Oscillatory flow tubular reactor of balking ring baffle

A technology of tubular reactor and oscillating flow, which is applied in the field of reactors, can solve the problems of limited application and the inability of the reactor to run continuously and stably for a long time, and achieve the effects of uniform residence time distribution, prevention of accumulation, and good heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

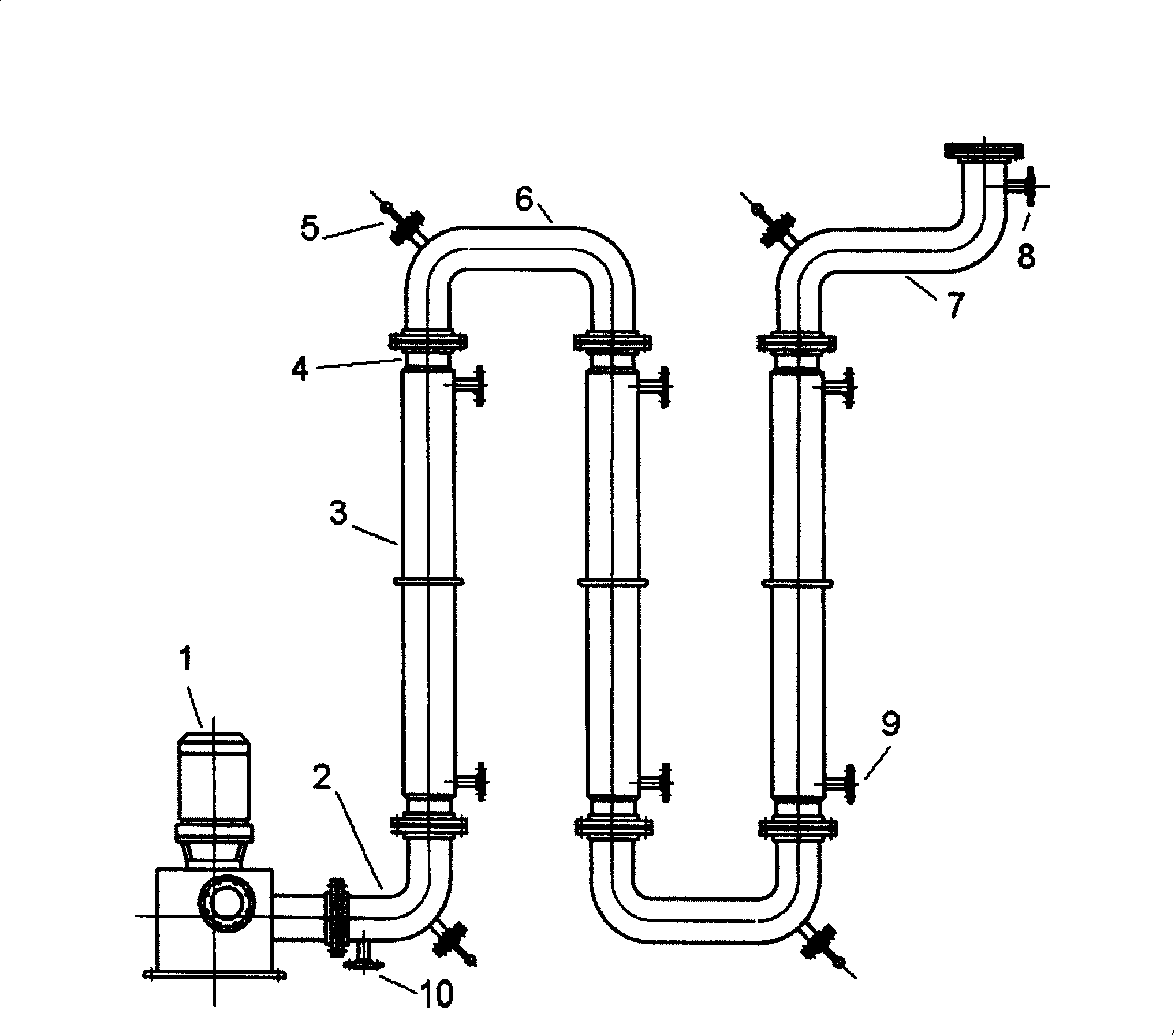

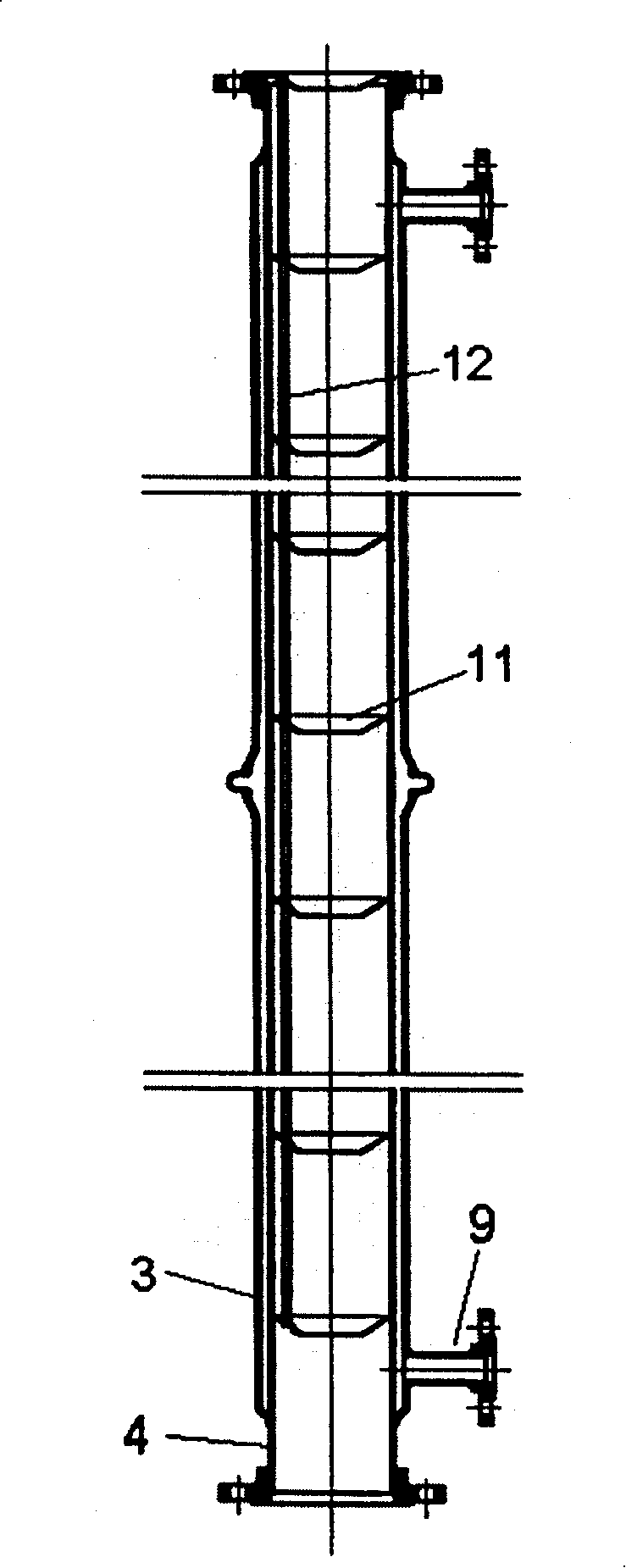

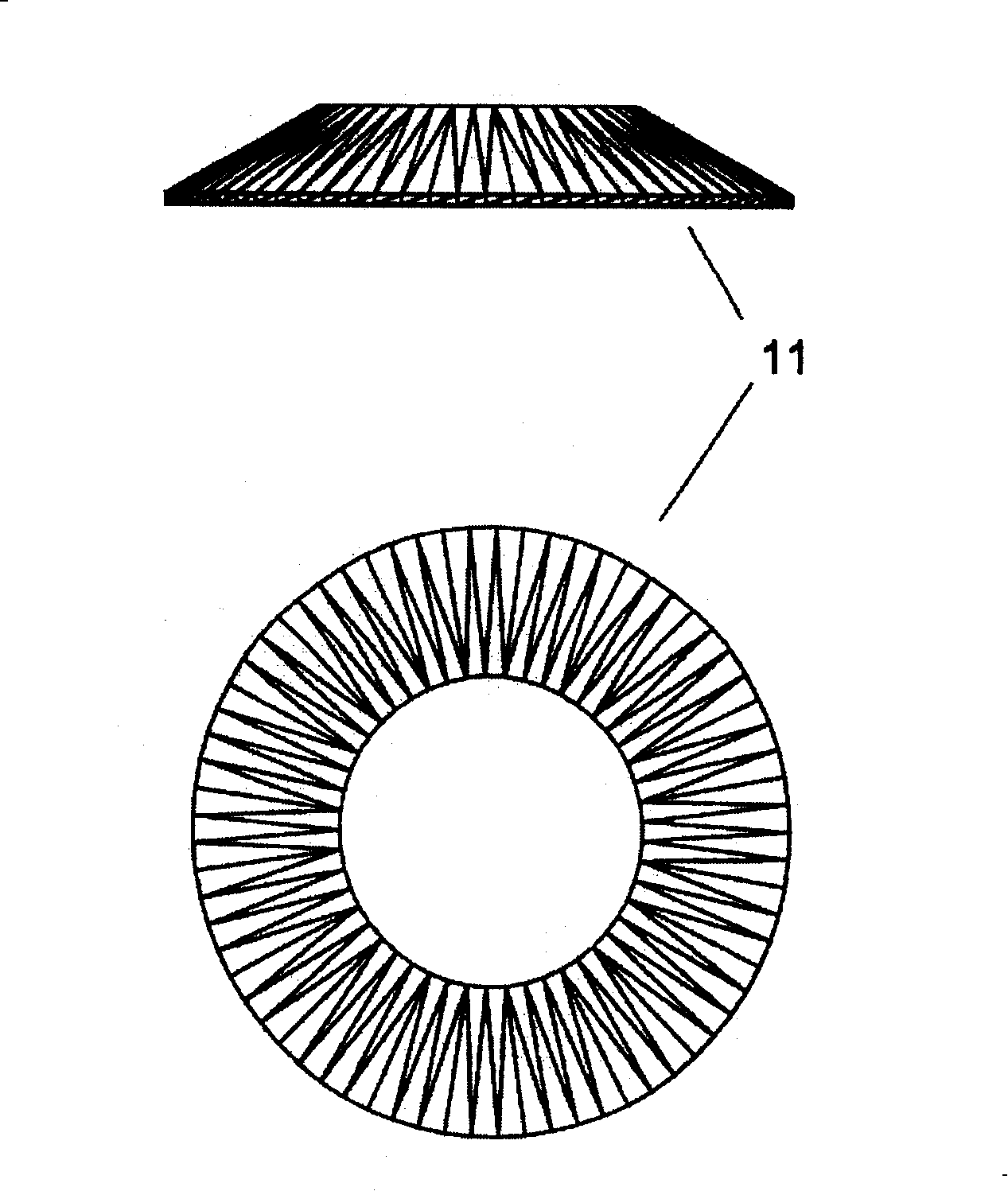

[0021] Cone ring baffle oscillating flow tubular reactor is composed of an oscillation generating mechanism 1, an inlet section 2, a reaction tube 4, and an outlet section 7 connected in sequence. A discharge port 8 is provided, and the reaction tube 4 is composed of vertically arranged circular reaction tubes. Conical ring baffles 11 arranged in an orderly vertical direction are arranged inside the tube to divide the space inside the tube into a multi-chamber structure.

[0022] The reaction section can be composed of multiple reaction tubes connected in series or in parallel to provide sufficient reaction space and residence time. The multiple reaction tubes are connected with connecting elbows.

[0023] The conical ring baffles 11 inside the reaction tube are connected and positioned by the baffle positioning rod 12, so as to keep the spatial position of each baffle and the distance between the baffles.

[0024] A heat exchange jacket 3 is arranged on the outside of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com