Preparation method for enabling 3-methyl-2-butene-1-alcohol to be synthesized into 3-methylcrotonaldehyde catalyst

A prenyl aldehyde catalyst and alcohol synthesis technology, which is applied in the direction of catalyst activation/preparation, carbon-based compound preparation, organic compound preparation, etc., can solve the problem of high catalyst cost and achieve the effect of low cost and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

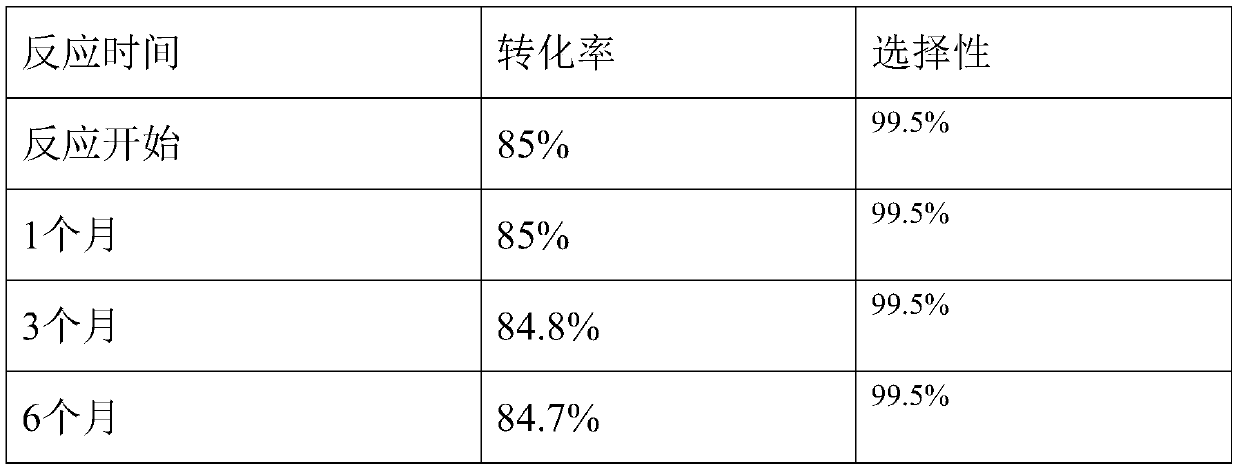

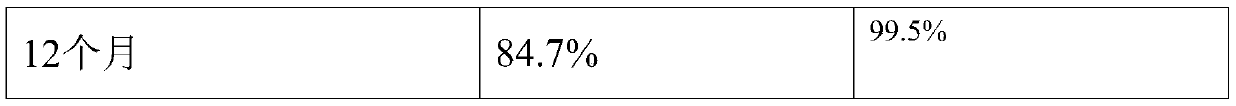

[0024] Take 500g of deionized water and put it into a four-necked reaction flask; raise the temperature to 60°C, and stir at a constant temperature; add 500g of 20% silica sol and 294.7g of 20% copper nitrate aqueous solution dropwise; add dropwise at a constant speed, and control the dropwise addition within 2 hours; Keep the temperature at 60°C and let it stand for aging for 6 hours; start stirring, control the temperature of the kettle at 60°C, add 245g of 5% ammonium heptamolybdate aqueous solution into the reaction bottle dropwise, and control the drop for one hour; then add 181g of 1% telluric acid aqueous solution dropwise Add it into the reaction bottle, control the dripping for 1 hour; keep the temperature at 60°C, let stand for aging for 2 hours; filter, wash the filter cake with deionized water until PH = 7; dry the filter cake at 120°C, and roast at 550°C for 6 hours; after roasting The catalyst is compressed into a 5*5mm cylinder and is ready for use. Take 50 g of...

Embodiment 2

[0027] Take 500g of deionized water and put it into a four-necked reaction flask; raise the temperature to 60°C, and stir at a constant temperature; add 500g of 20% silica sol and 333g of 20% copper nitrate aqueous solution; 60°C, stand for aging for 6 hours; start stirring, control the temperature of the kettle at 60°C, add 222g of 4.5% ammonium heptamolybdate aqueous solution dropwise into the reaction bottle, and control the dripping for one hour; then add 100g of 1% telluric acid aqueous solution Add it dropwise into the reaction bottle, and control the dripping for 1 hour; keep the temperature at 60°C, let it stand for aging for 2 hours; filter, wash the filter cake with deionized water until PH=7; dry the filter cake at 120°C, and roast at 550°C for 6 hours; roast The final catalyst was compressed into a 5*5mm cylinder for use. Take 50 g of the formed catalyst and fill it into the middle of the fixed-bed reactor, control the temperature at 230° C. and the hydrogen flow r...

Embodiment 3

[0030] Take 500g of deionized water and put it into a four-necked reaction flask; raise the temperature to 60°C, and stir at a constant temperature; add 500g of 20% silica sol and 294.7g of 20% copper nitrate aqueous solution dropwise; add dropwise at a constant speed, and control the dropwise addition within 2 hours; Keep the temperature at 60°C and let it stand for aging for 6 hours; start stirring, control the temperature of the kettle at 60°C, add 300g of 5% ammonium heptamolybdate aqueous solution into the reaction bottle dropwise, and control the dripping for one hour; then add 200g of 1% telluric acid aqueous solution dropwise Add it into the reaction bottle, control the dripping for 1 hour; keep the temperature at 60°C, let stand for aging for 2 hours; filter, wash the filter cake with deionized water until PH = 7; dry the filter cake at 120°C, and roast at 550°C for 6 hours; after roasting The catalyst is compressed into a 5*5mm cylinder and is ready for use. Take 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com