Heterogeneous catalyst and preparation method thereof as well as method for preparing 3-methyl-2-butene-1-ol in presence of catalyst

A heterogeneous catalyst, methyl technology, applied in the direction of isomerization preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of many by-products, increased energy consumption, difficult separation of hydrogenation by-product isoamyl alcohol, etc. , to achieve the effects of reducing impact, improving stability and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

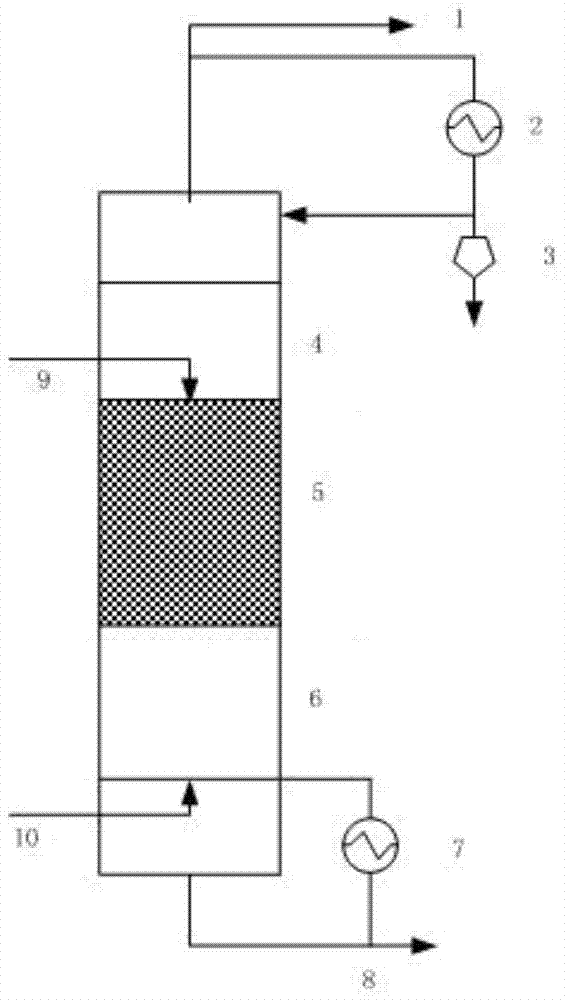

Method used

Image

Examples

Embodiment 1

[0039] Add 0.83g of palladium chloride, 0.03g of germanium chloride, and 0.045g of praseodymium chloride to 500mL of deionized water to prepare an aqueous solution, add 100g of ZSM-5 molecular sieves with a particle size of 2-3mm to the aqueous solution, and stir evenly , and then aged for 12 hours to obtain a catalyst precursor. After the catalyst precursor was dried, it was calcined at 200°C for 2h, and then reduced with hydrogen at 150°C for 2h at a hydrogen flow rate of 50mL / min to obtain 1# catalyst.

Embodiment 2-10

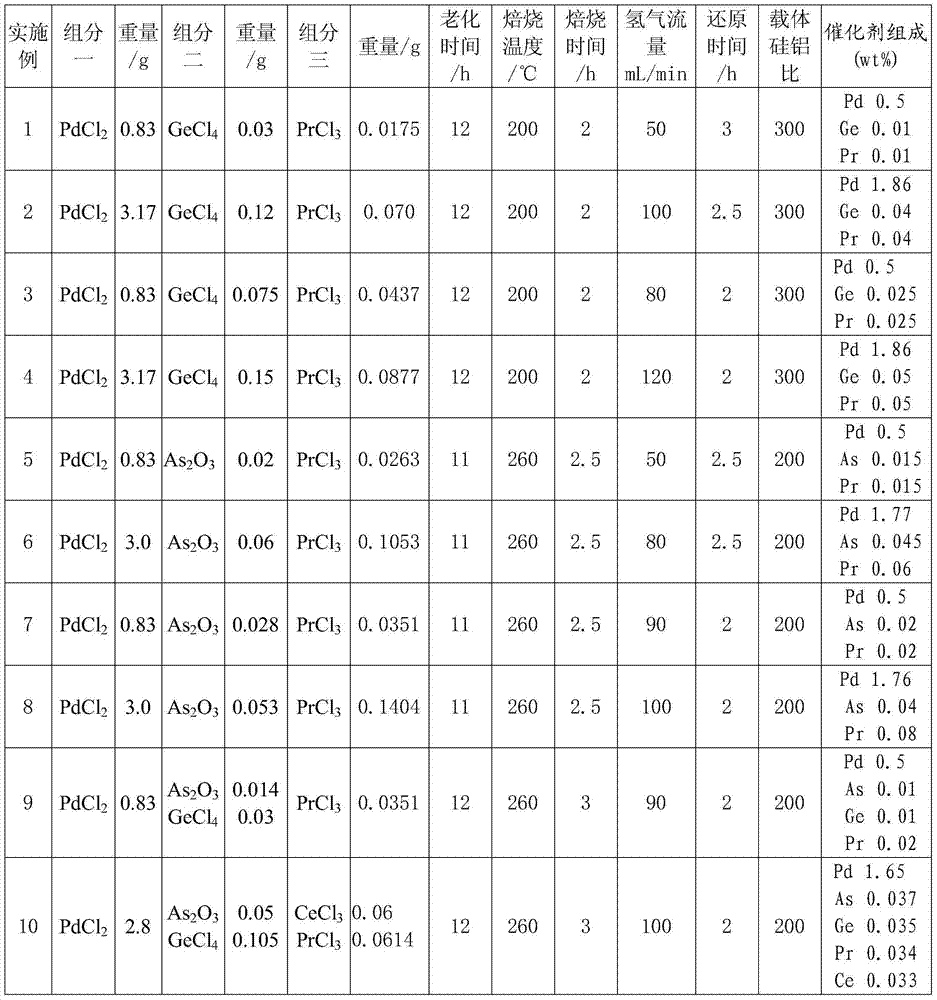

[0041] Using the same preparation steps as in Example 1, 500mL of deionized water, 100g of ZSM-5 molecular sieve carrier, hydrogen reduction temperature of 150°C, and other parameters according to Table 1 were used to prepare 2~10# catalysts respectively.

[0042] Table 1 catalyst preparation parameters

[0043]

[0044] Note: Catalyst composition = component weight / total weight of heterogeneous catalyst * 100%

Embodiment 11

[0048] Mix 100mL of 1# catalyst with 100mL of Φ2mm triangular spiral packing in the reaction section. The theoretical plate number of the reaction section is 30. Each of the rectification section and the stripping section is filled with 150mL of Φ2mm triangular spiral packing. The theoretical plate numbers are respectively 30 pieces. The system pressure is 50mmHg, the reaction temperature is 60°C, isoprenol is fed from the top of the reaction section, and the weight hourly space velocity is 3.0hr -1 , containing 20% hydrogen (volume ratio), hydrogen-nitrogen mixture gas is fed from the bottom of the stripping section, and the volume space velocity of the mixture gas is 200hr -1 , set total reflux at the top of the tower, hydrogen-nitrogen mixture gas and low boilers are discharged from the emptying system, a small amount of water produced by the reaction is separated through the water separator, and the reaction product is continuously extracted from the tower kettle. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com