Preparation method of carbon/carbon composite material HfB2 anti-oxidation outer coating

A carbon composite material and anti-oxidation technology, which is applied in the field of preparation of carbon/carbon composite HfB2 anti-oxidation outer coating, can solve the problems of easy cracking on the surface of the outer coating, inability to complete the preparation at one time, and insufficient thickness of the coating, etc., to achieve Combining the effects of high strength, controllable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

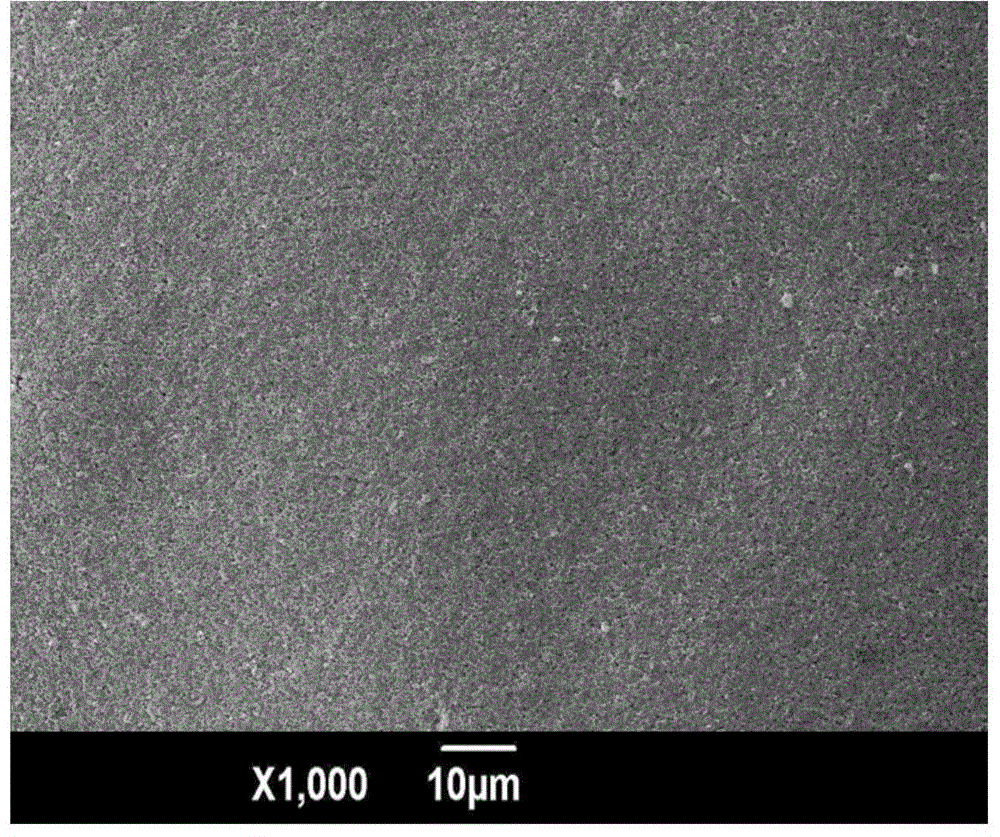

Image

Examples

Embodiment 1

[0025] 1) First take HfB 2 The powder is then dispersed in 150mL of isopentenol with a purity ≥ 99.8%, and prepared into a suspension with a concentration of 20g / L. Then, the suspension is placed in a 500W ultrasonic generator and shaken for 40min. After taking it out, put it into a magnetic rotor. Placed on a magnetic stirrer and stirred for 5h to obtain suspension A, wherein, HfB 2 The powder is wet ball milled and dried at 80°C for 4 hours, with an average particle size of 100-300nm;

[0026] 2) Add elemental iodine with a purity ≥ 99.7% to the suspension A, prepare a solution with an elemental iodine concentration of 3.0g / L, put it into a 500W ultrasonic generator and shake for 40min, take it out and stir it on a magnetic stirrer 5h to obtain solution B;

[0027] 3) Pour solution B into a device that uses graphite electrodes as anodes and conductive substrates as cathodes. The cathodes are fixed on the rotating body and rotated under the drive of the motor. The cathode a...

Embodiment 2

[0030] 1) First take HfB 2 The powder is then dispersed in 150mL of isopentenol with a purity ≥ 99.8%, and prepared into a suspension with a concentration of 20g / L. Then, the suspension is placed in a 600W ultrasonic generator and shaken for 40 minutes. After taking it out, put it into a magnetic rotor. Placed on a magnetic stirrer and stirred for 5h to obtain suspension A, wherein, HfB 2 The powder is wet ball milled and dried at 80°C for 4 hours, with an average particle size of 100-300nm;

[0031] 2) Add elemental iodine with a purity ≥ 99.7% to the suspension A, prepare a solution with an elemental iodine concentration of 3.0g / L, put it into a 600W ultrasonic generator and shake for 40min, take it out and stir it on a magnetic stirrer 5h to obtain solution B;

[0032] 3) Pour solution B into a device that uses graphite electrodes as anodes and conductive substrates as cathodes. The cathodes are fixed on the rotating body and rotated under the drive of the motor. The cath...

Embodiment 3

[0035] 1) First take HfB 2 The powder is then dispersed in 200mL of prenyl alcohol with a purity ≥ 99.8%, and prepared into a suspension with a concentration of 25g / L. Then, the suspension is placed in an 800W ultrasonic generator and shaken for 60 minutes. After taking it out, put it into a magnetic rotor. Placed on a magnetic stirrer and stirred for 5h to obtain suspension A, wherein, HfB 2 The powder is wet ball milled and dried at 80°C for 5 hours, with an average particle size of 100-300nm;

[0036] 2) Add elemental iodine with a purity ≥ 99.7% to the suspension A, prepare a solution with an elemental iodine concentration of 3.0g / L, put it into an 800W ultrasonic generator and vibrate for 60min, take it out and stir it on a magnetic stirrer 5h to obtain solution B;

[0037] 3) Pour solution B into a device that uses graphite electrodes as anodes and conductive substrates as cathodes. The cathodes are fixed on the rotating body and rotated under the drive of the motor. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com