Tail gas collecting and exhausting device for automobile assembly lines

An assembly line and tail gas collection technology, applied in the direction of smoke removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of short service life, air pollution, blackened equipment, etc., to reduce the air volume of the fan and facilitate exhaust and load-bearing, good collection and discharge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

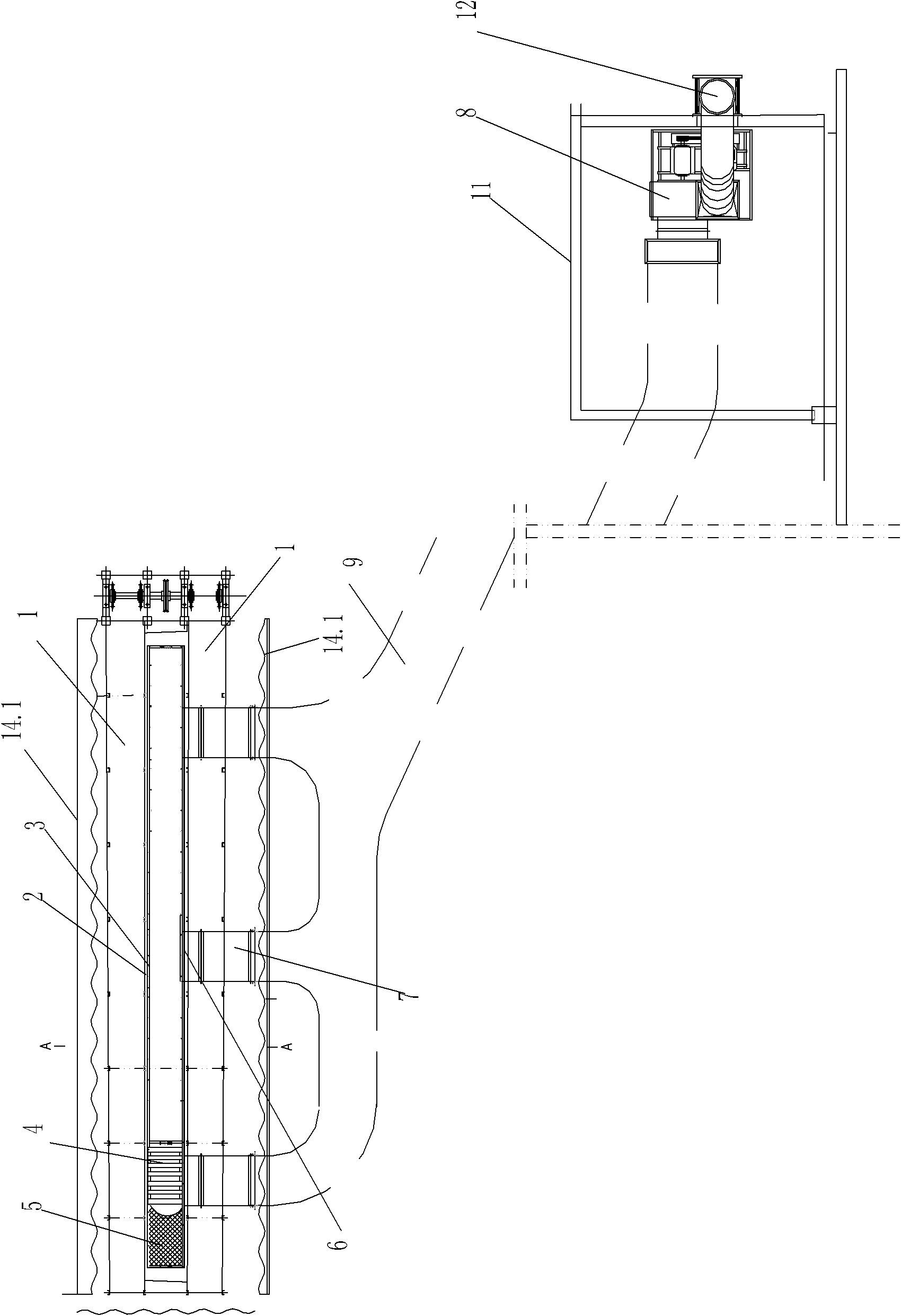

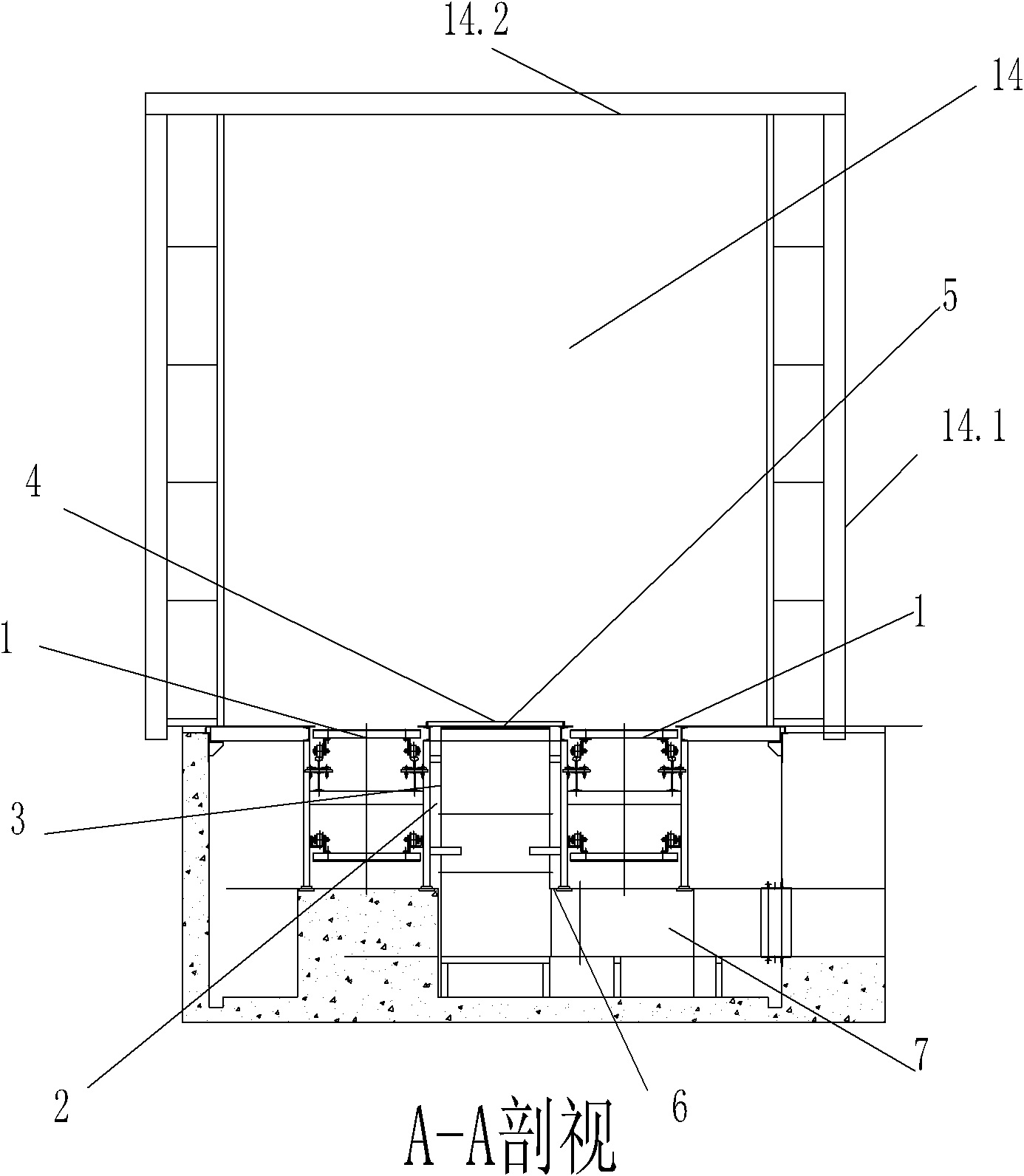

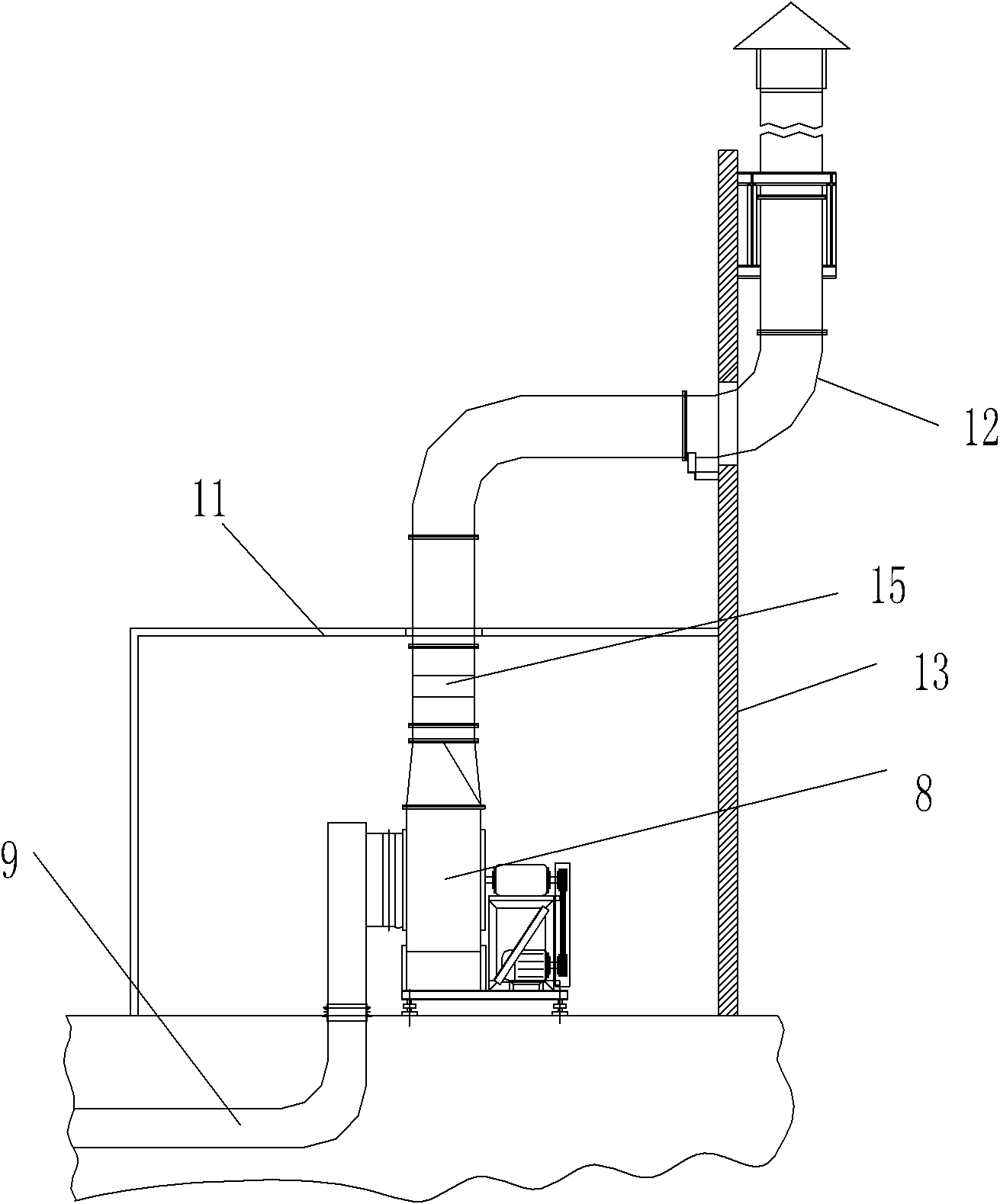

[0027] Such as figure 1 , 2 As shown, the automobile conveyor plate chain 1 is a conveying device for conveying automobiles on a complete vehicle assembly line, and it is an existing device in an existing complete vehicle assembly workshop. A section of upper-opening exhaust gas collection and exhaust duct 2 is set between the automobile conveyor plate chain 1 at the start-off station after the complete vehicle assembly is completed at the end. The exhaust gas collection and exhaust duct 2 is set under the ground, and the exhaust gas is collected and exhausted. The side partitions and bottom partitions of the trench 2 are galvanized plates to form the inner wall of the exhaust gas collection and exhaust duct 2 with low flow resistance; the upper opening of the exhaust gas collection and exhaust duct 2 is covered with a grid plate 4 ( It is arranged along the length direction of the exhaust gas collection and exhaust channel), the upper opening of the exhaust gas collection and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com