Non-contact collecting probe

A concentrated, non-contact technology, used in the generation of ultrasonic/sonic/infrasonic waves, measurement devices, instruments, etc., to solve the problems that the signal cannot reach the deep layer of the model, affect the excitation effect, and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

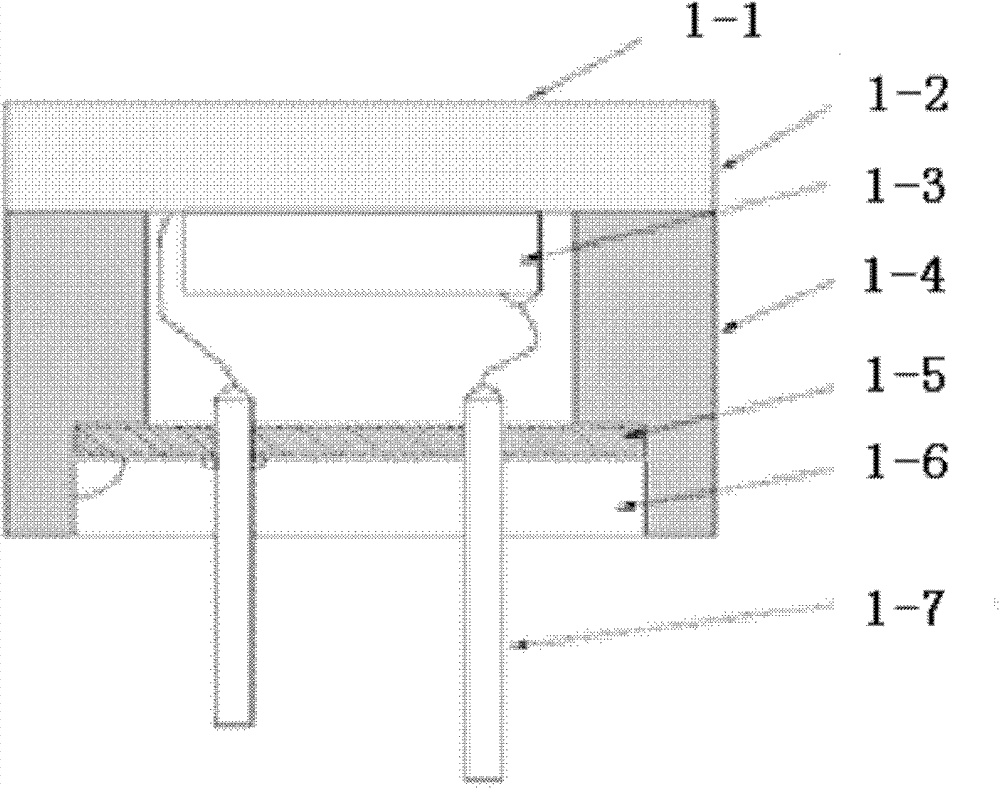

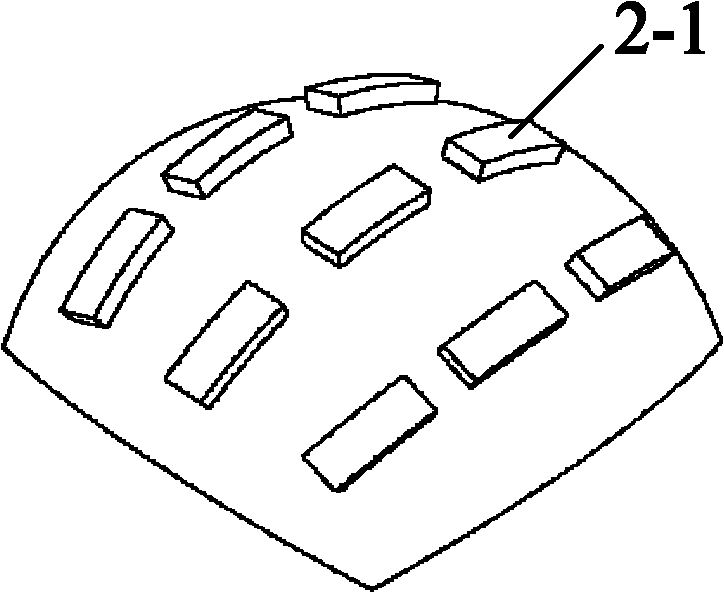

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

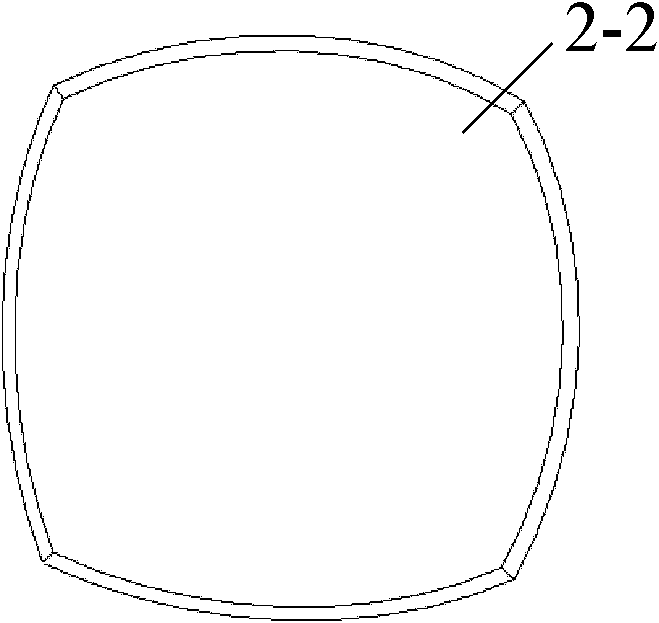

[0033] A non-contact focusing probe is designed as shown in Figure 2. Figure 2 shows the overall view of the non-contact focusing probe in a non-working state. It has a concave front and a convex back. The arc-shaped base 2- 3 is flexible, on the back side of the substrate 2-3 (such as Figure 2-1 As shown) a plurality of piezoelectric ceramics (high-performance PZT) 2-1 are pasted, and the polarization direction of each piezoelectric ceramic 2-1 is along the thickness direction, that is, the normal direction of the arc-shaped substrate 2-3. When an electric field along the polarization direction is applied to the piezoelectric ceramic 2-1, the d31 effect of the piezoelectric ceramic 2-1 can first generate a displacement response along the tangential direction in the piezoelectric ceramic 2-1, so that the electric energy can be effectively converted into mechanical e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com