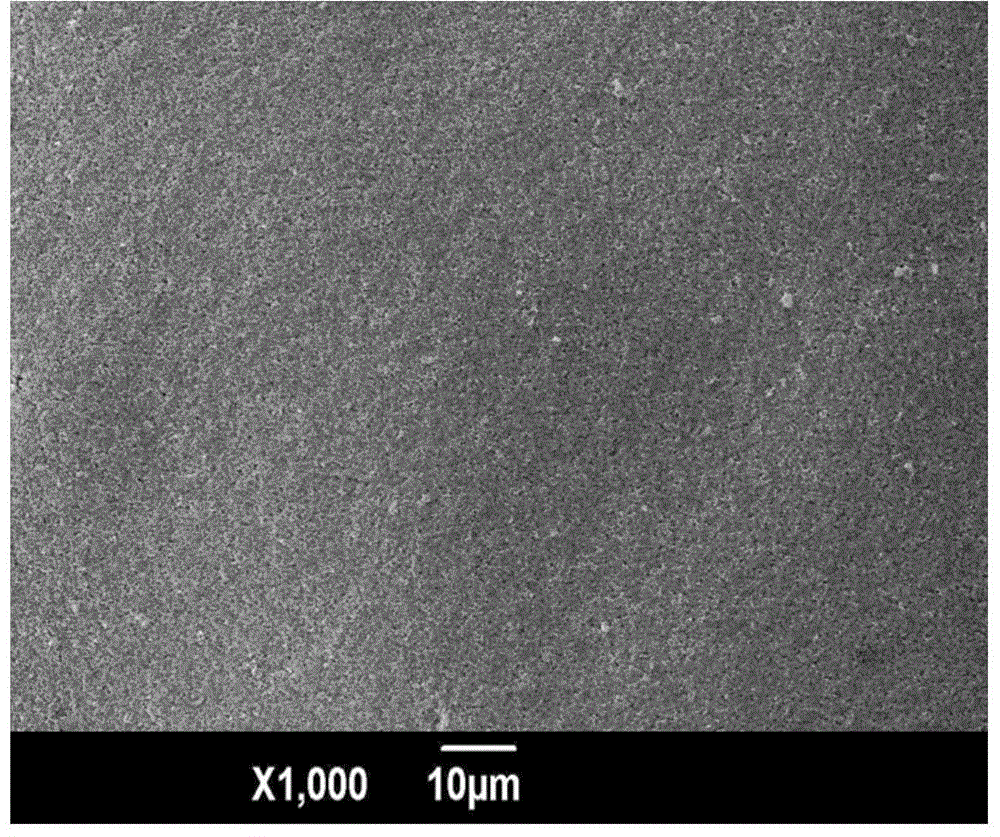

Preparation method of carbon/carbon composite material HfB2 anti-oxidation outer coating

ActiveCN103601533AHigh bonding strengthOptimal Control StructureCarbon compositesOxidation resistant

The invention provides a preparation method of a carbon / carbon composite material HfB2 anti-oxidation outer coating. The preparation method comprises the following steps of dispersing HfB2 powder in 3-methyl-2-buten-1-ol, performing ultrasonic oscillation and stirring to obtain a suspension A; adding an iodine elementary substance into the suspension A, performing ultrasonic oscillation and stirring to obtain a solution B; pouring the solution B into a device which takes a graphite electrode as an anode, takes a conductive matrix as a cathode, fixes the cathode on a rotating body and can rotate under the drive of a motor, wherein the cathode and anode of the device are connected with two corresponding electrodes of a constant-current power supply; then clamping a C / C composite material test sample with a SiC inner coating on the cathode in the device, placing the device into a constant-temperature oven, and closing the power supply of the device and the oven after the end of the reaction; opening the device, taking out the test sample and then drying to obtain the carbon / carbon composite material HfB2 anti-oxidation outer coating. The carbon / carbon composite material HfB2 anti-oxidation outer coating has no cracks on the surface and great bonding strength of the coating; the process is simple, raw materials are easy to obtain, and the preparation cost is relatively low.

Owner:SHAANXI UNIV OF SCI & TECH

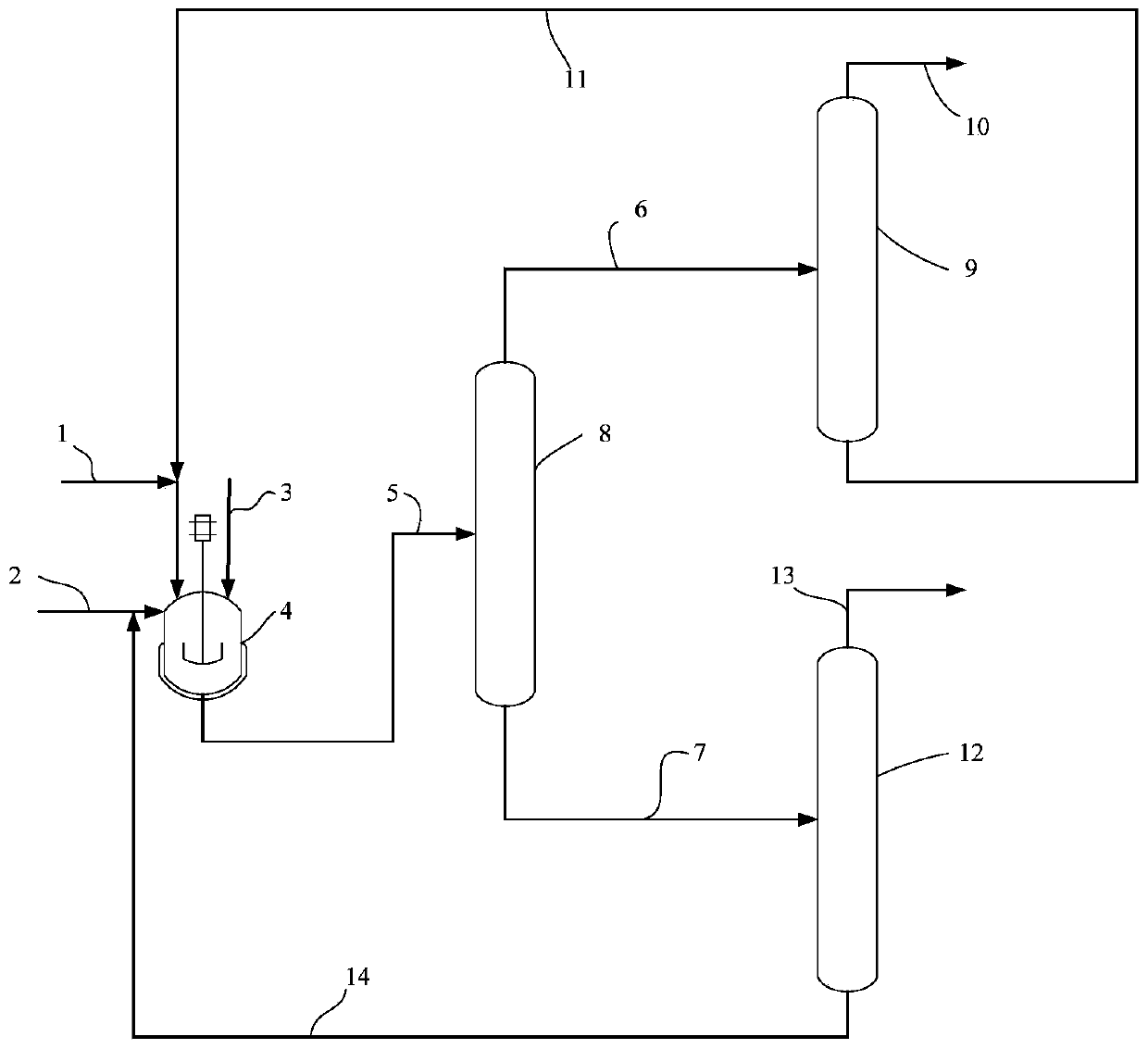

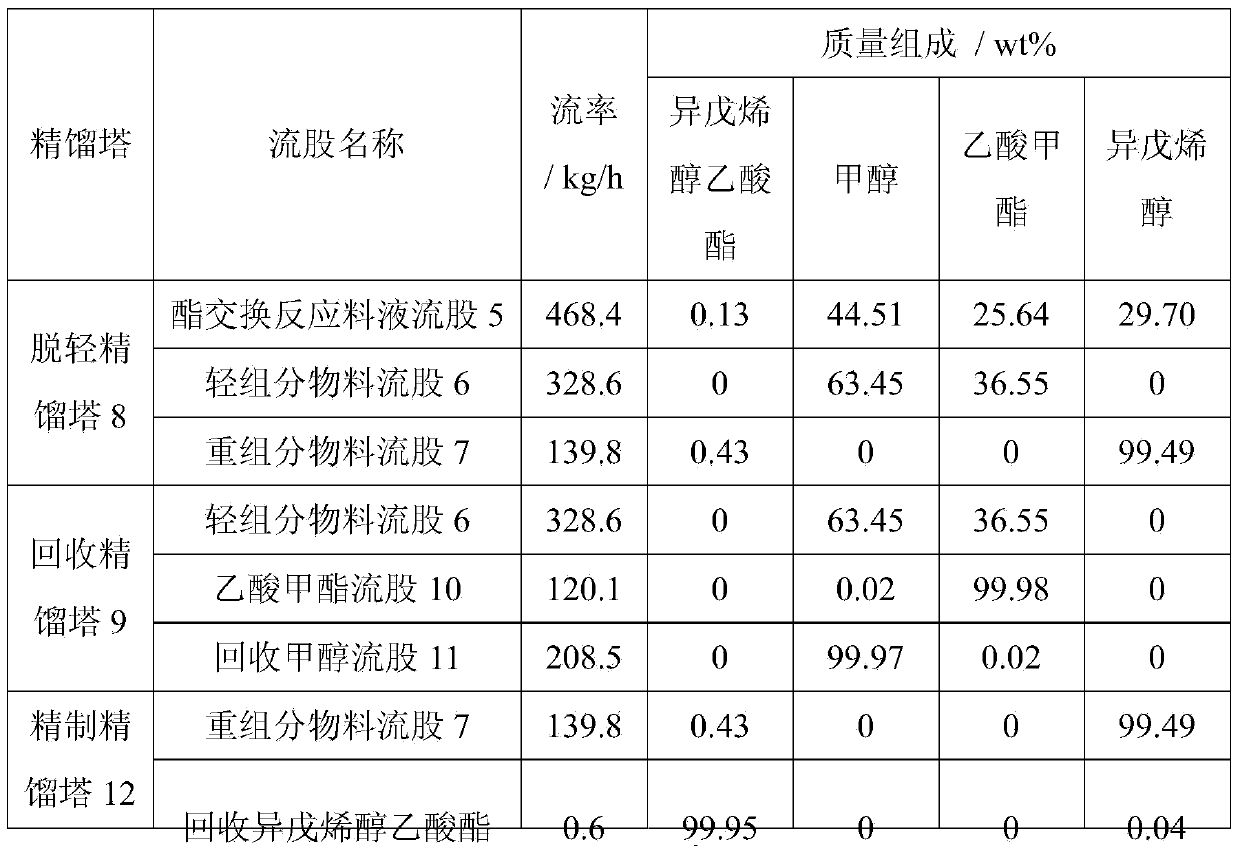

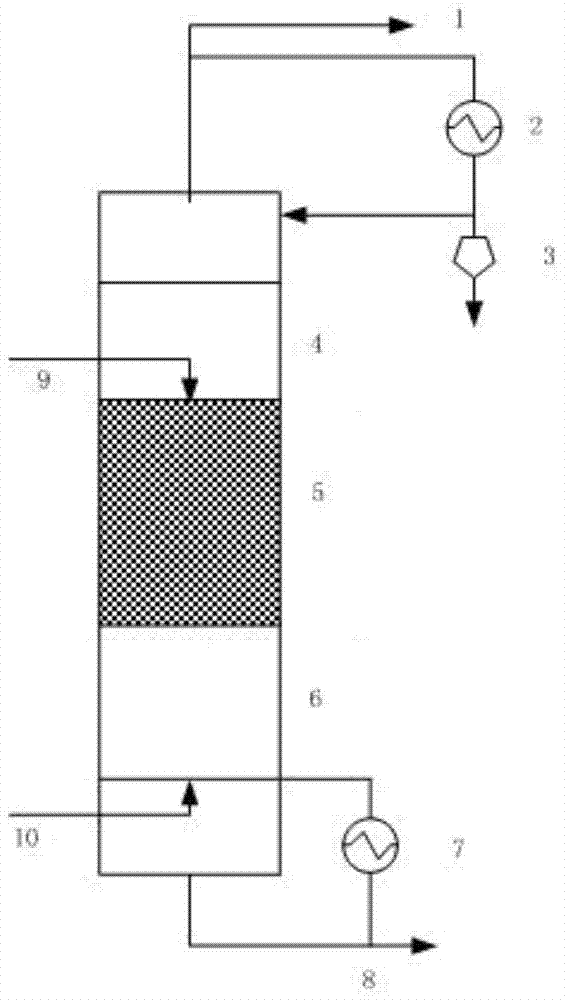

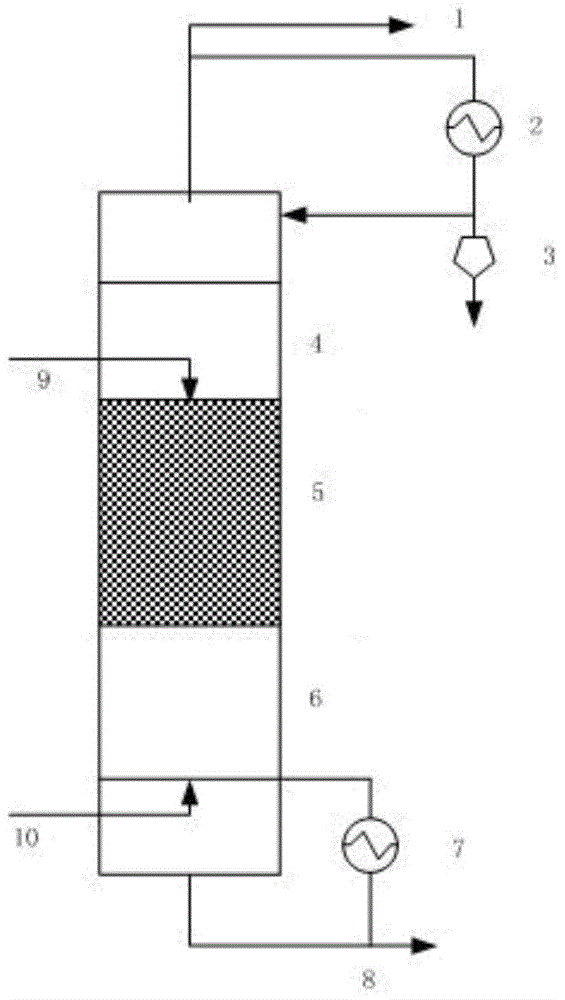

Method and system for preparing 3-methyl-2-buten-1-ol through ester exchange

ActiveCN103992206AEasy to separate and recycleEasy to recycleOxygen-containing compound preparationPreparation by ester-hydroxy reaction3-methyl-2-buten-1-olSolvent free

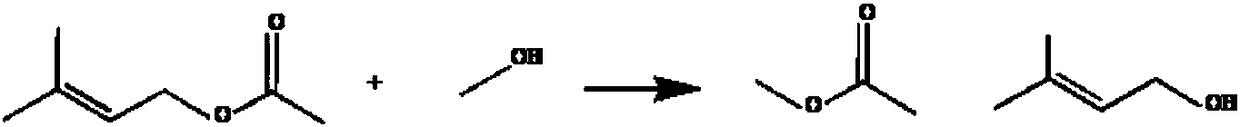

The invention relates to a method and a system for preparing 3-methyl-2-buten-1-ol through ester exchange. According to the method, solvent-free heterogeneous catalysis ester exchange reaction is carried out on 3-methyl-2-buten-1-ol acetic acid ester and methyl alcohol used as raw materials under the catalytic action of solid alkali or strongly alkaline anion exchange resin so as to obtain 3-methyl-2-buten-1-ol and methyl acetate, and after purification, the unreacted methyl alcohol and the unreacted 3-methyl-2-buten-1-ol acetic acid ester can be recycled. The method has the characteristics that the catalyst is easy to separate, recycle and reuse, no three wastes (waste gas, industrial wastewater and industrial residue) are generated, the yield of the 3-methyl-2-buten-1-ol product is high, and the like.

Owner:NANJING UNIV OF TECH

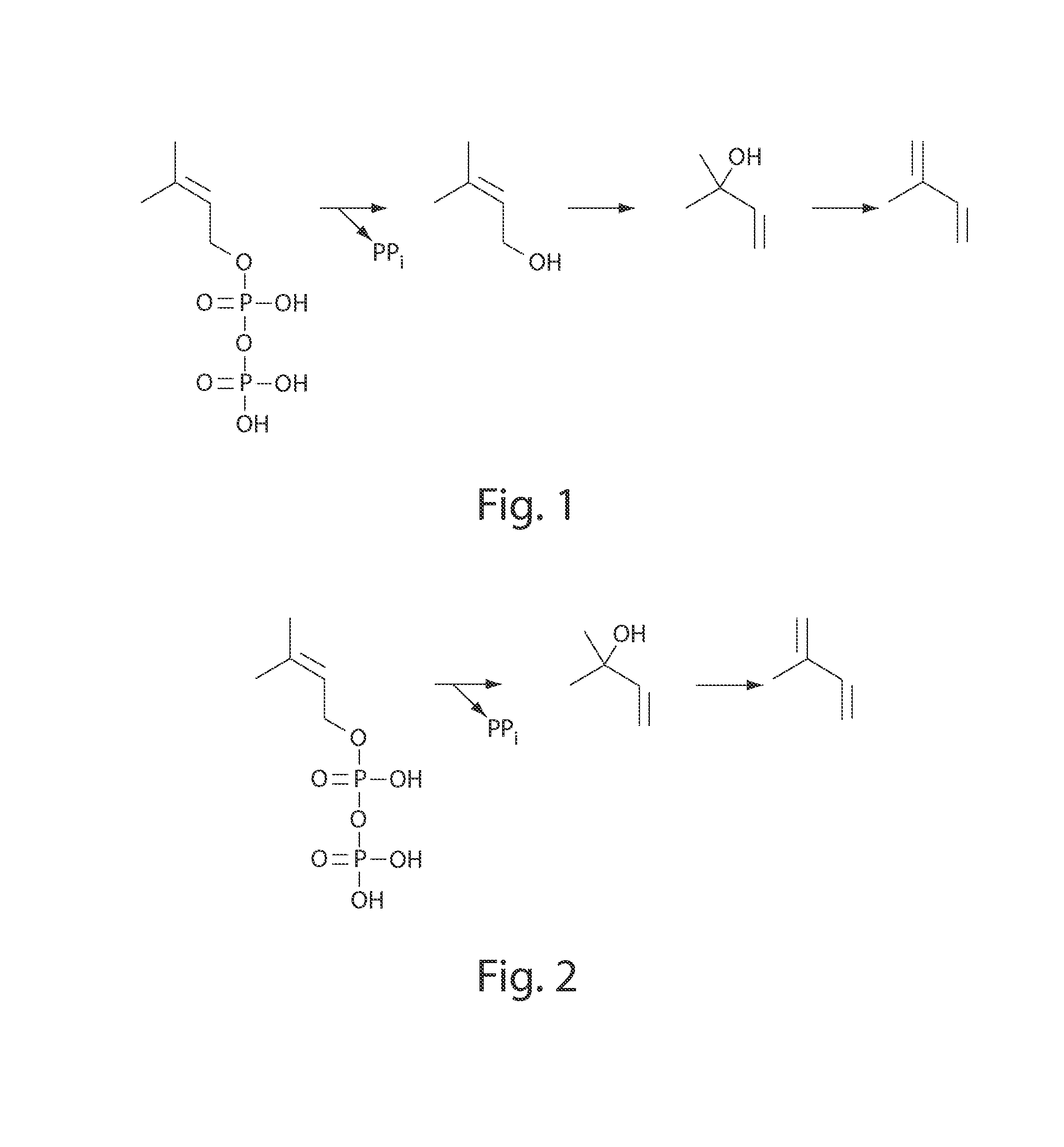

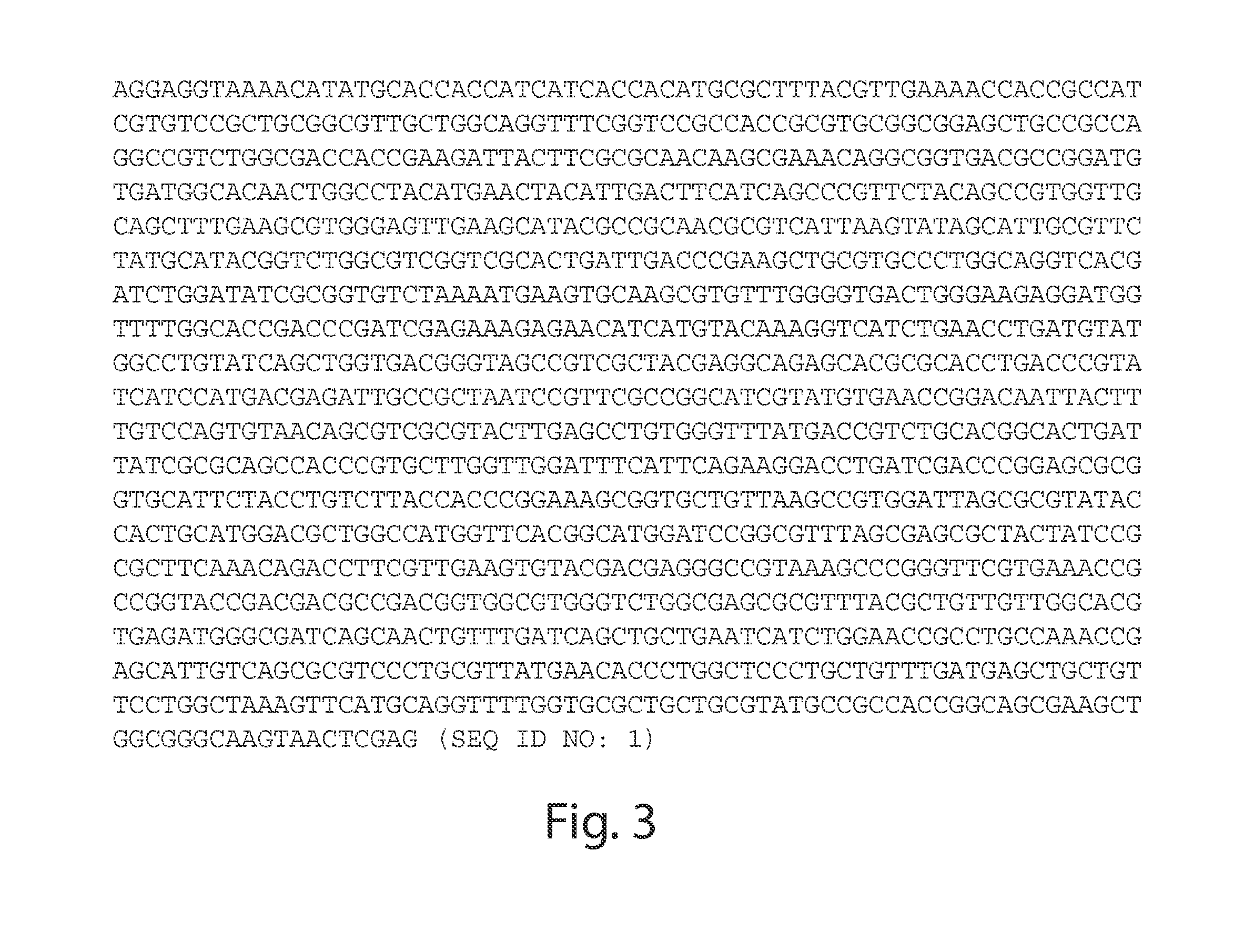

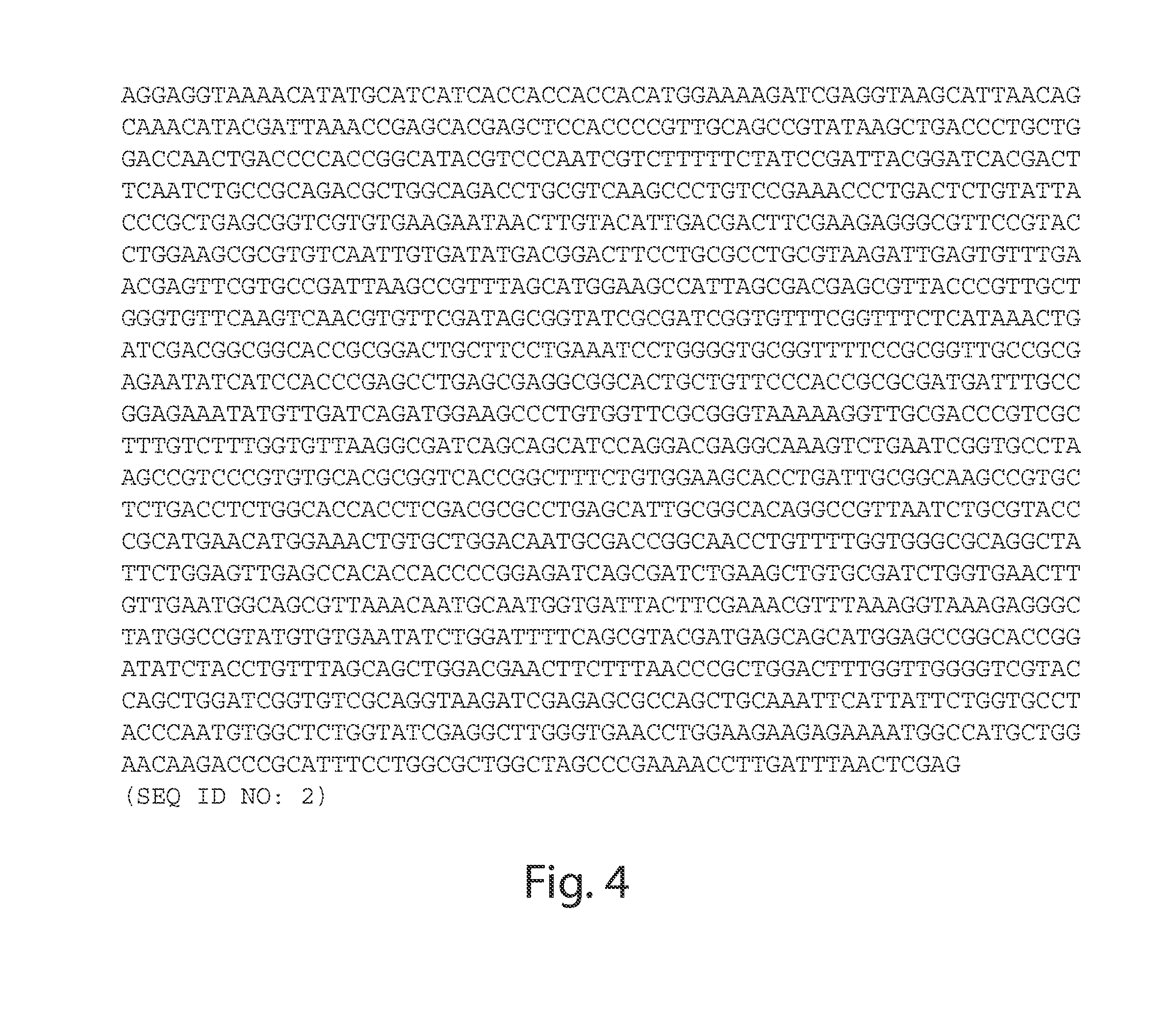

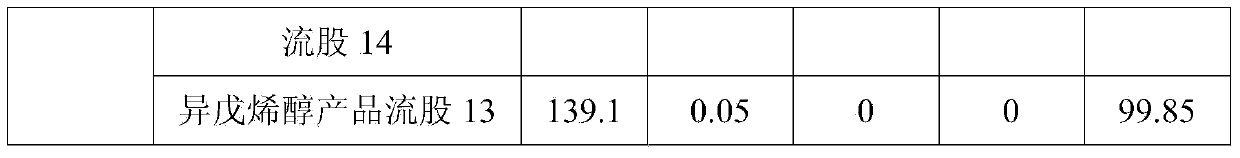

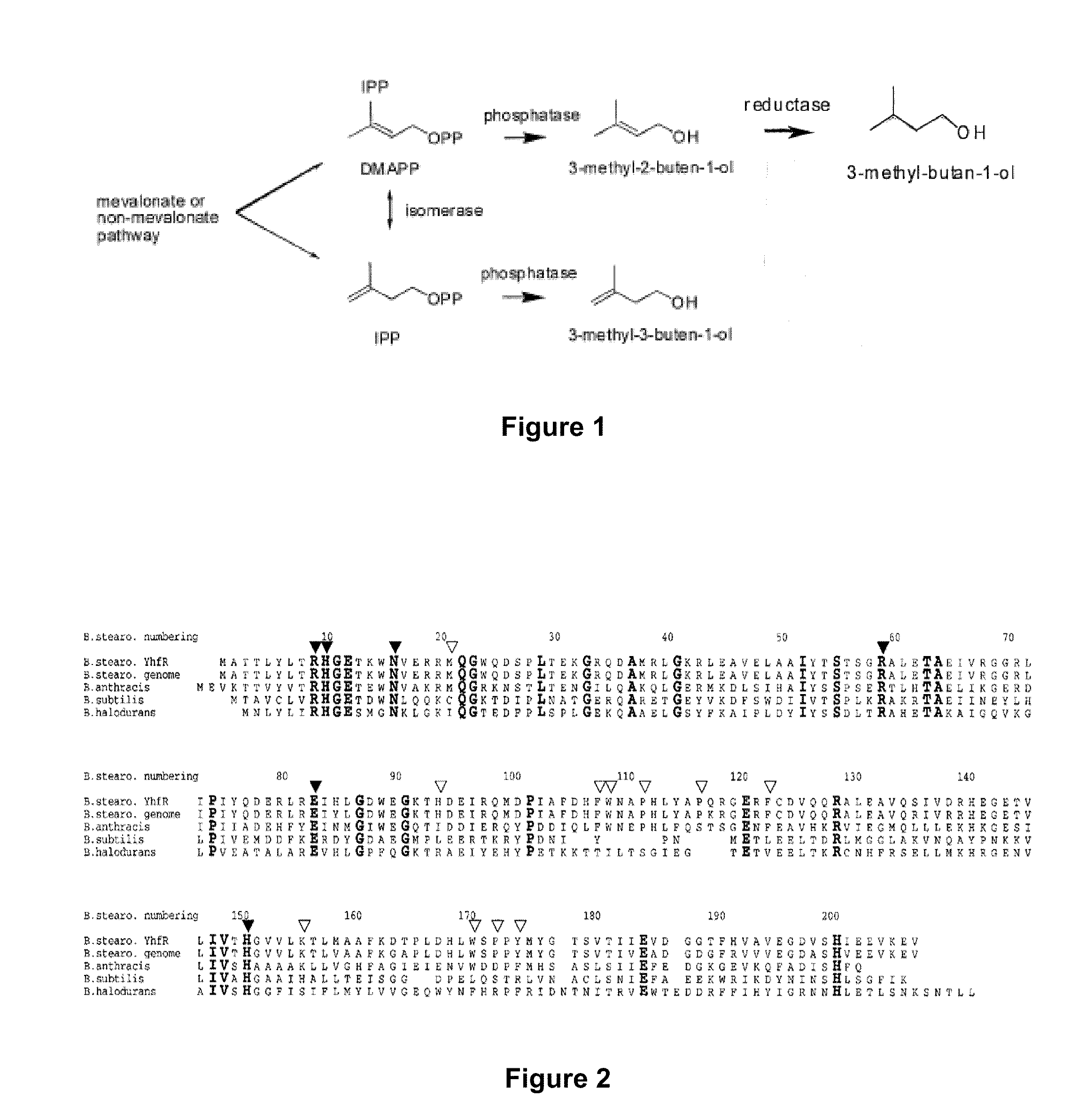

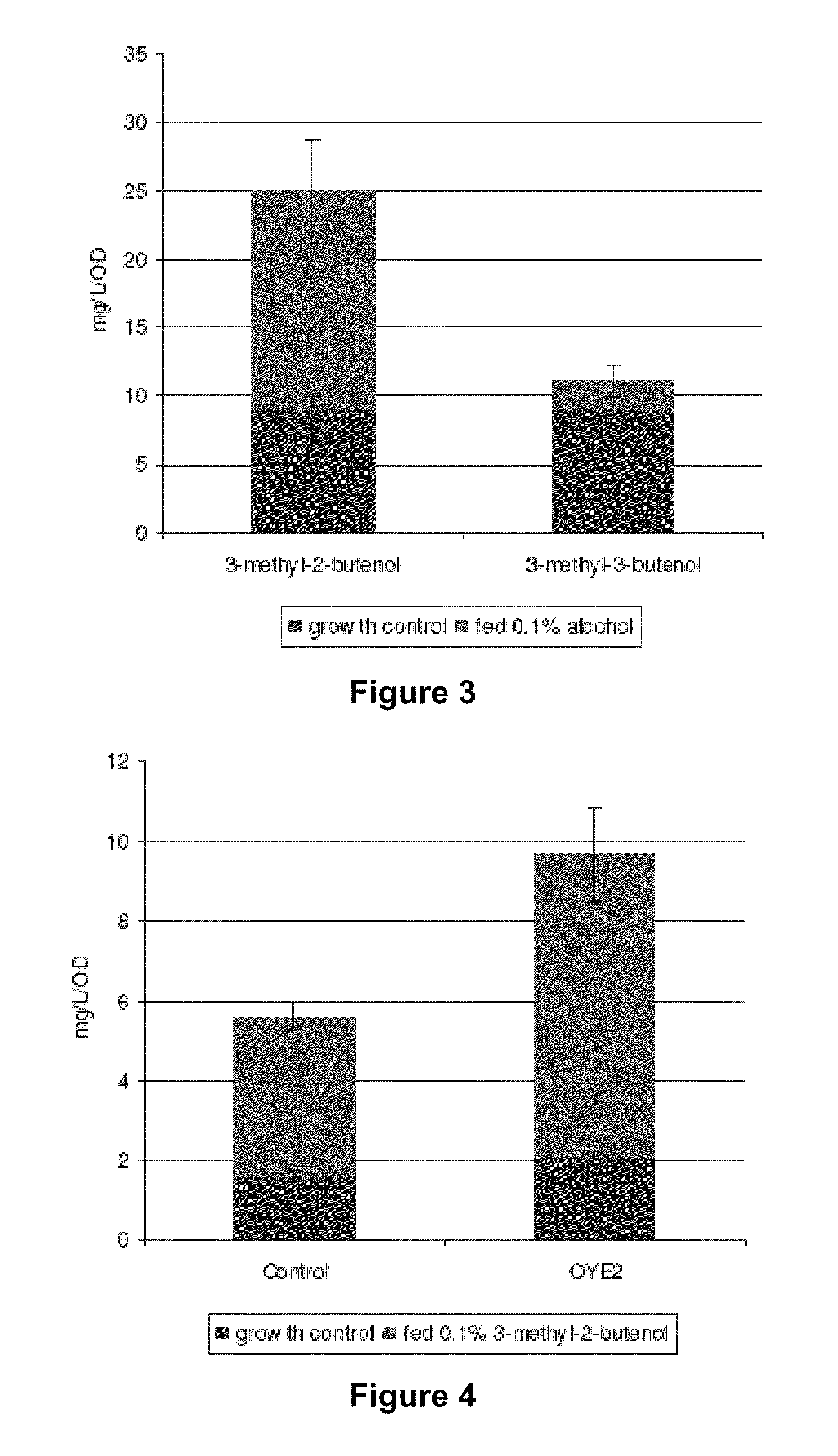

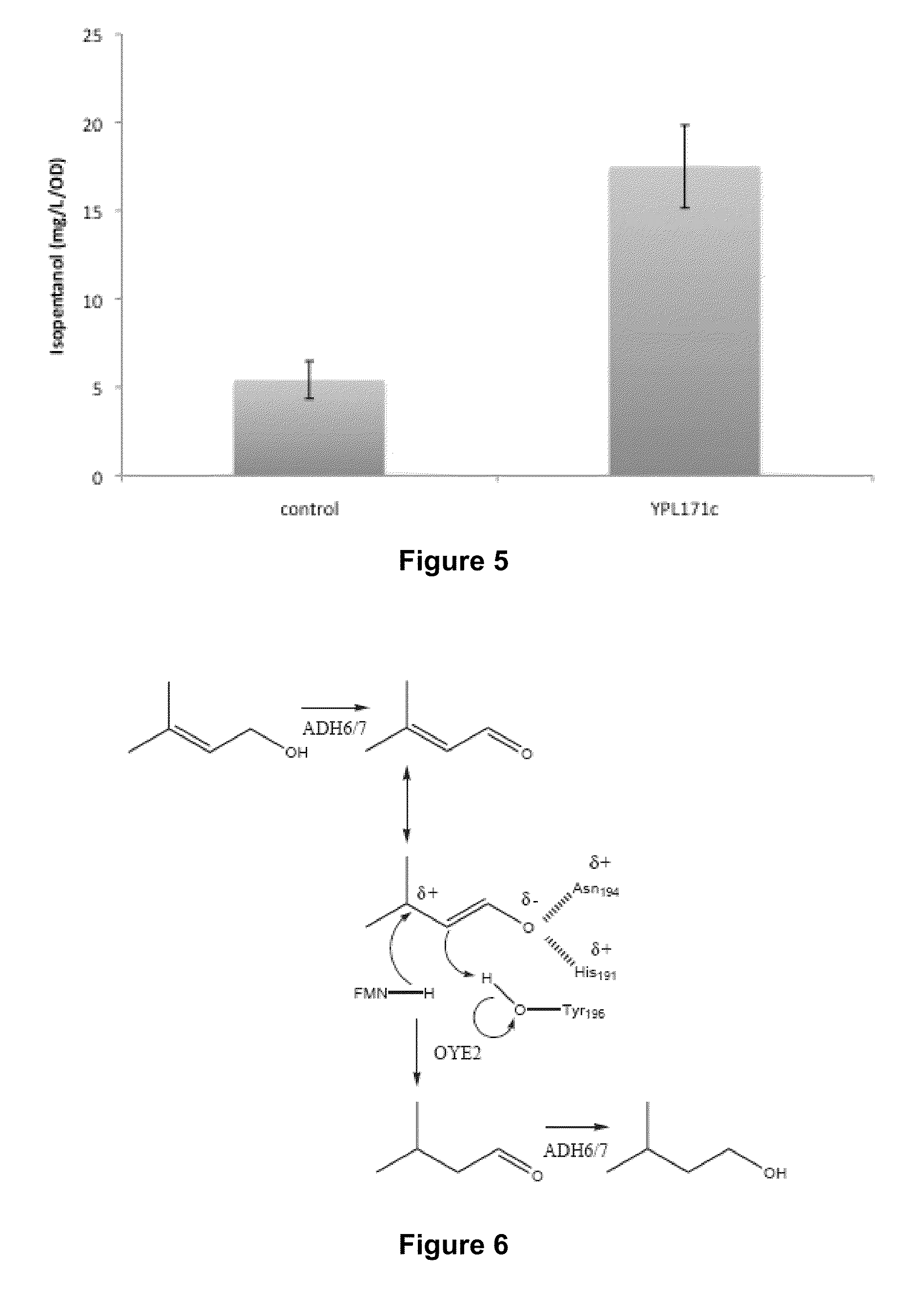

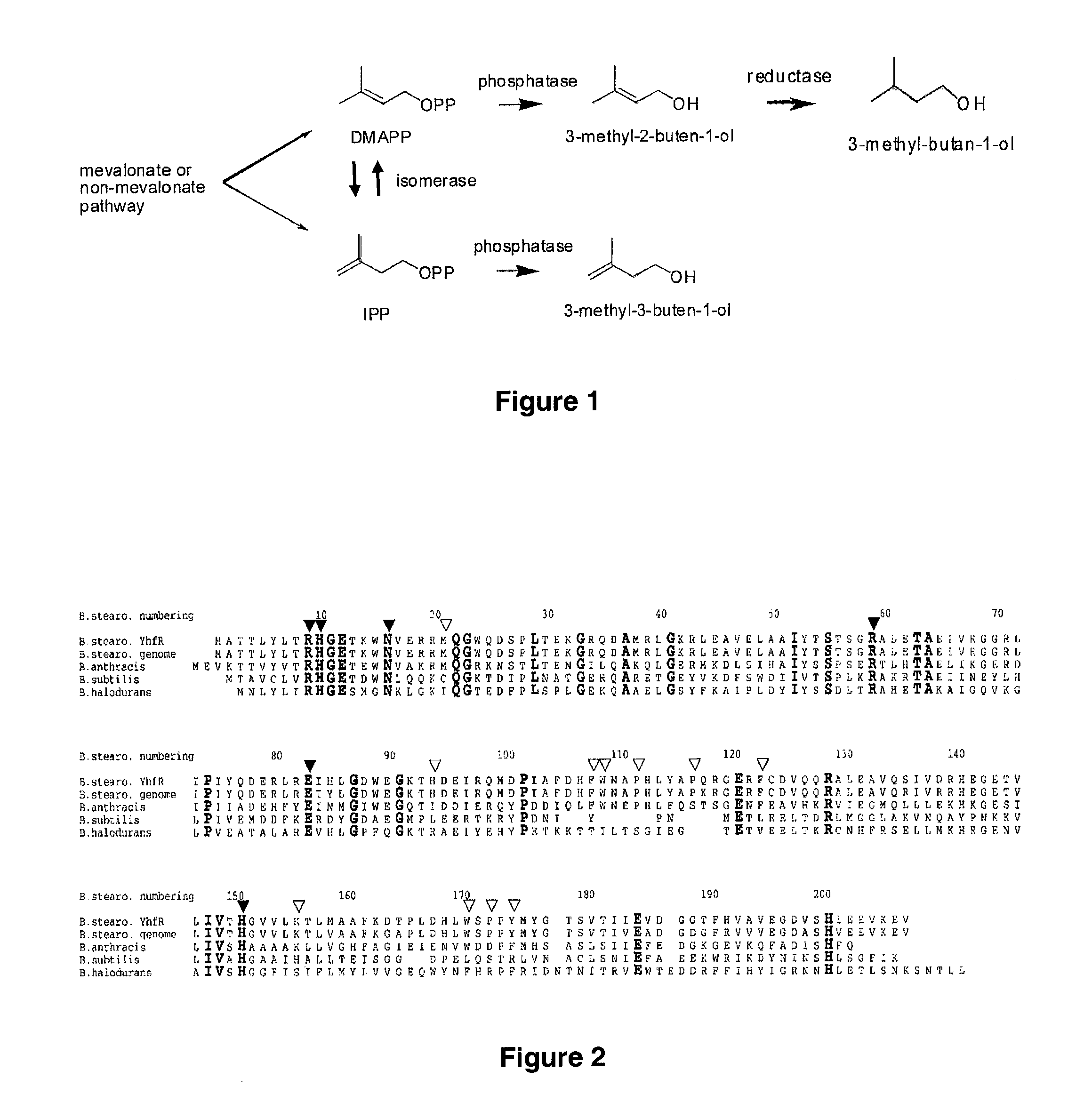

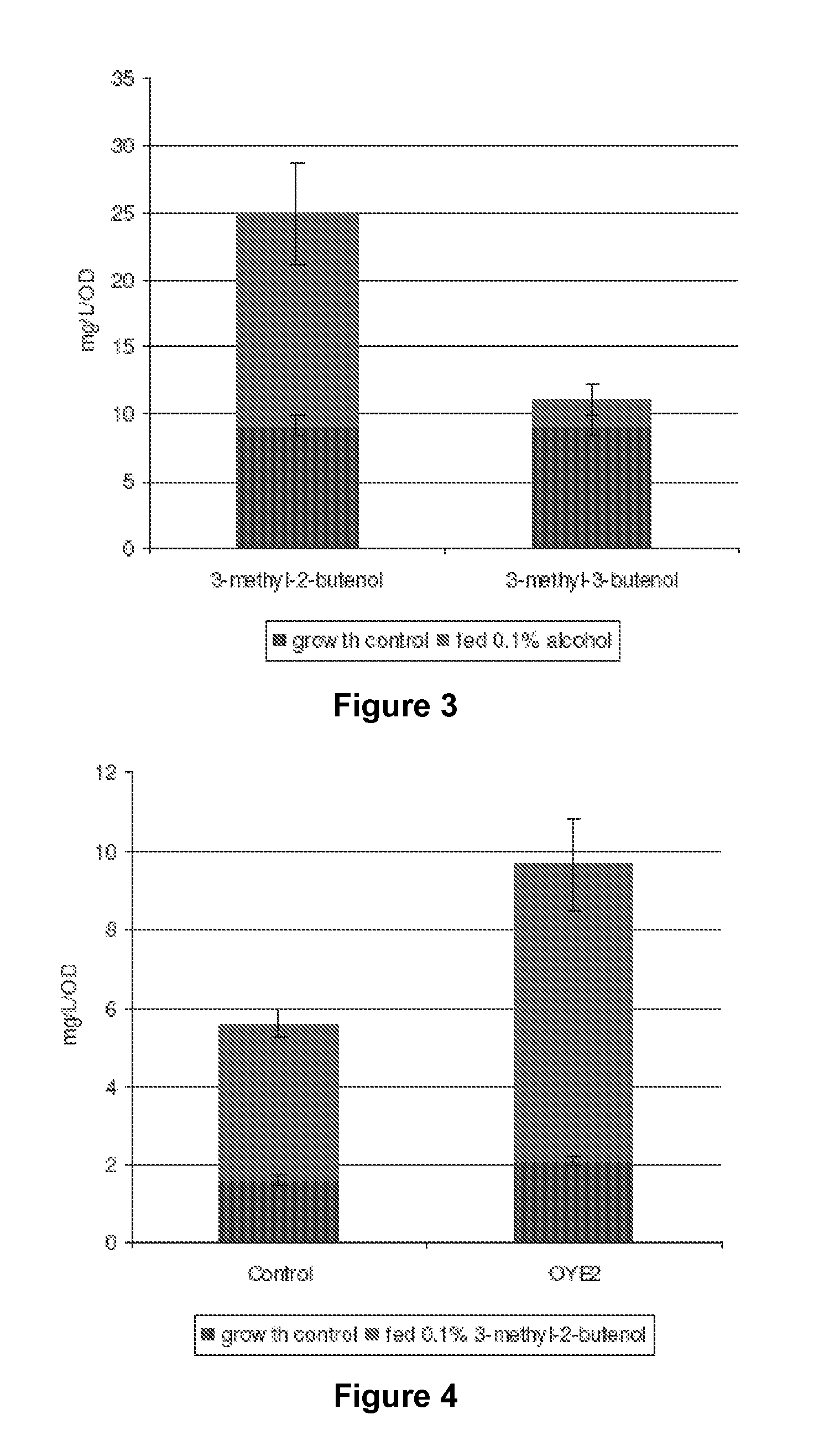

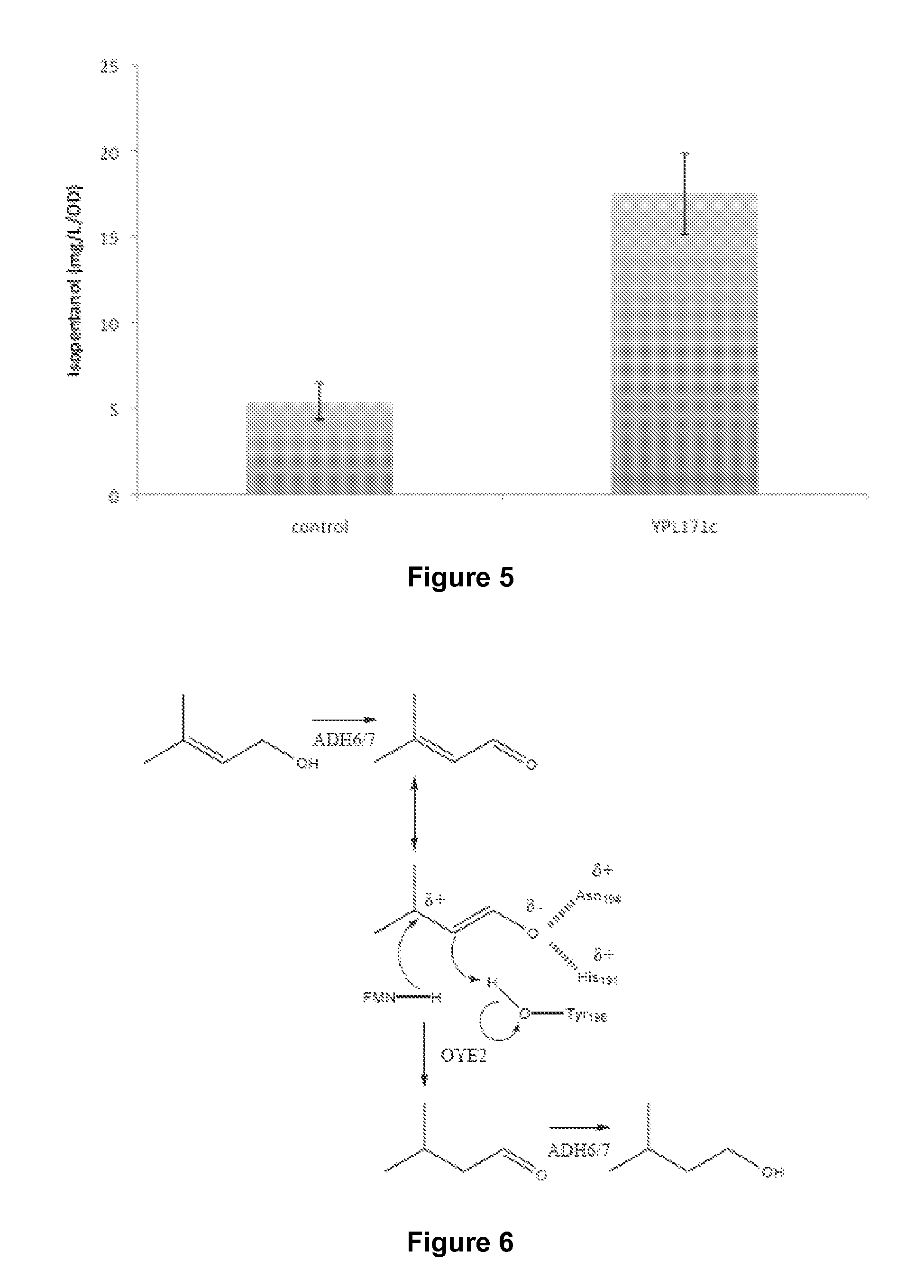

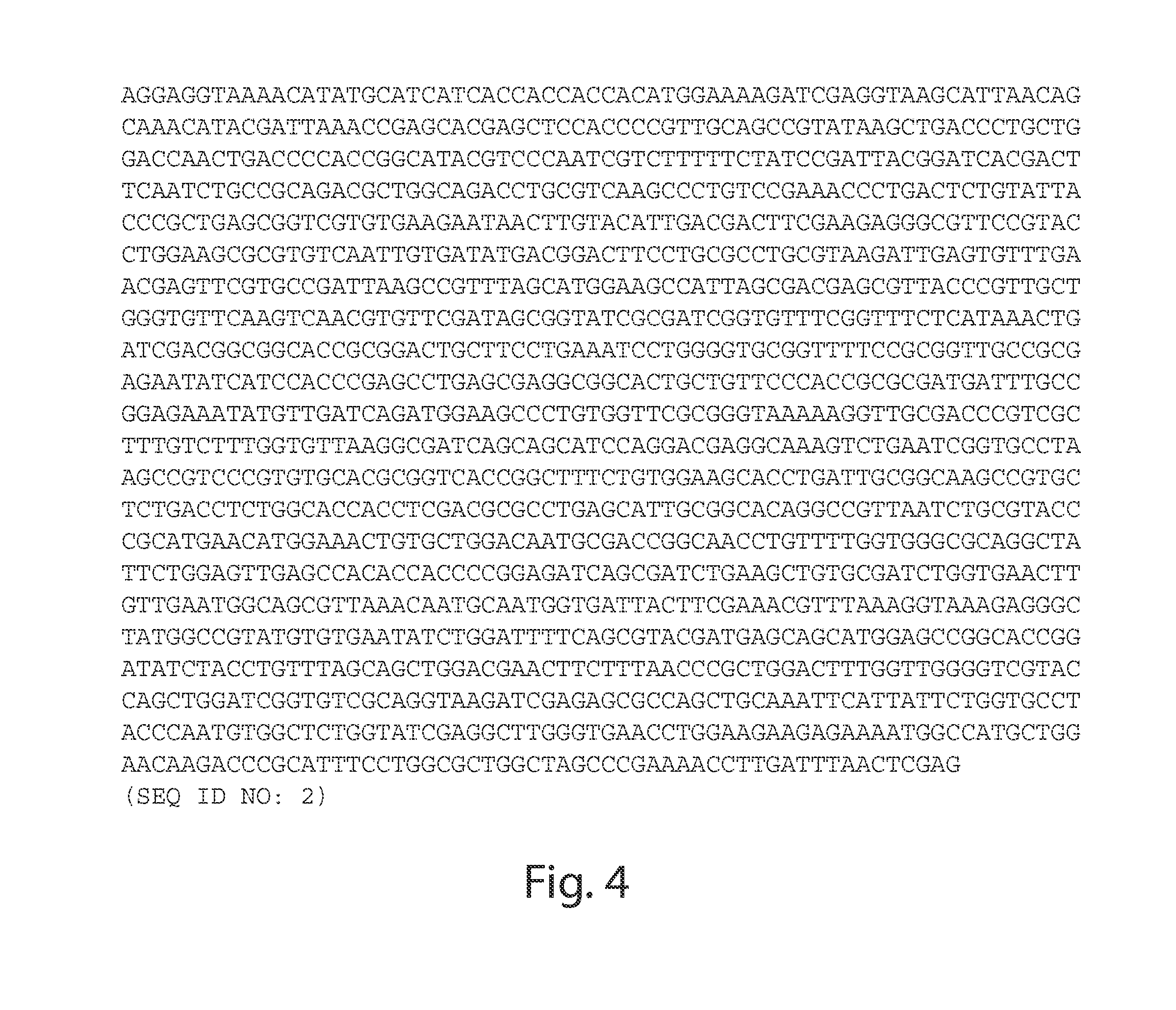

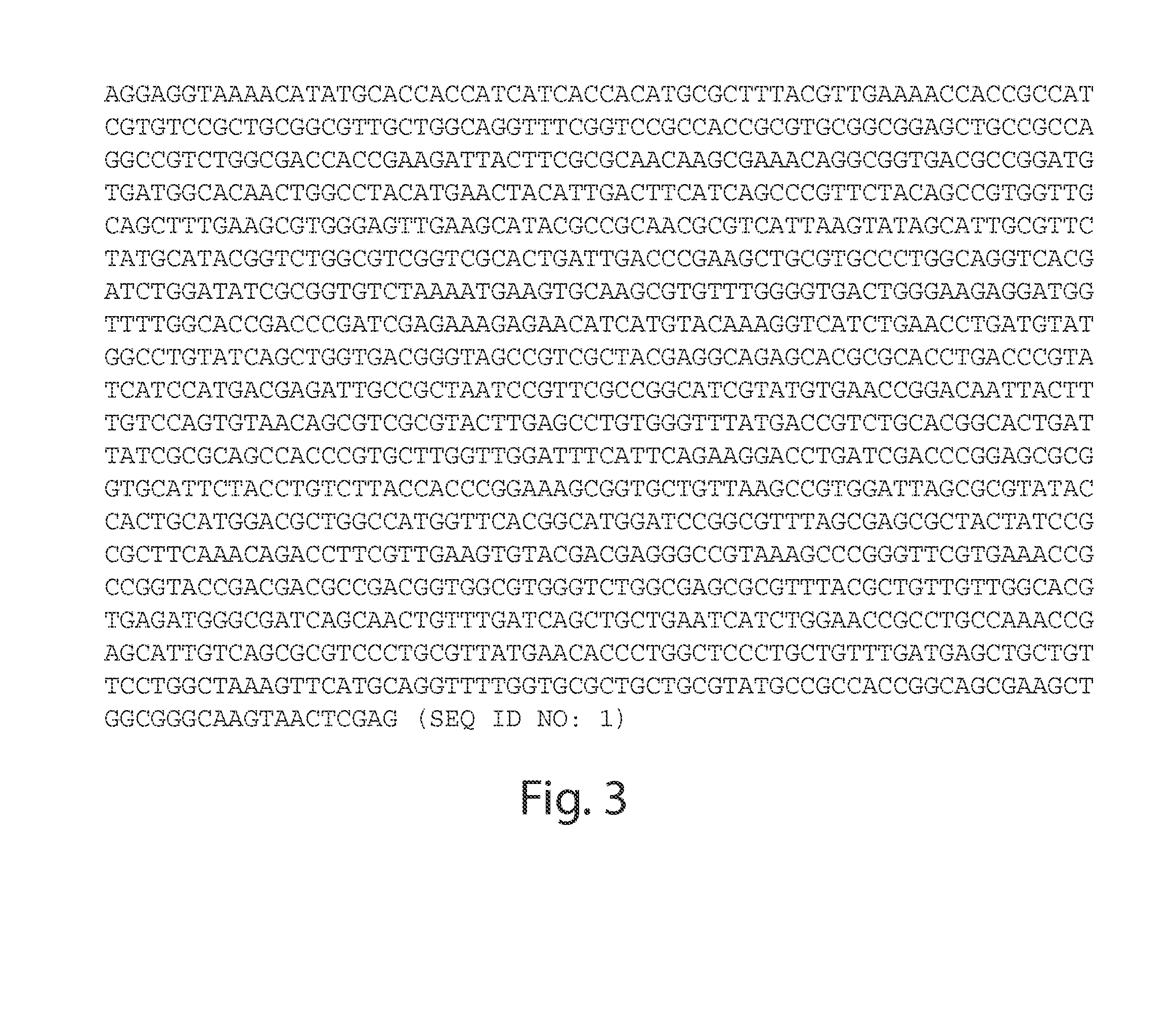

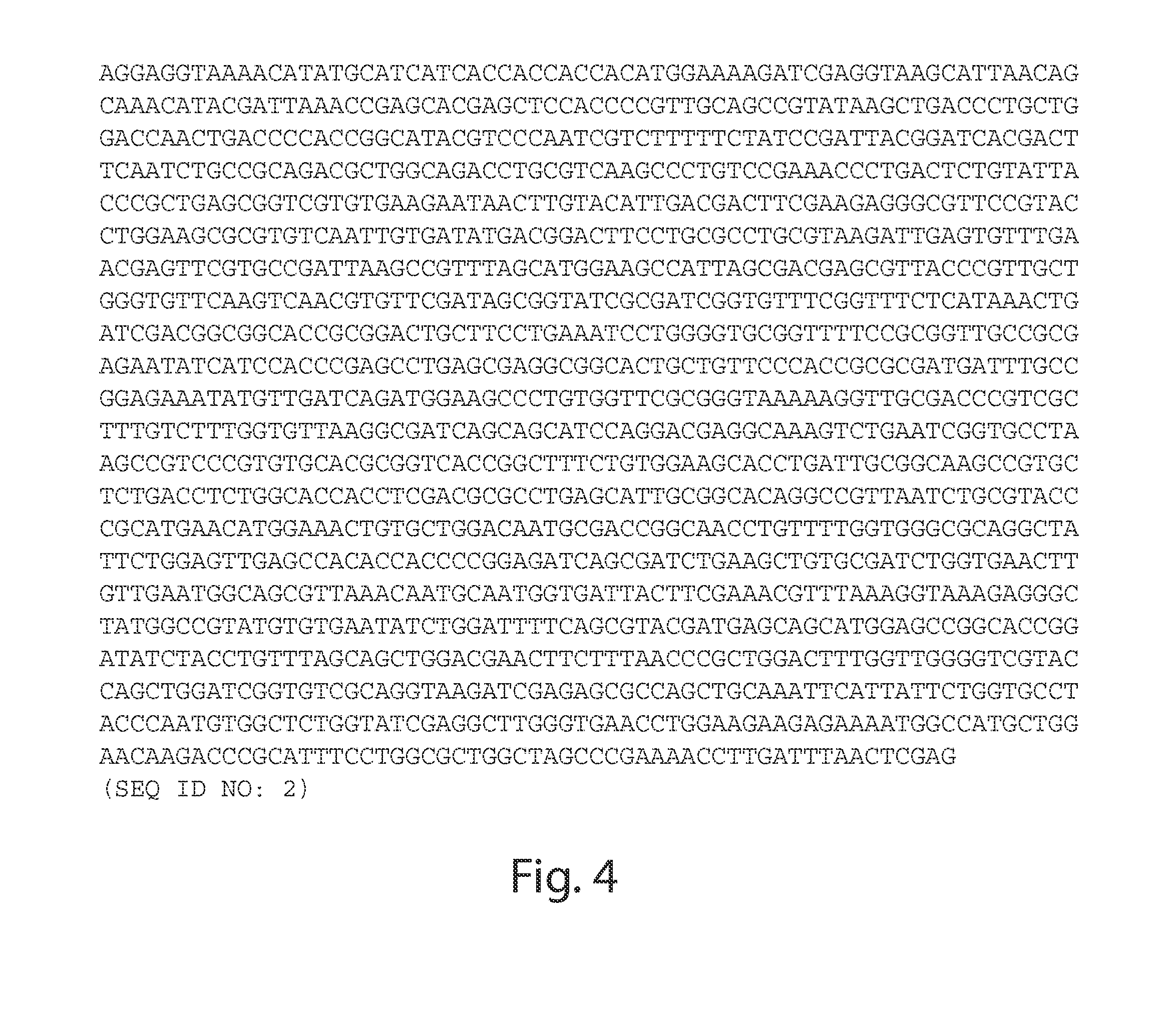

Host Cells and Methods for Producing 3-Methyl-2-buten-1-ol, 3-Methyl-3-buten-1-ol, and 3-Methyl-butan-1-ol

The invention provides for a method for producing a 5-carbon alcohol in a genetically modified host cell. In one embodiment, the method comprises culturing a genetically modified host cell which expresses a first enzyme capable of catalyzing the dephosphorylation of an isopentenyl disphosphate (IPP) or dimethylallyl diphosphate (DMAPP), such as a Bacillus subtilis phosphatase (YhfR), under a suitable condition so that 5-carbon alcohol is 3-methyl-2-buten-1-ol and / or 3-methyl-3-buten-1-ol is produced. Optionally, the host cell may further comprise a second enzyme capable of reducing a 3-methyl-2-buten-1-ol to 3-methyl-butan-1-ol, such as a reductase.

Owner:RGT UNIV OF CALIFORNIA

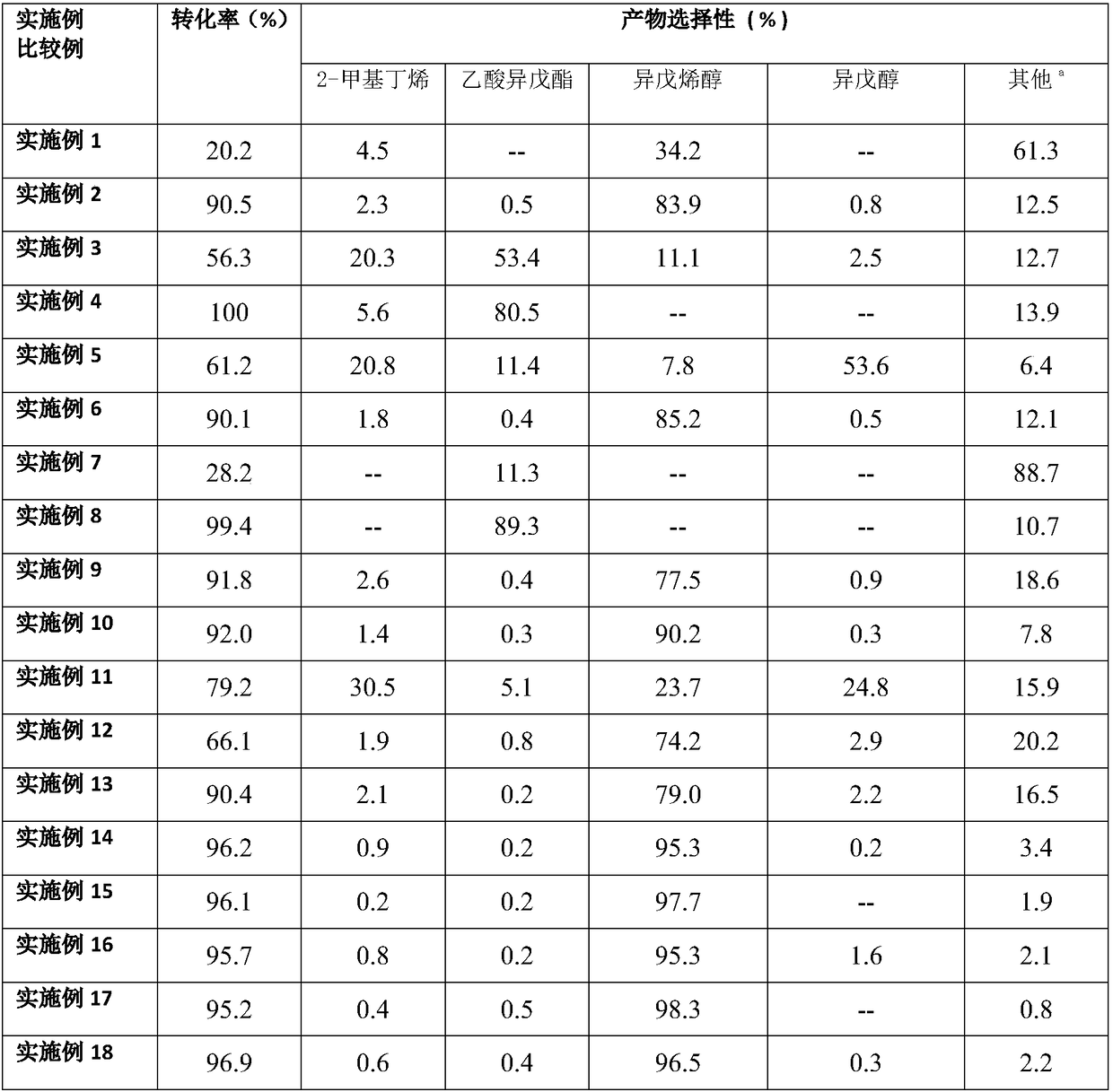

Preparation technique for florosa

InactiveCN104803958AHigh yieldLess investmentOrganic chemistry3-methyl-2-buten-1-olOrganic chemistry

The invention belongs to the technical field of fine chemical engineering, relates to florosa, and particularly relates to a preparation technique of florosa. The technical scheme provided by the invention is as follows: continuously putting isovaleraldehyde, 3-methyl-2-buten-1-ol and an acid catalyst into a jet mixing reactor for reaction according to a certain molar ratio under a certain temperature condition; meanwhile, continuously outputting reaction mixtures according to the feeding proportion so as to prepare florosa. The jet mixing reactor is used to carry out the continuous synthesis of florosa, and has better heat and mass transfer performance as compared with the conventional kettle-type batch reactor and the fixed reactor, and the reaction efficiency can be effectively improved; by adopting an acid compound as the catalyst, the conversion rate is greatly improved, the yield is up to 75-85%, and the conversion rate is up to 90% or above; meanwhile, during industrial application, by adopting the efficient jet mixing reactor, the hardware equipment investment in reaction units can be effectively reduced.

Owner:江苏绿源精细化工有限公司

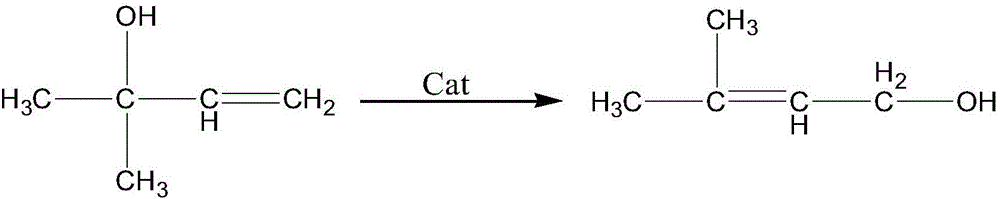

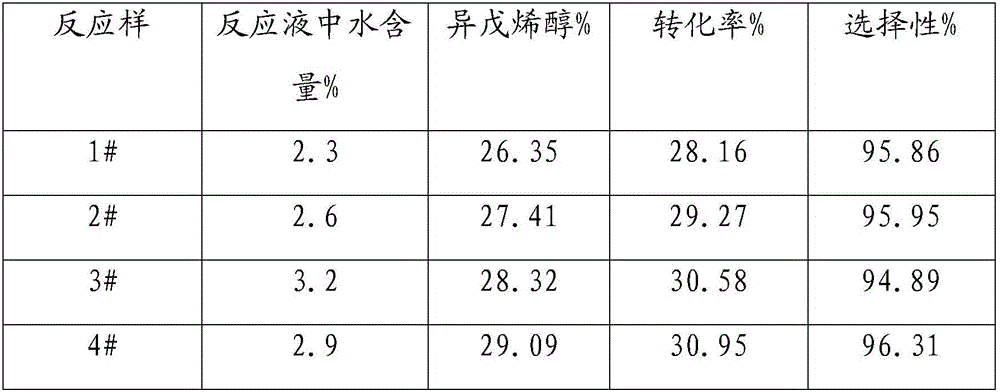

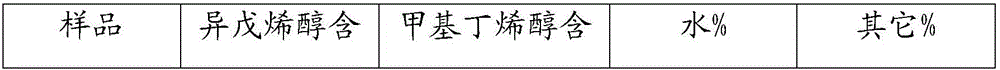

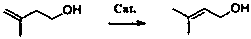

Isomerization synthesis of 3-methyl-2-buten-1-ol using water-containing methyl butenol

ActiveCN105967978AHigh reactivityHigh selectivityPreparation by isomerisationIsomerization3-methyl-2-buten-1-ol

The invention belongs to the field of chemical engineering and particularly relates to isomerization synthesis of 3-methyl-2-buten-1-ol using methyl butenol in a water-containing condition. In the invention, the methyl butenol is adopted as a raw material for isomerization synthesis of 3-methyl-2-buten-1-ol; in the reaction materials, the water content is 0.5-6.5%; the catalyst is vanadium oxide or vanadium-containing metal salt; the catalyst concentration is 0.1-5.0%, the reaction temperature is 120-190 DEG C, and the reaction time is 20-180min; the purity of the obtained 3-methyl-2-buten-1-ol product is higher than or equal to 98%; and the 3-methyl-2-buten-1-ol selectivity in the reaction process can be controlled at 95% or above. The invention has the following advantages: the adopted catalyst does not need to be prepared in advance and is relatively cheap; the raw material methyl butenol can be adopted for isomerization synthesis of 3-methyl-2-buten-1-ol in a water-containing condition; and the reaction activity and selectivity are relatively high.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

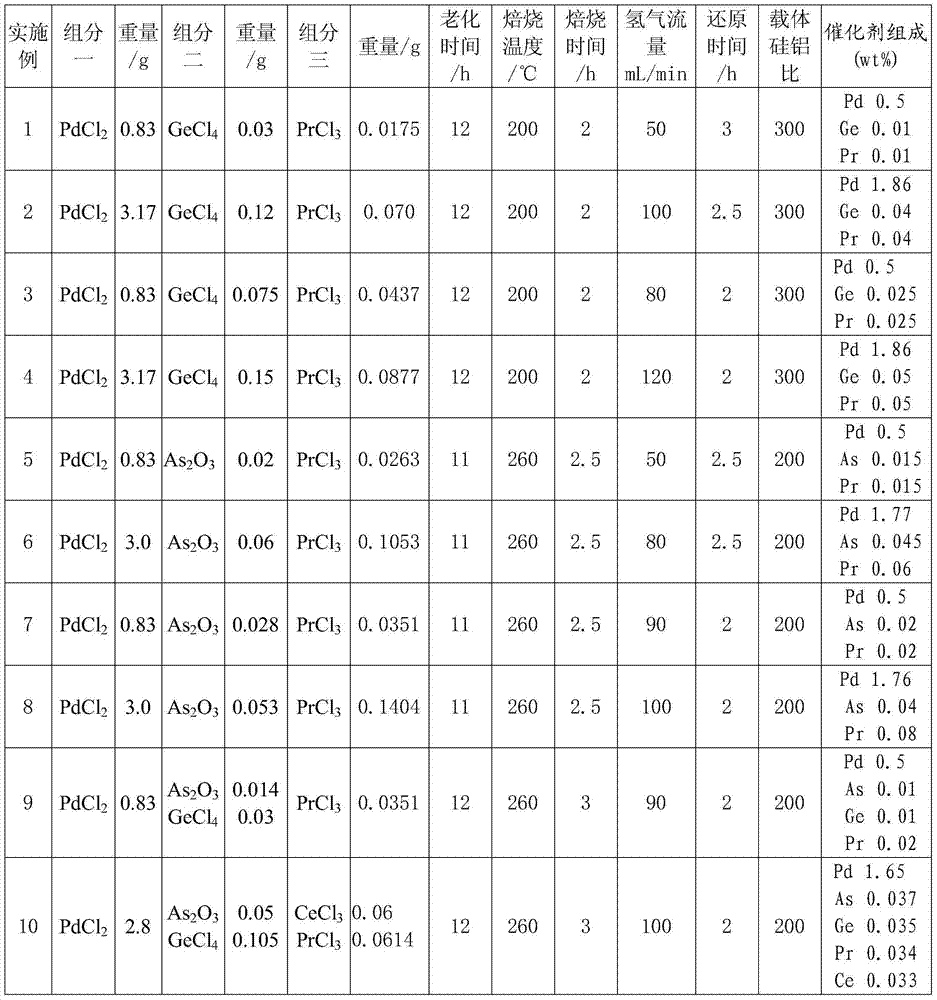

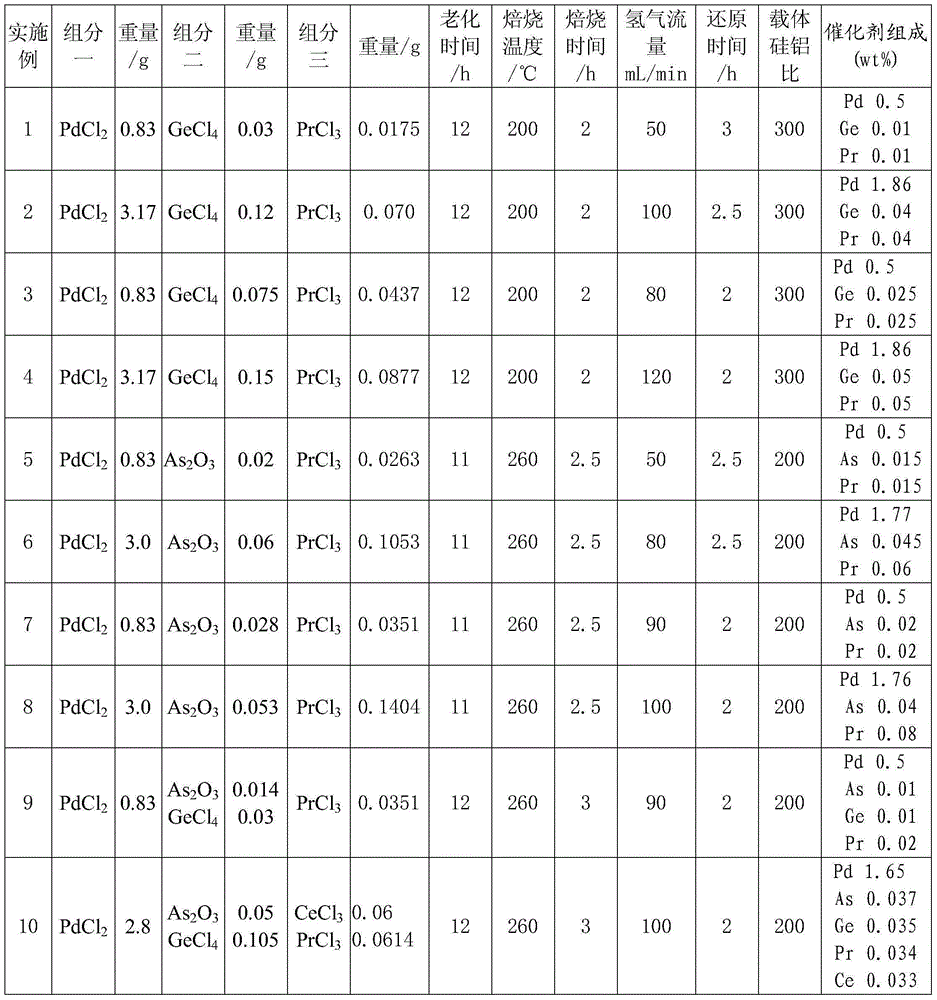

Heterogeneous catalyst and preparation method thereof as well as method for preparing 3-methyl-2-butene-1-ol in presence of catalyst

ActiveCN103861633AHigh selectivityImprove stabilityPreparation by isomerisationMolecular sieve catalystsLanthanide2-Butene

The invention provides a heterogeneous catalyst and a preparation method thereof as well as a method for preparing 3-methyl-2-butene-1-ol in the presence of the catalyst. The heterogeneous catalyst comprises a carrier and three components on the carrier, wherein the first component is selected from one or two or several in palladium, gold, platinum, nickel, chromium and molybdenum; the second component is selected from one or two or several in elements of groups IIIA, IVA and VA; the third component is selected from one or two or several in lanthanide elements. The preparation method comprises the step of performing a reactive distillation process on 3-methyl-3-butene-1-ol to prepare the 3-methyl-2-butene-1-ol in the presence of the heterogeneous catalyst. According to the method provided by the invention, the yield and selectivity of the 3-methyl-2-butene-1-ol can be obviously improved, and the stability of the catalyst is improved, so that the production cost is reduced.

Owner:WANHUA CHEM GRP CO LTD +1

Host cells and methods for producing 3-methyl-2-buten-1-ol, 3-methyl-3-buten-1-ol, and 3-methyl-butan-1-ol

The invention provides for a method for producing a 5-carbon alcohol in a genetically modified host cell. In one embodiment, the method comprises culturing a genetically modified host cell which expresses a first enzyme capable of catalyzing the dephosphorylation of an isopentenyl pyrophosphate (IPP) or dimethylallyl diphosphate (DMAPP), such as a Bacillus subtilis phosphatase (YhfR), under a suitable condition so that 5-carbon alcohol is 3-methyl-2-buten-1-ol and / or 3-methyl-3-buten-1-ol is produced. Optionally, the host cell may further comprise a second enzyme capable of reducing a 3-methyl-2-buten-1-ol to 3-methyl-butan-1-ol, such as a reductase.

Owner:RGT UNIV OF CALIFORNIA

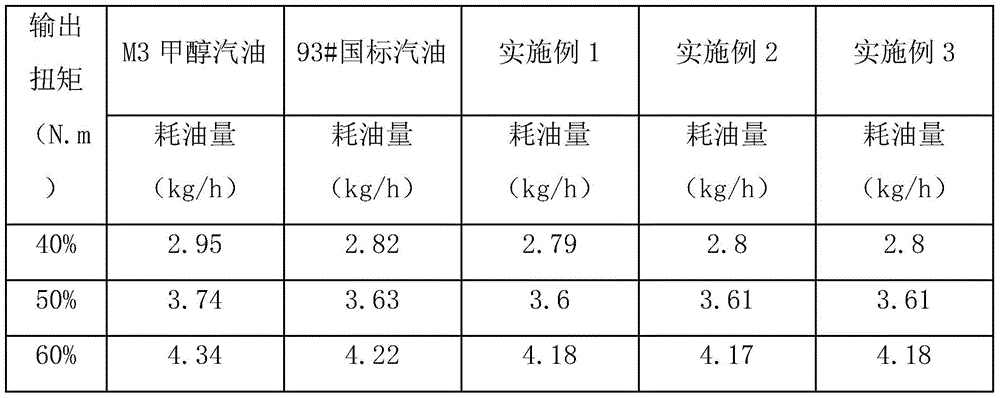

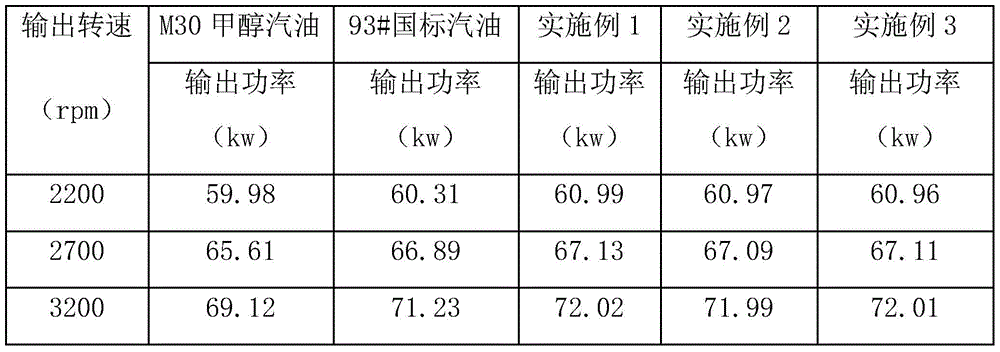

High-power liquid fuel composition for spark-ignition engines

InactiveUS20150007489A1Improve performanceIncrease engine speedLiquid carbonaceous fuelsButene3-methyl-2-buten-1-ol

A high-power liquid fuel composition for spark-ignition engines is provided. The fuel composition has a RON greater than or equal to 95 and a MON greater than or equal to 85, the RON and MON values being measured according to the ASTM D 2699-86 standard or D 2700-86 standard, and includes at least one C4-C5 unsaturated alcohol. The disclosure also relates to the use of a C4-C5 unsaturated alcohol, preferably 3-methyl-2-butene-1-ol or 3-methyl-3-butene-1-ol, in a petrol fuel composition, for improving the power of a naturally-aspirated or turbocharged spark-ignition engine, during the combustion. The disclosure also relates to a process for preparing such a fuel composition.

Owner:TOTAL MARKETING SERVICES SA

Microorganisms and processes for the production of isoprene

The present invention provides a novel biosynthetic pathway for the production of isoprene from 3-methyl-2-buten-1-ol or 2-methyl-3-buten-2-ol. Further embodiments provide non-naturally occurring microorganism that have been modified to produce isoprene from 3-methyl-2-buten-1-ol or 2-methyl-3-buten-2-ol and methods of producing isoprene using said microorganism.

Owner:GLYCOS BIOTECH

Defoaming agent

InactiveCN104548677AFast defoamingEnhanced inhibitory effectFoam dispersion/preventionSide effectPotassium iodine

The invention discloses a defoaming agent. The defoaming agent comprises the following components in parts by weight: 5-10 parts of fatty alcohol, 3-10 parts of polydimethylsiloxane, 5-10 parts of potassium iodide, 10-15 parts of boric acid, 6-9 parts of calcium stearate, 10-20 parts of 3-methyl-2-buten-1-ol, 3-10 parts of tert-amyl chloride, 5-10 parts of dimethyl silicon oil, 3-9 parts of mineral oil, 1-15 parts of polyether, 3-10 parts of fatty acid and 5-20 parts of ethylene glycol. The defoaming agent disclosed by the invention has the advantages of high defoaming speed, good inhibition performance and no influence on basic nature of a foaming system, as well as good diffusibility and permeability, stable chemical nature, no corrosion, no toxicity, no adverse side effects and high safety.

Owner:NANTONG SHUNYANG CHEM

Method for synthesizing 3-methyl-2-buten-1-ol from 3-methyl-3-buten-1-ol through trickle-bed transposition

InactiveCN110483245ALow costImprove conversion ratePreparation by isomerisationMolecular sieve catalysts3-methyl-2-buten-1-olOxygen

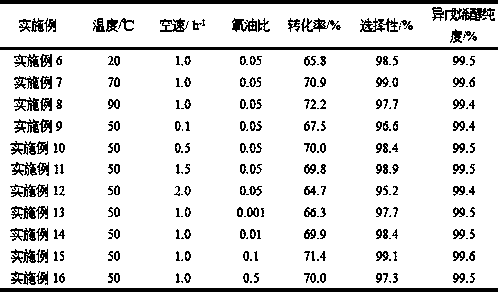

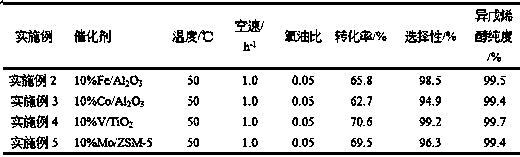

The invention provides a method for synthesizing 3-methyl-2-buten-1-ol from 3-methyl-3-buten-1-ol through trickle-bed transposition. The method comprises the following steps: introducing 3-methyl-3-buten-1-ol and an oxygen-containing atmosphere into a reactor, and carrying out a transposition reaction under the action of a non-noble metal supported catalyst. The catalytic reaction system is mild in reaction condition, high in raw material conversion rate, high in product selectivity and high in yield; wherein the raw material conversion rate is 62.7%-72.2%, the selectivity is 94.9%-99.2%, andthe yield is 59.5%-70.8%, and preferably, the raw material conversion rate is 69.8%-72.2%, the selectivity is 97.7%-99.2%, and the yield is 68.8%-70.8%. The catalyst is simple in component, is a non-noble metal catalyst and is low in cost; the reaction activity, selectivity and stability of the catalyst can be considered simultaneously.

Owner:SHANDONG NHU PHARMA

Method for producing 3-methyl-2-buten-1-ol by isobutene

InactiveCN104788287AReasonable methodEasy to makeOrganic compound preparationHydroxy compound preparationHydrogen phosphate3-methyl-2-buten-1-ol

The invention discloses a method for producing 3-methyl-2-buten-1-ol by isobutene, and relates to the technical field of chemical product processing and making. The method comprises the following steps: adding 95% polyformaldehyde in a stainless steel autoclave, using sodium hydrogen phosphate as a catalyst, then adding tert-butyl alcohol, replacing air in the autoclave with nitrogen after the raw materials are added, next adding isobutene, stirring for 2 hours at a constant speed, increasing the temperature to 200 DEG C after stirring, reacting for 4 hours, then cooling, discharging, and feeding the materials after reaction and cooling in a distiller for distillation to obtain 3-methyl-2-buten-1-ol after distillation. According to the method, the yield can reach 85%. The method is reasonable, the preparation is simple, the operation is convenient, the yield is high, the making cost can be reduced, and the production efficiency and the product quality are improved.

Owner:ANHUI HAIDE PETROCHEM

Organic silicon de-foaming agent and preparation method of organic silicon de-foaming agent

The invention discloses an organic silicon de-foaming agent and a preparation method of the organic silicon de-foaming agent. The organic silicon de-foaming agent is prepared from the following formula components in parts by mass: 10 to 20 parts of fluorite, 5 to 7 parts of tert-amyl chloride, 3 to 5 parts of thulium trifluoroacetylacetonate, 3 to 5 parts of sodium carbonate, 3 to 5 parts of benzyltriphenylphosphonium bromide, 2 to 4 parts of 3-methyl-2-buten-1-ol, 4 to 6 parts of hydrophobic silicon dioxide, 6 to 8 parts of dimethicone, 10 to 12 parts of tetrabutylphosphonium bromide, 10 to 20 parts of coke, 5 to 15 parts of mineral oil, 10 to 12 parts of albite and 40 to 60 parts of water. The organic silicon de-foaming agent provided by the invention is simple in process, convenient to use and high in production efficiency and the utilization effect of the obtained de-foaming agent is good.

Owner:QINZHOU UNIV

Processes for Producing 3-Methyl-2-Butenyl Acetate

InactiveUS20080275268A1Produced inexpensively and efficientlyOrganic compound preparationPreparation by transesterificationAcetic acidAcetic anhydride

The present invention relates to a method for producing 3-methyl-2-butenyl acetate which comprises reacting 3-methyl-2-buten-1-ol with acetic anhydride in the presence of an inorganic base catalyst and a method for producing purified 3-methyl-2-butenyl acetate which comprises subjecting crude 3-methyl-2-butenyl acetate to a step (A) of contacting it with an aqueous solution of an alkali metal hydrogen sulfite, or a step (B) of contacting it with an aqueous solution of a base, or both steps (A) and (B).

Owner:SUMITOMO CHEM CO LTD

Method for preparing 3-methyl-2-buten-1-ol through transesterification reaction of isopentenyl acetate

ActiveCN108940278AOxygen-containing compound preparationPreparation by ester-hydroxy reactionIridiumSolid acid

The invention relates to a method for preparing 3-methyl-2-buten-1-ol through a transesterification reaction of isopentenyl acetate. The method is characterized in that a transesterification reactionis catalyzed by adopting a solid acid catalyst. The solid acid catalyst is one or more selected from the following components: a composite oxide consisting of ceric oxide and one or two selected fromsilicon dioxide and aluminum trioxide, and a supported noble metal catalyst taking one or more selected from the composite oxide and ceric oxide as a carrier, wherein the noble metal component is oneor more selected from iridium, gold and rhodium, the supported noble metal catalyst contains or does not contain an auxiliary agent, and the auxiliary agent is one or two selected from iron or cobalt.According to the synthetic method adopted by the invention, under the catalysis of the prepared solid acid catalyst, the 3-methyl-2-buten-1-ol can be generated through high-conversion-rate high-selectivity transesterification of isopentenyl acetate and methanol under a certain pressure and temperature.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Polishing agent for nickel plated metal

The invention discloses a polishing agent for nickel plated metal. The polishing agent comprises, by mass, 8-15 parts of sodium citrate, 4-9 parts of 1-hydroxyethylidene-1,1-diphosphonic acid, 6-10 parts of 3-methyl-2-buten-1-ol, 20-30 parts of propylene glycol and 90-110 parts of deionized water. A use method of the polishing agent for the nickel plated metal comprises the following steps that firstly, the sodium citrate, the 1-hydroxyethylidene-1,1-diphosphonic acid, the 3-methyl-2-buten-1-ol and the propylene glycol are sequentially added into the deionized water, heating is conducted, the temperature ranges from 40 DEG C to 50 DEG C, and the mixture is stirred to be uniform; secondly, the surface of a nickel plated metal piece to be treated is rubbed down through sand paper and subjected to sand blasting treatment; thirdly, the nickel plated metal piece treated in the second step is placed into the polishing agent with the temperature being 40-50 DEG C, and the placement time ranges from 20 min to 30 min; and fourthly, the nickel plated metal piece is taken out, cooled and washed.

Owner:QINGDAO WINCHANCE TECH

A kind of heterogeneous catalyst and its preparation method and the method of using the catalyst to prepare 3-methyl-2-buten-1-ol

ActiveCN103861633BHigh selectivityImprove stabilityPreparation by isomerisationMolecular sieve catalysts2-ButeneMethyl group

The invention provides a heterogeneous catalyst and a preparation method thereof as well as a method for preparing 3-methyl-2-butene-1-ol in the presence of the catalyst. The heterogeneous catalyst comprises a carrier and three components on the carrier, wherein the first component is selected from one or two or several in palladium, gold, platinum, nickel, chromium and molybdenum; the second component is selected from one or two or several in elements of groups IIIA, IVA and VA; the third component is selected from one or two or several in lanthanide elements. The preparation method comprises the step of performing a reactive distillation process on 3-methyl-3-butene-1-ol to prepare the 3-methyl-2-butene-1-ol in the presence of the heterogeneous catalyst. According to the method provided by the invention, the yield and selectivity of the 3-methyl-2-butene-1-ol can be obviously improved, and the stability of the catalyst is improved, so that the production cost is reduced.

Owner:WANHUA CHEM GRP CO LTD +1

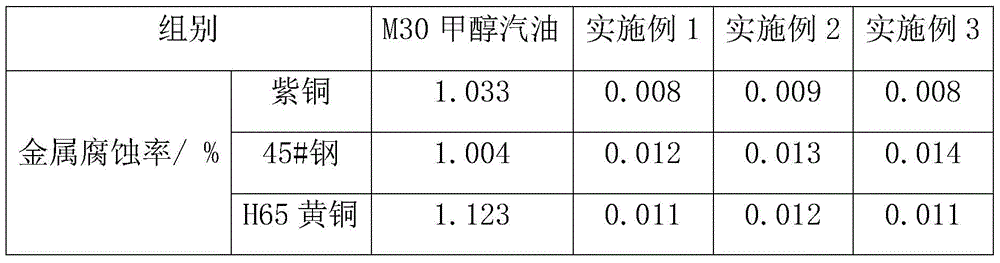

Methanol gasoline additive for improving power

ActiveCN105670720AImprove combustion efficiencyReduce corrosionLiquid carbonaceous fuelsIsobutanolIndium

The invention provides a methanol gasoline additive for improving power. The additive comprises the following components in parts by weight: 15-18 parts of petroleum ether, 6-8 parts of isobutanol, 6-8 parts of dimethyl carbonate, 2-3 parts of nanometer indium hydroxide, 4-5 parts of 2-methyl-2-butanol, 3-4 parts of amino-2-propanol, 3-4 parts of alkyl phenyl polyoxyethylene ether, 2-3 parts of 2-[2-[(2-ethylhexyl)oxy]ethoxy]-ethanol, 5-6 parts of 1H-benzotriazole, and 6-8 parts of 3-methyl-2-buten-1-ol. The methanol gasoline additive for improving power employs nanometer indium hydroxide, 2-methyl-2-butanol, amino-2-propanol, and alkyl phenyl polyoxyethylene ether for composing a composite combustion-supporting component, and employs 2-[2-[(2-ethylhexyl)oxy]ethoxy]-ethanol, 1H-benzotriazole and 3-methyl-2-buten-1-ol for composing a composite corrosion-resisting component; Synergistic effects between each component are obvious, effects for improving combustion efficiency of the methanol gasoline and enhancing power are realized, and at the same time corrosion of the methanol gasoline to automobile metal parts is reduced.

Owner:李戈 +2

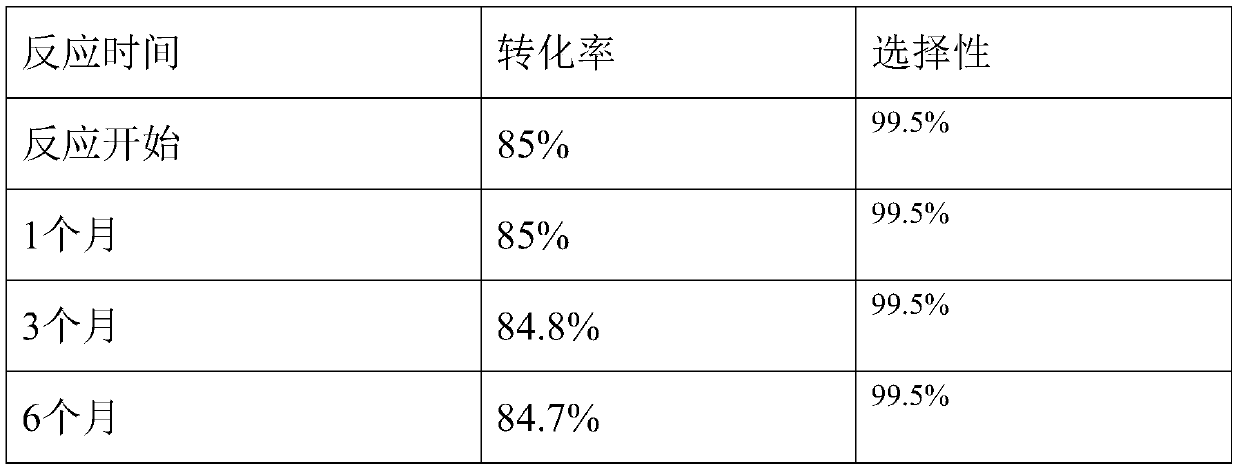

Preparation method for enabling 3-methyl-2-butene-1-alcohol to be synthesized into 3-methylcrotonaldehyde catalyst

ActiveCN110368938ASolution to short lifeLow costOrganic compound preparationPreparation by dehydrogenationFixed bedOxygen

The invention discloses a preparation method for enabling 3-methyl-2-butene-1-alcohol to be synthesized into a 3-methylcrotonaldehyde catalyst. The preparation method for enabling 3-methyl-2-butene-1-alcohol to be synthesized into the 3-methylcrotonaldehyde catalyst comprises the steps that firstly a certain proportion of a copper-silicon carrier is prepared by a gel method, and then active component molybdenum and ruthenium are loaded by a certain ratio by a dipping method, and the mixture is dried, calcined and shaped to obtain the catalyst. The catalyst is charged to a fixed bed reactor foractivation. Feeding and reaction are carried out, it is verified that the catalyst has a conversion rate of up to 80% and selectivity of up to 99% for the synthesis of 3-methyl-2-butene-1-alcohol into 3-methylcrotonaldehyde, the catalyst can be used for reaction without air and oxygen, the catalyst is long in service life and low in cost, and continuous production and environmental protection areachieved.

Owner:CHINA CATALYST HLDG CO LTD

Microorganisms and processes for the production of isoprene

The present invention provides a novel biosynthetic pathway for the production of isoprene from 3-methyl-2-buten-1-ol or 2-methyl-3-buten-2-ol. Further embodiments provide non-naturally occurring microorganism that have been modified to produce isoprene from 3-methyl-2-buten-1-ol or 2-methyl-3-buten-2-ol and methods of producing isoprene using said microorganism.

Owner:GLYCOS BIOTECH

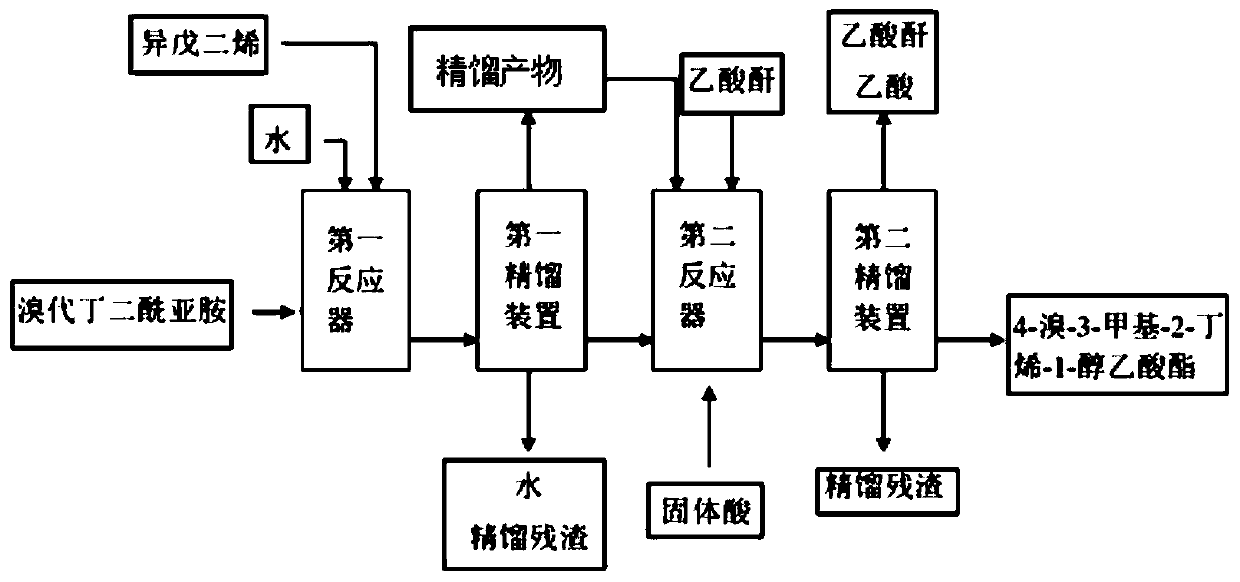

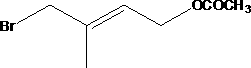

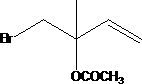

Preparation method of 4-bromine-3-methyl-2-butene-1-alcohol acetate

ActiveCN110240543AIncrease reaction rateNo need to separateOrganic compound preparationCarboxylic acid esters preparationAcetic acidButene

The invention discloses a preparation method of 4-bromine-3-methyl-2-butene-1-alcohol acetate. The method comprises the following steps that a mixture of isoprene and water is continuously pumped into a first reactor filled with bromo-succinimide to perform bromine alcoholization reaction; after rectification by a first rectification device, rectification products of 4-bromine-3-methyl-2-butene-1-alcohol and 1-bromine-2-methyl-3-butene-2-alcohol are obtained; a mixture of the rectification products and acetic anhydride is continuously pumped into a second reactor filled with solid acid catalysts for performing esterification rearrangement reaction; reaction liquid is obtained; the reaction liquid is subjected to reduced pressure distillation to recover acetic acid and unreacted acetic anhydride; through rectification by a second rectification device, the 4-bromine-3-methyl-2-butene-1-alcohol acetate is obtained. The preparation method of the 4-bromine-3-methyl-2-butene-1-alcohol acetate has the advantages that the product yield is high; the continuous and scaled production can be easily realized.

Owner:南京瑞鼎生物医药有限公司

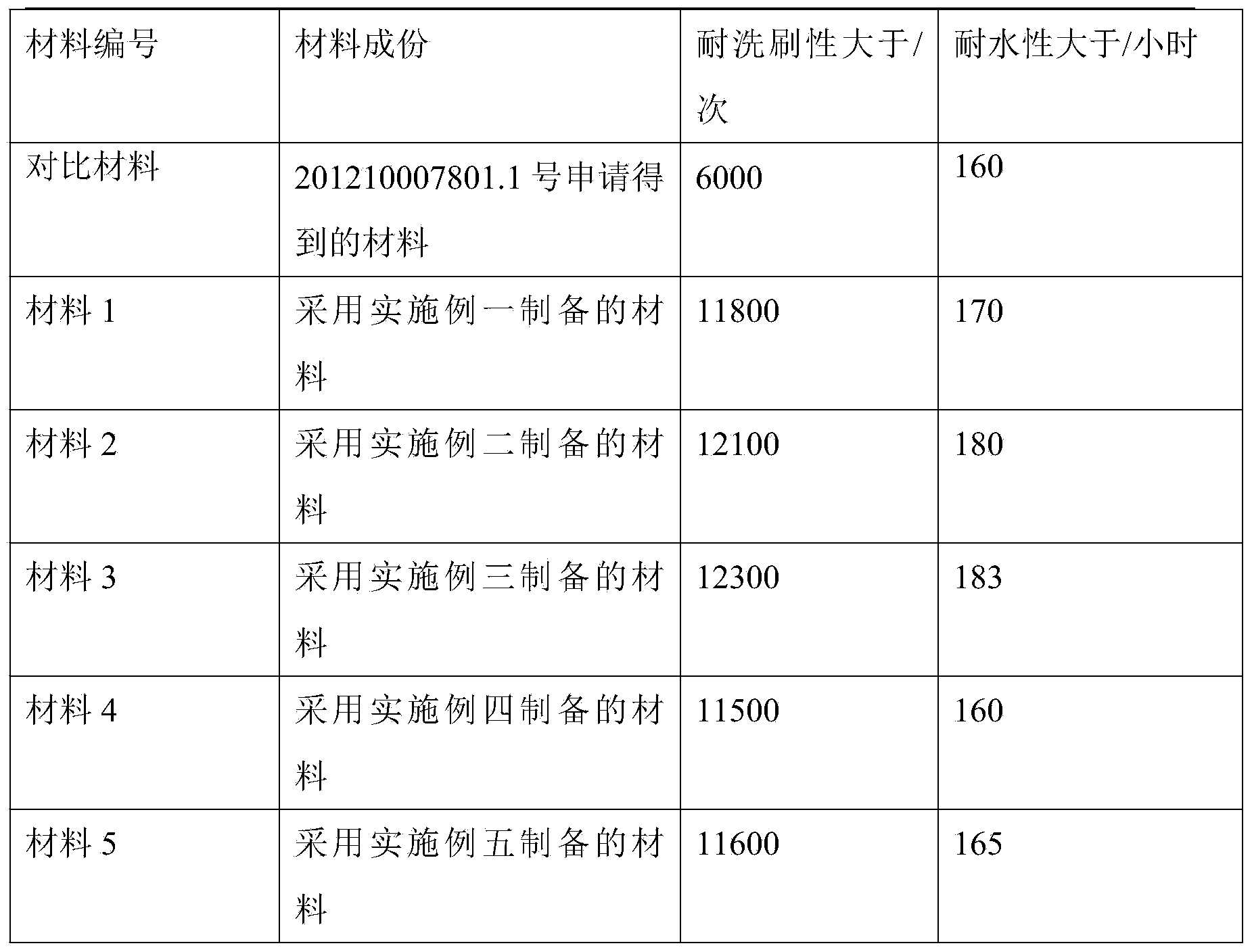

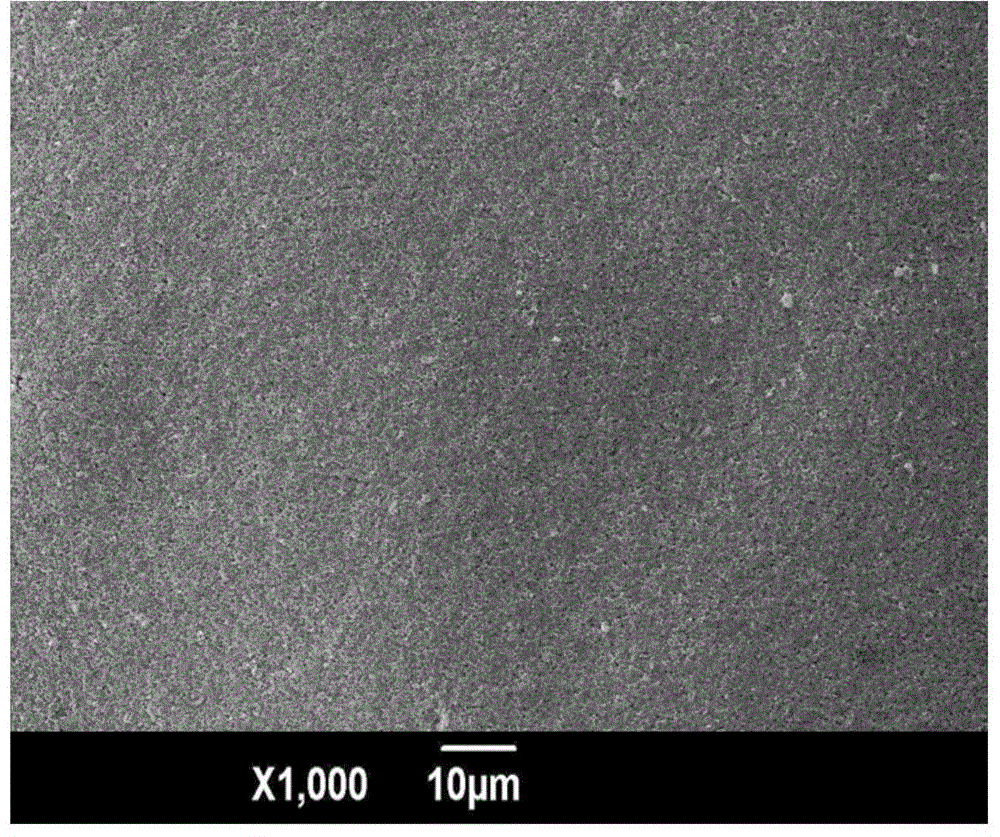

Washable coating material and preparation method thereof

InactiveCN103073959BGood scrub resistanceGood heat insulationCellulose coatingsAcetic acid3-methyl-2-buten-1-ol

The invention provides a washable coating material and a preparation method thereof. The coating material comprises the following components by weight percentage: 20-25% of titaniferous microcrystalline cellulose composite powder, 12-16% of slag powder, 0.15-0.2% of polyurethane, 2-5% of titanium dioxide, 0.1-0.5% of silica sol, 3-5% of silica powder and the balance of 3-methyl-2-butylene-1-alcohol acetate composite solution, wherein the slag powder comprises the following components by weight percentage: 36-40% of CaO, 13-15% of Al2O3, 6-9% of MgO, 0.3-0.5% of FeO and the balance of SiO2; the particle size of the slag powder is 80-100 micrometers; the fineness of titanium dioxide is 80-100 micrometers; the particle size of the titaniferous microcrystalline cellulose composite powder is 80-100 nanometers; and the particle size of the silica powder is 0.5-0.8 millimeters.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Synthesis method of 3-methyl-2-butene-1-geranoil formate

ActiveCN108129301AHigh yieldExtended reaction timeOrganic compound preparationCarboxylic acid esters preparationChemical synthesisHydrogen

The invention belongs to the technical field of chemical synthesis and particularly relates to a synthesis method of 3-methyl-2-butene-1-geranoil formate. According to the synthesis method of the 3-methyl-2-butene-1-geranoil formate and on the basis of the existing technical process, sodium hydrogen sulfite serves as a catalyst, the yield of a 3-methyl-2-butene-1-geranoil formate product is further increased, more preferably, reaction is conducted under the existence of ionic liquid, the reaction time is effectively increased besides the yield of the products is effectively increased, and higher product yield can be obtained within shorter time.

Owner:GUANGXI FORESTRY RES INST

Preparation method of carbon/carbon composite material HfB2 anti-oxidation outer coating

ActiveCN103601533BHigh bonding strengthOptimal Control StructureCarbon compositesOxidation resistant

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method for purified 3-methyl-2-butenyl acetate

ActiveCN100509748CCheap and efficient preparationOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic anhydride

The present invention relates to a method for producing 3-methyl-2-butenyl acetate which comprises reacting 3-methyl-2-buten-1-ol with acetic anhydride in the presence of an inorganic base catalyst and a method for producing purified 3-methyl-2-butenyl acetate which comprises subjecting crude 3-methyl-2-butenyl acetate to a step (A) of contacting it with an aqueous solution of an alkali metal hydrogen sulfite, or a step (B) of contacting it with an aqueous solution of a base, or both steps (A) and (B).

Owner:SUMITOMO CHEM CO LTD

Unsaturated acetal preparation method

ActiveCN102942460BEvenly distributedSmooth responseOrganic chemistryOrganic compound preparationButene3-methyl-2-buten-1-ol

The present invention discloses an unsaturated acetal preparation method. According to the preparation method, an unsaturated alcohol and an unsaturated aldehyde are subjected to a reaction in a pre-reactor to achieve a thermodynamic equilibrium, and then enter a tower type reactor, a water carrying agent is subjected to gasification through a gas generator, and then is subjected to reverse contact with a reaction liquid, and the water generated from the reaction is removed, such that the unsaturated alcohol and the unsaturated aldehyde are subjected to a continuous condensation reaction to prepare the unsaturated acetal. The preparation method has the following characteristics that: the method can be performed under a normal pressure condition, the reaction temperature is constant, low cost synthesis of the unsaturated acetal can be achieved, particularly 3-methyl-2-buten-1-ol and 3-methyl-2-butenal can be adopted as raw materials to synthesize 3-methyl-2-butenal-1 diisopentenyl acetal, wherein the compound is an important intermediate of a synthetic perfume citral.

Owner:WANHUA CHEM GRP CO LTD +1

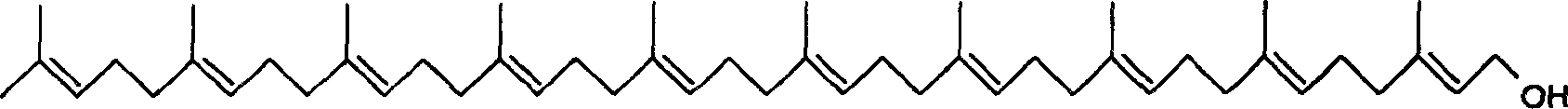

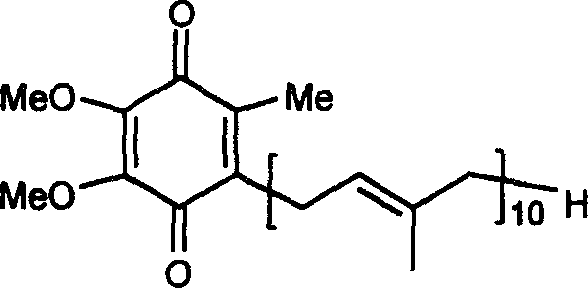

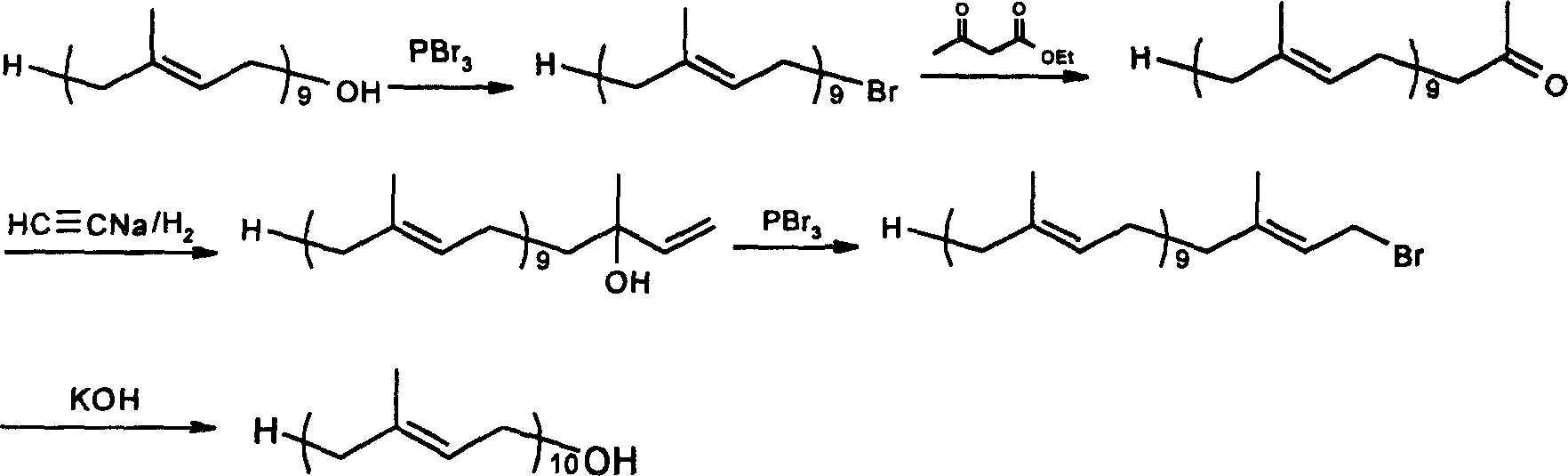

Method for synthesizing deca-isoprene alcohol

InactiveCN1226260CWide variety of sourcesReduce usageOrganic compound preparationHydroxy compound preparationSodium iodidePotassium

The invention provides a process for synthesizing deca-isoprene alcohol comprises, in the mixed solvent of tetrahydrofuran and dimethyl formamide, using tert-butanol potassium as alkaline reagent, and using sodium iodide or sodium bromide as halogen exchanger, condensing nicotine based sulfone with 4-chlorin-3-methyl-2-butylene-1-alcohol acetic acid ester, thus obtaining 5-sulfuryl deca-isoprene alcohol acetic acid ester, removing sulfuryl in methylamine by using lithium, thus preparing destination product deca-isoprene alcohol.

Owner:ZHEJIANG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com