Method for performing tubular continuous nitrification on naphthalene-2,7-disulfonic acid during production of H acid

A technology of disulfonic acid and disulfonic acid sulfuric acid, which is applied in the direction of sulfonic acid preparation and organic chemistry, can solve the problems of low production efficiency, uneven concentration distribution, low yield, etc., and achieve large production capacity and large heat transfer area , high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The tubular continuous nitration method of naphthalene-2,7-disulfonic acid in the production of H acid includes:

[0024] 1. Prepare naphthalene-2,7-disulfonic acid sulfuric acid solution;

[0025] 2. Preparation of nitric acid and sulfuric acid mixture;

[0026] 3. Complete the nitration reaction in the nitration reactor.

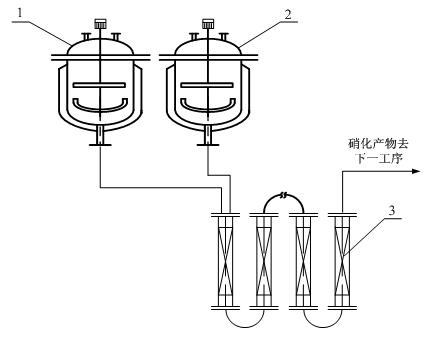

[0027] Such as figure 1 As shown, the prepared naphthalene-2,7-disulfonic acid sulfuric acid solution and the nitric acid sulfuric acid mixture are continuously added to the tubular continuous nitration reactor 3 in proportion, while flowing, mixing, reacting, heat exchange, and the reactants are removed. The first step: control the reaction temperature 40~50℃, the reaction time is 60 minutes; control the total amount of sulfuric acid in the naphthalene-2,7-disulfonic acid sulfuric acid solution and the nitric acid sulfuric acid mixed solution, so that the adiabatic temperature rise of the reaction process is less than 160℃; H The equipment used in the pip...

Embodiment 2

[0029] The difference between the second embodiment and the first embodiment is that the tubular continuous nitration reactor 3 is equipped with a chemical packing Raschig ring.

Embodiment 3

[0031] The third embodiment is different from the first embodiment in that the tubular continuous nitration reactor 3 is a commercially available SV type static mixer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com