Waste collection equipment for silk drawing production line

A collection equipment and production line technology, applied in the direction of electronic waste recycling, garbage collection, solid waste removal, etc., can solve the problems of waste of resources, poor sealing degree at the interface, unable to pull silk screening, etc., to achieve good collection effect and sealing degree Good, avoid wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

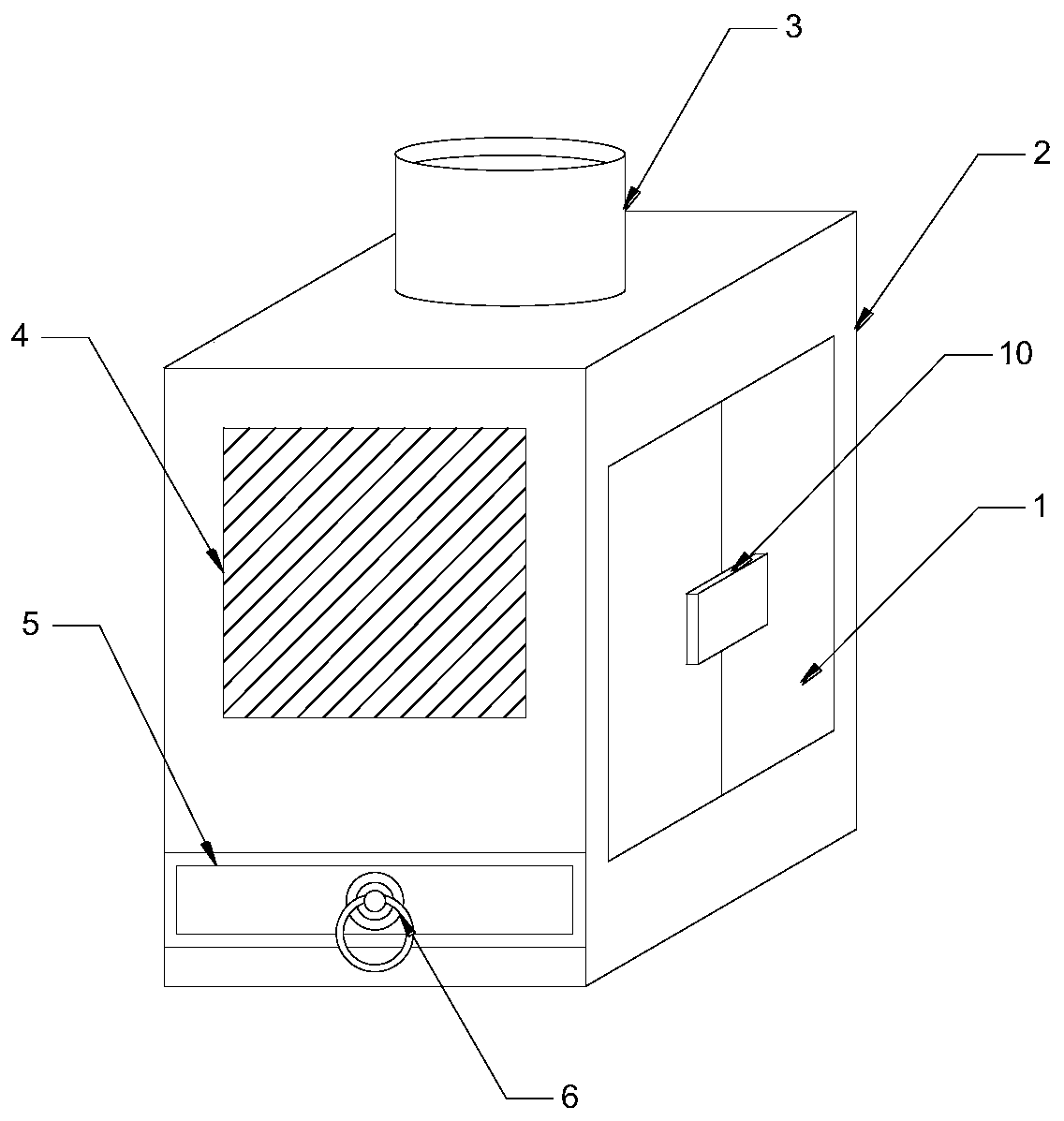

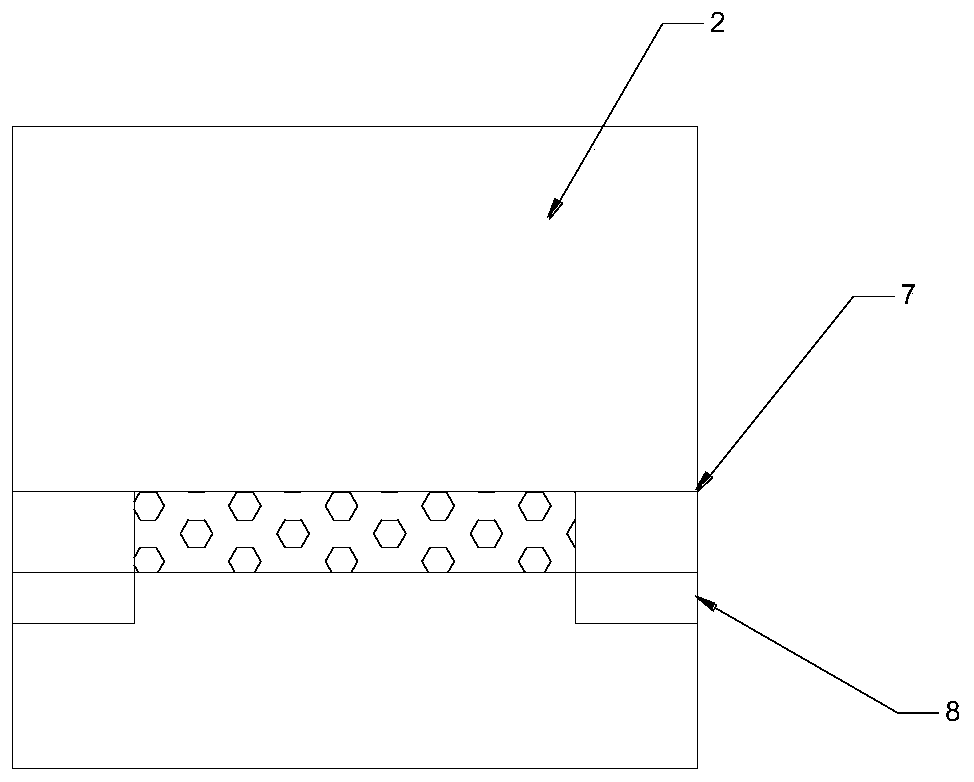

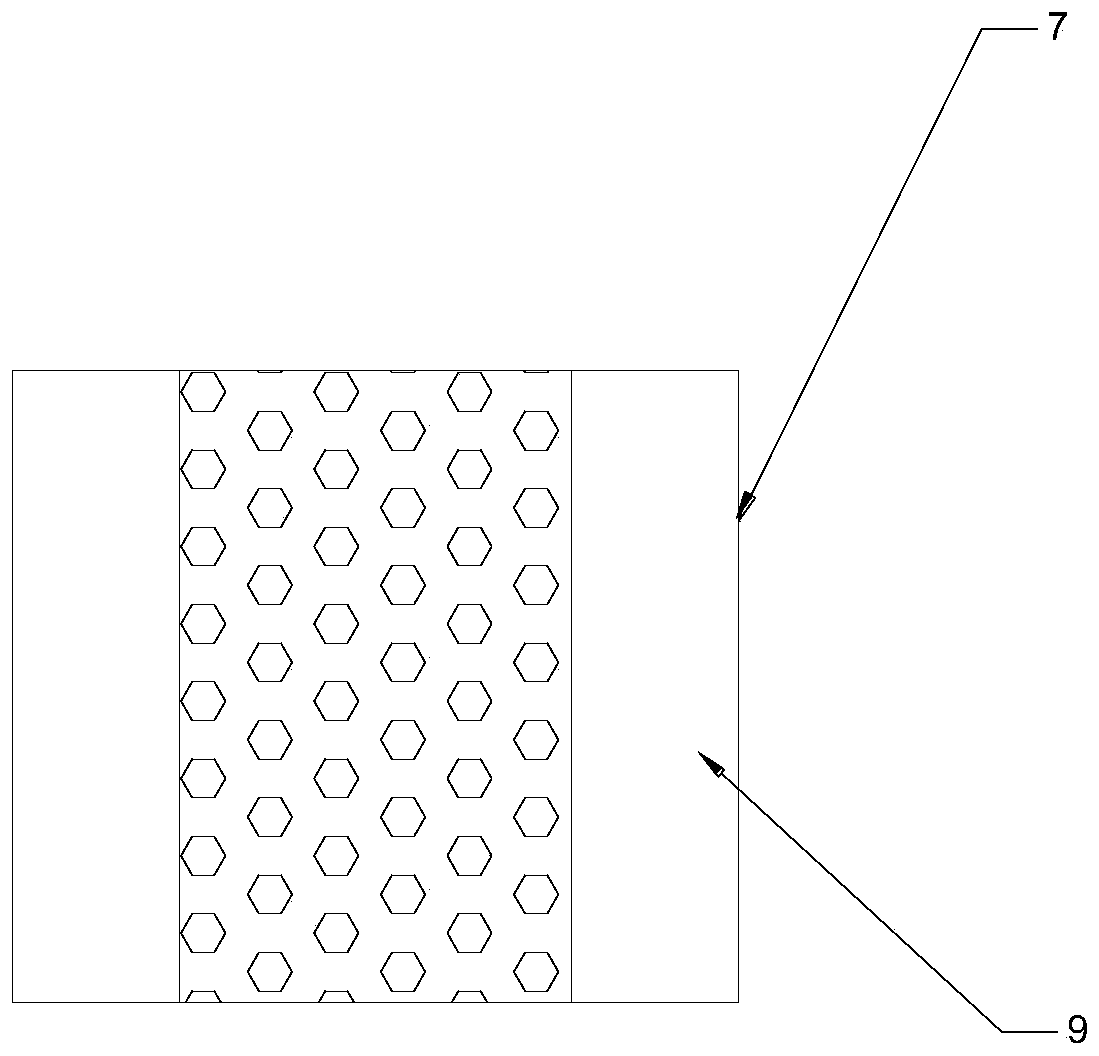

[0020] Example: such as figure 1 , figure 2 with image 3 As shown, the waste collection equipment of a drawn silk production line of the present invention includes a collection box 2. The top of the collection box 1 is fixedly provided with a feed port 3, and the inner wall of the feed port 3 is provided with internal threads, wherein the inner wall of the feed port 3 is provided Some internal threads are matched with the external threads of the external waste discharge port. The feed port 3 is cylindrical. The bottom of the collection box 2 is interspersed with a drawer box 5, and the side of the collection box 2 is hinged with a door body 1, and the door body 1 is provided with a lock 10, the front and back of the top of the inner wall of the collection box 2 are both provided with support plates 8, a partition 7 is placed between the top ends of the two support plates 8, and the middle of the top of the partition 7 is provided with several passages. Hole 9.

[0021] Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com