Patents

Literature

34results about How to "Good collection effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-contact ultrasonic testing method

ActiveCN102819035ARealistic simulation effectLarge dynamic rangeSeismic signal processingHigh pressureGeophysical prospecting

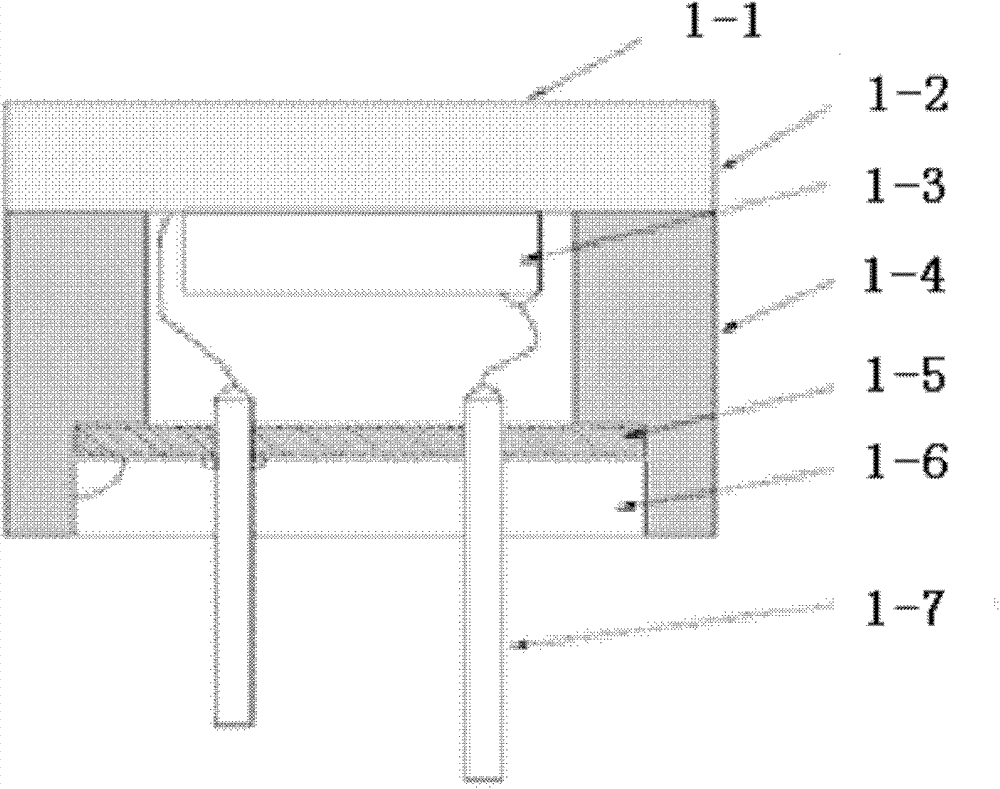

The invention provides a non-contact ultrasonic testing method and belongs to the field of ultrasonic vibration testing. The method is characterized in that high-voltage pulses or alternating voltage is adopted to excite high-frequency vibration of a non-contact focusing probeand further to induce sound waves to be transmitted out, sound wave radiation energy is focused, focused sound waves are emitted to a shot point of a tested geologic model, ultrasonic waves are generated on the shot point and transmitted to the interior of the tested geologic model, simultaneously a detection point of the tested geologic model is detected to obtain voltage signals, and the voltage signals are converted to digital signals and transmitted to a computer to be processed. The non-contact ultrasonic testing method solves the problem of various normal geologic model simulation methods, can perform large-scale multipoint non-contact ultrasonic detection for complex surface models and meets special requirements of modern geophysical prospecting fine simulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

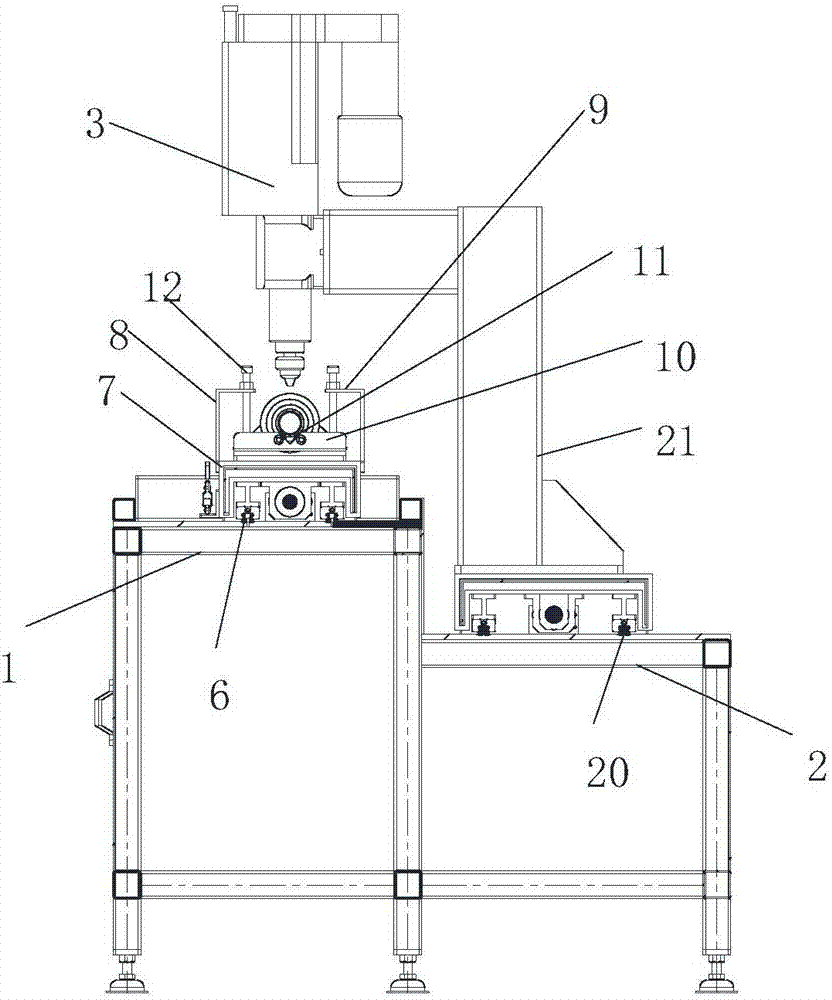

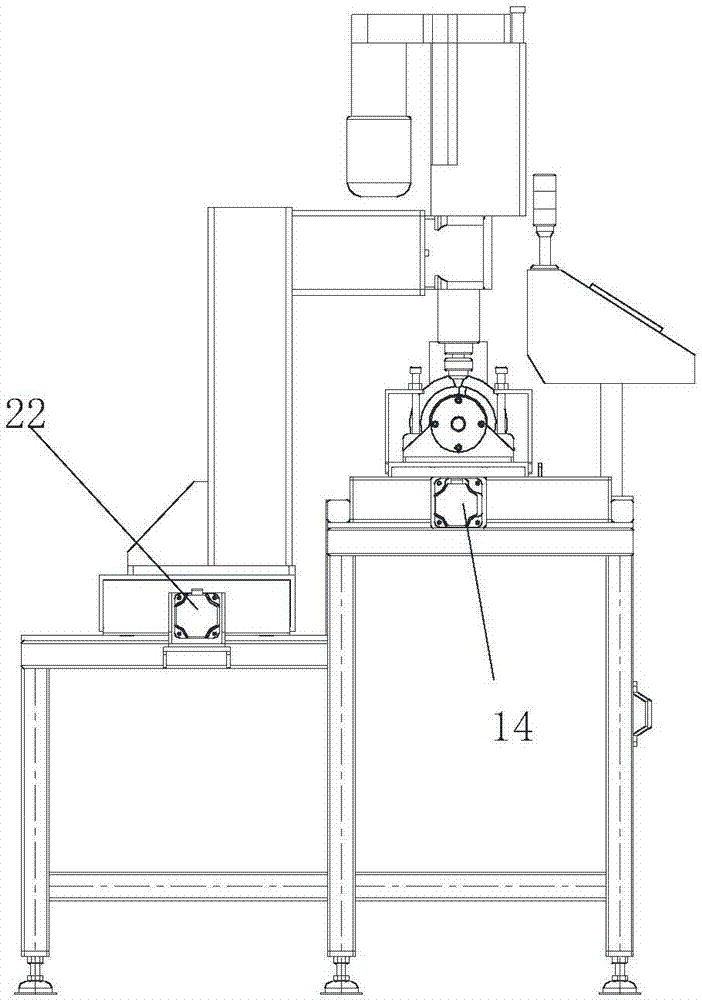

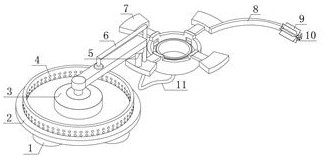

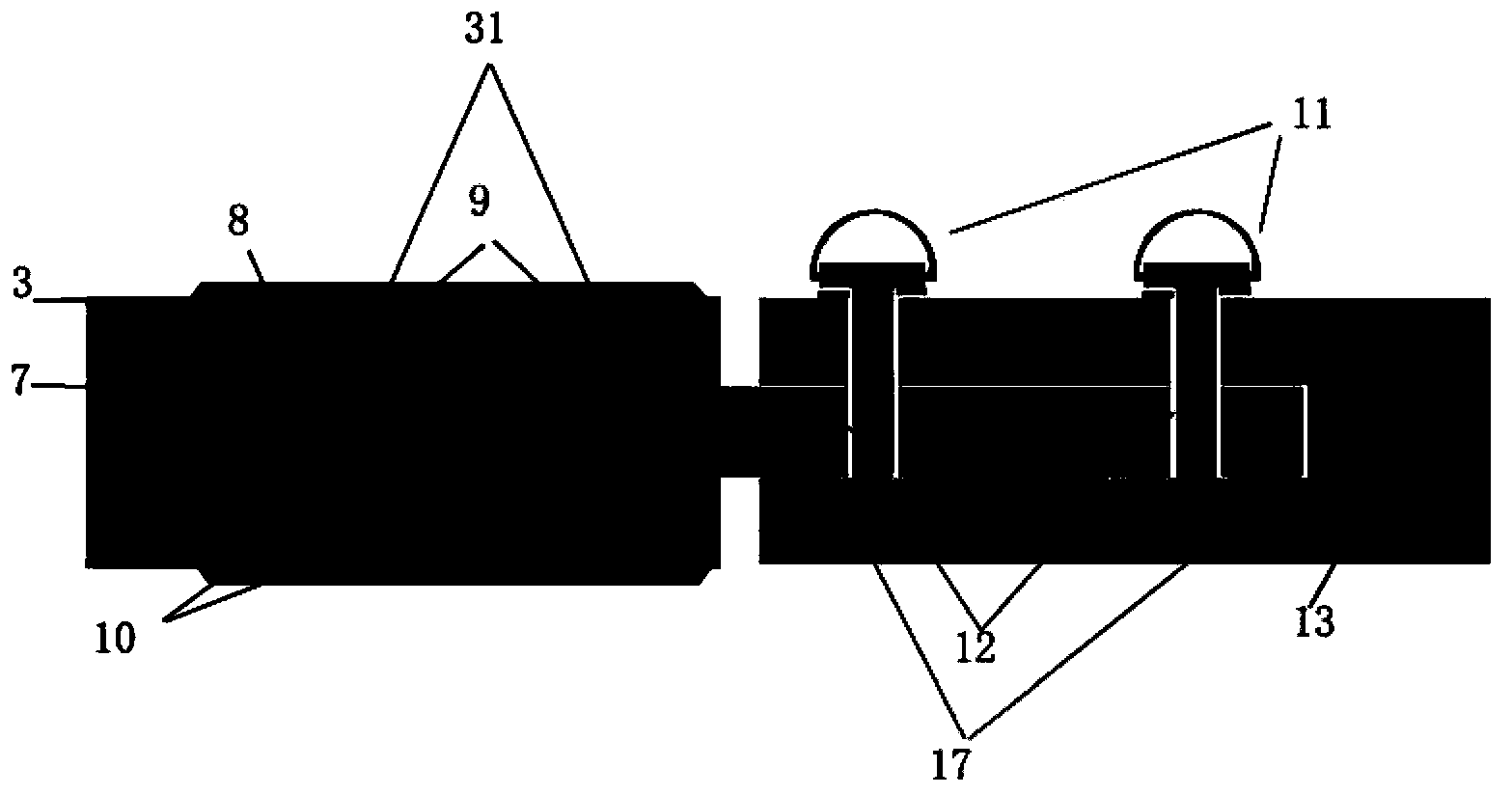

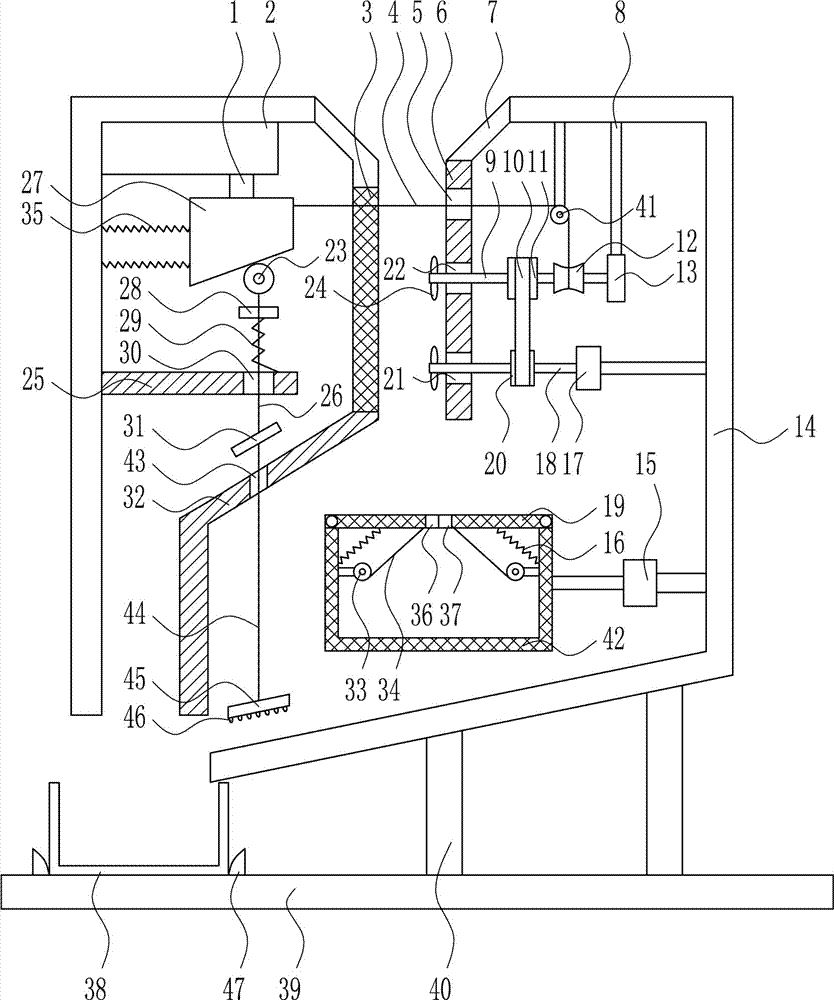

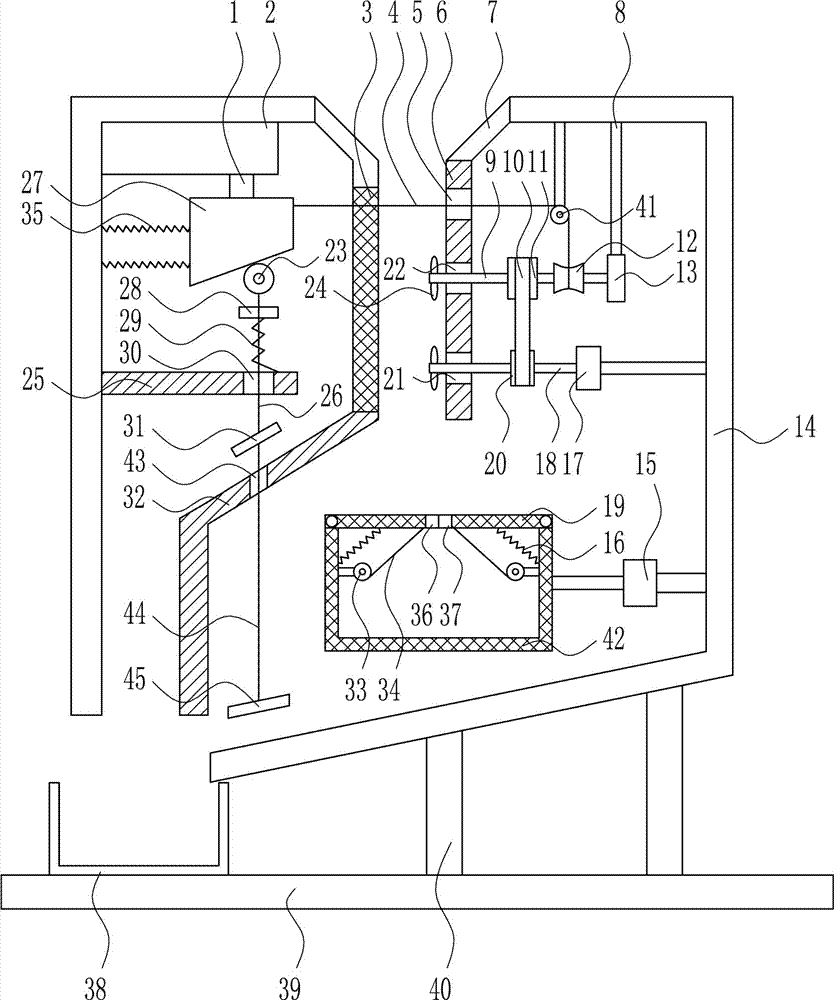

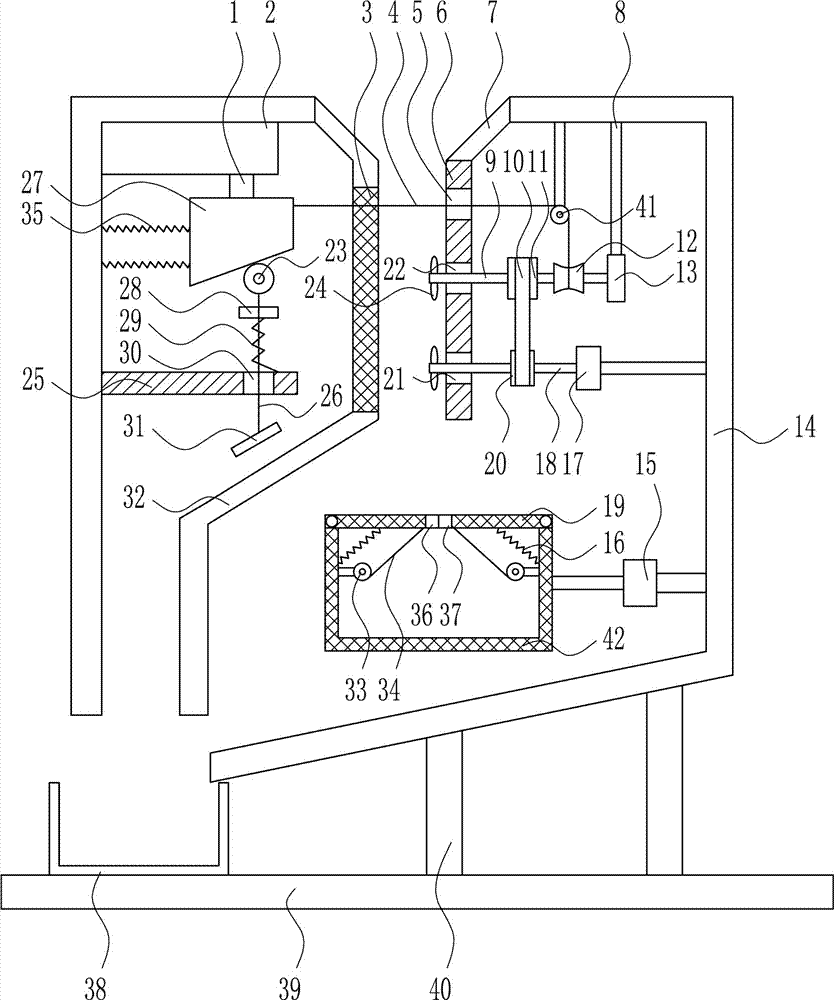

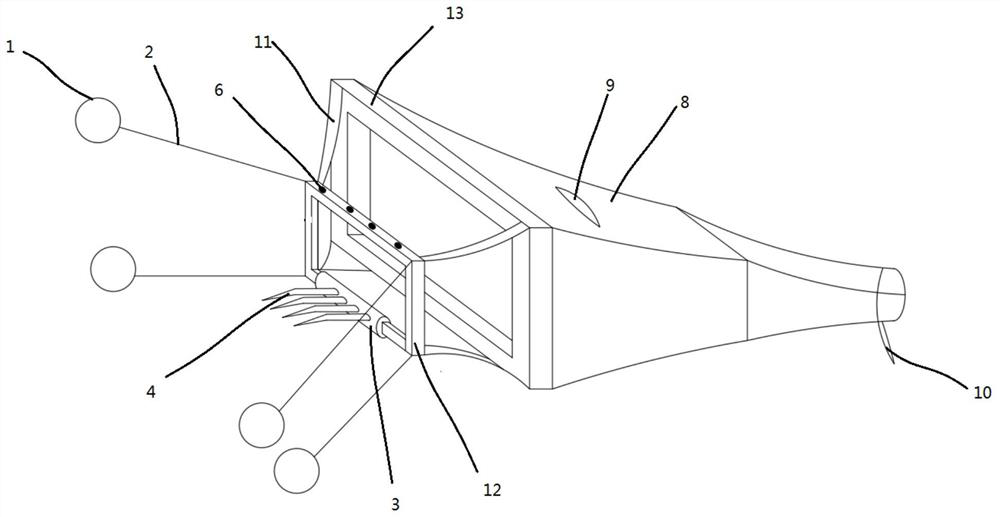

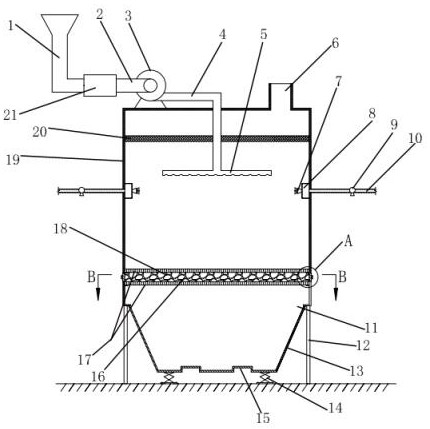

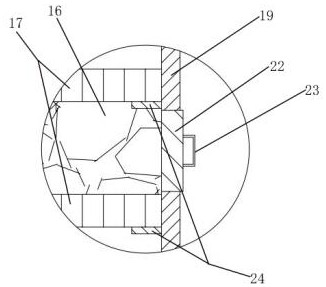

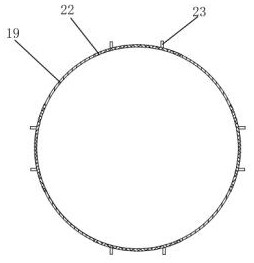

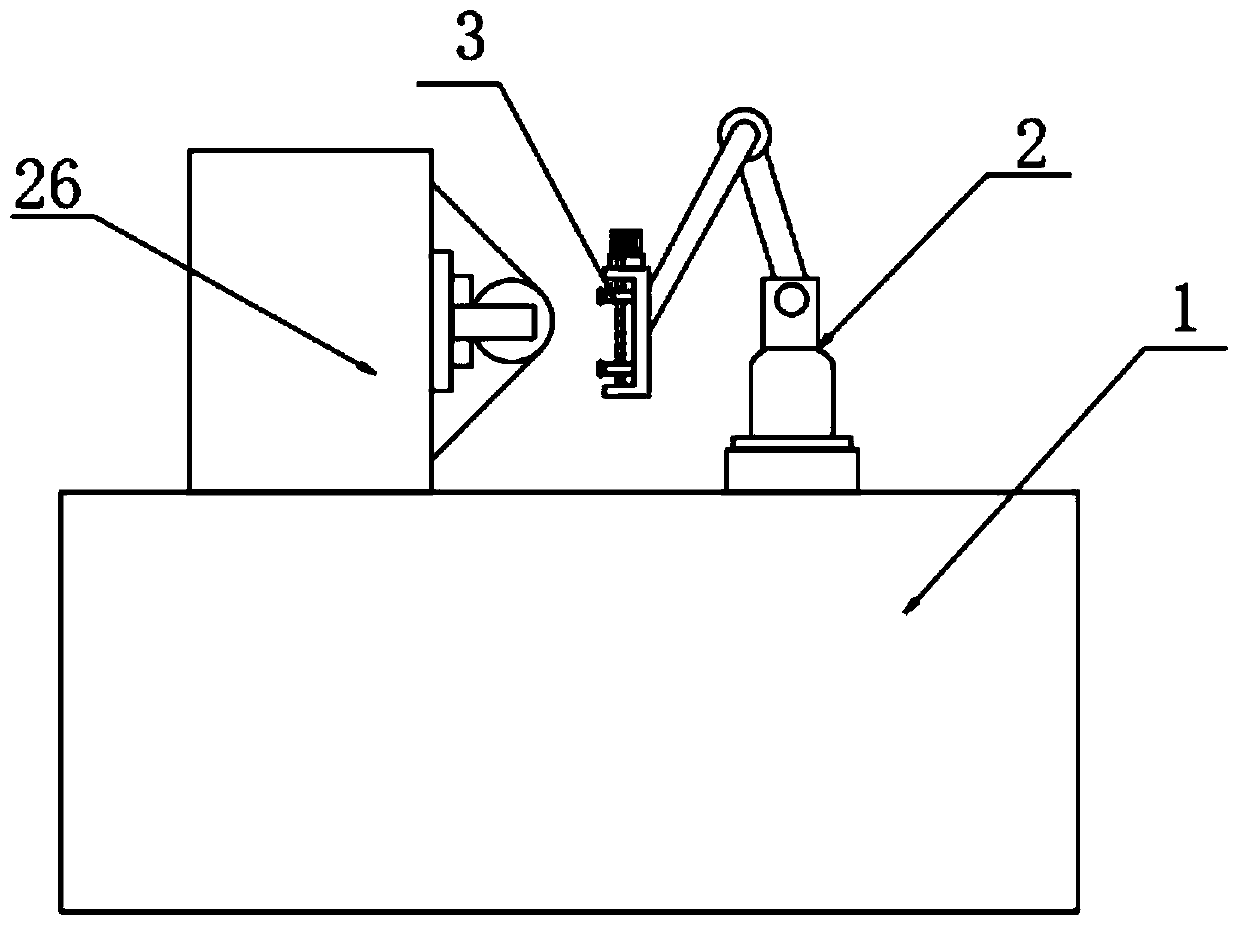

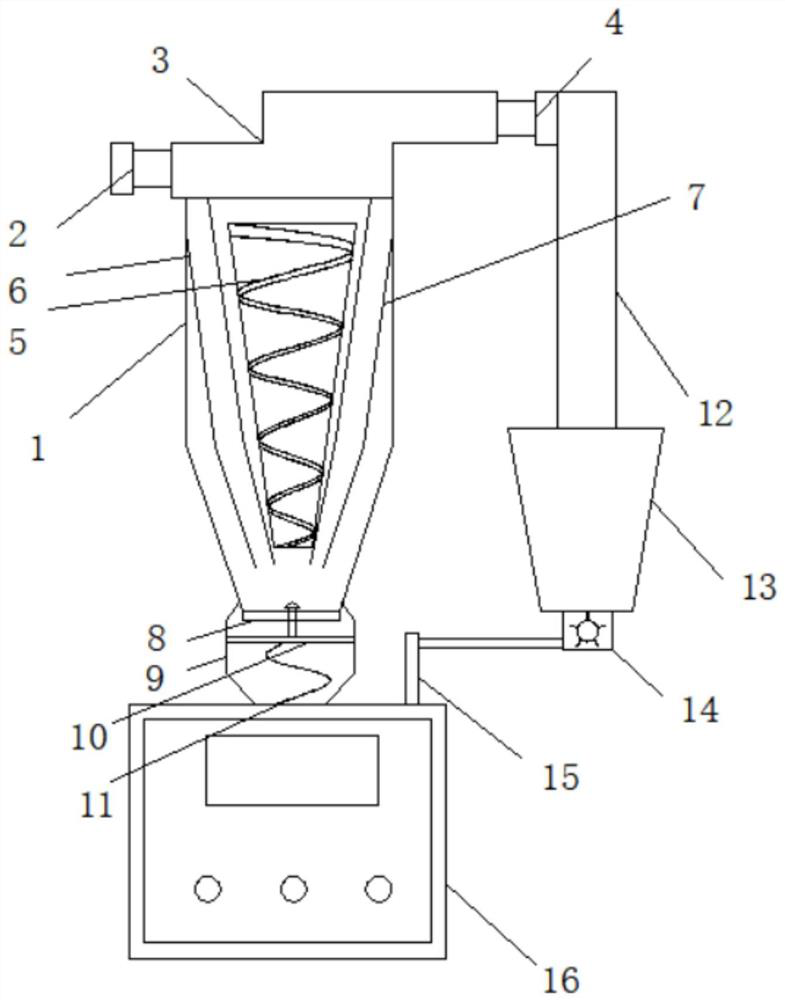

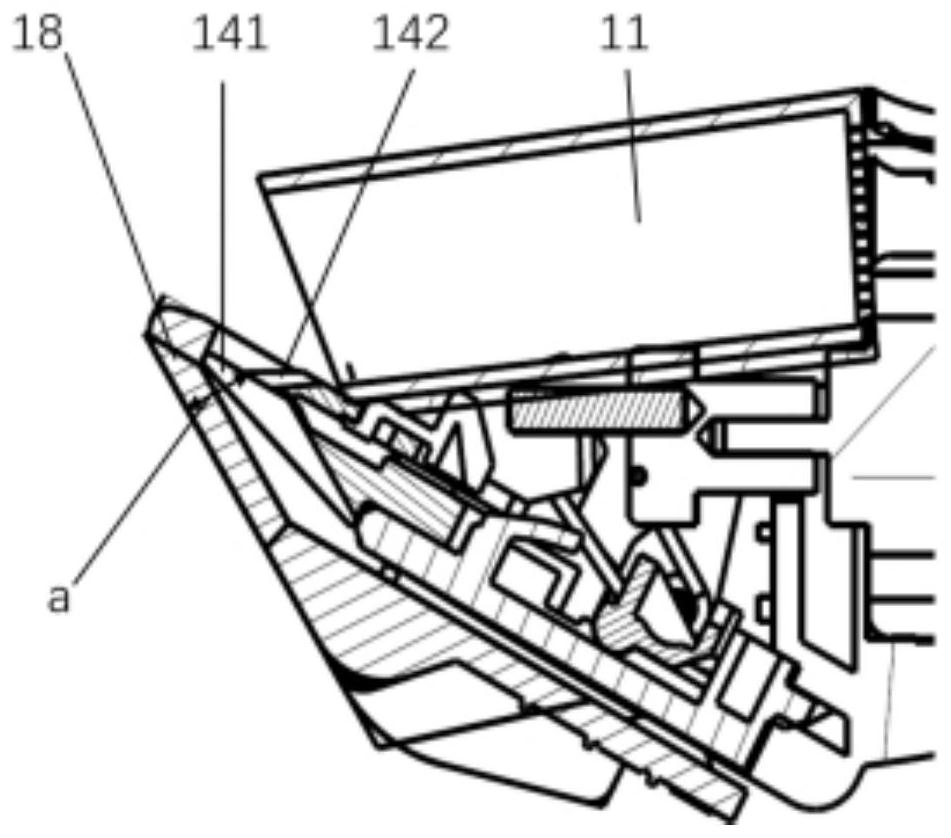

Intelligent steel pipe drilling device

InactiveCN106914640AGood collection effectClean upChucksMaintainance and safety accessoriesPipe supportScrap

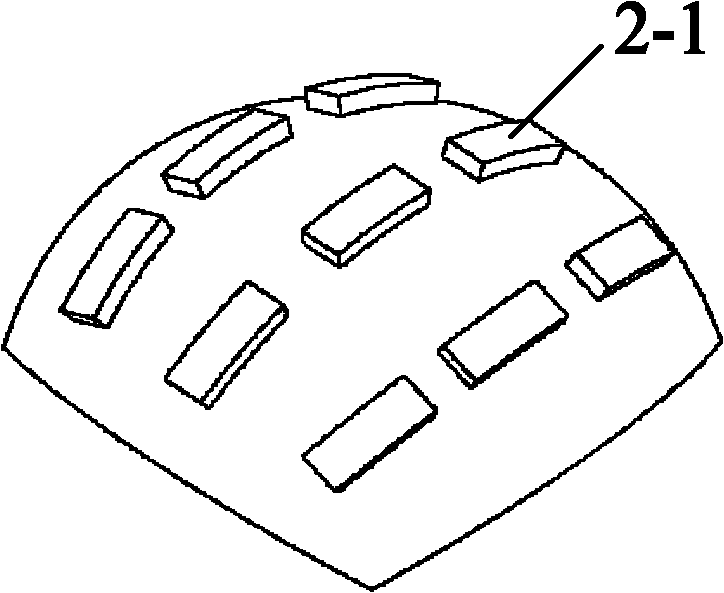

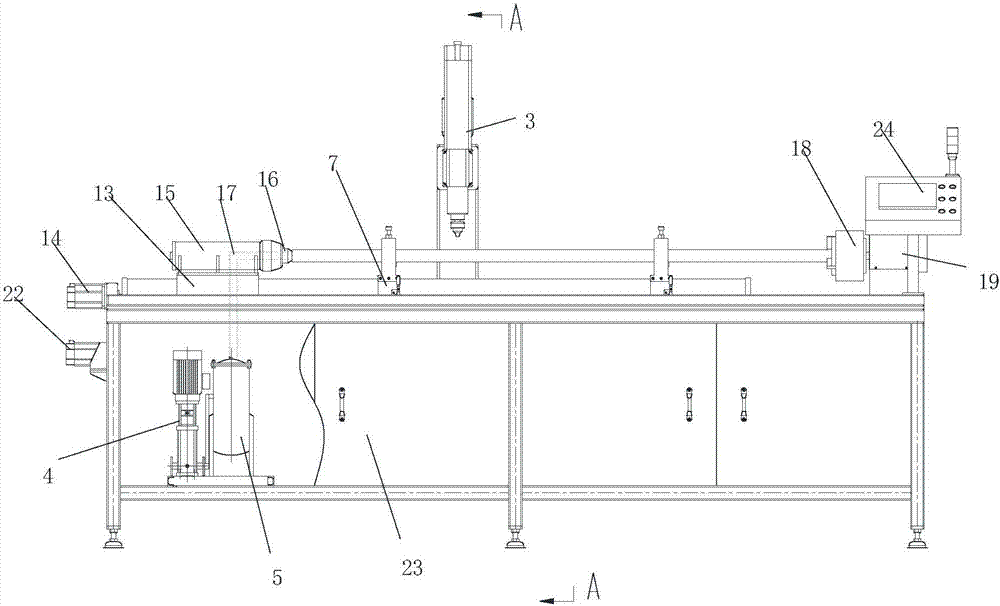

The invention relates to the technical field of drilling devices, in particular to an intelligent steel pipe drilling device. The intelligent steel pipe drilling device comprises a steel pipe fixing workbench, a drilling machine moving workbench, an automatic feed drilling machine, a negative-pressure pump and a negative-pressure tank. A first guide rail is fixedly arranged on the steel pipe fixing workbench. Steel pipe support mechanisms are arranged on the first guide rail. The steel pipe support mechanisms are in sliding fit with the first guide rail. The drilling machine moving workbench is arranged on one side of the steel pipe fixing workbench. A second guide rail is arranged on the drilling machine moving workbench. The bottom of the automatic feed drilling machine is in sliding fit with the second guide rail through a drilling machine bracket. A third stepping motor is arranged on one side of the drilling machine moving workbench. According to the intelligent steel pipe drilling device, the negative-pressure pump and the negative-pressure tank are arranged and communicate with a jackscrew through a gas pipe, scrap iron in a steel pipe enters the negative-pressure tank from the jackscrew under the negative-pressure function, the purpose of collecting the scrap iron is achieved, and it is indicated by the actual use of the applicant that the effect of collecting the scrap iron is extremely good, and the steel pipe is internally cleaned extremely clearly.

Owner:COLLEGE OF APPLIED SCI JIANGXI UNIV OF SCI & TECH

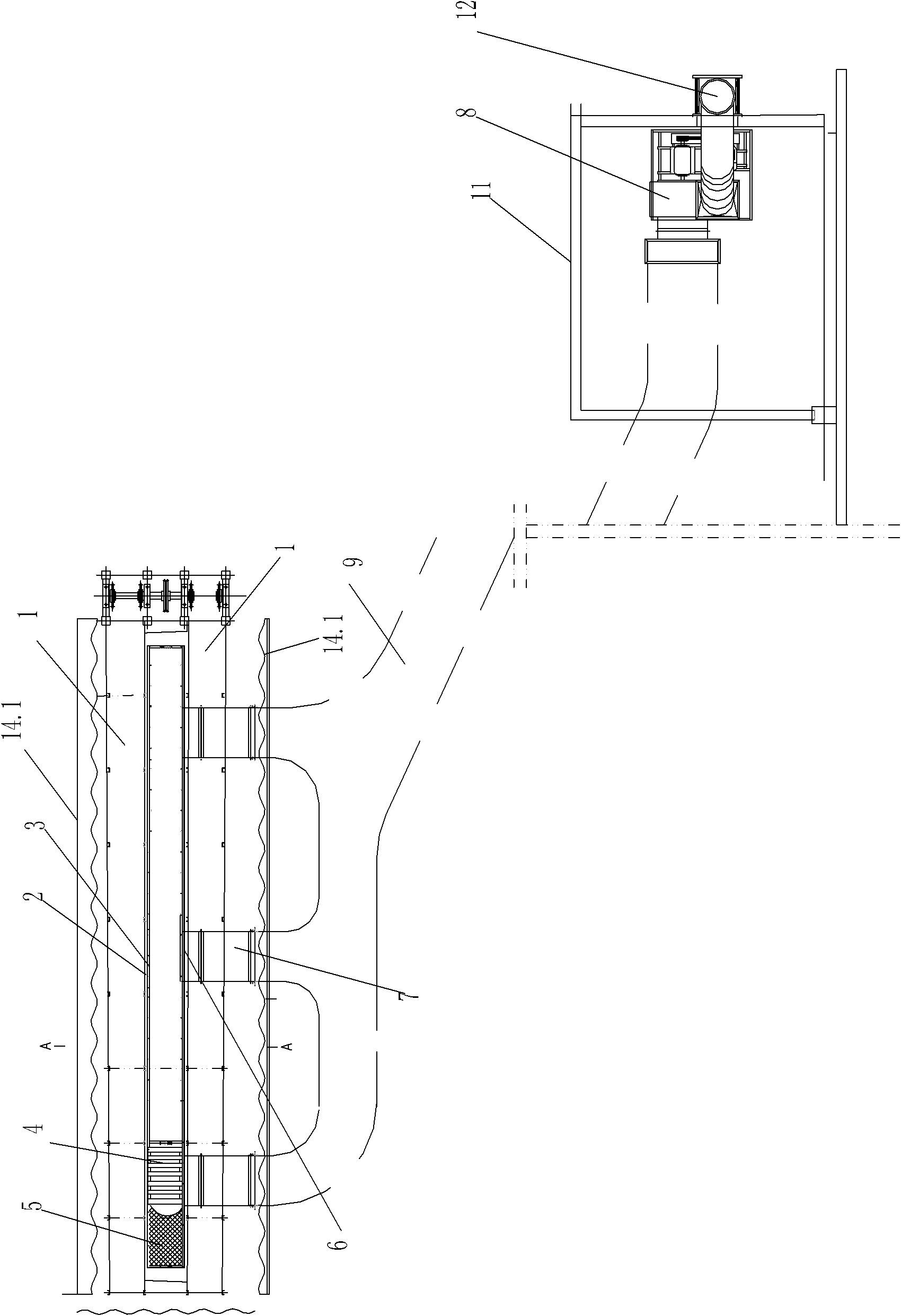

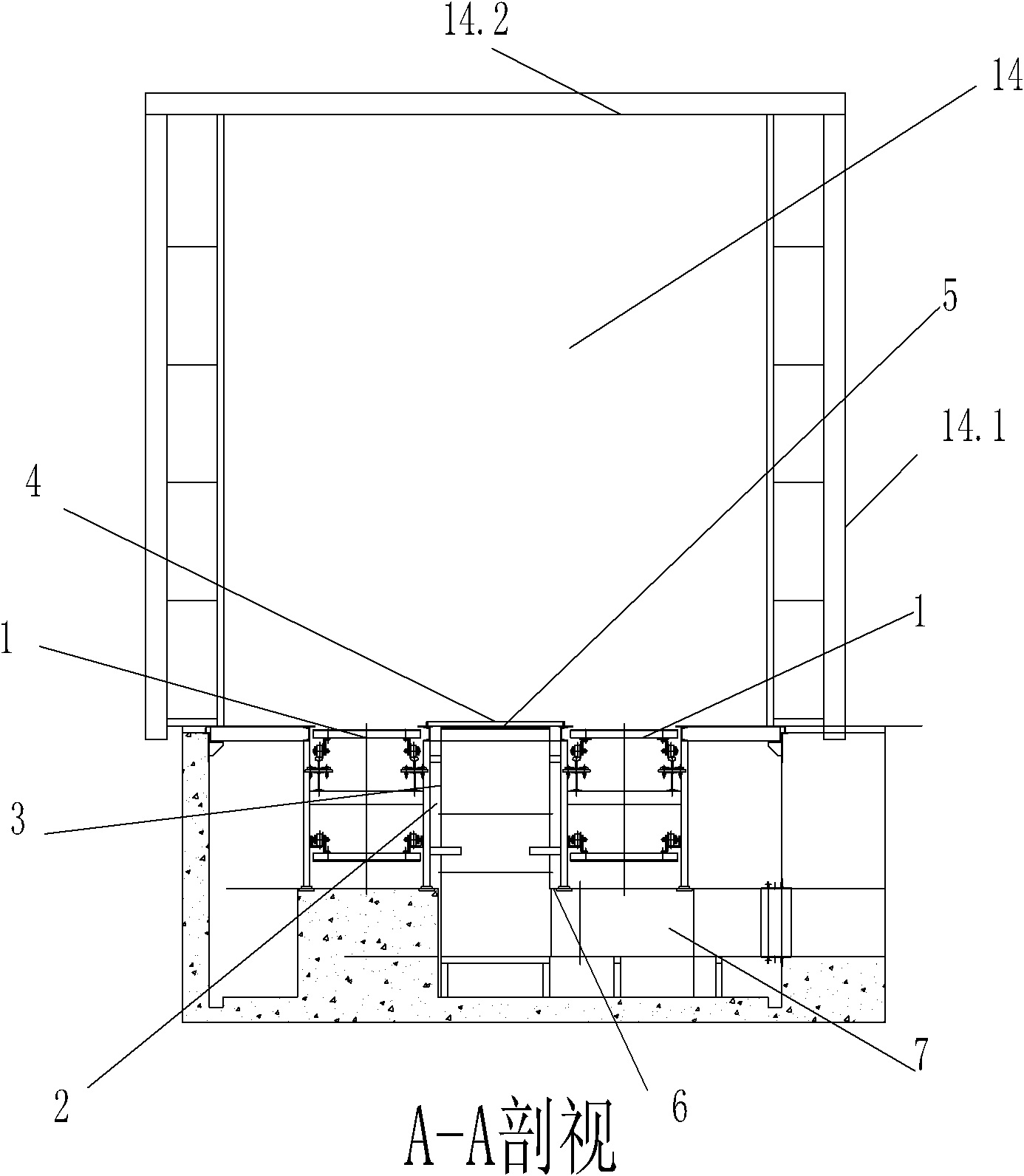

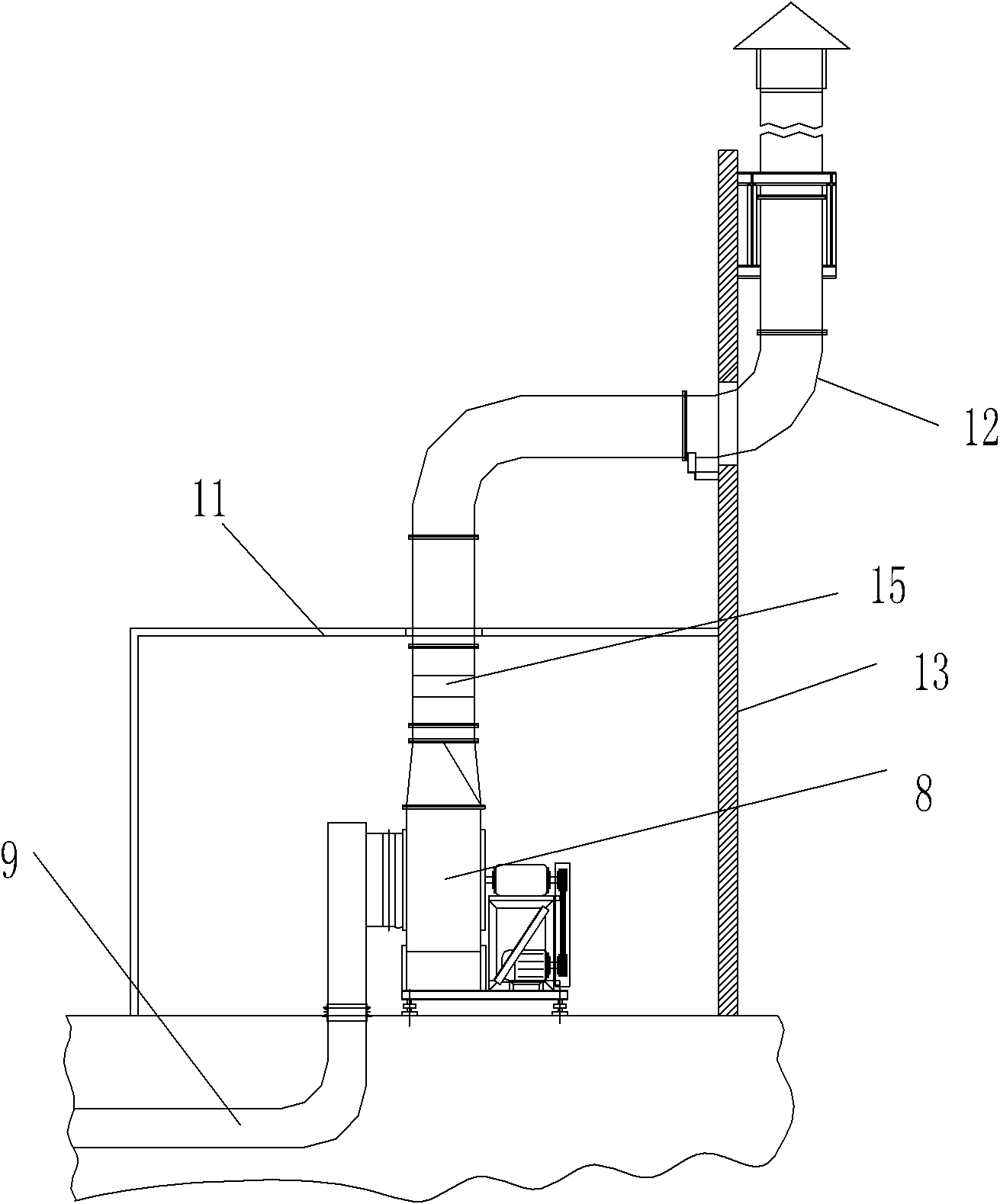

Tail gas collecting and exhausting device for automobile assembly lines

The invention discloses a tail gas collecting and exhausting device for automobile assembly lines, which comprises automobile conveying plate chains arranged on the indoor ground, wherein a section of tail gas collecting and air exhausting channel with an upper opening is arranged between the automobile conveying plate chains; a grating plate is covered on the upper opening of the tail gas collecting and air exhausting channel; exhaust holes are formed on the wall and / or the bottom of the tail gas collecting and air exhausting channel; the exhaust holes are connected and communicated with an inner exhaust pipe; an exhaust blower is connected on the inner exhaust pipe; the gas outlet of the exhaust blower is connected with an outer exhaust pipe; the outer exhaust pipe is arranged outside; and an automobile tail gas collecting chamber cover with two open ends is arranged on the ground of the tail gas collecting and air exhausting channel. Because the chamber type collecting chamber cover is adopted, the blowing quantity of the blower can be greatly reduced, and simultaneously, the emission of automobile tail gas is effectively controlled. The invention well ensures that the air outside the chamber type collecting chamber cover can not be polluted, and simultaneously, the power of the blower is greatly reduced, thereby achieving the purpose of saving energy sources.

Owner:武汉东研智慧设计研究院有限公司

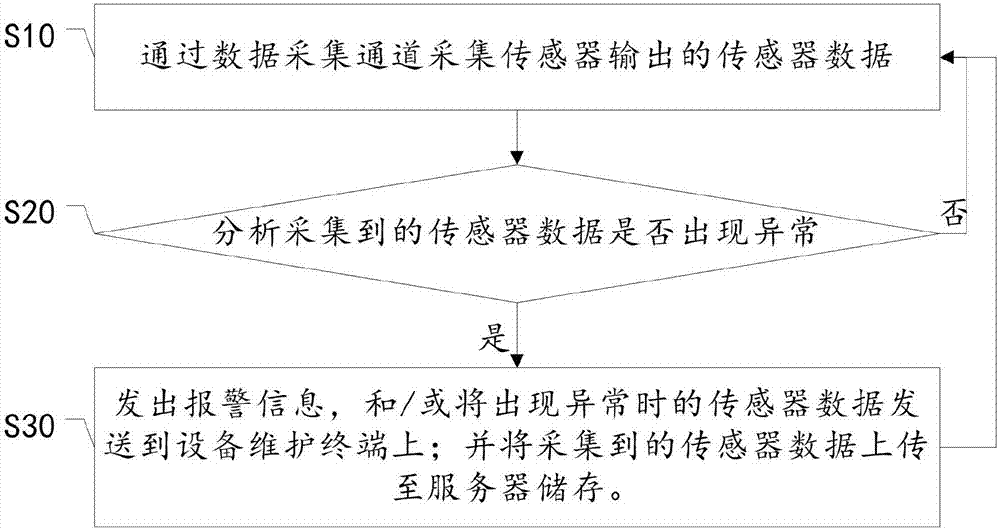

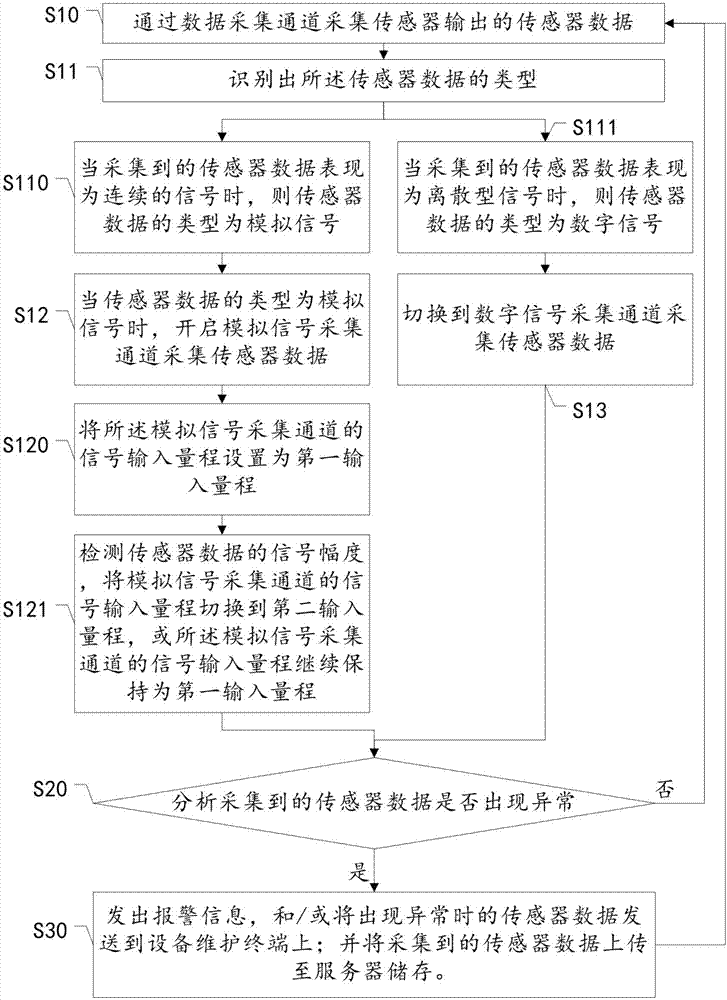

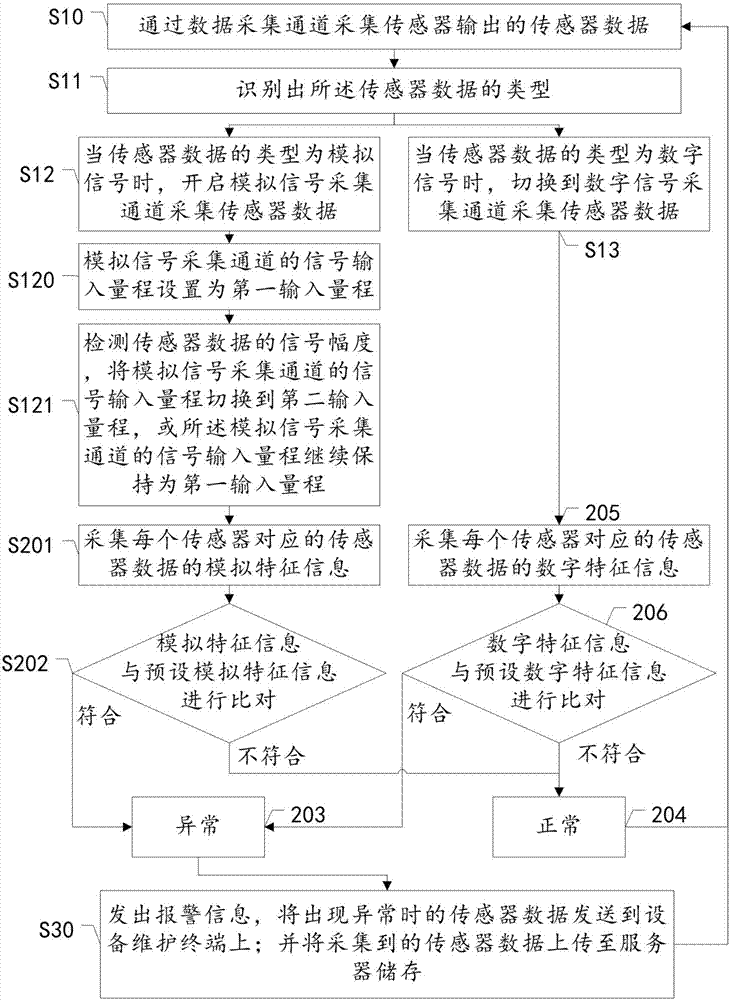

Method and system for detecting industrial fault

ActiveCN107544464AIntegrity guaranteedGood collection effectElectric testing/monitoringData acquisitionDigital signal

Owner:天津达芸科技有限公司

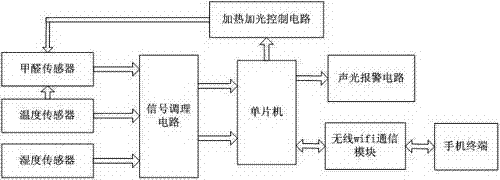

Formaldehyde detector based on WIFI

InactiveCN103940958AHigh sensitivityGood collection effectMaterial analysisMoisture sensorMobile phone

The invention discloses a formaldehyde detector based on WIFI. The detector comprises a single-chip processor, a formaldehyde sensor, a temperature sensor, a humidity sensor, a signal modulating circuit, a heating and lighting control circuit, a sound and light alarming circuit, and a wireless WIFI communication module; the formaldehyde sensor, the temperature sensor, and the humidity sensor are all connected to the single chip processor through the signal modulating circuit; the temperature sensor is arranged on the formaldehyde sensor; the single chip processor is connected to the input terminal of the heating and lighting control circuit; the output terminal of the heating and lighting control circuit is connected to the formaldehyde sensor; the single chip processor is connected to the sound and light alarming circuit; and the single chip processor communicates with a mobile phone terminal through the wireless WIFI communication module. The detector is excited by ultraviolet lights and a heating temperature of 75 DEG C to carried out formaldehyde collection, has the advantages of high sensitivity and good collecting effect, is convenient for users to observe the indoor formaldehyde concentration, is low in cost, is easy to promote, and has a very good application prospect.

Owner:李雅帝

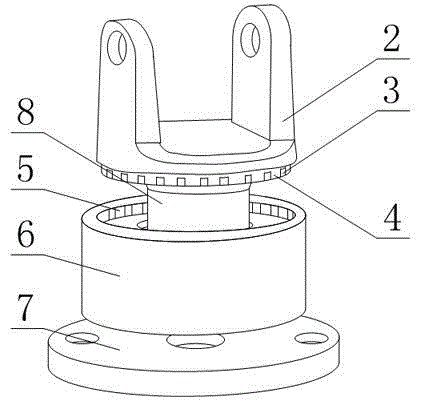

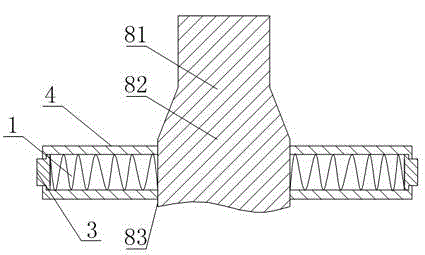

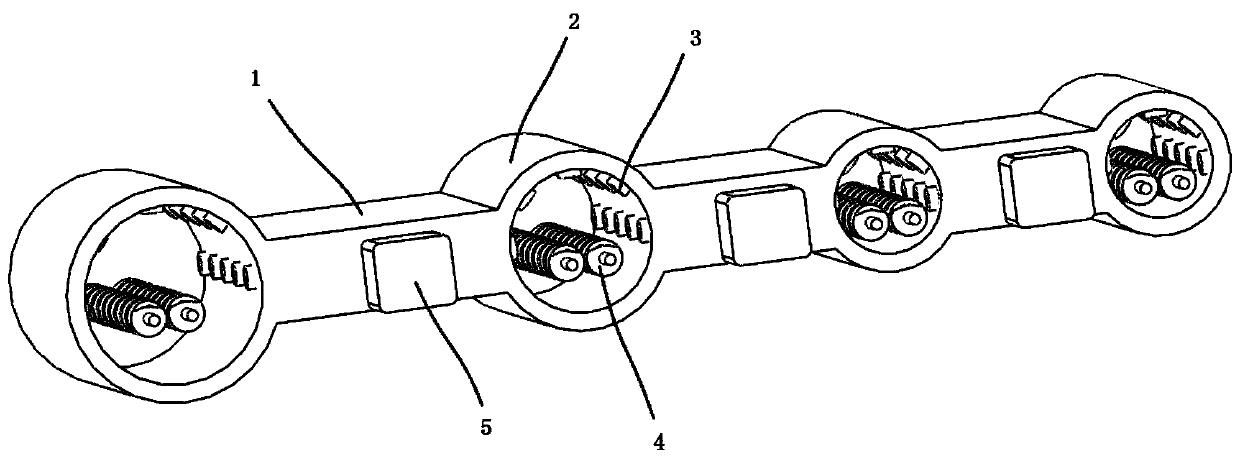

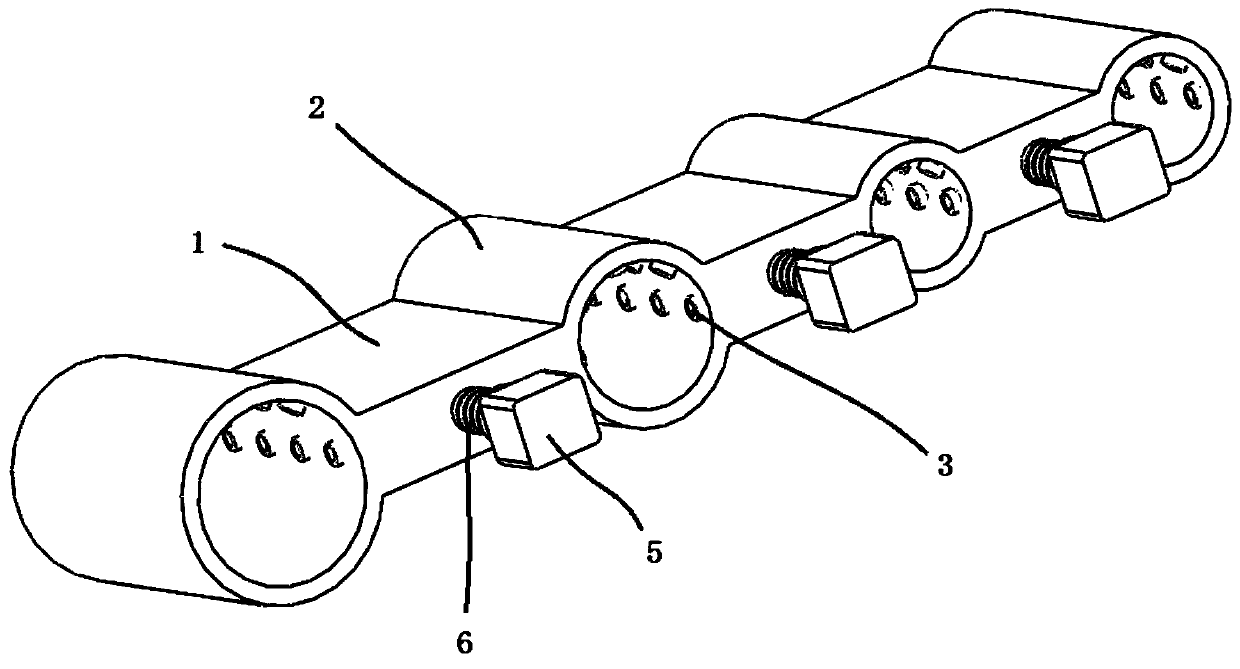

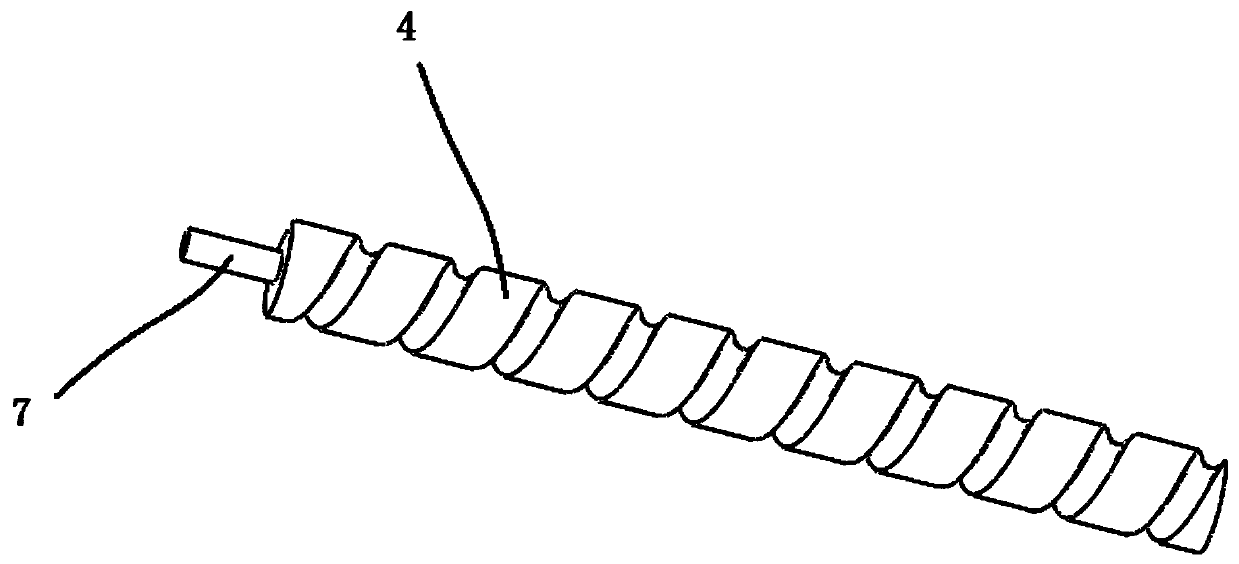

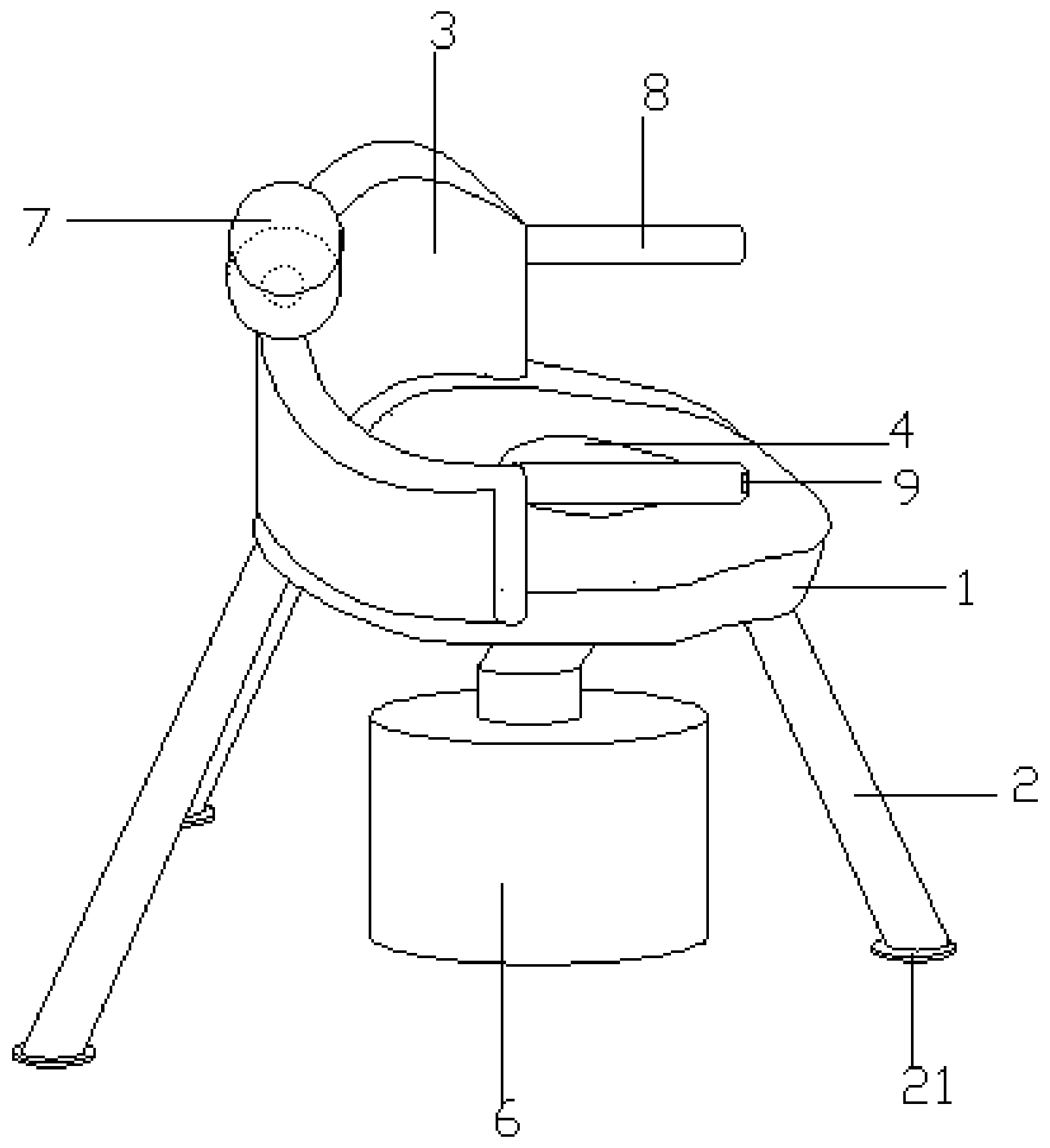

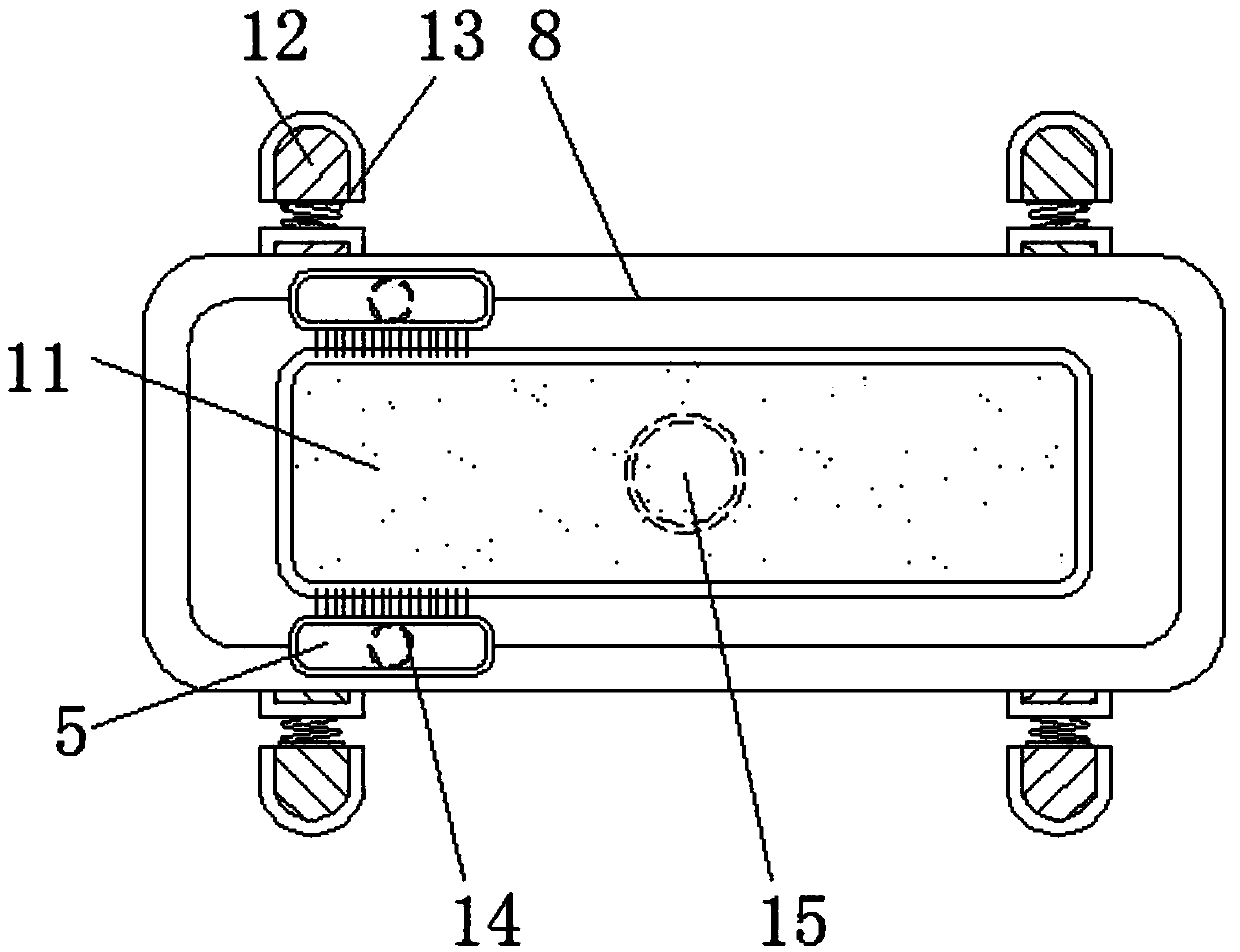

Information acquisition device mounting base

ActiveCN104455977AOrientation adjustmentOrientation is convenient and simpleStands/trestlesEngineeringMechanical engineering

The invention discloses an information acquisition device mounting base. The information acquisition device mounting base comprises a mounting plate and a mounting part arranged on the mounting plate. The mounting part comprises a rotary wheel seat and a rotary frame, wherein the rotary wheel seat is provided with a circular-ring-shaped rotary groove, and the side wall face of the rotary groove is provided with multiple tooth grooves; the rotary frame is provided with a rotary wheel, and the rotary wheel is provided with at least one anti-rotating part; the anti-rotating part comprises a limit plate and a spring; the rotary wheel is provided with a spring groove; a locating rod is further arranged on the rotary frame in a threaded connection mode; the locating rod comprises a threaded section, a variable-diameter section and an equal-diameter section; the center of the rotary wheel is provided with a threaded hole, the side face of the limit plate is a smooth face, and the limit plate protrudes relative to the side face of the rotary wheel. The information acquisition device mounting base is simple in structure and convenient to process and manufacture, an operator can adjust the facing direction of the rotary frame conveniently and easily, the facing direction of a camera can be adjusted by any tenderfoot, the optimal shooting or information recording effect can be achieved conveniently, and meanwhile the adjustment range of the facing direction of a reading device is large.

Owner:双环传动(嘉兴)精密制造有限公司

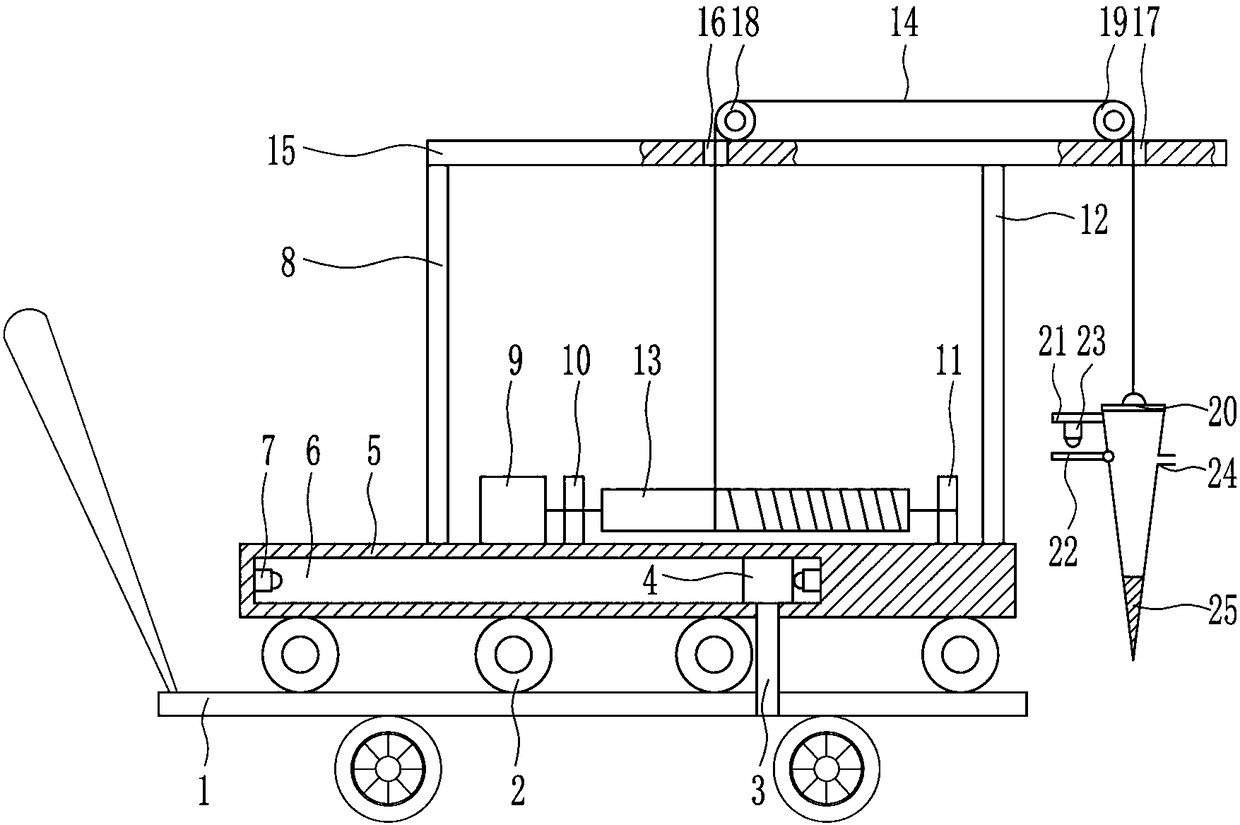

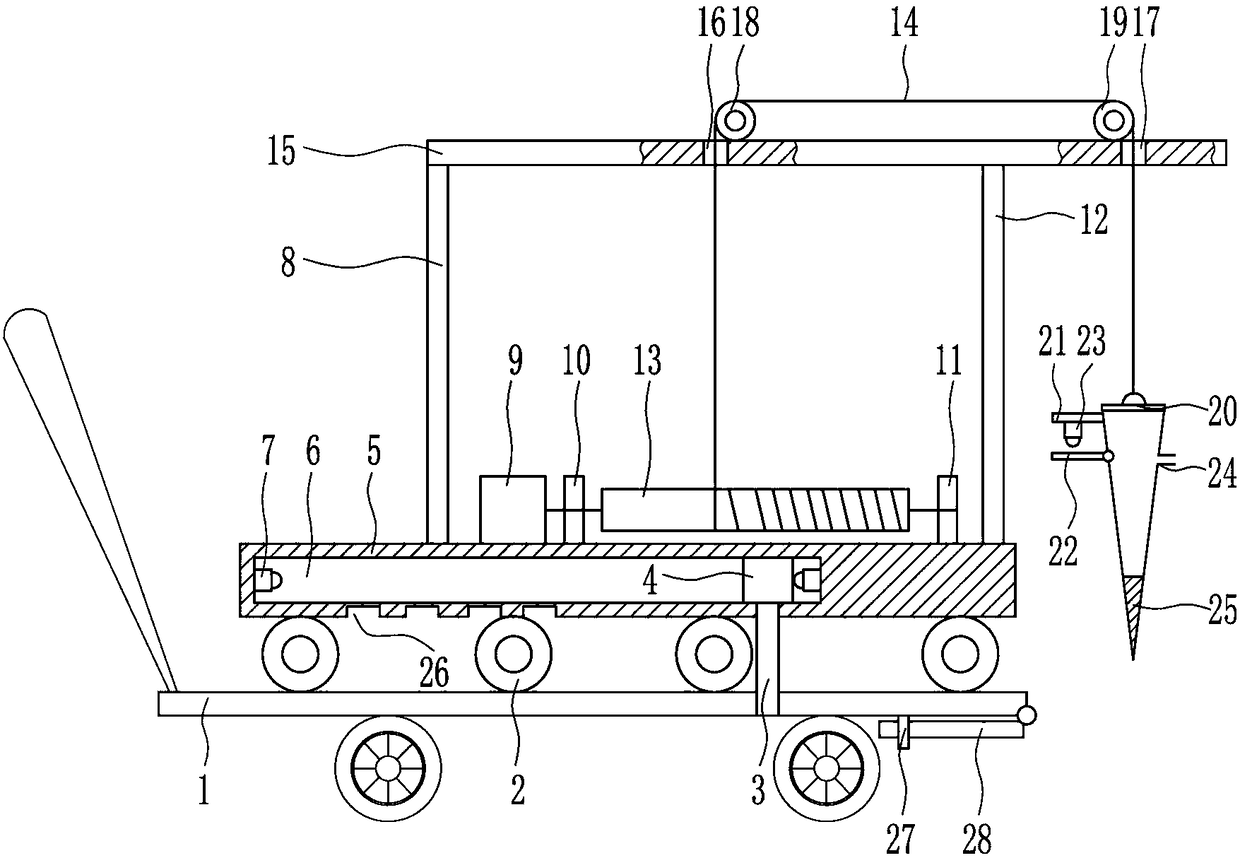

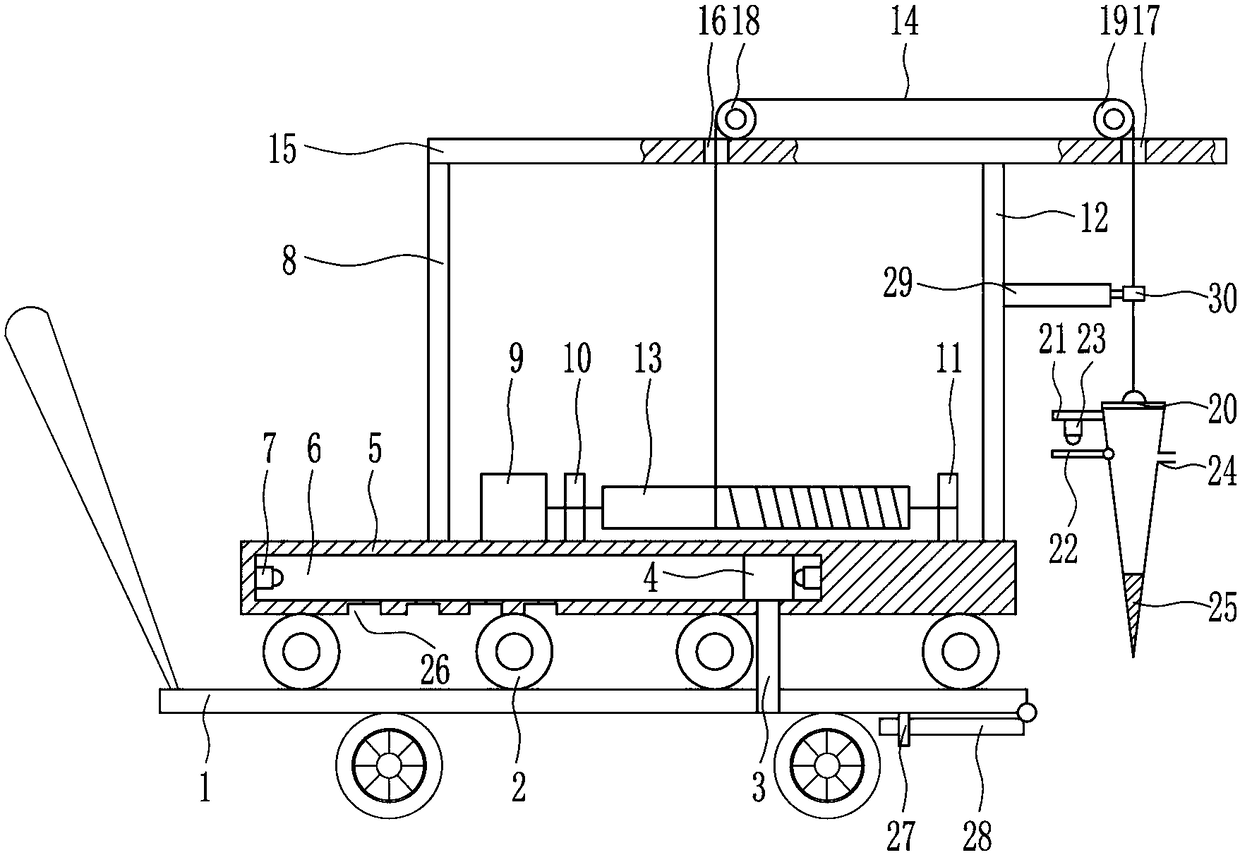

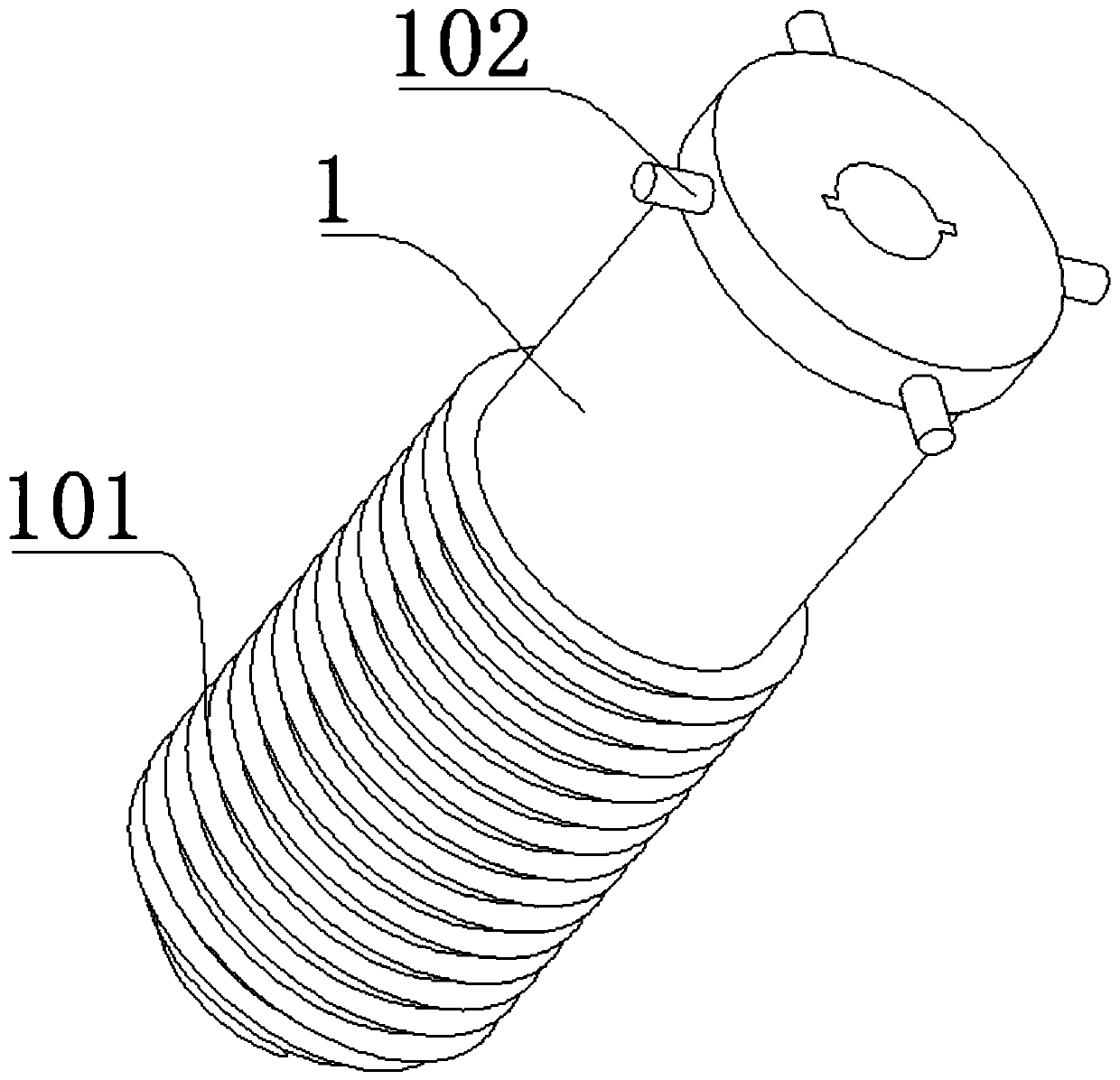

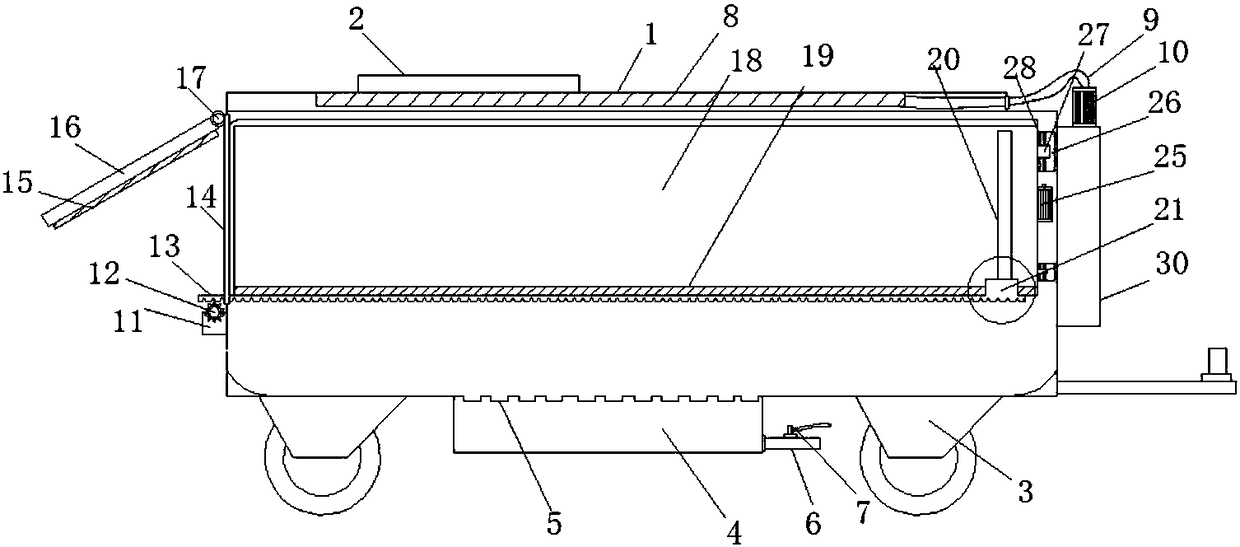

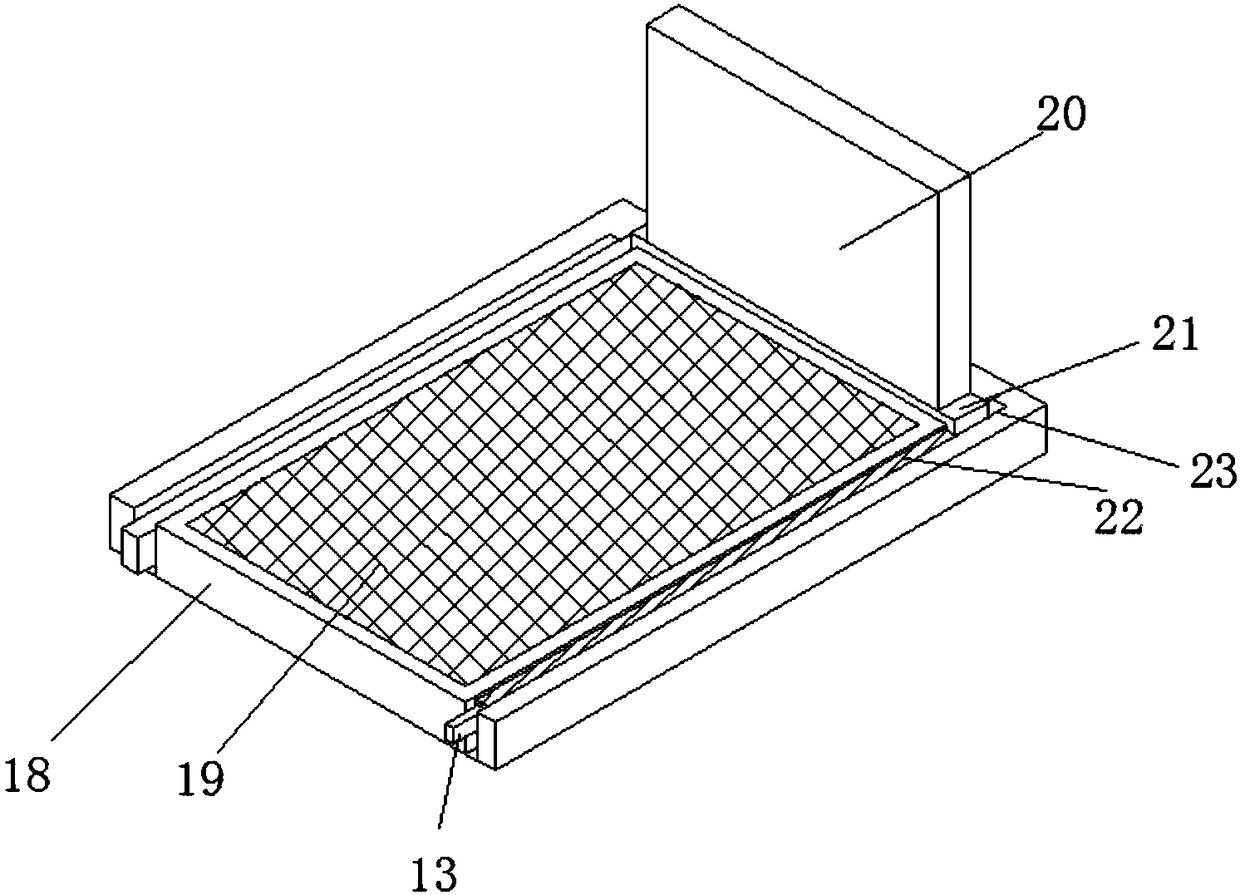

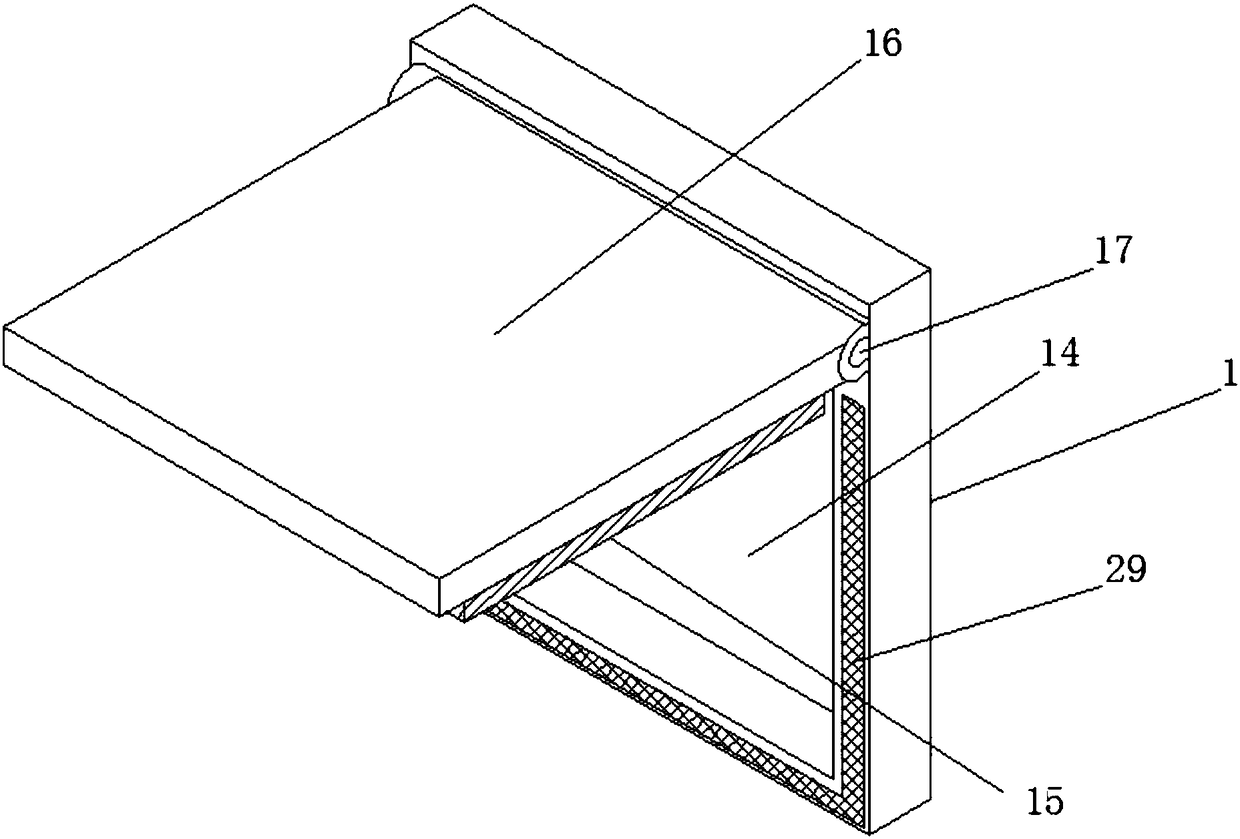

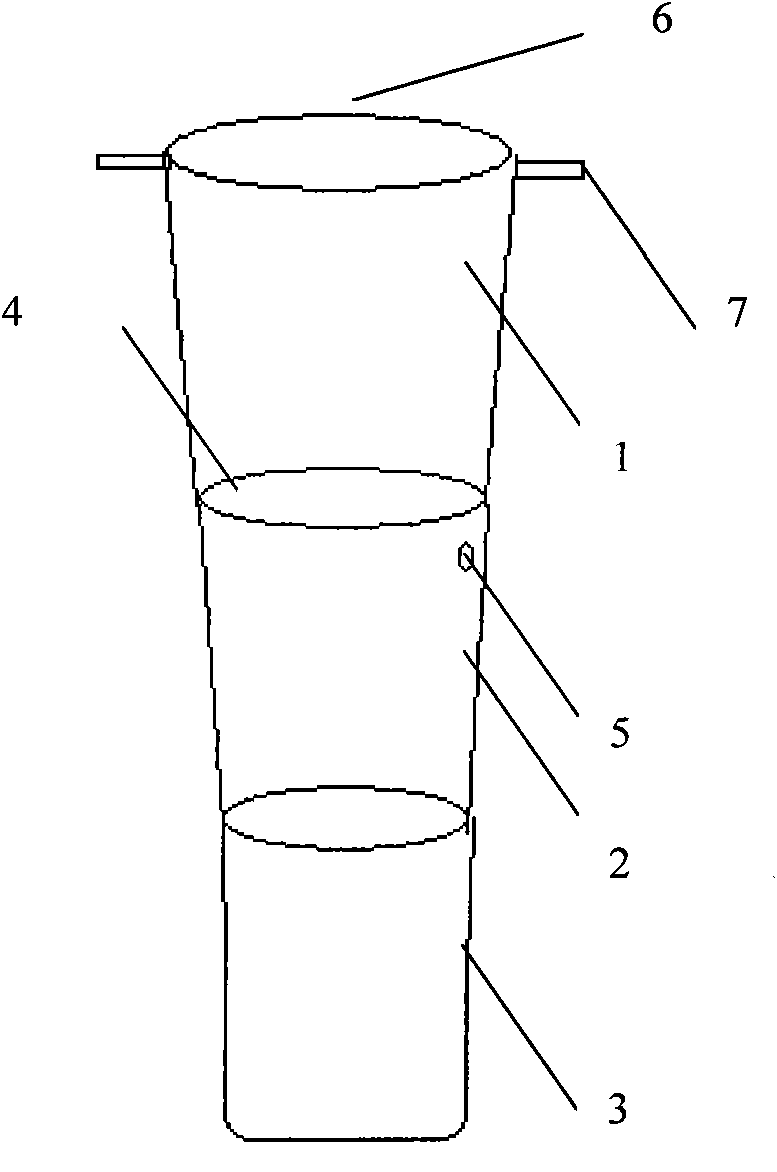

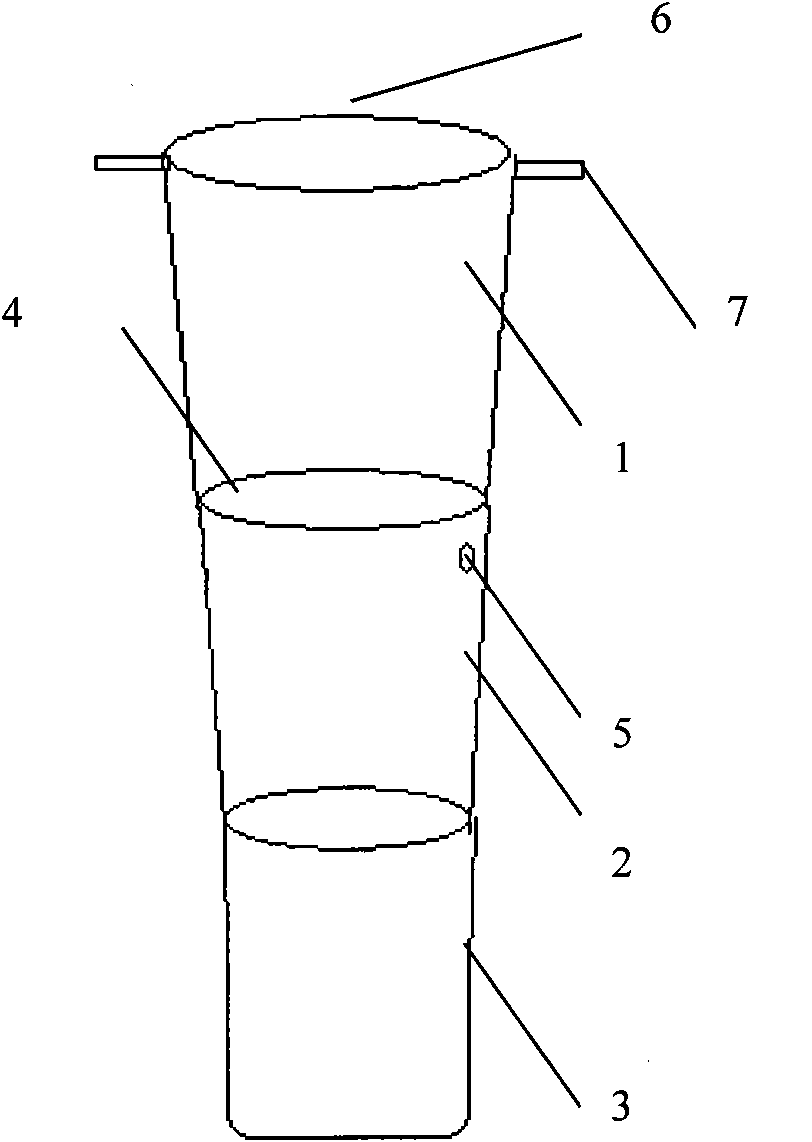

Surface water sample collecting device for river water detection and manufacturing and collecting method thereof

InactiveCN108082236AAcquisition stableImprove detection resultsWithdrawing sample devicesHand carts with multiple axesSurface waterCart

Technical problems to be solved are that the collection effect is poor, the surface water is difficult to sample, the accuracy of the river water detection result is low and the working efficiency islow in the existing surface water sample collecting device for river water detection. In order to solve the technical problems, the invention provides a surface water sample collecting device for river water detection. The surface water sample collecting device for river water detection comprises a push cart, electric rollers, a supporting rod, a slide block, a base, a first button, a first bracket, a first motor, a left bearing seat, a right bearing seat, a second bracket and so on; the electric rollers are horizontally arranged at the top of the push cart at equal intervals; the supporting rod is vertically arranged on the front side of the push cart; and the upper end of the supporting rod is connected with the slide block. According to the surface water sample collecting device for river water detection, the surface water sample of the river water is collected by using a conical barrel; and a conical weight block is arranged at the bottom of the conical barrel.

Owner:NANJING CUIZHI WATER CONSERVANCY TECH CO LTD

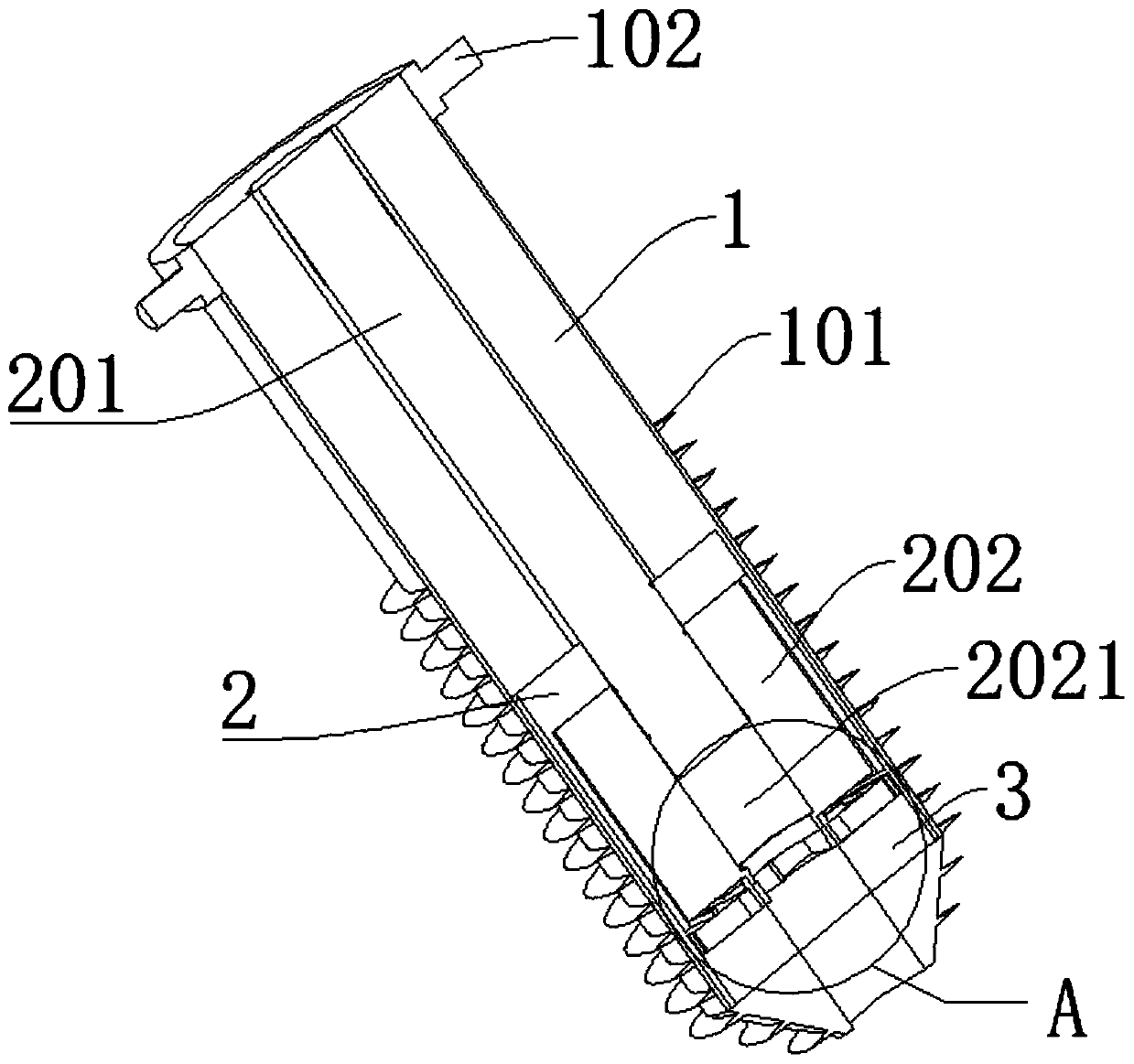

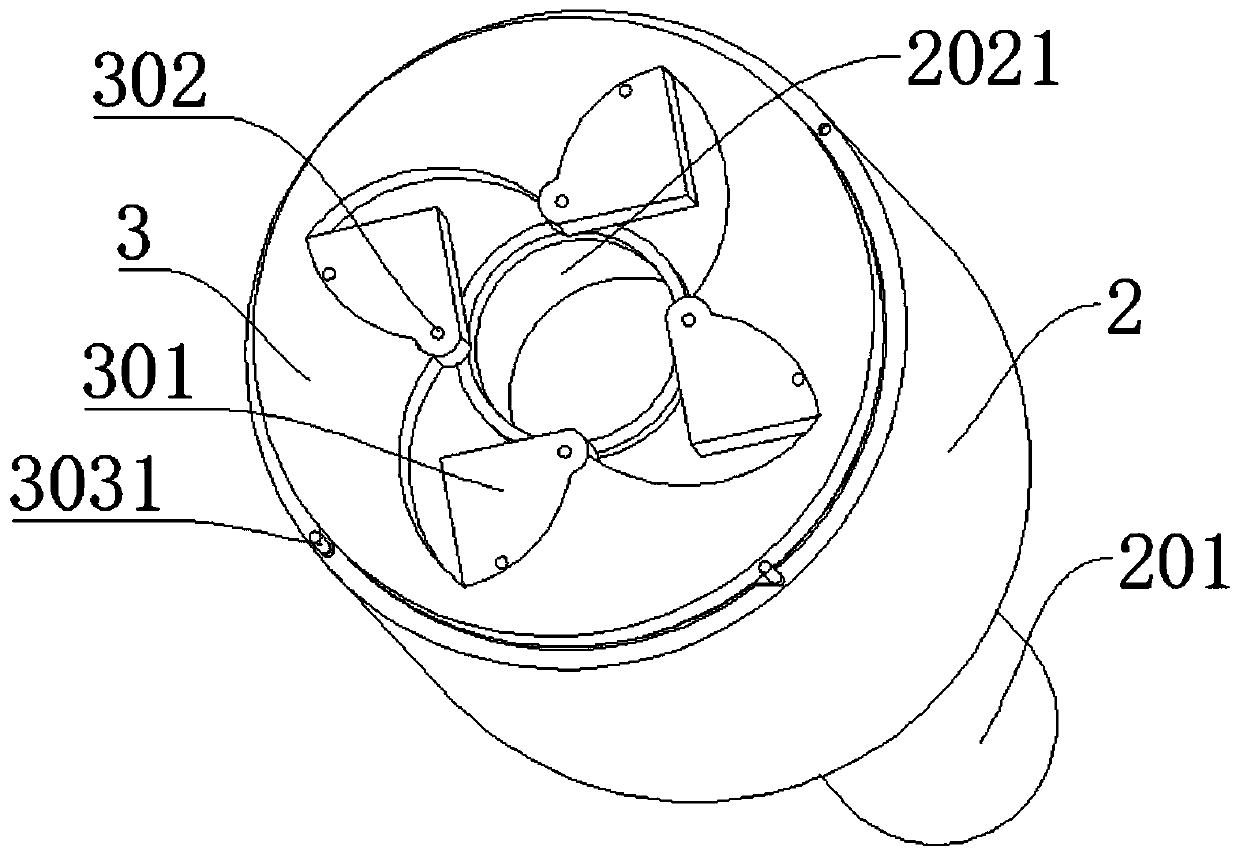

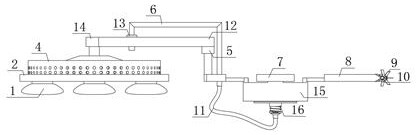

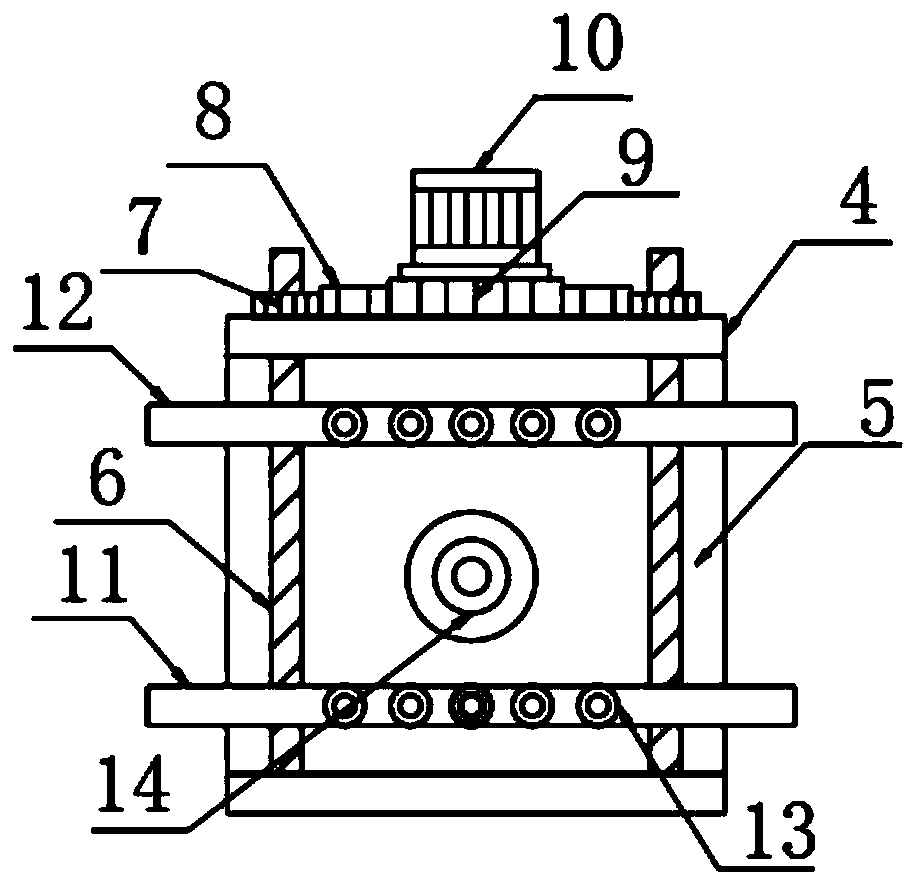

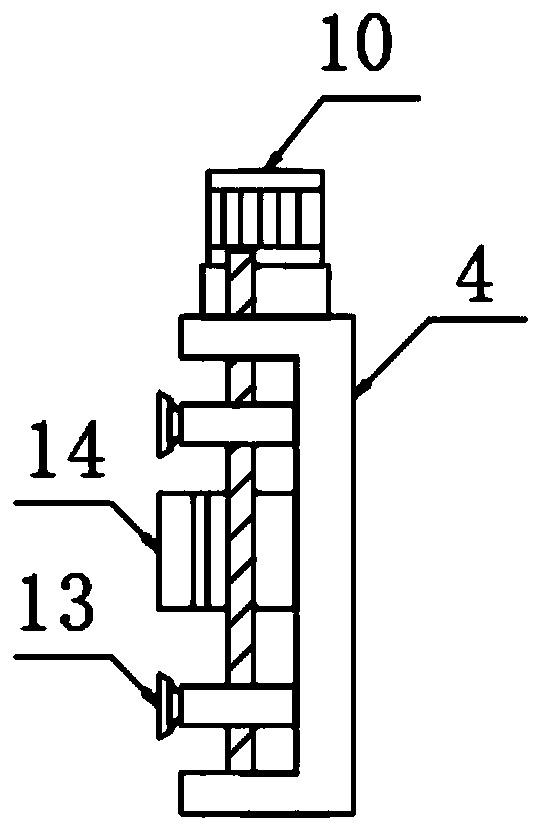

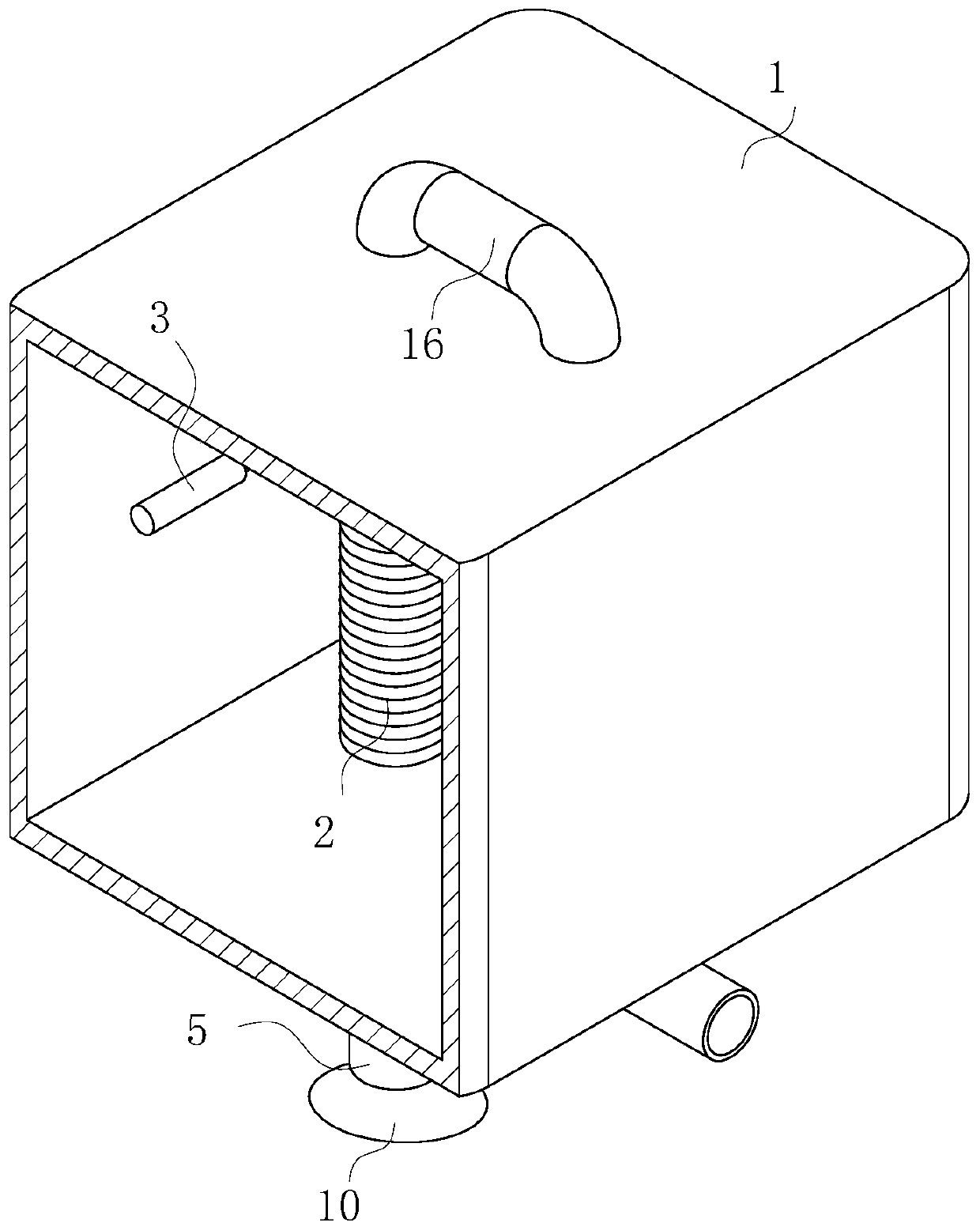

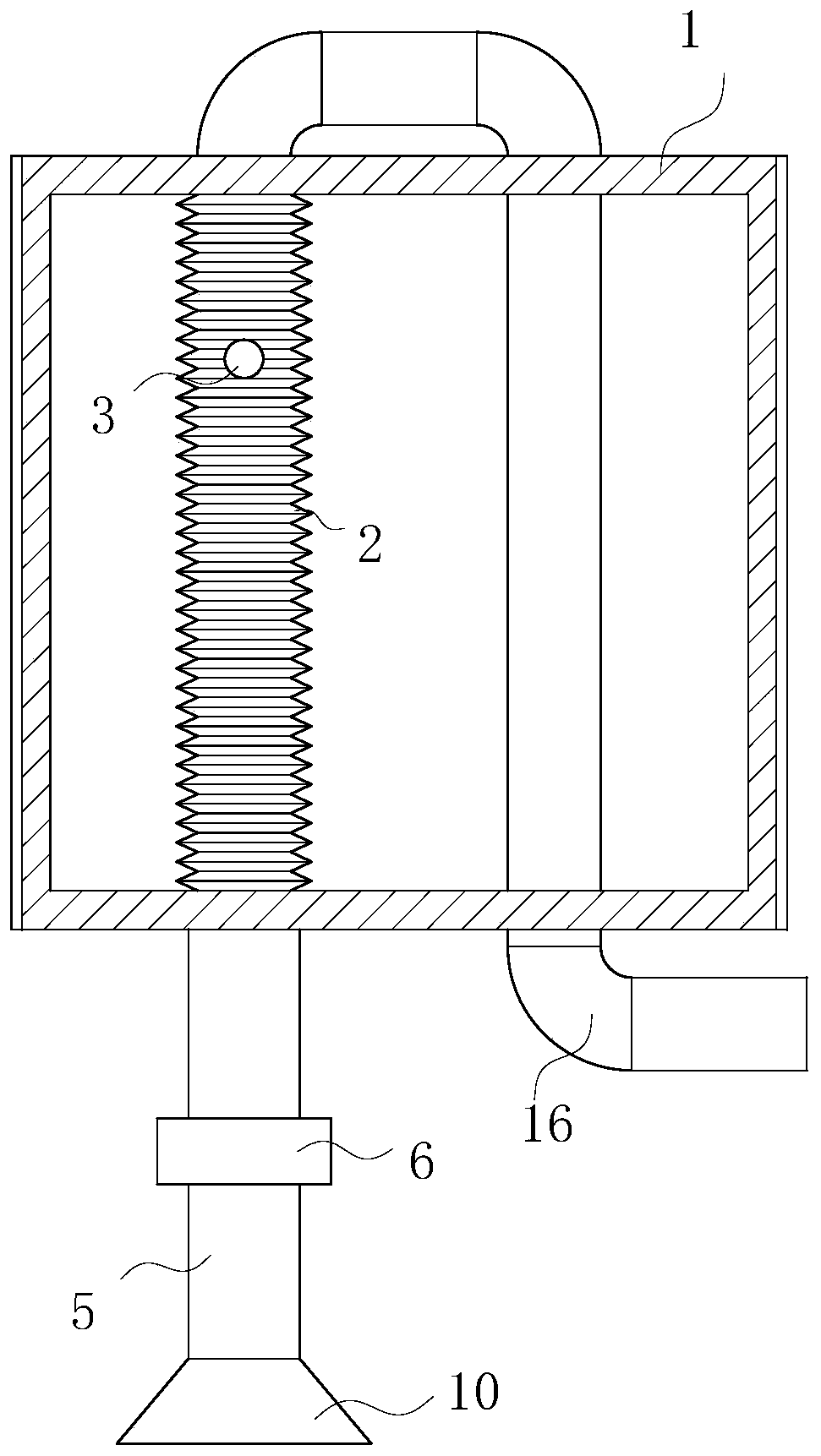

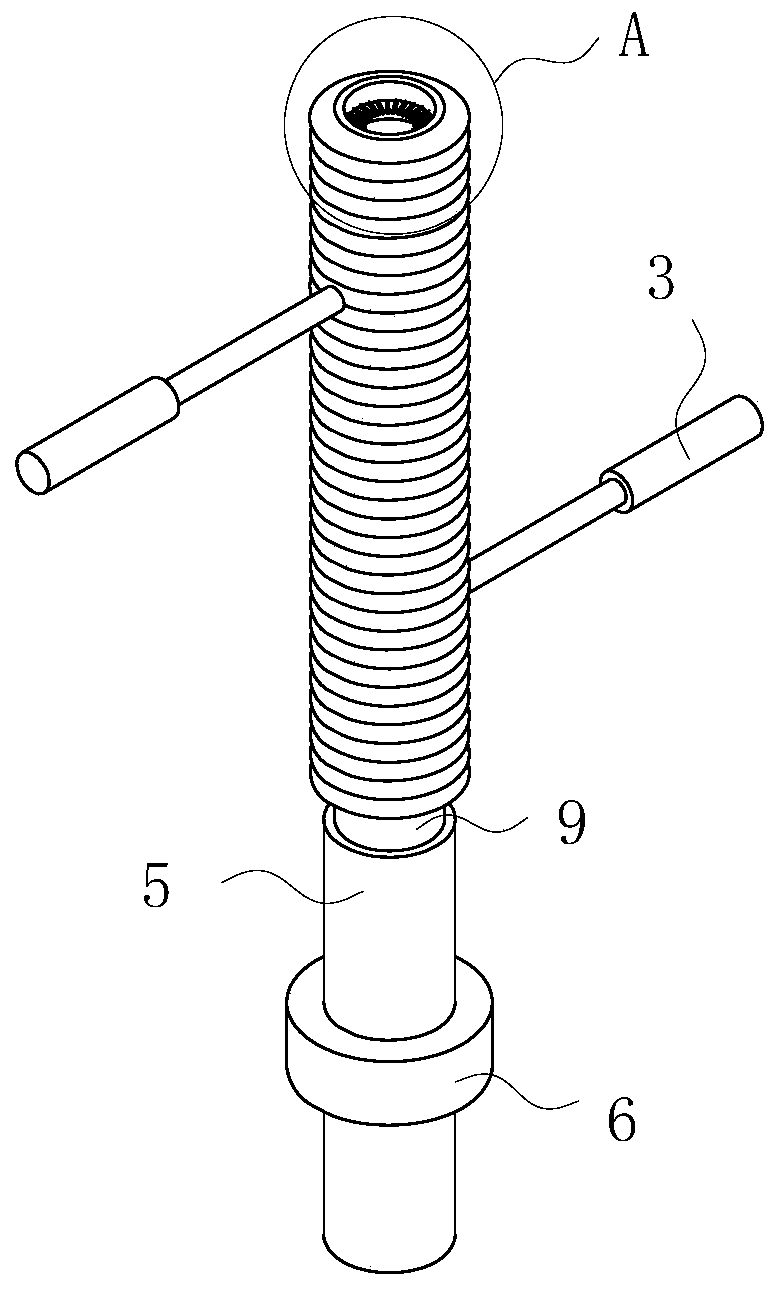

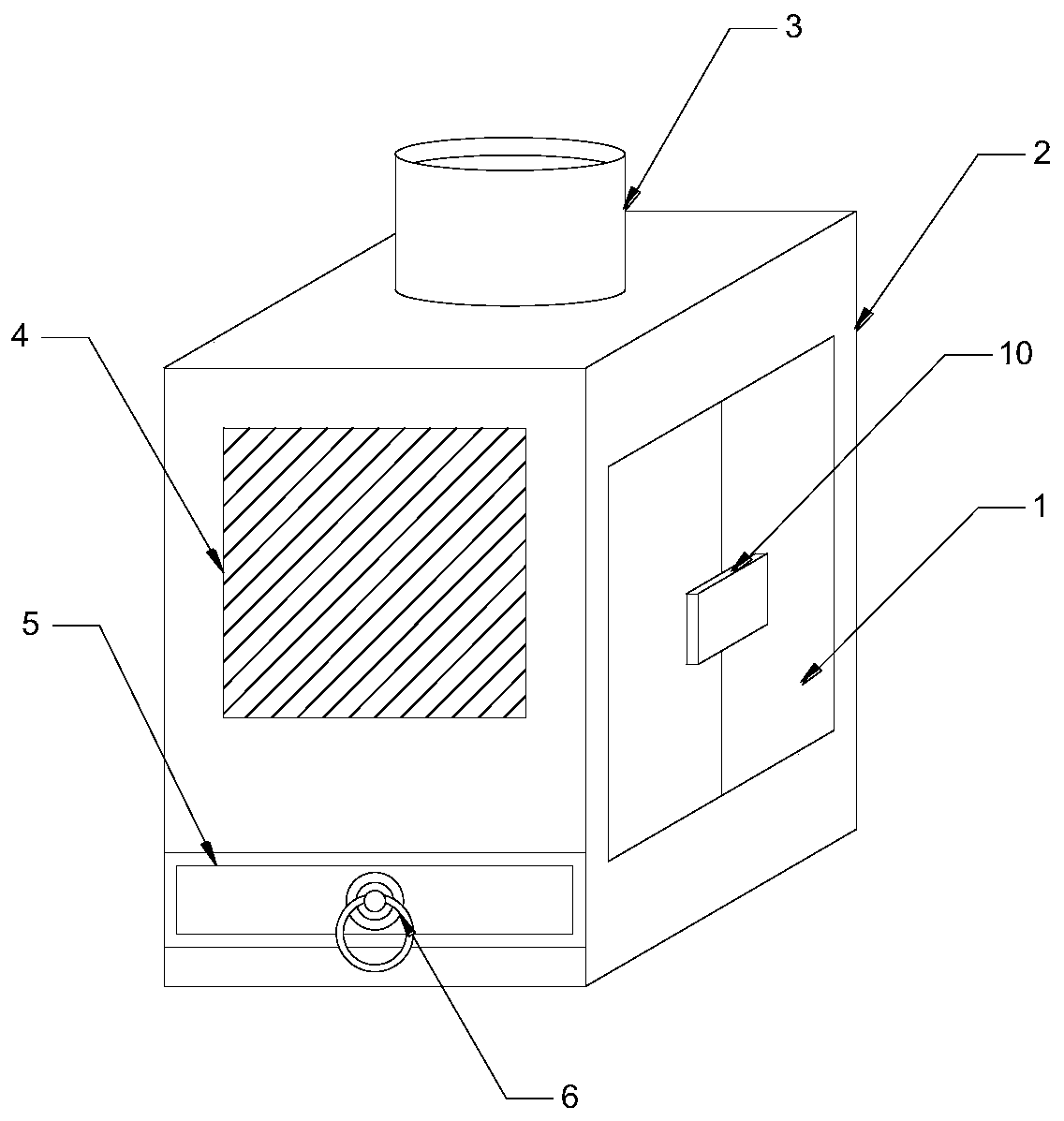

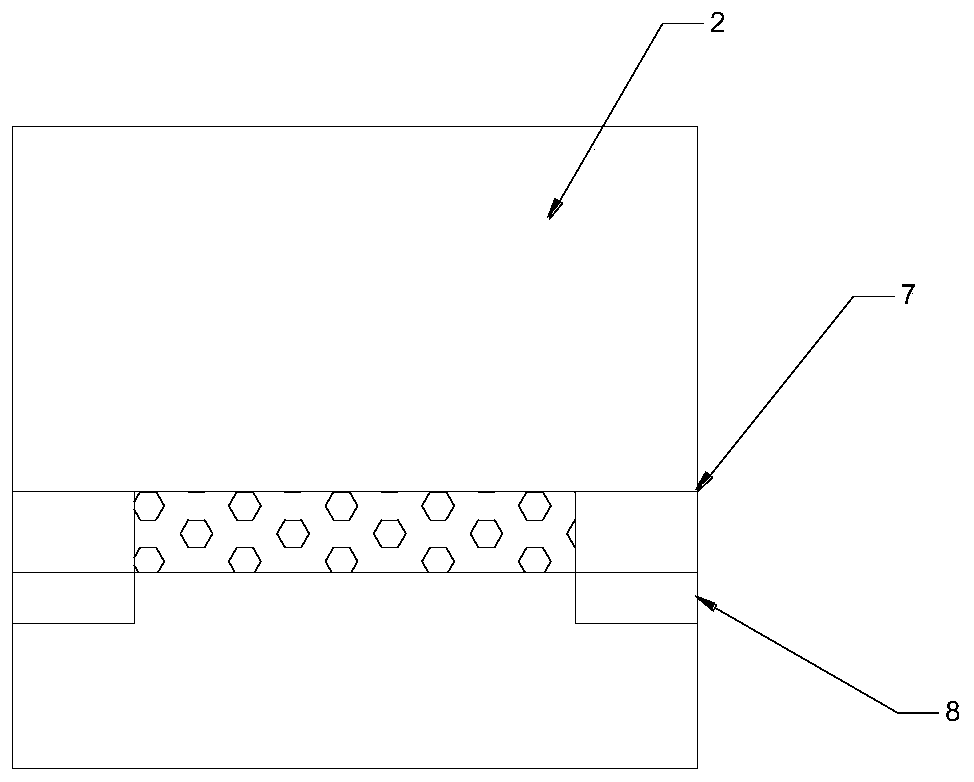

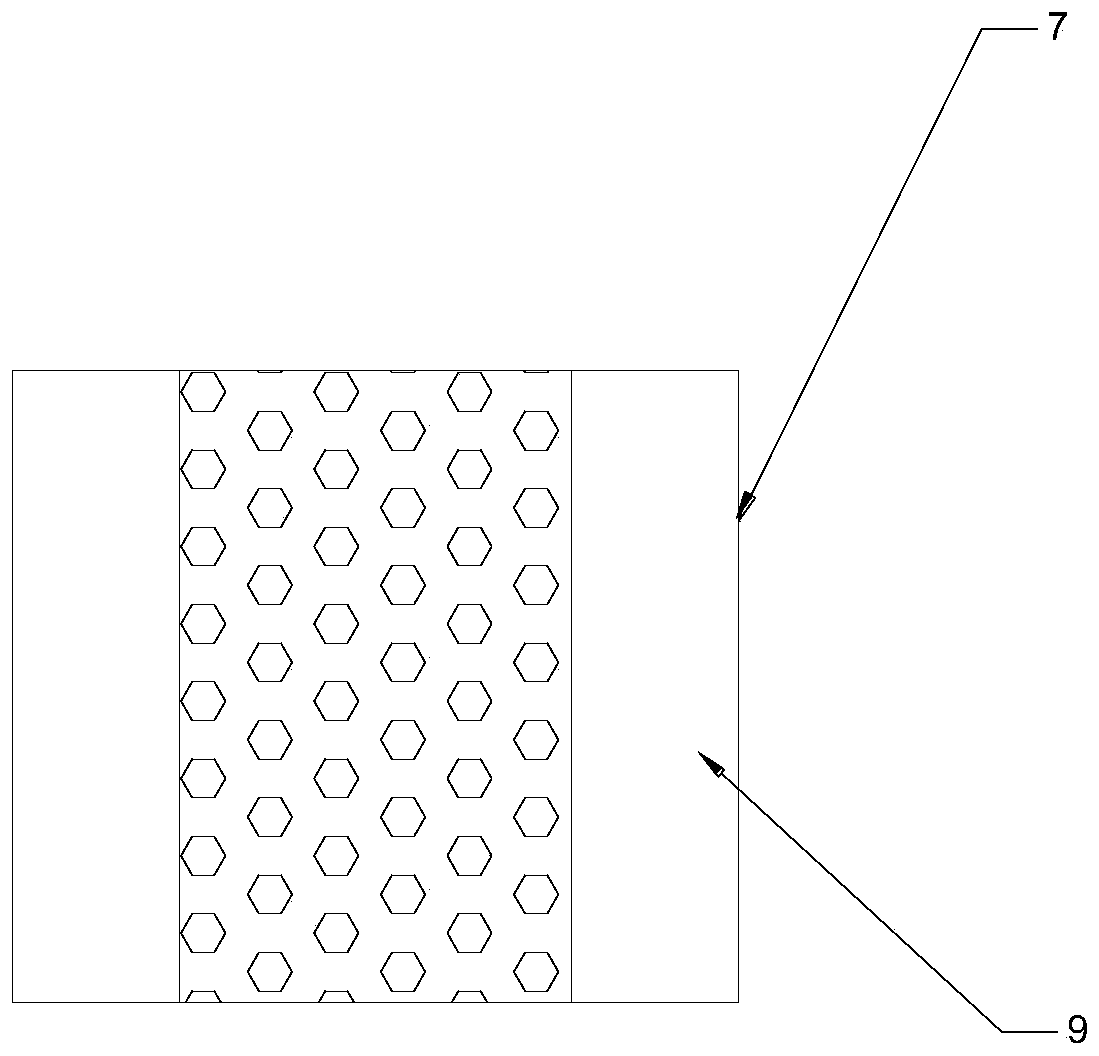

Soil layer drilling device

ActiveCN110411782AShorten the timeGood collection effectWithdrawing sample devicesSoil horizonEngineering

The invention discloses a soil layer drilling device, and belongs to the technical field of soil sampling. The soil layer drilling device comprises a box body, and a spiral blade is sleeved with the side wall of the box body. The device further comprises a rotating block and a lifting column, the rotating block is rotationally connected to the interior of the box body, the inner wall of the rotating block is connected with a collecting ring column, a collecting chamber is formed in the inner wall of the collecting ring column, the lifting column is connected to the interior of the box body, the lifting column and the rotating block are connected through a threaded strip, one end of the lifting column is arranged in the collecting chamber, and a closer is connected to the bottom of the rotating block. When soil is collected by the device, the soil cannot be scattered, the collecting effect is good, the soil can be conveniently taken out from a sampler, and the device is convenient to carry.

Owner:HUNAN ZHUANGYUAN GEOLOGICAL EQUIP

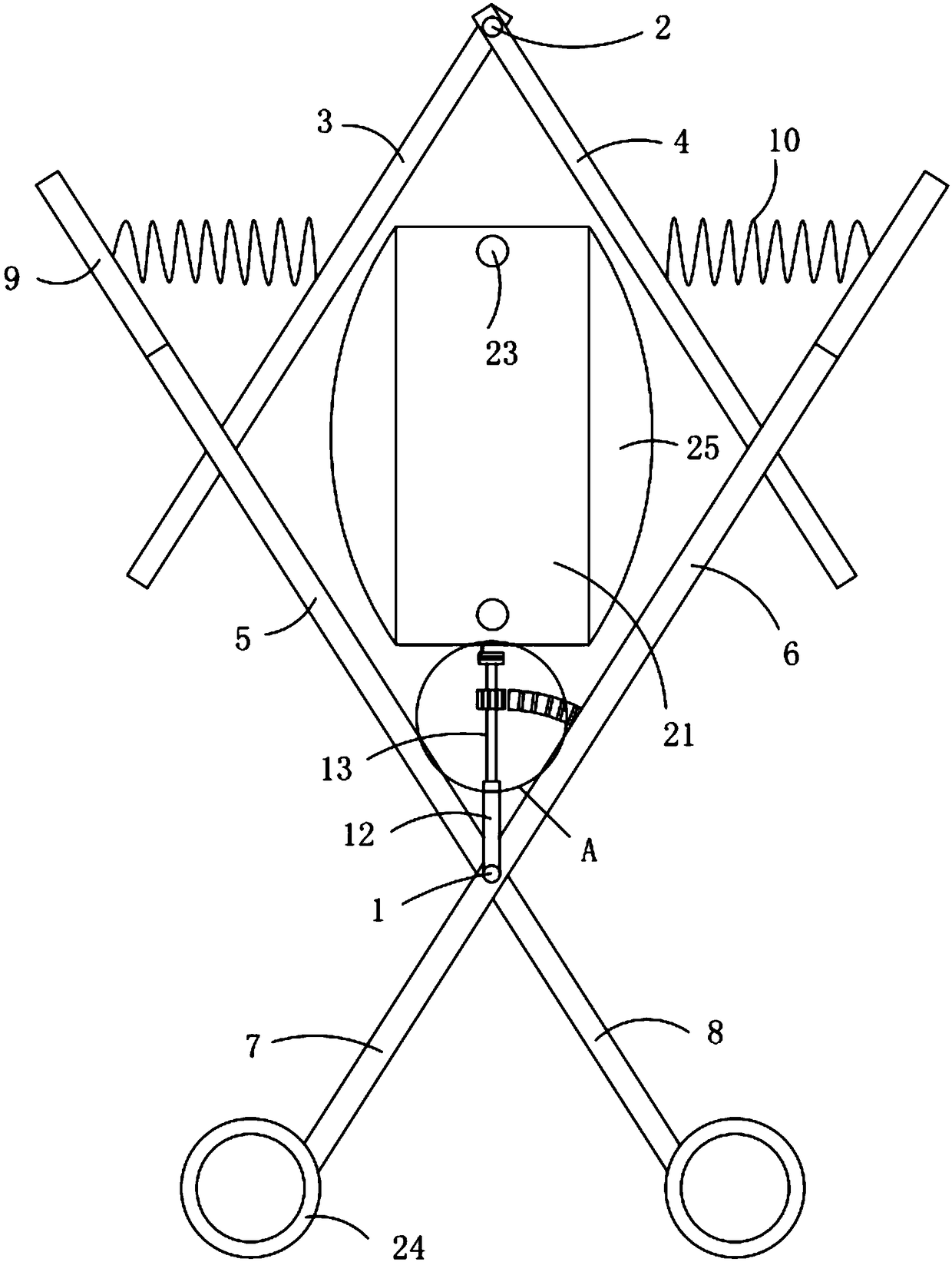

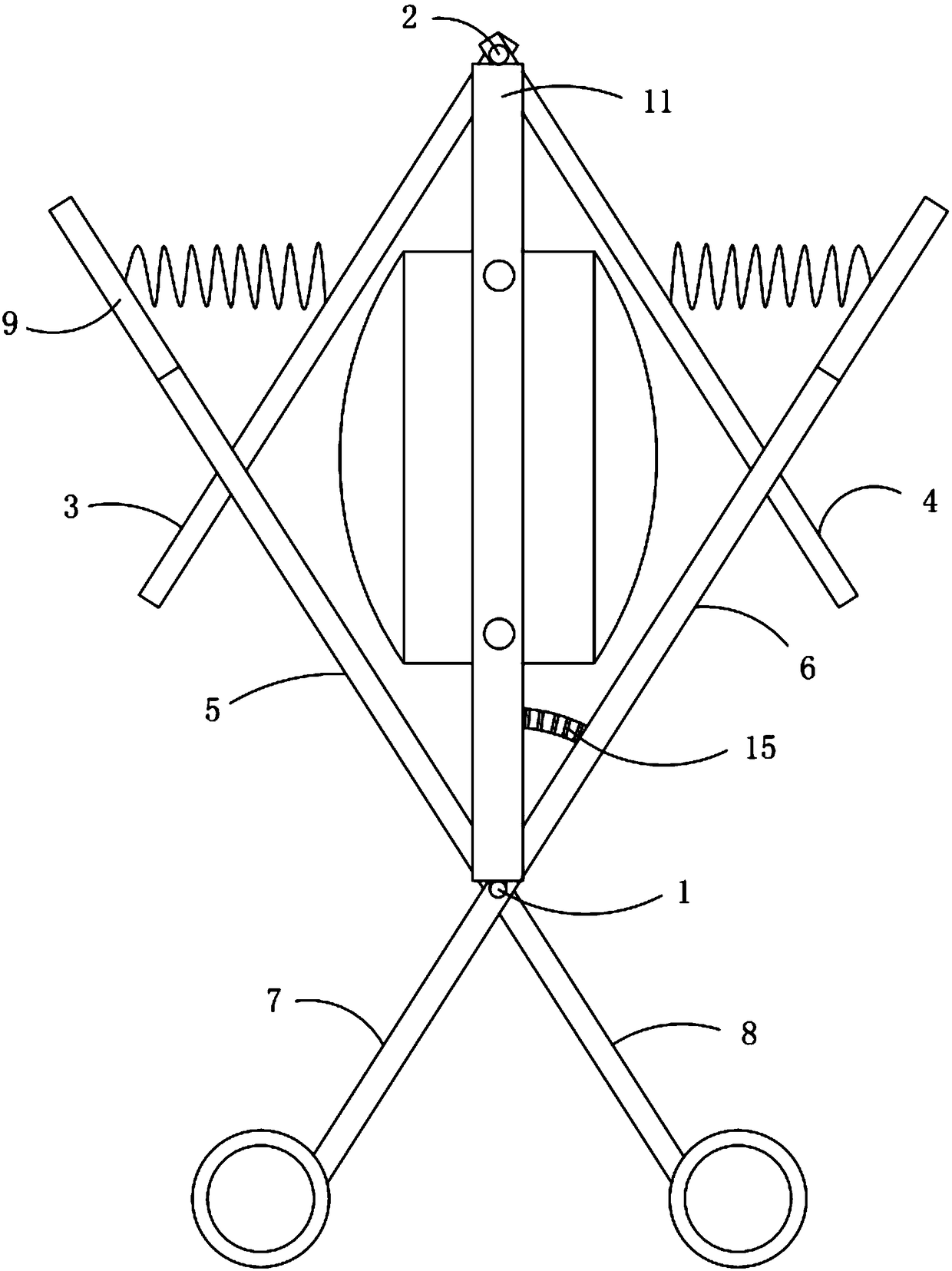

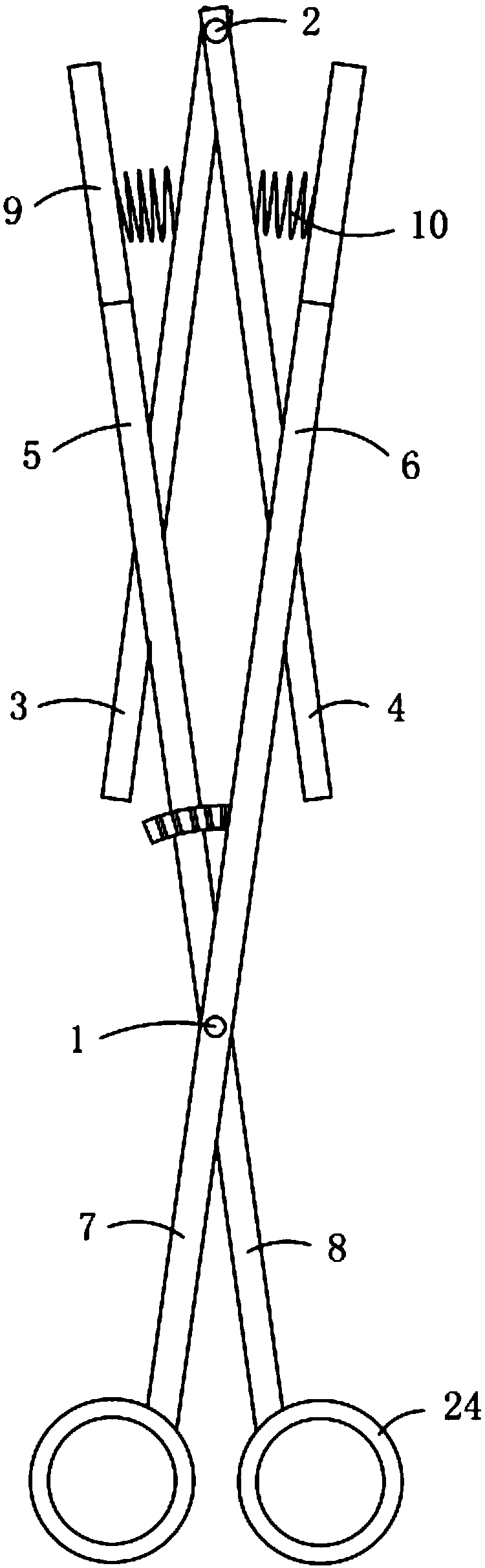

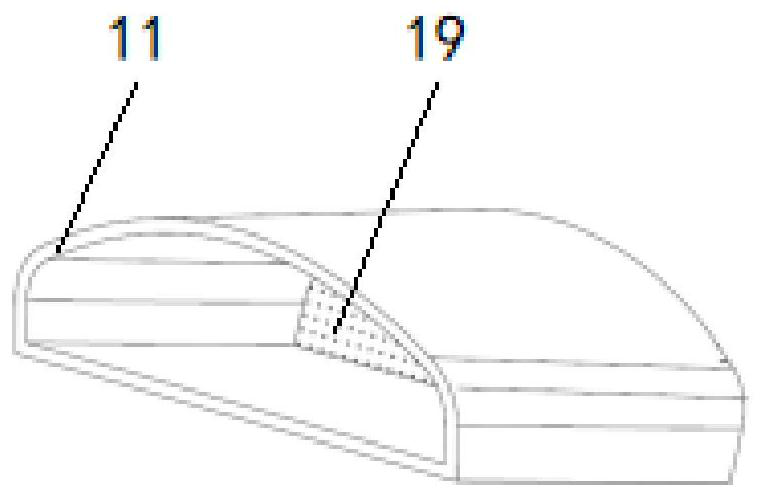

Enveloping adhesive type tumor resection scissors

ActiveCN109091203AGood collection effectPrevent tumors from scattering and fallingSurgical scissorsMedicineExtrusion

The invention discloses enveloping adhesive type tumor resection scissors. The enveloping adhesive type tumor resection scissors comprise a hinged column and a pin, wherein the pin is movably connected with a first scissors head and a second scissors head, the side, close to the pin, of the hinged column is movably connected with a third scissors head and a fourth scissors head, the third scissorshead is fixedly connected with a second handle, and the fourth scissors head is fixedly connected with a first handle; connecting blocks are fixed at the end, away from the hinged column, of the third scissors head and the end, away from the hinged column, of the fourth scissors head respectively, extrusion springs are fixed on the first scissors head and the second scissors head respectively, the extrusion springs are fixedly connected with connecting blocks, and a fixed rod is fixedly connected between the hinged column and the pin. The enveloping adhesive type tumor resection scissors havethe advantages that it can be ensured that the situation of relative sliding between the tumor and the scissors heads cannot occur during resection, resection space of the scissors heads cannot be occupied, the collection effect is better, a tumor body can be effectively prevented from scattering and falling off, the practicability is strong, and the enveloping adhesive type tumor resection scissors are very worth popularizing.

Owner:陕西省肿瘤医院

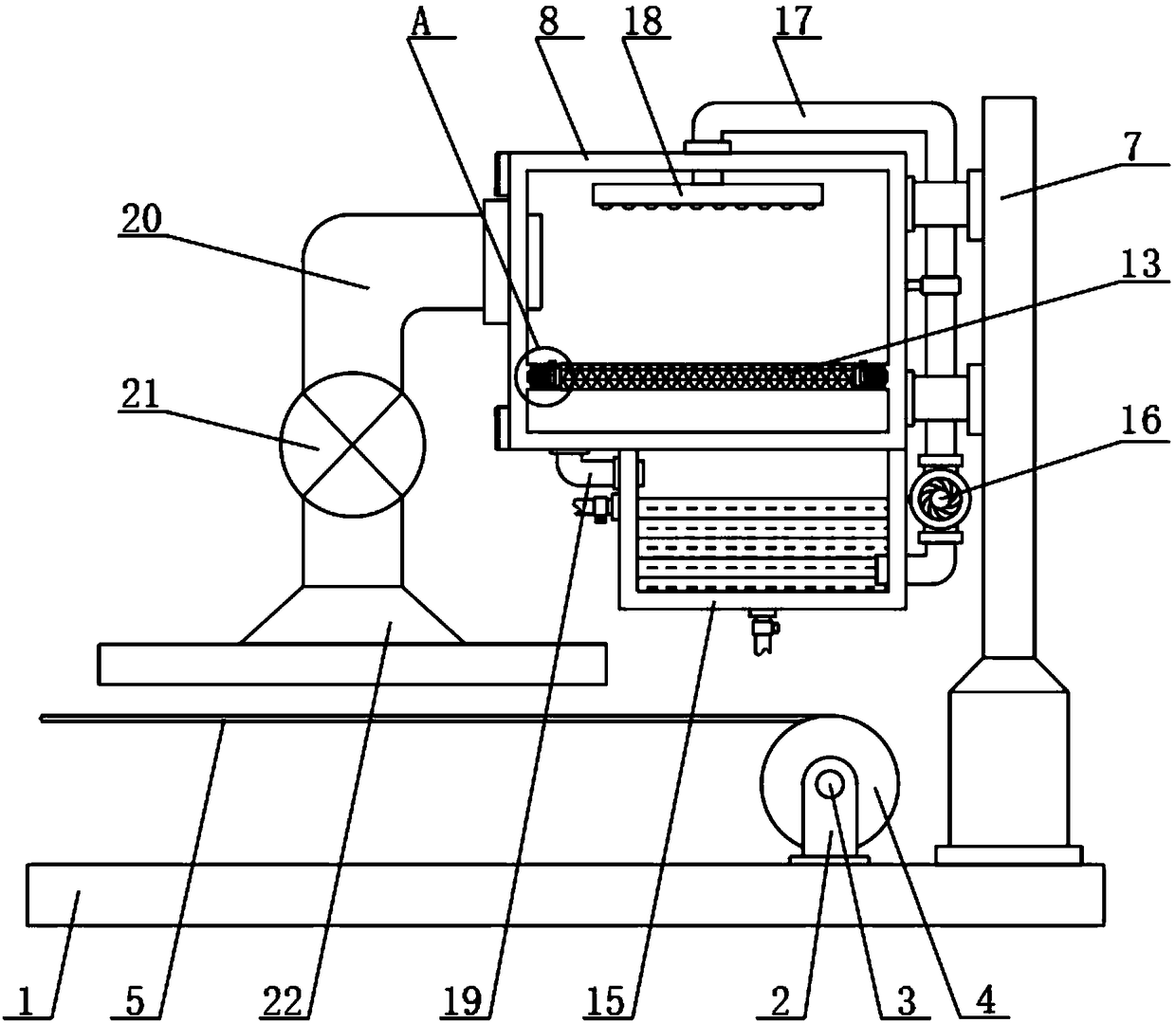

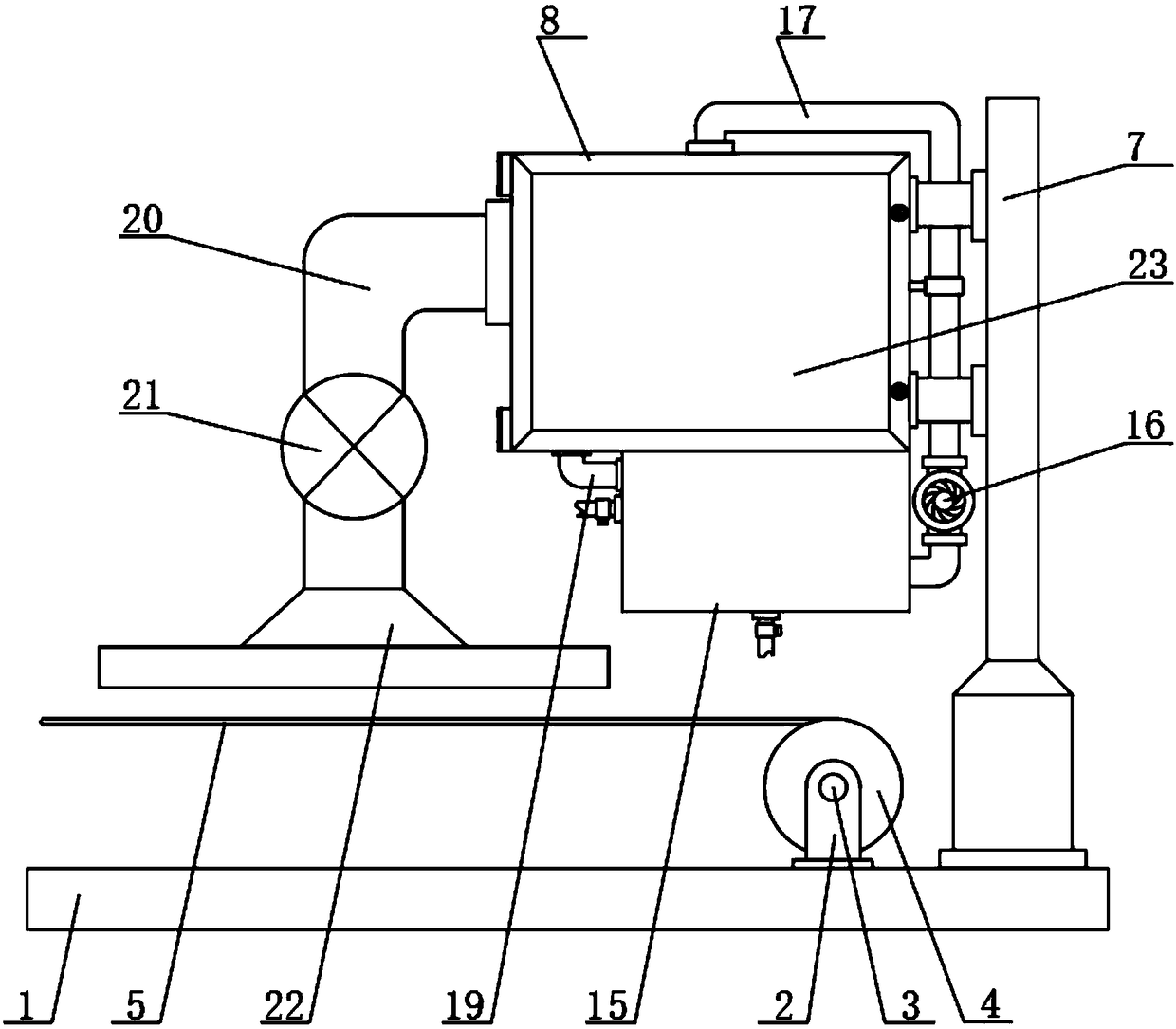

Textile fabric surface dust collection device

InactiveCN109338697AGood collection effectEasy to remove the filterMechanical cleaningPressure cleaningEngineeringTextile

The invention belongs to the technical field of dust collection and discloses a textile fabric surface dust collection device. The device comprises a base; a supporting seat is fixedly mounted on theright side of the top of the base; the center of the supporting base is movably sleeved with a rotating shaft; the outer surface of the rotating shaft is fixedly sleeved with a reeling drum inside thesupporting seat; the outer surface of the reeling drum is wound with a textile fabric; the back surface of the supporting seat is fixedly provided with a motor; the output shaft of the motor is fixedly connected with the top end of the rotating shaft; and the top of the base is fixedly provided with a supporting column to the right side of the supporting seat. According to the textile fabric surface dust collection device of the invention, a suction fan and a spray head are adopted; the suction fan is adopted to suck dust on the surface of the textile fabric into a dust removal box; the dustremoval box is adopted to spray water, so that dust in the dust removal box can fall on a filter screen, and therefore, the collection effect of the dust collection device can be improved, and the practicability of the dust collection device can be enhanced.

Owner:张启轩

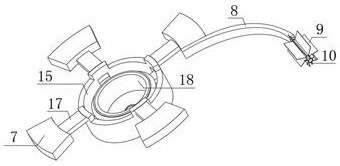

Corn stigma collecting device and method

ActiveCN110431987AGood collection effectSimple and flexible operationHarvestersEngineeringPressure difference

The invention relates to a corn stigma collecting device and method. The corn stigma collecting device comprises a plurality of collecting barrels, corn stigma storage cavities, conveying mechanisms and a plurality of air suction holes, wherein the collecting barrels are arranged horizontally in sequence, the corn stigma storage cavities are respectively arranged between the adjacent collecting barrels, the conveying mechanisms are respectively arranged inside the collecting barrels, and the air suction holes are formed in the inner walls of the collecting barrels; the conveying mechanisms candrive corn cobs to rotate while moving along the length of the collecting barrels; the air suction holes can generate pressure difference between the collecting barrels and the corn stigma storage cavities, and can suck corn stigma on the outer side of the corn cobs into the corn stigma storage cavities; corn stigma cutting mechanisms capable of cutting off corn stigma are arranged in the corn stigma storage cavities respectively.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

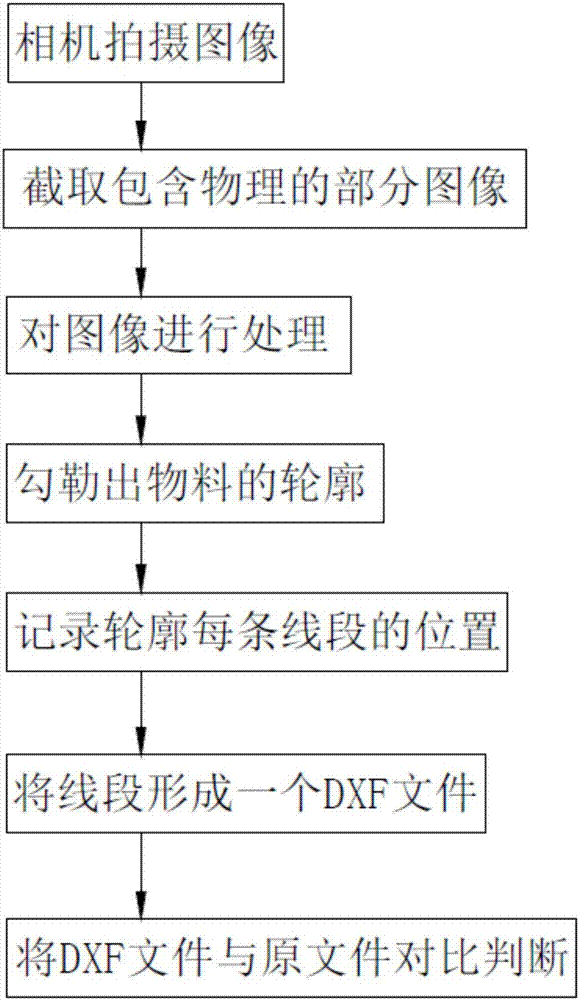

Image processing method for visual inspection system

The invention relates to the technical field of visual inspection processing, in particular to an image processing method for a visual inspection system. The visual inspection system comprises a camera for collecting images, image processing software for processing the images and comparison processing software for comparing and processing, wherein the comparison processing software stores the original images. The image processing method comprises the steps of obtaining the to-be-processed images through the camera, intercepting parts, containing a material, of the images, processing the images through the image processing software, drawing the outline of the target material, recording breakpoint positions of each line section of the outline, the positions of the centers of circles and the radii of the circles, producing a DXF file containing the above line sections and the circles, importing the DXF file into the comparison processing software, and using the images of the DXF file as comparison images. The image processing method for the visual inspection system is high in working efficiency, comparison efficiency and judgment efficiency.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

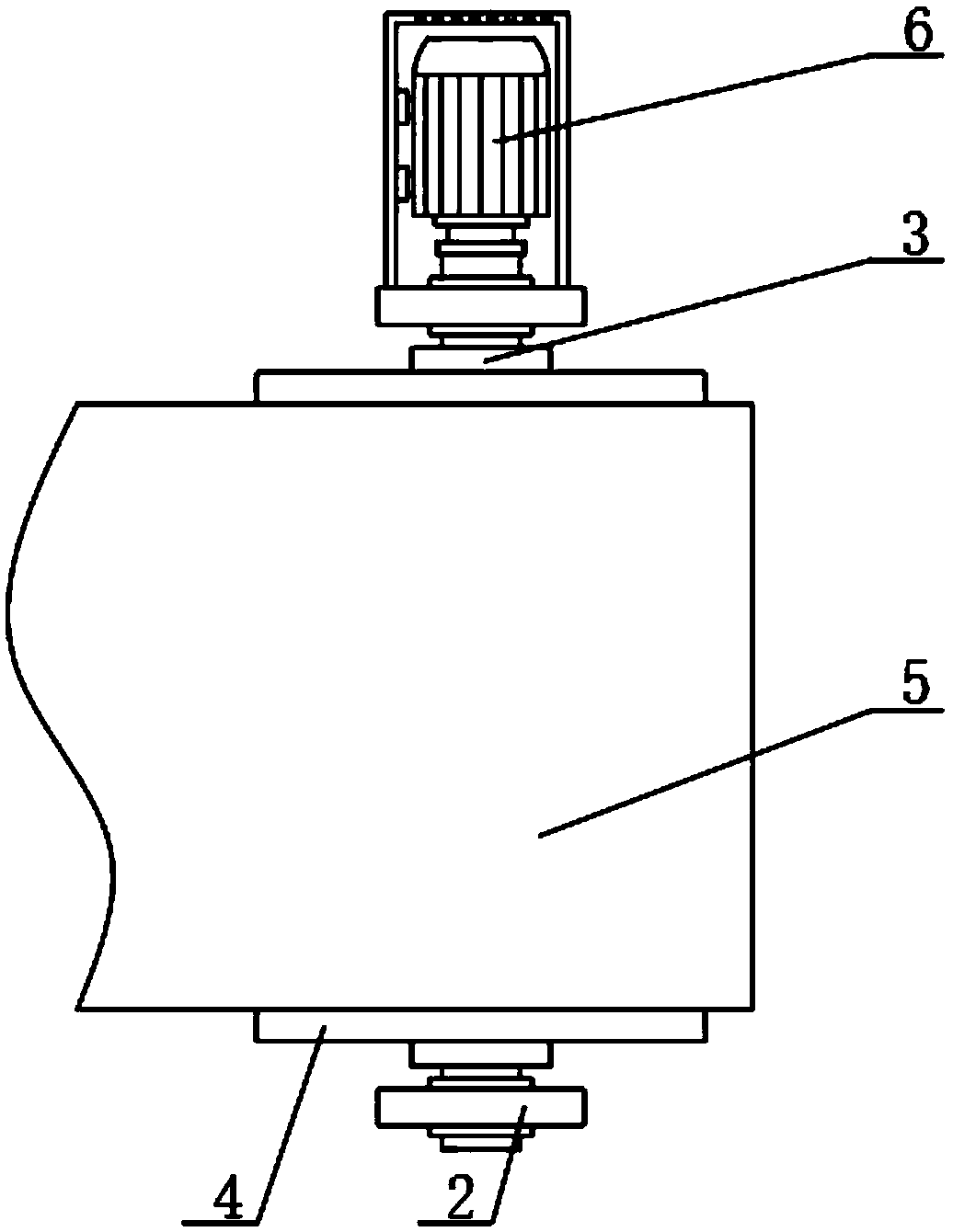

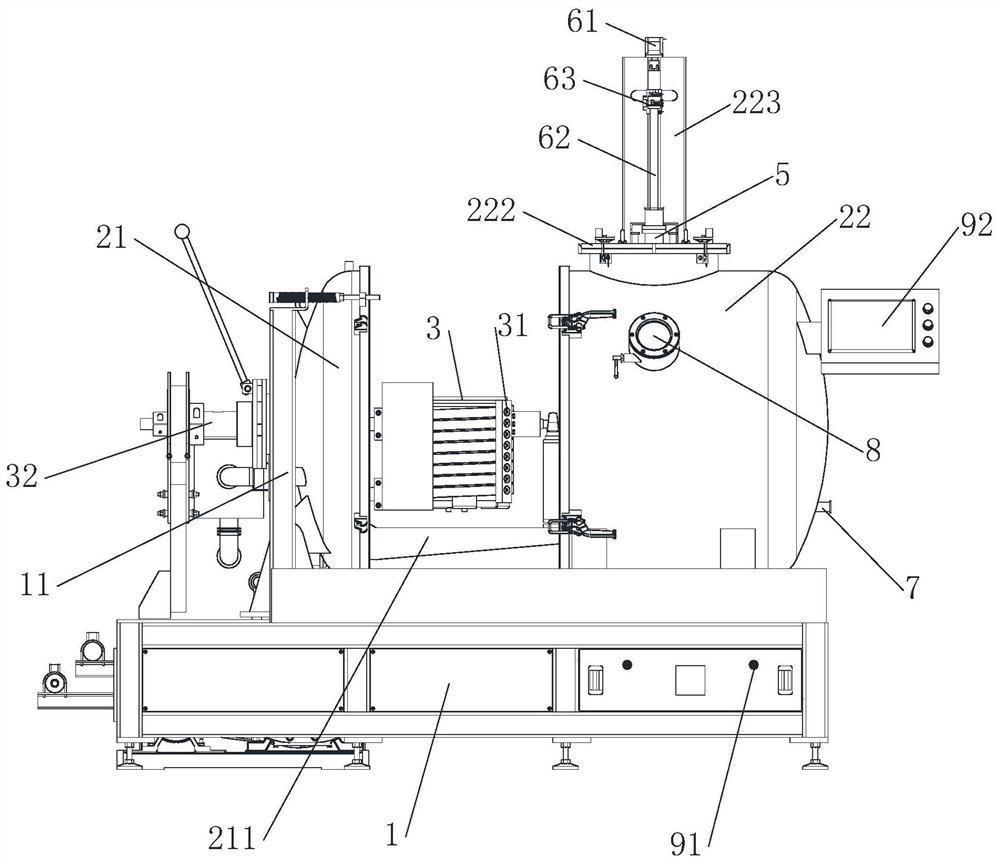

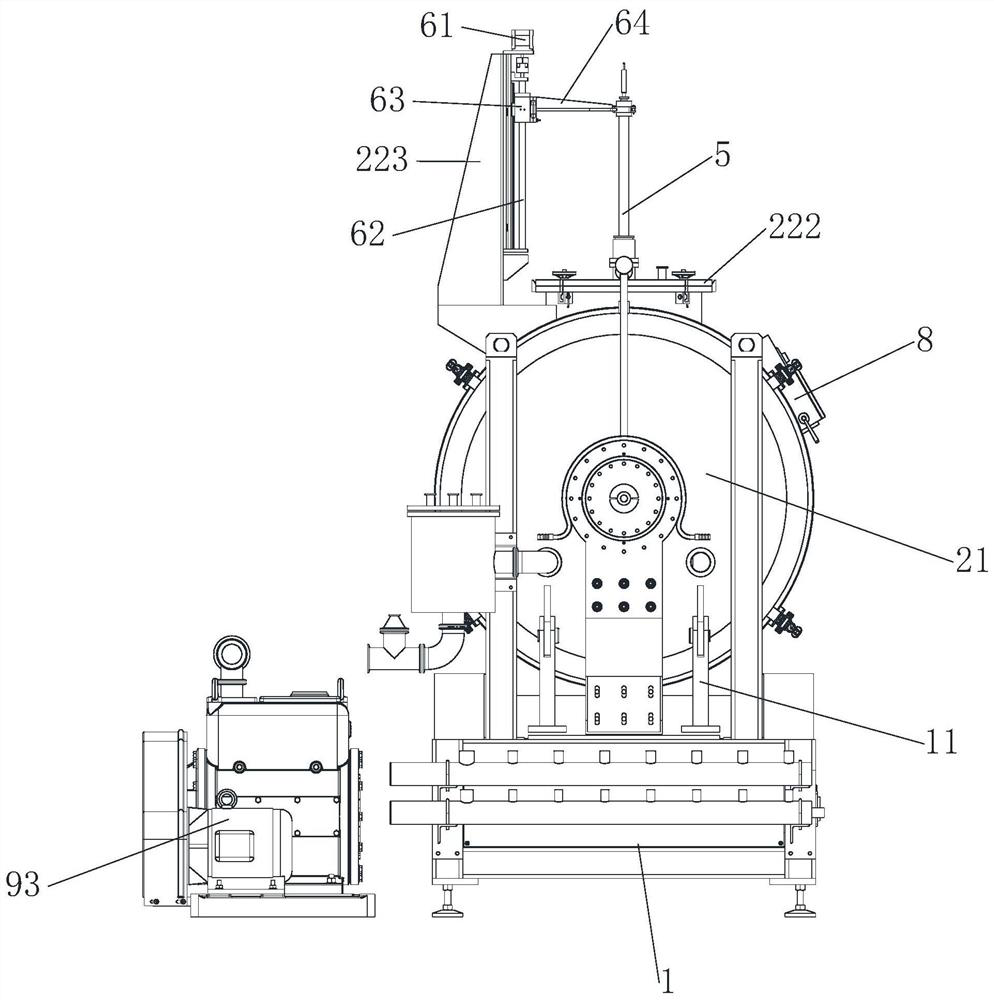

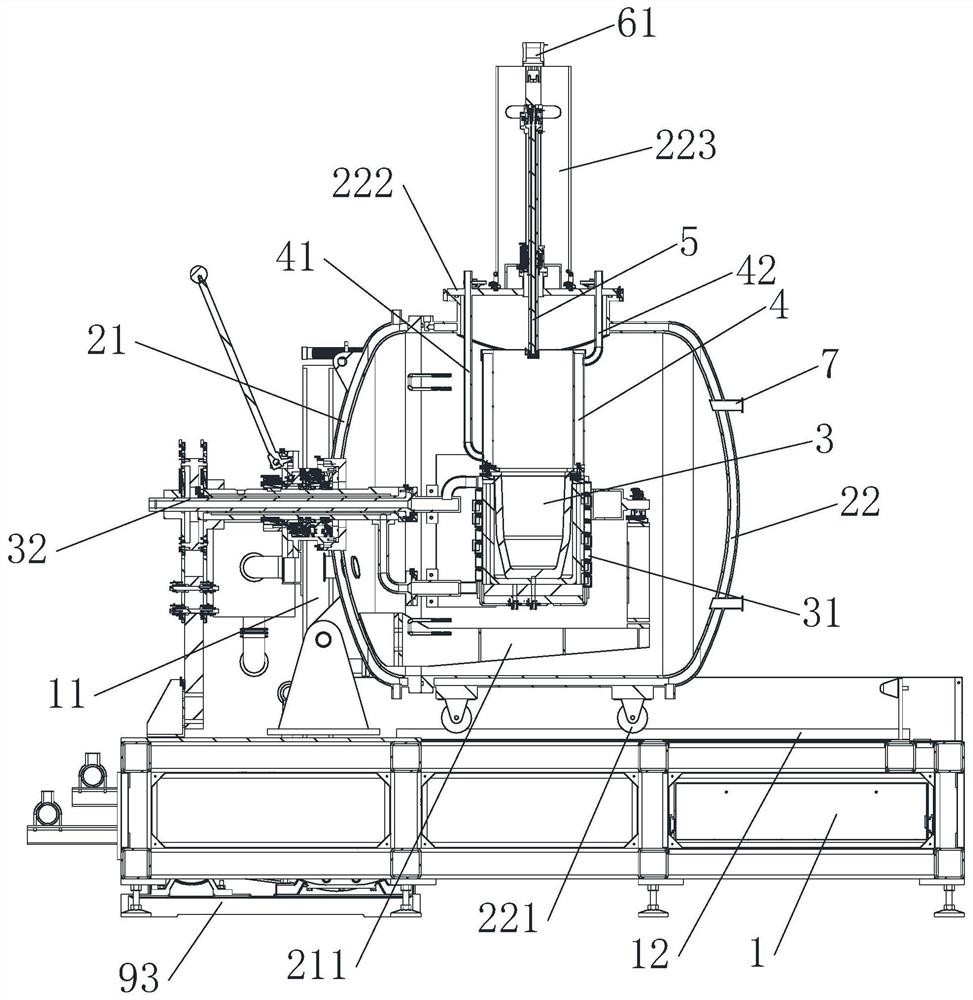

Vacuum induction distillation furnace

InactiveCN111928652AFast collectionGood collection effectIncreasing energy efficiencyCrucible furnacesVacuum furnaceElectrical control

The invention relates to the technical field of distillation furnaces, in particular to a vacuum induction distillation furnace. The furnace comprises a base and a furnace body, the furnace body is arranged on the base, a crucible and a condensation cover are arranged in the furnace body, the condensation cover covers the open end of the crucible, the furnace body is a vacuum furnace, a high-frequency induction coil is arranged around the crucible, the high-frequency induction coil is connected with an electrode interface extending out of the furnace body, the condensation cover adopts a watercooling mode, a thermocouple is arranged on the condensation cover, one end of the thermocouple extends into the condensation cover and is connected with the condensation cover, the other end of thethermocouple extends out of the furnace body and is connected with the furnace body, the furnace body comprises a furnace cover and a furnace stack, the furnace stack is in sliding fit with the base,the furnace cover is fixedly connected to the base, the crucible is connected with the furnace cover, the condensation cover is connected with the furnace stack, a control part is arranged on the base, the control part adopts a mode of combining PLC control, operation buttons and an operation interface, and an electric control box is arranged on one side of the base. According to the furnace, by arranging the crucible subject to induction heating by the high-frequency coil, the furnace cover capable of being opened in a sliding mode and the condensation cover capable of being lifted, the separation and purification on rare metal are achieved in a vacuum environment, and the purification effect is good.

Owner:河南酷斯特仪器科技有限公司

Elderly patient excrement collection nursing device

The invention discloses an elderly patient excrement collection nursing device. The device includes a nursing seat, supporting legs arranged at the lower end of the nursing seat, a backrest arranged on the rear side of the upper end of the nursing seat, a toilet hole formed in the nursing seat, and a telescopic flushing structure arranged on the rear side of the interior of the nursing seat and communicated with the toilet hole. An excrement collecting box is detachably connected to the lower end of the toilet hole through a pipeline, a water storage structure communicated with the telescopicflushing structure through a guide pipe is arranged on the backrest, handles movably connected with the backrest are arranged on the two sides of the backrest, and switches electrically connected withthe telescopic flushing structure are arranged on the handles; the device is simple in structure, convenient to operate, high in practicability and good in excrement collecting effect on the elderlypatient, the patient can be effectively nursed in time, infection is prevented, and the health of the elderly patient is protected.

Owner:THE SECOND AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Garbage truck capable of preventing liquid from leakage

The invention discloses a garbage truck capable of preventing liquid from leakage. The garbage truck capable of preventing the liquid from leakage comprises a truck body, an inlet, a liquid storing box, a water tank and an outlet, wherein the inlet is formed in the top end of the truck body, and the liquid storing box is mounted at the bottom end of the truck body; the outlet is formed in the leftside of the truck body, and the water tank is mounted at the right side of the truck body; a rotating shaft which is connected to a box cover is mounted on the outlet; a motor is mounted at the leftside of the truck body; a board slot in which a box fixing plate is arranged is formed in the inner wall of the truck body; a garbage box is connected to the box fixing plate; and a vibrating motor ismounted at the right side of the garbage box. According to the garbage truck capable of preventing the liquid from leakage, the garbage box is arranged in the truck body, and a water draining plate is mounted at the inner bottom end of the garbage box; garbage is kept in the garbage box while being poured inside through the inlet, and liquid in the garbage can be separated through the water draining plate and flows into the liquid storing box to be stored, so that the garbage liquid can be prevented from flowing out of the truck body; the practicability is improved; and the garbage truck is suitable for wide popularization and application.

Owner:南安市如兴智能家居开发有限公司

Lake surface duckweed cleaning device

InactiveCN112176970AGood collection effectIngenious and reasonable designWater cleaningStructural engineeringMechanical engineering

The invention discloses a lake surface duckweed cleaning device. The problems that time and labor are consumed and duckweed cannot be intensively cleaned when the lake surface is manually fished and cleaned are solved. According to the following scheme, the lake surface duckweed cleaning device comprises a floating plate and a mounting frame. Four connecting plates distributed at equal intervals are fixedly connected to the periphery of the outer wall of the top of the mounting frame, floaters are fixedly connected to one ends of the four connecting plates, four sliding grooves distributed atequal intervals are formed in the inner wall of the mounting frame, sliding blocks are slidably connected to the inner walls of the four sliding grooves, and the same collecting barrel is fixedly connected to the outer walls of the opposite sides of the four sliding blocks. The fluctuating motion of a fluctuating plate drives the collecting barrel to float up and down in the sliding grooves in theinner wall of the mounting frame, the floating collecting barrel is matched with a limiting plate on the outer wall of the top of the floating collecting barrel, duckweed on the outer side of the mounting frame is continuously ripped into the collecting barrel, the resistance of water flow in the rotating process is effectively utilized, and the collecting effect is remarkable.

Owner:陈如华

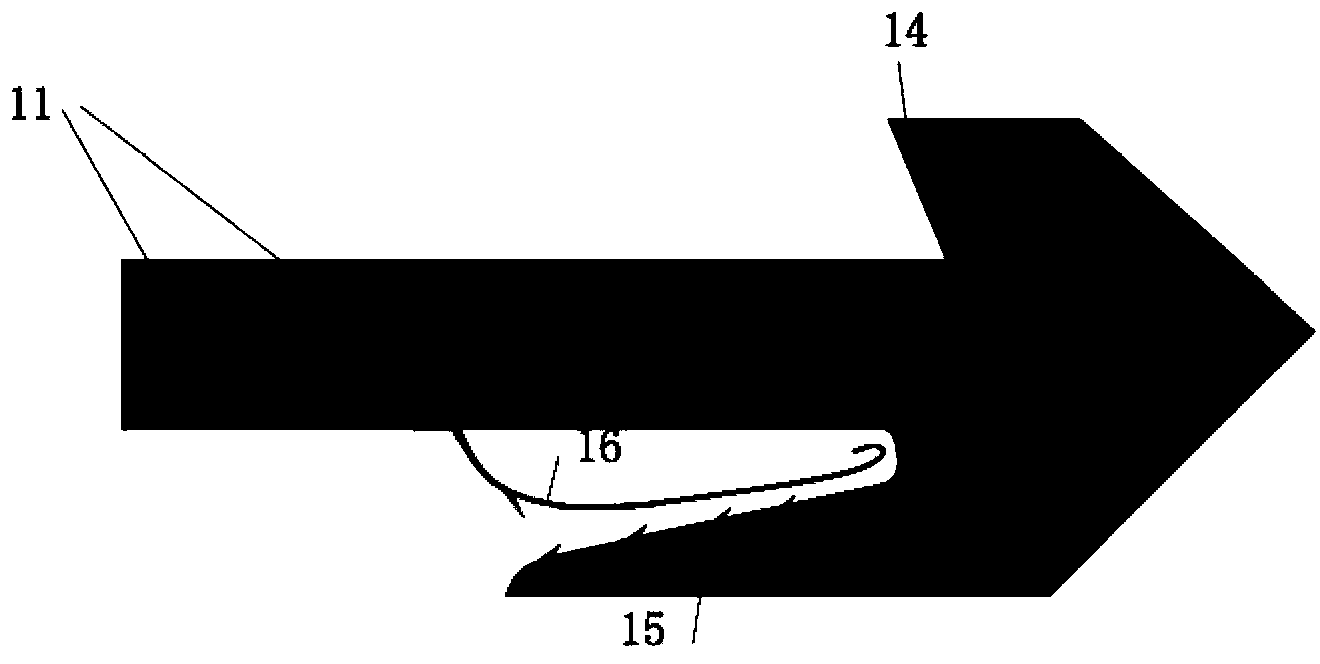

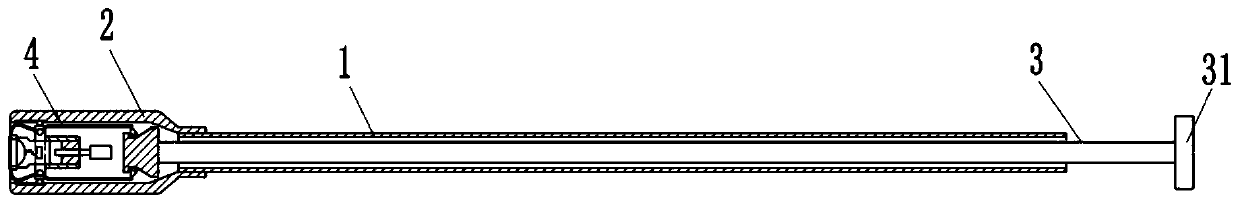

Lopper hook

InactiveCN103348814ASolve the problem of incompetent ultra-long-distance collectionSimple structureHarvestersEngineeringMechanical engineering

The invention discloses a lopper hook. The lopper hook has a simple structure and utilizes a telescopic pole to extend a work distance. A hook body adopts hook blade design and is a cutter and is also a hook. A collector uses arm force to rotate and pull so as to complete work, the remote operation is simple and convenient, and branches of tall arbors and cliff epiphytes can be conveniently and effectively collected, so that the lopper hook can be completely competent to collect remote branches and the cliff epiphytes. The collecting effect is good, and the problem that a lopper machine cannot carry out very long-distance collection can be solved. The lopper hook adopts split design and can be dismantled into the telescopic pole, a connecting device and the hook body to be respectively taken in when not in use, so that the lopper hook is conveniently carried.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

Rapid rapeseed screening device for rapeseed oil pressing

ActiveCN107042204AGood collection effectFast screeningSievingGas current separationEngineeringFast speed

The invention relates to a screening device, in particular to a rapid rapeseed screening device for rapeseed oil pressing. According to the rapid rapeseed screening device for rapeseed oil pressing, the screening speed is high. The rapid rapeseed screening device for rapeseed oil pressing comprises a sliding block, a sliding rail, a filtering net, a first pulling rope, a first guiding plate, a feeding hopper, a supporting rod, a first rotating shaft, a flat belt, a large belt pulley, a first winding wheel and the like. A collecting tank is located on the left of the supporting rod. A screening box is arranged on the top of the supporting rod. The sliding rail, third elastic elements and a third guiding plate are sequentially arranged on the left wall in the screening box from top to bottom. A first guiding hole is formed in the third guiding plate. The sliding block is arranged on the sliding rail. The effects of rapid screening speed, simple structure of the device and easy operation of the device are achieved.

Owner:安徽劲龙粮油股份有限公司

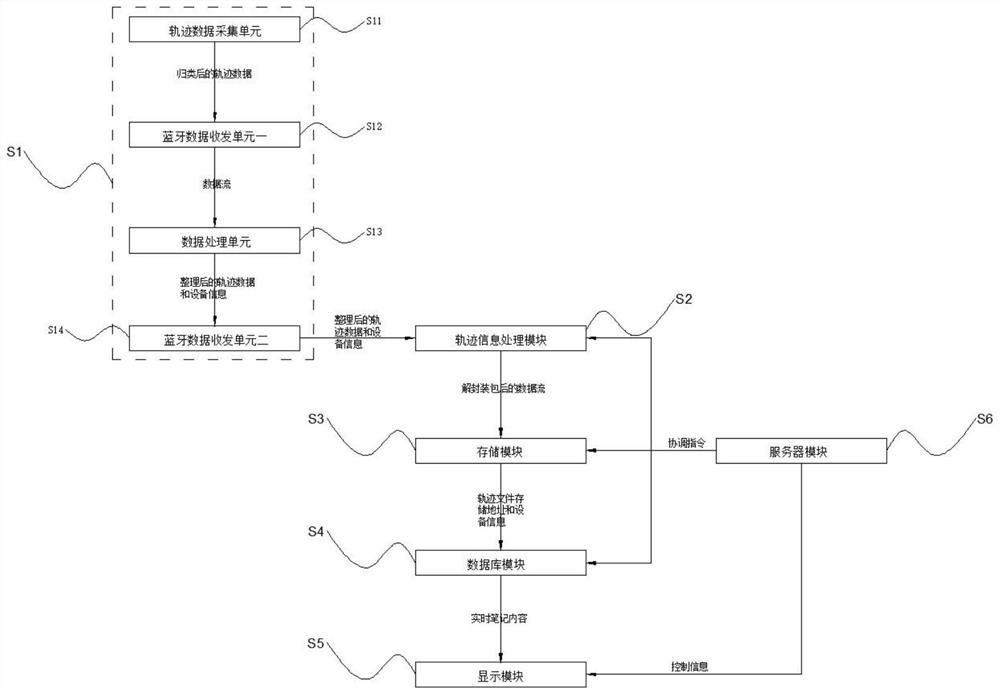

Real-time classroom and conference note effect evaluation method based on paper handwriting

ActiveCN113157644AGood collection effectEasy to detectData processing applicationsFile system administrationHandwritingInformation transfer

The invention discloses a real-time classroom and conference note effect evaluation method based on paper handwriting. A system comprises a track data acquisition module, a track information processing module, a storage module, a database module, a display module and a server module; the track data acquisition module is used for acquiring track data of notes in the intelligent handwritten book in real time, classifying and sorting the track data acquired in real time, and transmitting classified and sorted data streams to the track information processing module, and the track data acquisition module is used for collecting the track data and equipment information of the handwritten book, the track information processing module is used for decapsulating the received data stream and transmitting the obtained track data and equipment information to the storage module; the track information processing module is matched with a plurality of child threads through a parent thread to complete the de-encapsulation and packing of the data, and the storage module is used for storing the received track data.

Owner:上海创建达一智能科技有限公司

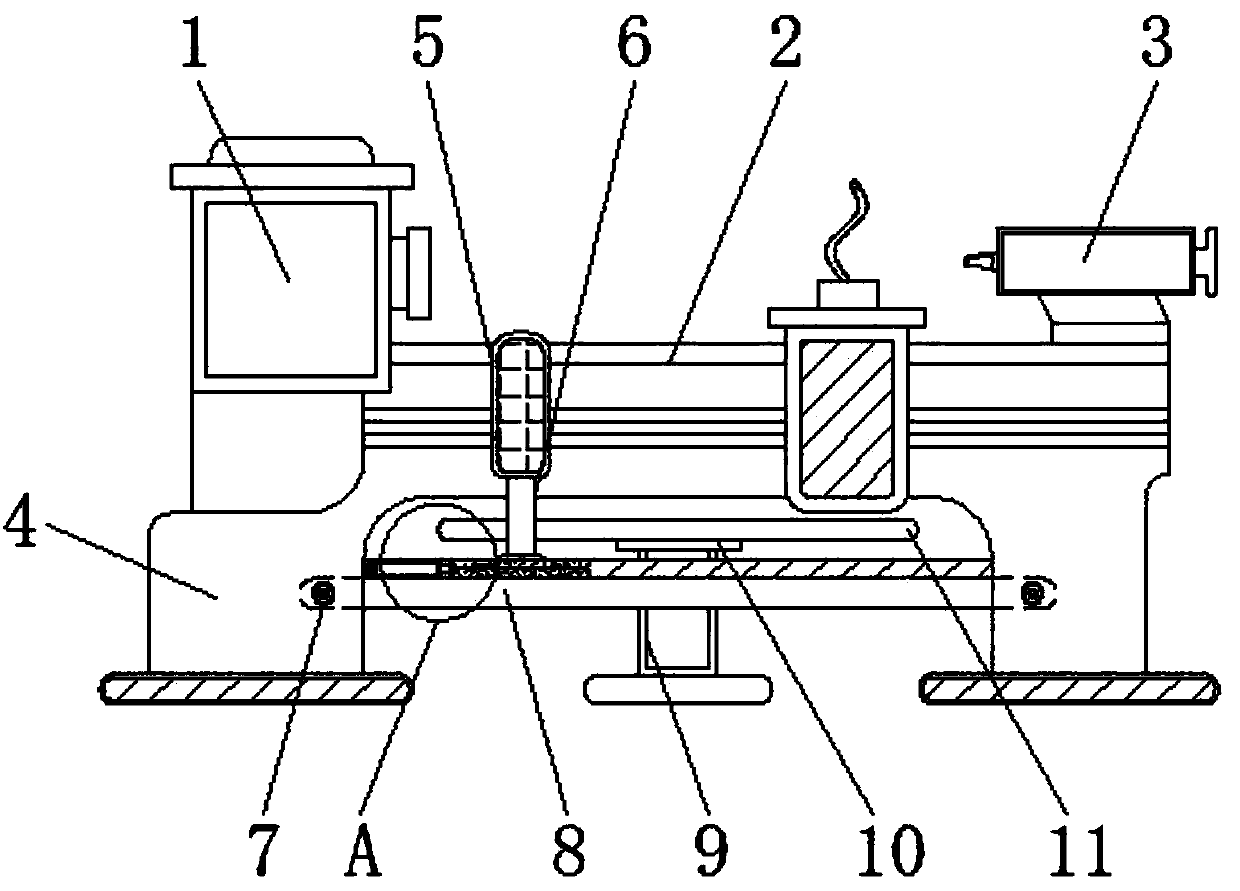

Lathe scrap iron recovery device for machining

PendingCN107649941AGood collection effectWill not affect normal workMaintainance and safety accessoriesScrapEngineering

The invention discloses a lathe scrap iron recovery device for machining. The lathe scrap iron recovery device comprises a lathe body, a washing brush fixing head, a through hole and a hydraulic cylinder; a sliding arm is fixedly connected to the right side of the lathe body, a lathe tool bit is arranged on the right side of the sliding arm, the upper portion of a device body is connected with a washing brush through a connecting rod, and punching holes are formed in the two sides of the device body; a rotating rod is installed in the middle of the device body, a pressing plate is arranged above the rotating rod, a bearing is installed above the rotating rod, the pressing plate is connected to the upper portion of the bearing, a spring is fixed to the middle of a fixing head, and the device body is installed at the bottom of the fixing head; and the pressing plate is arranged outside the through holes, the device body is installed outside the pressing plate, and a fixing base is connected to the right side of the hydraulic cylinder. The lathe scrap iron recovery device for machining is provided with the washing brush, the washing brush is in threaded connection with the connectingrod, the overall washing brush can be well demounted, mounted and washed, and meanwhile, normal work of an overall lathe cannot be influenced.

Owner:GUIZHOU UNIV

Intestine mucosa collector

InactiveCN101907526AEasy to operateGood collection effectWithdrawing sample devicesPreparing sample for investigationWoven fabricBiology

The invention relates to an intestine mucosa collector comprising at least three bags connected sequentially from top to bottom. A filter screen, i.e., the bottom of an upper bag is arranged between the adjacent bags; the bottom bag is the non-leakage bag bottom; the upper bag, the middle bag and the lower bag especially formed by sewing with fabric are used; the filter screen is fixed in the sewing, splicing or welding manner by using thin fabrics of gauze and the like or non-woven fabrics with holes. The invention provides a device for collecting excrement, called as a disposable intestine mucosa collector, is convenient for inspectors to operate, has good collection effect and low cost, can be made of environmental-friendly materials and can collect more intestine mucosa, thereby being convenient for inspecting personnel and patients.

Owner:NANJING PUPAI MEDICAL TECH CO LTD

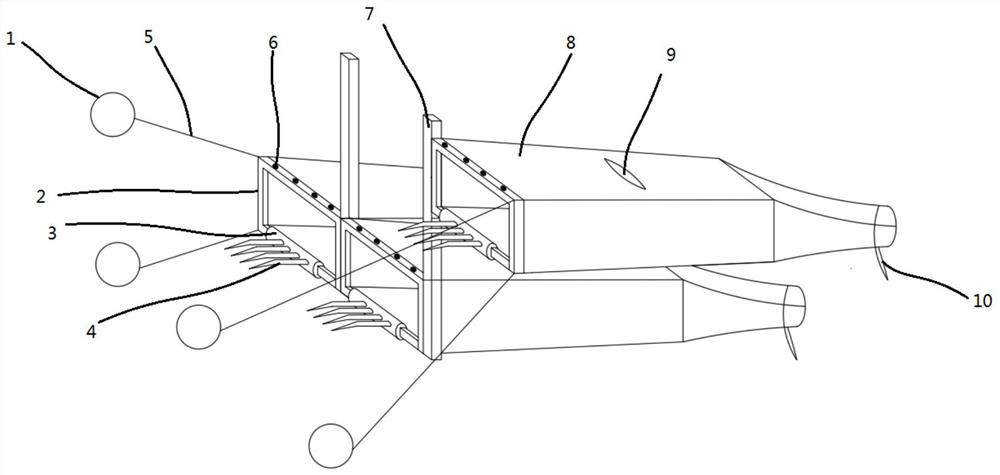

Ecological environment-friendly rake thorn and using method thereof

ActiveCN112400821AGood collection effectImprove collection efficiencyClimate change adaptationFishingEcologyEcological environment

The invention discloses an ecological environment-friendly rake thorn and a using method thereof. The ecological environment-friendly rake thorn comprises a plurality of frames and net bags connectedwith the frames in a matched manner. The multiple frames are arranged side by side, telescopic rods are arranged between the adjacent frames, and the telescopic rods can adjust the adjacent frames tobe distributed in a staggered manner. A plurality of buoys are arranged at the top of any one of the frames at intervals, a rotating shaft is arranged at the bottom of any one of the frames, a plurality of hook thorns are connected to the rotating shaft in a matched manner, and the hook thorns are evenly distributed in the length direction of the rotating shaft at intervals; and at least one traction rope is arranged on the two frames located at the edges of the two sides, the net bags correspond to the frames in a one-to-one manner, closing-up ropes are arranged at the tail portions of the net bags, and at least one escape opening is formed in each net bag.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Fly ash collecting device for hazardous waste incineration disposal

PendingCN113262603AIncrease collection rateGood collection effectCombination devicesPulverizerWater pipe

The invention relates to a fly ash collecting device, in particular to a fly ash collecting device for hazardous waste incineration disposal. The device comprises supporting legs, a device shell, an air inlet, an exhaust port, an exhaust pipe and a fly ash outlet, and is technically characterized in that an air blower is fixed to the upper portion of the device shell, and an inlet of the air blower is sequentially connected with a feeding pipe, a turbo type pulverizer and an air inlet pipe; an outlet of the air blower is connected with a discharging pipe, a filter screen is fixed to the upper portion of the interior of the device shell, the tail end of the discharging pipe extends into the device shell, penetrates through the filter screen and is communicated with a material distributing spray head, an annular water pipe is fixed to the inner circumferential face of the device shell, and a plurality of water spraying spray heads are arranged on the inner side of the annular water pipe; the outer side of the annular water pipe is communicated with a plurality of water inlet pipes with one ends penetrating out of the device shell, a drying layer is fixed to the lower portion in the device shell, and a collecting groove communicating with the fly ash outlet is formed in the lower portion of the device shell. Fly ash pretreatment and reasonable collection are achieved.

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

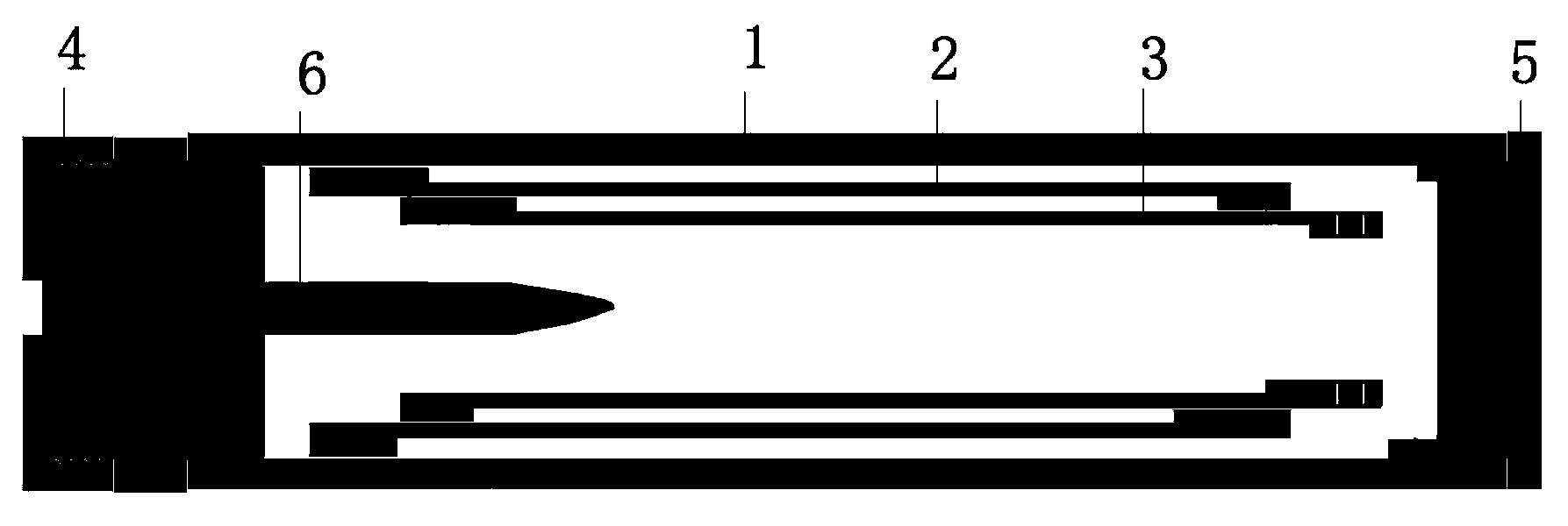

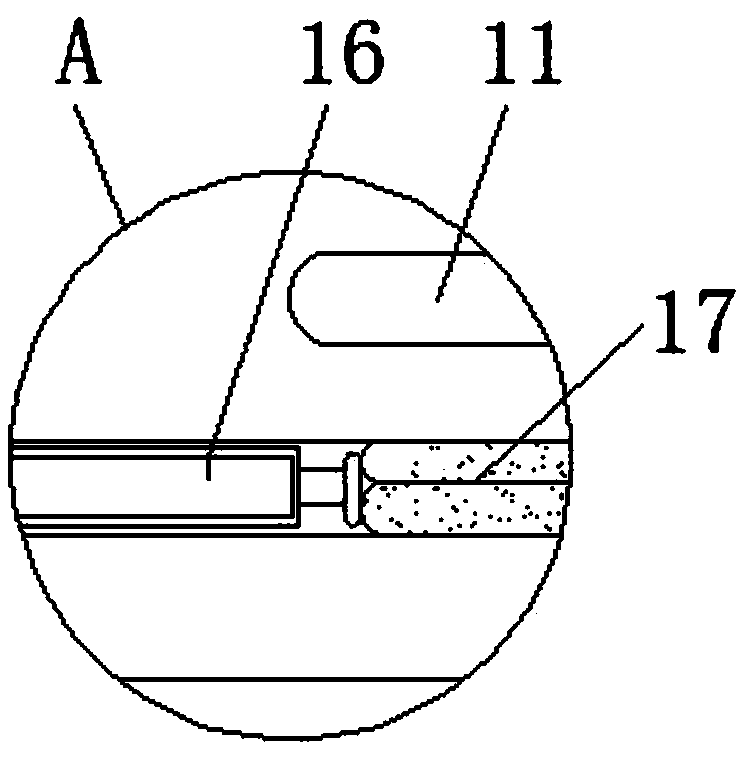

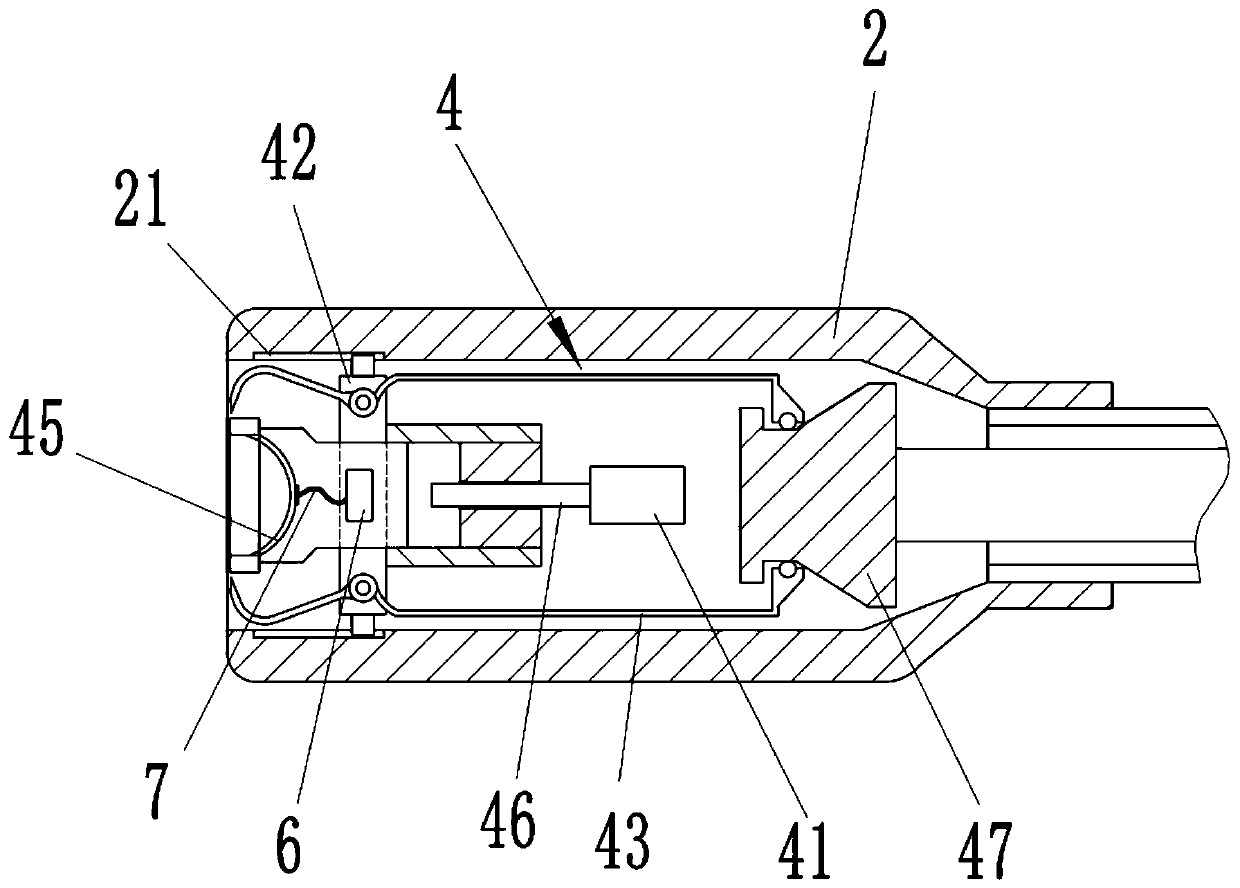

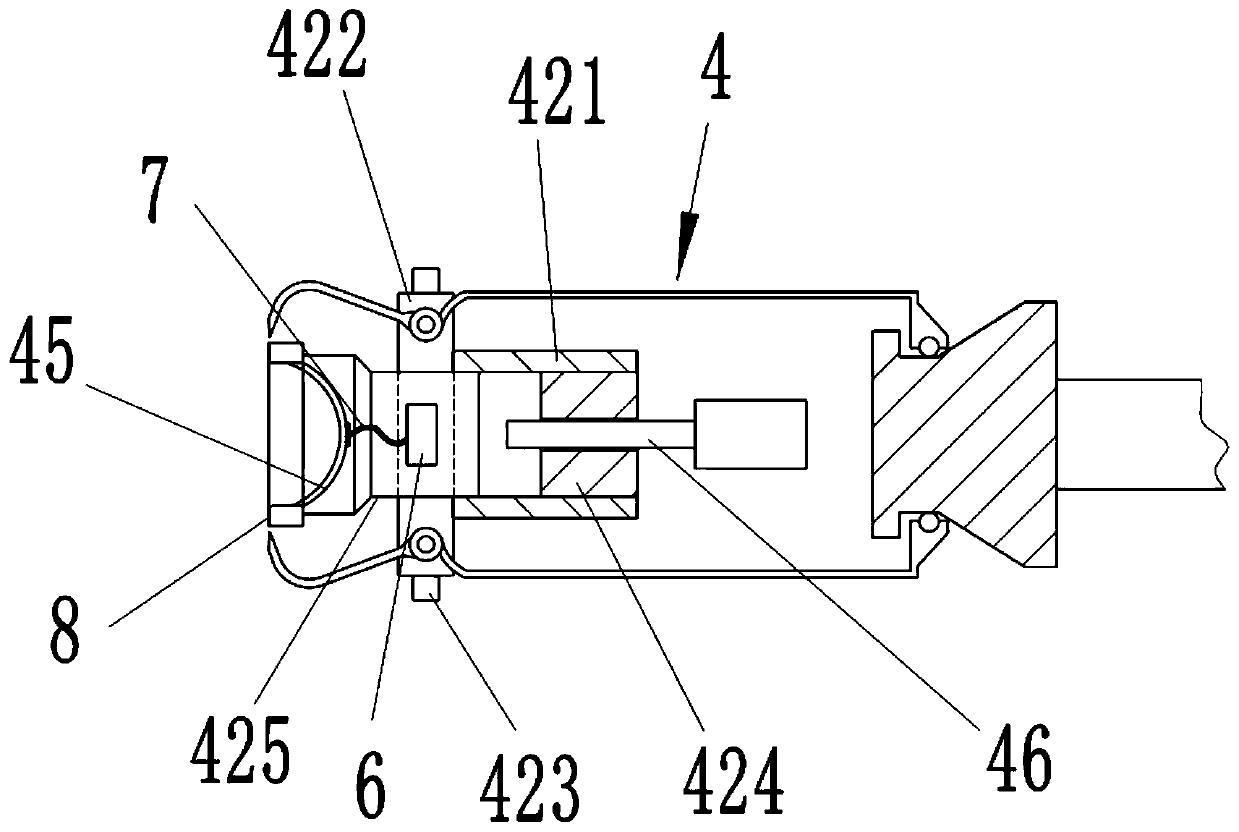

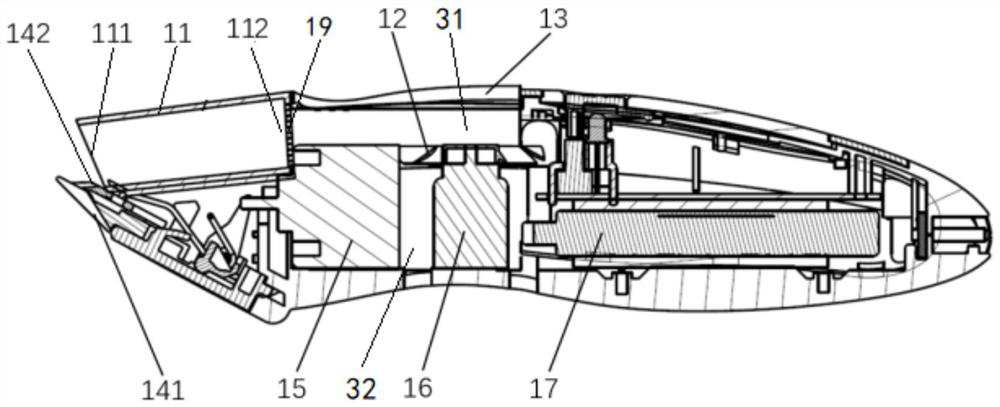

Endometrium collection device

ActiveCN110448340AImprove practicalityGood collection effectSurgical needlesVaccination/ovulation diagnosticsEndometrial tissueEngineering

The invention provides an endometrium collection device. The device comprises an outer tube, a tube head, a center tube and a collection assembly, the tube head is connected to one end of the outer tube, and the center tube is movably arranged in the outer tube; the collection assembly is movably arranged in the tube head and comprises a slide part, a negative pressure semisphere cover arranged atthe front end of the slide part, a motor driving the slide part to slide along the inner wall of the tube head, a pair of linkage parts in pivot joint with the slide part, and a driving block used for driving connection blade parts at the front ends of the linkage parts to collect endometrium tissue, wherein the driving block is connected to the front end of the center tube. The provided endometrium collection device solves the technical problems that an existing endometrium collection device is poor in sampling effect and low in practicability.

Owner:兖矿新里程总医院

Hardware fitting grinding device

InactiveCN110900398AShorten processing timeGood collection effectBelt grinding machinesGrinding work supportsScrapEngineering

The invention discloses a hardware fitting grinding device. The device comprises a machine table; a mechanical arm, a clamping mechanism and a grinding mechanism are arranged above the machine table;the clamping mechanism is arranged at an end portion of the mechanical arm; and a scrap collection mechanism is arranged in the machine table. According to the hardware fitting grinding device, a newhardware fitting fixing mode is set, so that the to-be-machined surface of a sheet-shaped or thin-plate-shaped hardware fitting can be ground in an all-around mode; and the fixing position of the hardware fitting does not need to be replaced, and therefore, machining time is saved.

Owner:嘉兴日正五金制造有限公司

Sampling method and device suitable for low-concentration particles

ActiveCN111521456AGood collection effectHigh precisionWithdrawing sample devicesParticle suspension analysisEngineeringMechanical engineering

The invention belongs to the technical field of atmospheric environment sampling, and particularly relates to a sampling method and device suitable for low-concentration particles. The device comprises a sampling box, a folding pipe is arranged in the sampling box, and hydraulic rods are connected to the front side and the rear side of the folding pipe. The top of the sampling pipe is provided with the folding pipe which can be changed into a snake shape through pulling of the two hydraulic rods; the controller controls the two hydraulic rods to work at the same time; the hydraulic rod pulls the folding pipe to be snake-shaped; therefore, the gas entering the folding pipe can have a longer moving path; when the gas passes through the bent part of the snake-shaped folding pipe,the gas can make full contact with the filter bristles in the folding pipe, particles in gas are filtered out by the filter bristles, finally the particles collected in the folding pipe and the particles on the filter membrane are concentrated, the total amount of the particles contained in the sampled gas is obtained, the collection effect of the particles in the gas is better, and the collection precision isimproved.

Owner:河北正态环境检测有限公司

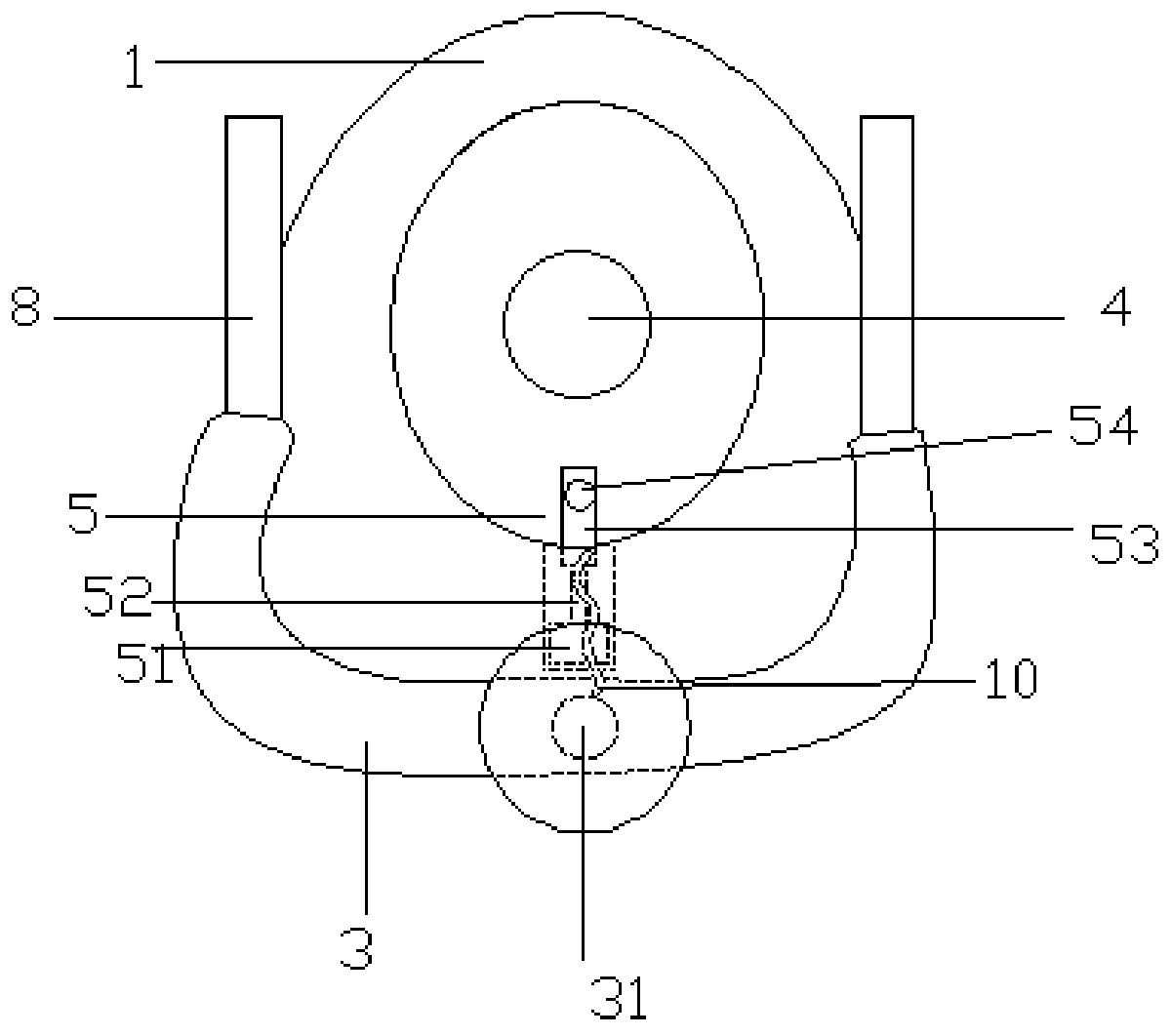

Cyclone separator for air sampler

PendingCN112461609AGood collection effectThe test results are accurateWithdrawing sample devicesPreparing sample for investigationAir samplerAir separation

The invention discloses a cyclone separator for an air sampler, and belongs to the technical field of cyclone separation equipment. The cyclone separator comprises a cone, a spiral pipe is mounted above the cone, a dusty air inlet is formed in the left side of the spiral pipe, a clean air outlet is formed in the right side of the spiral pipe, and a vortex cover is mounted in the cone. A first cyclone separation space is formed in the left side of the vortex cover, a second cyclone separation space is formed in the right side of the first cyclone separation space, a discharging opening is formed in the lower portion of the cone, and an ash hopper is installed below the discharging opening. When the device is used for separating air, graded air separation is adopted so that the separation effect is good, air backflow cannot be caused, backflow of the whole device is avoided, the backflow effect is avoided, separated air is further separated, and when the air sampler is used, the test result is more accurate; and convenience is brought to use of workers.

Owner:常熟市顺欣仪器仪表有限公司

Waste collection equipment for silk drawing production line

PendingCN110860551AGood sealingGood collection effectSolid waste disposalSilk reelingEnvironmental geologyMechanical engineering

Owner:江西金铭丝绸有限公司

Hair collecting device and method

PendingCN113276173AAvoid cross contaminationGood collection effectSurgeryVaccination/ovulation diagnosticsElectric machineryEngineering

Owner:CHINA INNOVATION INSTR CO LTD

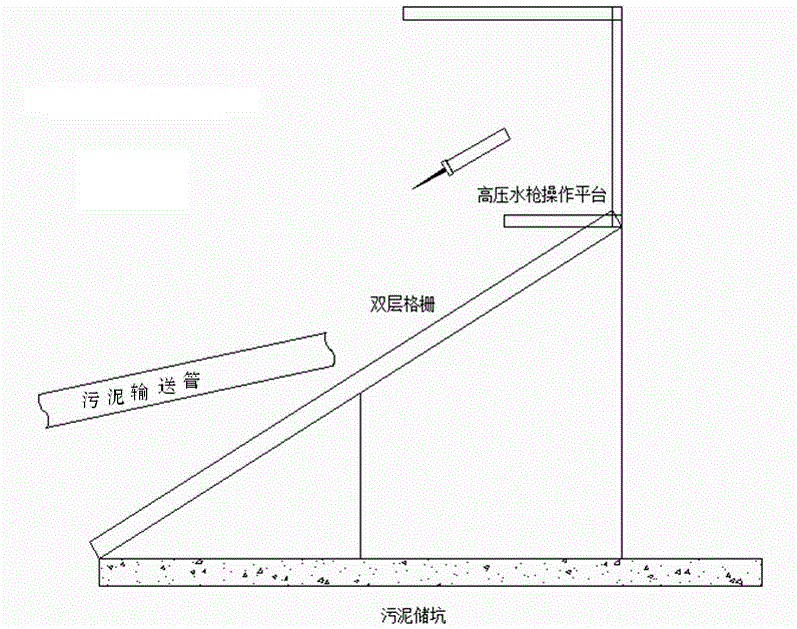

Separation and collection system and method for solid pollutants in solid-liquid mixed solution

ActiveCN104524838ASimple structureLow costStationary filtering element filtersRefuse collectionCollection system

The invention discloses a separation and collection system and method for solid pollutants in a solid-liquid mixed solution. The system includes: a solid pollutant separation device, which mainly comprises a screen mesh; a screened garbage collection subsystem, which mainly comprises a solid pollutant flushing device for flushing solid pollutants separated by the solid pollutant separation device, a driving device of the solid pollutant flushing device, and a garbage storage device for storing the screened solid pollutants. The separation and collection system for solid pollutants in the solid-liquid mixed solution provided by the invention has the characteristics of simple structure and low cost, and the making cost is lowered by 50%-70% than ordinary vibrating screens. The screened garbage collection system adopted by the separation and collection system for solid pollutants in the solid-liquid mixed solution provided by the invention successfully solves the problems that planar screen garbage separation has large labor cost and the vibration screen cannot guarantee the screened garbage collection effect, and has excellent separation and collection effects in practical application.

Owner:上海同济环境工程科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com