Non-contact ultrasonic testing method

A detection method, non-contact technology, applied in the direction of measuring devices, geophysical measurement, instruments, etc., can solve the problems that the signal cannot reach the deep layer of the model, the ultrasonic emission energy is not enough, and the excitation effect is affected, so as to solve the problem of the detection and emission devices on the model. The influence of the simulation effect, the simulation effect is realistic, and the effect of increasing the acquisition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

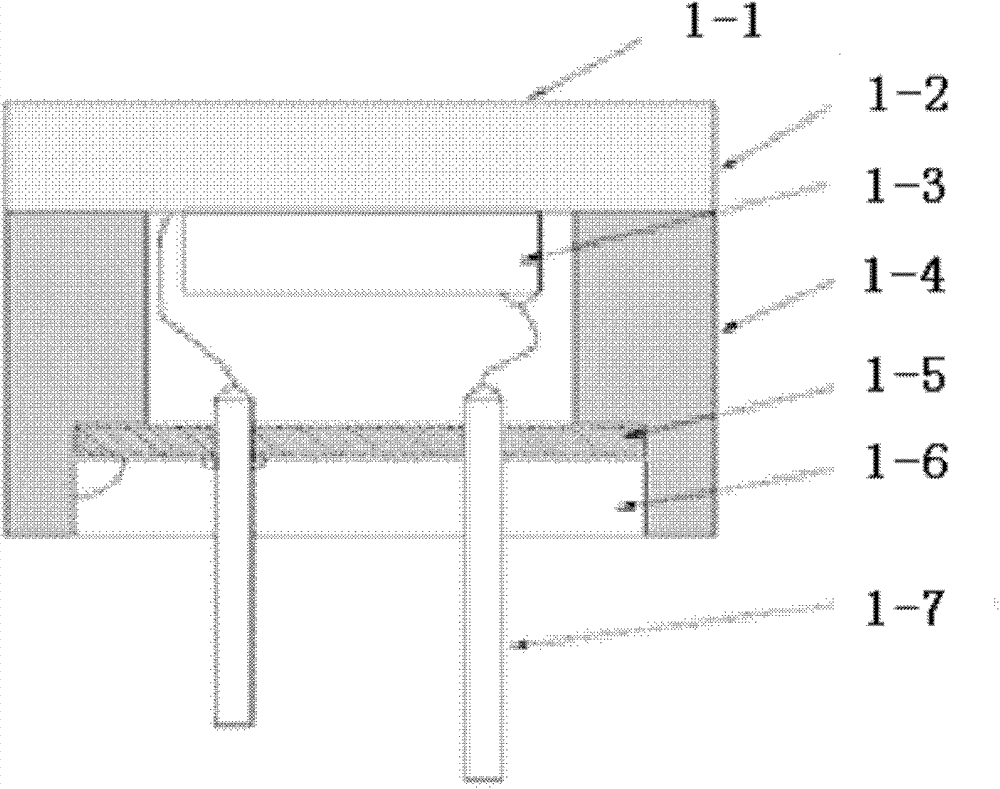

[0042] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0043] A non-contact ultrasonic detection method, the method uses high-voltage pulse or alternating voltage to excite the high-frequency vibration of the non-contact focused probe, and then induces the transmission of sound waves, and focuses the radiated energy of the sound waves, and then the focused The sound wave is emitted to the shot point of the geological model to be tested, and the ultrasonic wave is generated at the shot point and transmitted to the inside of the geological model to be tested. At the same time, the detection point of the geological model to be tested is detected to obtain a voltage signal, and then the voltage signal It is converted into a digital signal and transmitted to a computer for processing.

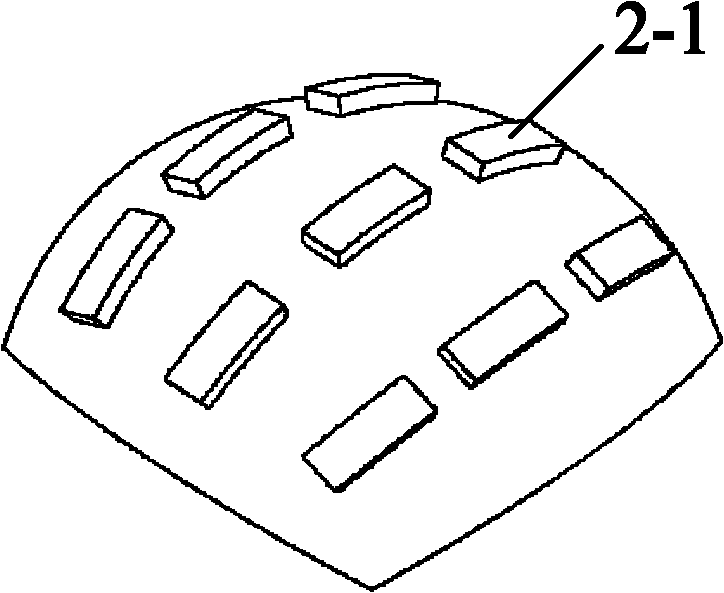

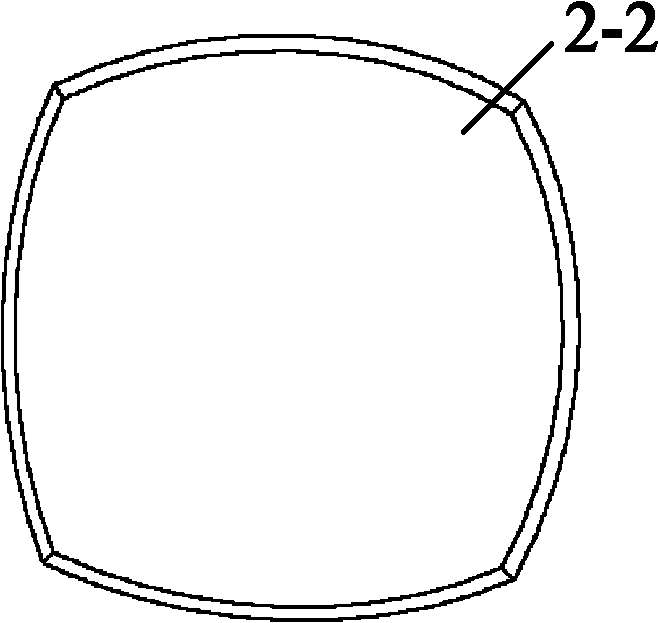

[0044] The non-contact focusing probe used in the method is designed as shown in Figure 2. What Figure 2 provides is the overall view of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com