Methanol gasoline additive for improving power

A technology for methanol gasoline and additives, which is applied in the field of methanol replacing vehicle fuels, can solve problems such as affecting the power output of automobile engines and low calorific value of methanol, and achieve the effects of improving combustion efficiency, reducing corrosion and enhancing power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] a, 16 kilograms of petroleum ether, 7 kilograms of isobutanol, 7 kilograms of dimethyl carbonate, 2.5 kilograms of nano-indium hydroxide and 3.5 kilograms of alkylphenol polyoxyethylene ether (OP-10) with an average particle diameter of 20 nm were added to In the reaction kettle, seal and ultrasonically disperse for 60-80 minutes at 35-40°C;

[0015] b. Mix 3.5 kg of isopropanolamine, 2.5 kg of diethylene glycol monooctyl ether, 5.5 kg of benzotriazole, and 7 kg of isopentenol, and stir for 20 to 30 minutes;

[0016] c. Add 4.5 kg of 2-methyl-2-butanol and the mixture in step b to the mixture in step a in sequence, and ultrasonically disperse at 33-35° C. for 50-70 minutes to obtain the product. When in use, it is directly added to M15 methanol gasoline in an amount of 0.4% to 0.5% of the weight of the methanol gasoline, and can be used after mixing evenly.

Embodiment 2

[0018] a, 15 kilograms of petroleum ether, 6 kilograms of isobutanol, 6 kilograms of dimethyl carbonate, 2 kilograms of nanometer indium hydroxide with an average particle diameter of 20 nm, and 3 kilograms of alkylphenol polyoxyethylene ether (OP-10) were added to In the reaction kettle, seal and ultrasonically disperse for 60-80 minutes at 35-40°C;

[0019] b. Mix 3 kg of isopropanolamine, 2 kg of diethylene glycol monooctyl ether, 5 kg of benzotriazole, and 6 kg of isopentenol, and stir for 20 to 30 minutes;

[0020] c. Add 4 kg of 2-methyl-2-butanol and the mixture in step b to the mixture in step a in sequence, and ultrasonically disperse at 33-35° C. for 50-70 minutes to obtain the product. When in use, it is directly added to M15 methanol gasoline in an amount of 0.4% to 0.5% of the weight of the methanol gasoline, and can be used after mixing evenly.

Embodiment 3

[0022] a, 18 kilograms of petroleum ether, 8 kilograms of isobutanol, 8 kilograms of dimethyl carbonate, 3 kilograms of nanometer indium hydroxide of 20 nm, and 4 kilograms of alkylphenol polyoxyethylene ether (OP-10) are added to In the reaction kettle, seal and ultrasonically disperse for 60-80 minutes at 35-40°C;

[0023] b. Mix 4 kg of isopropanolamine, 3 kg of diethylene glycol monooctyl ether, 6 kg of benzotriazole, and 8 kg of isopentenol, and stir for 20 to 30 minutes;

[0024] c. Add 5 kg of 2-methyl-2-butanol and the mixture in step b to the mixture in step a in sequence, and ultrasonically disperse at 33-35° C. for 50-70 minutes to obtain the product. When in use, it is directly added to M15 methanol gasoline in an amount of 0.4% to 0.5% of the weight of the methanol gasoline, and can be used after mixing evenly.

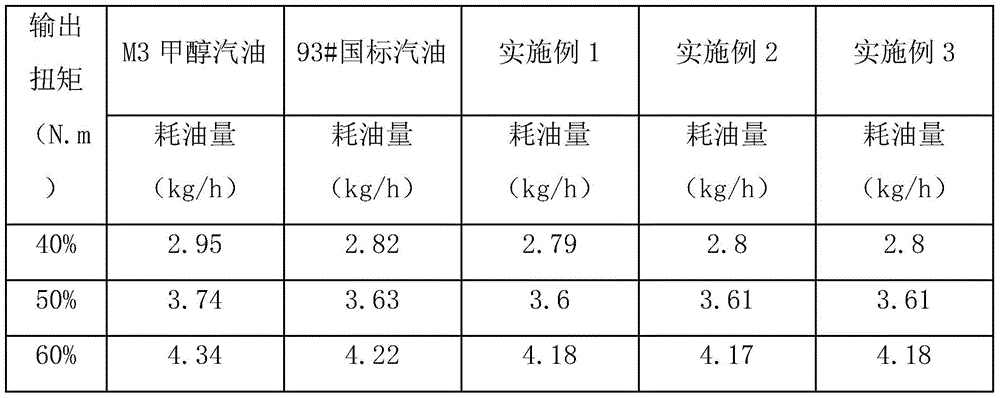

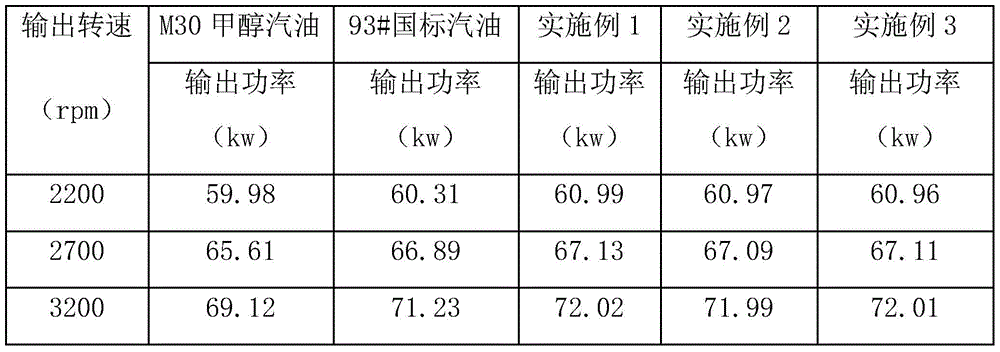

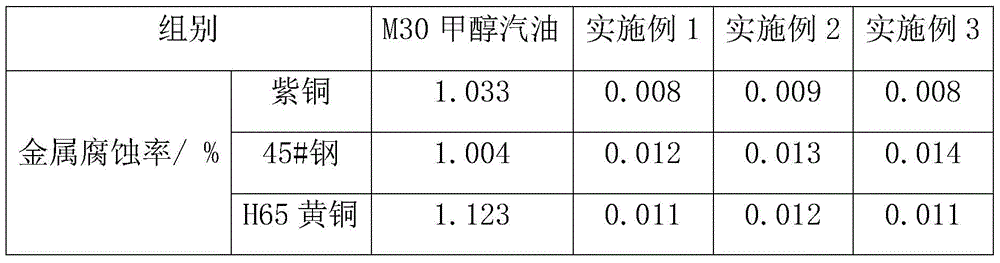

[0025] Related experiments: Gasoline engine bench test is an important means to test the comprehensive performance of vehicle fuels, and it is also a ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com