Washable coating material and preparation method thereof

A technology of coating material and washability, which is applied in the field of washability coating material and its preparation, can solve the problems of poor washability, etc., and achieve the goal of improving heat insulation capacity, good heat insulation, and good washability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

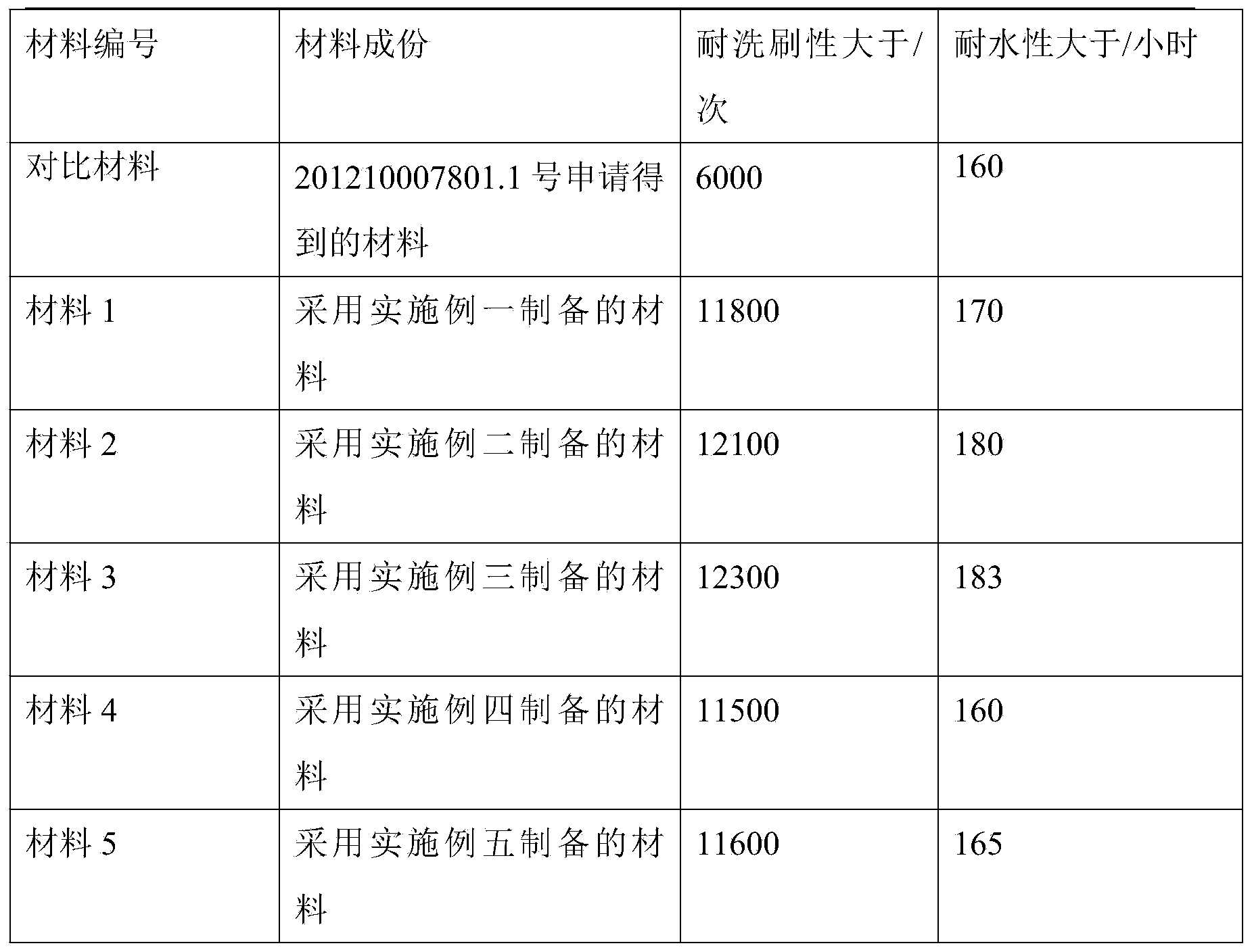

Examples

Embodiment 1

[0034] The preparation method of washable coating material of the present invention, the method comprises the following steps:

[0035] 1) Preparation of titanium-containing microcrystalline cellulose composite powder:

[0036] In an ice-water bath (0°C), slowly drop 90mL of titanium tetrachloride into 420mL of isopropanol to form a solution, add 4.8mL of concentrated hydrochloric acid (37% by mass) to the solution, stir well, then add dropwise 135mL Ammonia water (mass percentage concentration 28%) forms solution A.

[0037] Mix the microcrystalline cellulose and the concentrated sulfuric acid solution with a mass percent concentration of 50% in a weight ratio of 1:20, and ultrasonically treat at 50-55° C. for 1 hour at an ultrasonic frequency of 50 kHz and 400 W to obtain a milky white suspension B. Stand-by; wherein the particle diameter of microcrystalline cellulose is 70-75nm;

[0038] Mix the above liquid A and solution B at a mass ratio of 1:1.3. After mixing, ultraso...

Embodiment 2

[0047]The mass ratio of liquid A and solution B in step 1) is 1:1.4;

[0048] The percentage by weight of each composition in the coating material in step 3) is: nano-scale titanium-containing microcrystalline cellulose composite powder 25%, slag powder 16%, polyurethane 0.2%, titanium dioxide 5%, silica sol 0.5%, quartz powder 5%, and the rest is 3-methyl-2-buten-1-ol acetate complex solution.

[0049] Other preparation process is the same as embodiment one.

Embodiment 3

[0051] The mass ratio of liquid A and solution B in step 1) is 1:1.5;

[0052] The percentage by weight of each composition in the coating material in step 3) is: nano-scale titanium-containing microcrystalline cellulose composite powder 23%, slag powder 14%, polyurethane 0.17%, titanium dioxide 4%, silica sol 0.3%, quartz powder 4%, and the rest is 3-methyl-2-buten-1-ol acetate complex solution.

[0053] Other preparation process is the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com